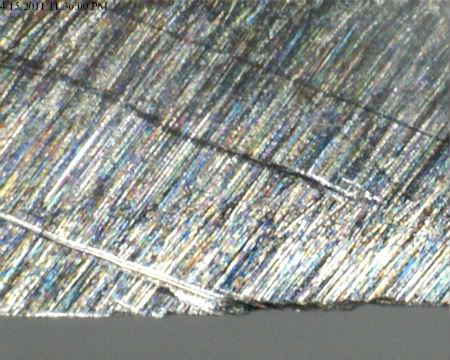

ZDP-189 edge chipping test:

Even without much magnification, there is some serious abrasion evident in that area of the blade. Shoes can be a bit complex perhaps? There must be something somewhere in that thing that is more than basic nylon/cotton/poly fabric and rubber.

People sometimes trip on these demonstrations (I do not call them tests). I got an odd comment on one I had posted elsewhere last night. You do not need to cut cans or shoes every day to see some value in these demonstrations. People trip, but being able to see how edges fail/degrade (and using your brain to ponder those images) can teach you a thing or two about how materials behave.

Thanks for sharing.

People sometimes trip on these demonstrations (I do not call them tests). I got an odd comment on one I had posted elsewhere last night. You do not need to cut cans or shoes every day to see some value in these demonstrations. People trip, but being able to see how edges fail/degrade (and using your brain to ponder those images) can teach you a thing or two about how materials behave.

Thanks for sharing.

Thanks,

Ken (my real name)

...learning something new all the time.

Ken (my real name)

...learning something new all the time.

Many years ago, I had a job as a lab technician and one of my jobs involved using a very expensive Swiss optical dissecting scope with very fine Swiss tweezers, so fine they could pick up a single hair easily. The tips of these tweezers used to wear or get damaged and frequently needed sharpening which was one of my responsibilities. I used to sharpen them under the scope with a small stone. The interesting thing was that under that kind of magnification in real time, it was easy to see how every single stroke had a significant effect on the metal and what that effect was. That experience was really helpful in that as a result of it I have a much better idea about what is actually happening at the edge as I sharpen. I think looking at magnified images like these or using even a 10x jewelers loupe (as Sal has said he does, btw) is also very helpful in learning about what is going on with the metal at the actual edge and that ultimately it makes one a better sharpener.

Nowadays, I mostly use the loupe to observe the scratch pattern and how it changes as I sharpen and to help determine where I'm grinding on the bevel. I think it's really helpful overall.

Nowadays, I mostly use the loupe to observe the scratch pattern and how it changes as I sharpen and to help determine where I'm grinding on the bevel. I think it's really helpful overall.

Peter - My :spyder:'s:

Caly~3.5 (VG-10 & S. Blue); Para2~(20CP~M390~S30v); Military~(M390~S30v); Endura & Delica~4~FFG; Native~(S30v); Caly~Jr.~(ZDP); Manix~2~(M4); Ladybug~3~(VG-10. SE); Mules~(M390).

Caly~3.5 (VG-10 & S. Blue); Para2~(20CP~M390~S30v); Military~(M390~S30v); Endura & Delica~4~FFG; Native~(S30v); Caly~Jr.~(ZDP); Manix~2~(M4); Ladybug~3~(VG-10. SE); Mules~(M390).

-

jimnolimit

- Member

- Posts: 254

- Joined: Sat Jan 15, 2011 1:25 am

- Location: brooklyn

-

jimnolimit

- Member

- Posts: 254

- Joined: Sat Jan 15, 2011 1:25 am

- Location: brooklyn

i decided to cut the other sneaker up using my spyderco para 2 s30v. i set the edge around 18-20 degrees, with the same stone i finished the ZDP with. the s30v would easily cut newspaper against the grain before the test, just like the ZDP. i cut the same sneaker as i did with the ZDP (just the other side). i also cut this sneaker into about 27-28 pieces just like i did with the ZDP. the only thing i did differently was that i oiled a paper towel and kept wiping the blade so it wouldn't get gummed up. i didn't use oil on the ZDP until i was close to the end of the test which made cutting more difficult. this caused me to use some more effort with the ZDP as opposed to the s30v.

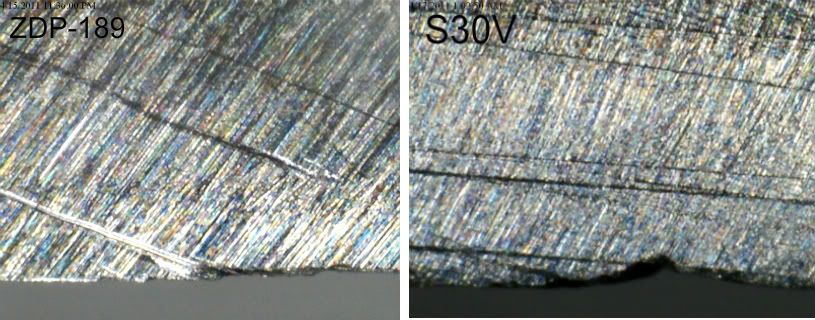

this is the edge and the part of the edge i marked before the test, 40x-50x magnification:

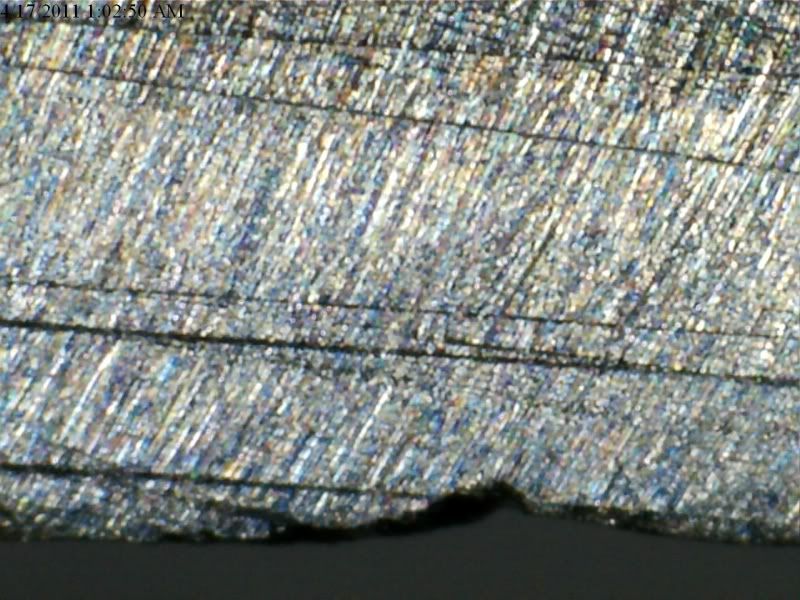

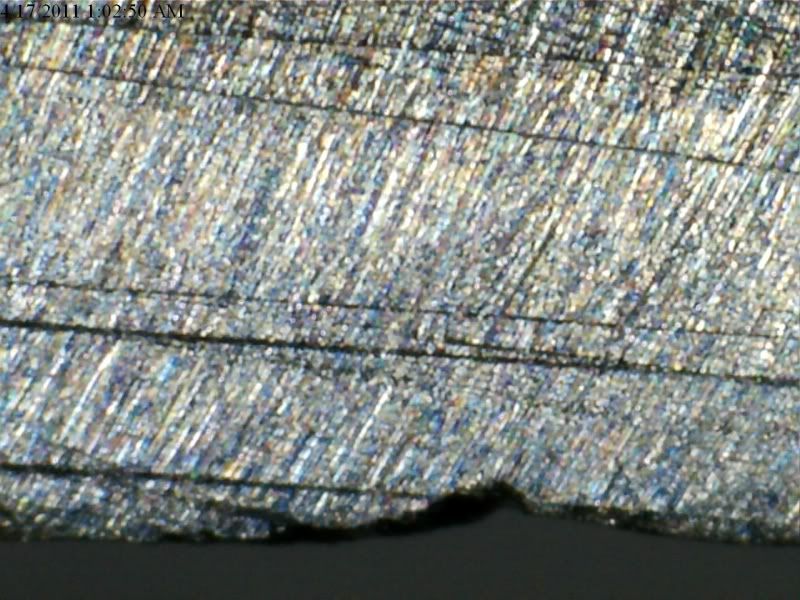

this is the edge after the test, 40x-50x magnification:

this is the edge at 375x magnification. the s30v took on more damage than the ZDP. also, the s30v wouldn't cut either paper or cardboard after the test. ZDP had some trouble with newspaper, but still cut cardboard pretty easily. note the scoring on the edge just like the ZDP had. i don't know if that is caused by microscopic pieces of s30v getting caught in the rubber or if the rubber has abrasive in it (example: they use silica in the rubber for car tires).

this is the edge and the part of the edge i marked before the test, 40x-50x magnification:

this is the edge after the test, 40x-50x magnification:

this is the edge at 375x magnification. the s30v took on more damage than the ZDP. also, the s30v wouldn't cut either paper or cardboard after the test. ZDP had some trouble with newspaper, but still cut cardboard pretty easily. note the scoring on the edge just like the ZDP had. i don't know if that is caused by microscopic pieces of s30v getting caught in the rubber or if the rubber has abrasive in it (example: they use silica in the rubber for car tires).

Jim, I think you will find that the edge erosion and subsequent scoring, is due to silica and rock fragments embedded in the uppers and sole of the shoe. It is actually such microscopic silica that causes the stitches to fail in shoes.

Regards, Al

The "soul" of hi-tech materials like G-10, H1, ZDP, Titanium, carbon fiber, etc is found in the performance. That appreciation of the "spirit" comes out in time, after use. It's saying, you can depend on me! I'm there for you no matter what! - Sal Glesser

The "soul" of hi-tech materials like G-10, H1, ZDP, Titanium, carbon fiber, etc is found in the performance. That appreciation of the "spirit" comes out in time, after use. It's saying, you can depend on me! I'm there for you no matter what! - Sal Glesser

- defenestrate

- Member

- Posts: 2672

- Joined: Fri Sep 24, 2004 10:33 am

- Location: RTP NC area

- Contact:

Adding silica to rubber is pretty common to aid traction (particularly on ice). It can be pretty rough on edges...but I have also used it (silica enriched rubber) in a pinch to strop an edge to a more usable state.A.P.F. wrote:Jim, I think you will find that the edge erosion and subsequent scoring, is due to silica and rock fragments embedded in the uppers and sole of the shoe. It is actually such microscopic silica that causes the stitches to fail in shoes.

Thanks,

Ken (my real name)

...learning something new all the time.

Ken (my real name)

...learning something new all the time.

I've always found S30V to have a little more tendency to develop small chips when subjected to moderately heavy use than I like to see. Your test and photo confirms what I've observed in my own usage. It's still a pretty decent blade steel though that I find fairly easy to sharpen and it takes a nice edge.

Peter - My :spyder:'s:

Caly~3.5 (VG-10 & S. Blue); Para2~(20CP~M390~S30v); Military~(M390~S30v); Endura & Delica~4~FFG; Native~(S30v); Caly~Jr.~(ZDP); Manix~2~(M4); Ladybug~3~(VG-10. SE); Mules~(M390).

Caly~3.5 (VG-10 & S. Blue); Para2~(20CP~M390~S30v); Military~(M390~S30v); Endura & Delica~4~FFG; Native~(S30v); Caly~Jr.~(ZDP); Manix~2~(M4); Ladybug~3~(VG-10. SE); Mules~(M390).

-

jimnolimit

- Member

- Posts: 254

- Joined: Sat Jan 15, 2011 1:25 am

- Location: brooklyn

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

That will be interesting. I hope you'll have it up soon. :Djimnolimit wrote: im thinking about starting a thread where i test different steels under the same conditions.

Thanks for taking the time and exerting the effort(not to mention the use of your spydies) to do this.

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

-

Hammerlock

- Member

- Posts: 3

- Joined: Mon Apr 18, 2011 12:10 pm

- Location: Virginia

I'm of the same mind as Hammerlock, yet something in my mind keeps telling me to polish the edge more, take away as many of those microscopic scratches on the edge as you can and minimize the points of stress accumulation. Discontinuity on the edge will always lead to stress accumulation. Smoother is better and stronger :) A finer finish will help with any material.

Charlie

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

-

jimnolimit

- Member

- Posts: 254

- Joined: Sat Jan 15, 2011 1:25 am

- Location: brooklyn

i change my sneakers every 3-5 months and they're always US made new balances. the pair i use now will get retired within the next week.Blerv wrote:I would love to see m4 go at it. Sorry about your shoes!

when bento box ships out my M4 manix2, there is a very good chance a sneaker will get sacrificed

-

jimnolimit

- Member

- Posts: 254

- Joined: Sat Jan 15, 2011 1:25 am

- Location: brooklyn

i made the thread: http://spyderco.com/forums/showthread.p ... post667764chuck_roxas45 wrote:That will be interesting. I hope you'll have it up soon. :D

Thanks for taking the time and exerting the effort(not to mention the use of your spydies) to do this.

i have pics of the:

1. endura 4 ZDP

2. para 2 s30v

3. 52100 mule

4. buck vantage (420HC)

.

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

Thanks for all the time and effort expended. Outstanding!jimnolimit wrote:i made the thread: http://spyderco.com/forums/showthread.p ... post667764

i have pics of the:

1. endura 4 ZDP

2. para 2 s30v

3. 52100 mule

4. buck vantage (420HC)

.

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank