The Mule Thumb Ramp

The Mule Thumb Ramp

The thumb ramp on the Mule is abrupt, and prone to hurt the thumb when using sabre grip, if the blade stops short. Would the mule series be "ruined" if the thumb ramp were relaxed a few degrees in upcoming mules? More of a Manix-style thumb ramp, perhaps?

That might mean the plunge line tilting a few degrees forward (ie, plunge line at spine tilting more toward tip) of how it sits now. Change one thing and it might make a chain-reaction (a change-reaction?) of other things changing, and the purpose of the Mule team is to keep everything but the steel constant from Mule to Mule.

Maybe an idea that's D.O.A. But I do wish I could find a solution for the abrupt thumb ramp other than grinding it myself and potentially running the thumb ramp past the plunge line, which would not be satisfactory IMO.

I've toyed with the idea of adding some material behind the thumb ramp to make it less abrupt but haven't had any genius ideas yet. Would Spyderco consider adding some material behind the existing thumb ramp to make it less abrupt? Adding material in this area would not affect the blade itself, or the hole patterns. But it might mess with sheath fitment.

A cobra-hood add-on maybe?

OK, I've almost talked myself out of the idea at this point; not seeing any elegant solutions. Do you have any?

That might mean the plunge line tilting a few degrees forward (ie, plunge line at spine tilting more toward tip) of how it sits now. Change one thing and it might make a chain-reaction (a change-reaction?) of other things changing, and the purpose of the Mule team is to keep everything but the steel constant from Mule to Mule.

Maybe an idea that's D.O.A. But I do wish I could find a solution for the abrupt thumb ramp other than grinding it myself and potentially running the thumb ramp past the plunge line, which would not be satisfactory IMO.

I've toyed with the idea of adding some material behind the thumb ramp to make it less abrupt but haven't had any genius ideas yet. Would Spyderco consider adding some material behind the existing thumb ramp to make it less abrupt? Adding material in this area would not affect the blade itself, or the hole patterns. But it might mess with sheath fitment.

A cobra-hood add-on maybe?

OK, I've almost talked myself out of the idea at this point; not seeing any elegant solutions. Do you have any?

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

- standy99

- Member

- Posts: 2303

- Joined: Sat Jul 22, 2017 11:07 am

- Location: Between Broome and Cairns somewhere

Re: The Mule Thumb Ramp

38 already and you want to mess with perfect…..

Sal straightened the spine a little and that caused polls and outrage

Sal straightened the spine a little and that caused polls and outrage

Im a vegetarian as technically cows are made of grass and water.

Re: The Mule Thumb Ramp

The only things that come to mind are steel epoxy or silver soldering, but the former would be hideous and the latter would likely (read ‘definitely’) mess up the heat treat. If I were inclined to do it myself I’d nibble it into a new shape with a sanding drum on my Foredom. I don’t really notice the ramp though so maybe it’s a hand size thingBolster wrote: ↑Mon Apr 03, 2023 8:48 pmThe thumb ramp on the Mule is abrupt, and prone to hurt the thumb when using sabre grip, if the blade stops short. Would the mule series be "ruined" if the thumb ramp were relaxed a few degrees in upcoming mules? More of a Manix-style thumb ramp, perhaps?

That might mean the plunge line tilting a few degrees forward (ie, plunge line at spine tilting more toward tip) of how it sits now. Change one thing and it might make a chain-reaction (a change-reaction?) of other things changing, and the purpose of the Mule team is to keep everything but the steel constant from Mule to Mule.

Maybe an idea that's D.O.A. But I do wish I could find a solution for the abrupt thumb ramp other than grinding it myself and potentially running the thumb ramp past the plunge line, which would not be satisfactory IMO.

I've toyed with the idea of adding some material behind the thumb ramp to make it less abrupt but haven't had any genius ideas yet. Would Spyderco consider adding some material behind the existing thumb ramp to make it less abrupt? Adding material in this area would not affect the blade itself, or the hole patterns. But it might mess with sheath fitment.

A cobra-hood add-on maybe?

OK, I've almost talked myself out of the idea at this point; not seeing any elegant solutions. Do you have any?

- Al

Work: Jumpmaster 2 H1 and Temp 1 SE CPM Cruwear Sprint.

Home: DF2 K390 Wharncliffe/DF2 Salt H1 SE and K390 Police 4 LW SE/15V Shaman

Dream knives -

Chinook in Magnacut (any era)

Manix 2 XL SE Salt in Magnacut

A larger Rockjumper in Magnacut SE

Work: Jumpmaster 2 H1 and Temp 1 SE CPM Cruwear Sprint.

Home: DF2 K390 Wharncliffe/DF2 Salt H1 SE and K390 Police 4 LW SE/15V Shaman

Dream knives -

Chinook in Magnacut (any era)

Manix 2 XL SE Salt in Magnacut

A larger Rockjumper in Magnacut SE

-

TTFulltimer

- Member

- Posts: 111

- Joined: Wed Feb 01, 2023 12:25 pm

Re: The Mule Thumb Ramp

Scales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see the filler. I make all my mules with that handle shape as I intend to do some serious stabbing and I do not want my hand to move forward. I use a $14 Ottoza sheath from AmazonBolster wrote: ↑Mon Apr 03, 2023 8:48 pm

I've toyed with the idea of adding some material behind the thumb ramp to make it less abrupt but haven't had any genius ideas yet. Would Spyderco consider adding some material behind the existing thumb ramp to make it less abrupt? Adding material in this area would not affect the blade itself, or the hole patterns. But it might mess with sheath fitment.

OK, I've almost talked myself out of the idea at this point; not seeing any elegant solutions. Do you have any?

Just a crotchety old curmudgeon who has seen a thing or two

Re: The Mule Thumb Ramp

Yeah, good point. Though to be fair, Sal asked for the poll.

Does CQI apply to mules?

TTFulltimer wrote: ↑Tue Apr 04, 2023 11:32 amScales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see

Clever, and looks maximum comfortable.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

-

CasperFatone

- Member

- Posts: 110

- Joined: Sat Nov 19, 2022 9:02 am

Re: The Mule Thumb Ramp

I decided to grind down the ramp on my first folding Mule to give it a less abrupt angle. I also added some jimping and have been very pleased with the overall feel of it.

Sorry this isn’t the best picture to show how much material I removed.

Sorry this isn’t the best picture to show how much material I removed.

Amateur maker of folding knives and addicted to modding Spyderco knives

Folding Mules- m398 liner lock, Rex76 compression lock flipper, 15v liner lock flipper, 15v LW compression lock flipper

Folding Mules- m398 liner lock, Rex76 compression lock flipper, 15v liner lock flipper, 15v LW compression lock flipper

- defenestrate

- Member

- Posts: 2660

- Joined: Fri Sep 24, 2004 10:33 am

- Location: RTP NC area

- Contact:

Re: The Mule Thumb Ramp

Very nice work! I don't have much space or gear but I'd definitely like to make a decent handle soon.TTFulltimer wrote: ↑Tue Apr 04, 2023 11:32 amScales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see the filler. I make all my mules with that handle shape as I intend to do some serious stabbing and I do not want my hand to move forward. I use a $14 Ottoza sheath from Amazon

Re: The Mule Thumb Ramp

Bolster wrote: ↑Tue Apr 04, 2023 12:06 pm

Yeah, good point. Though to be fair, Sal asked for the poll.

Does CQI apply to mules?

TTFulltimer wrote: ↑Tue Apr 04, 2023 11:32 amScales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see

Clever, and looks maximum comfortable.

As Bolster stated, I did ask for the poll.

sal

- standy99

- Member

- Posts: 2303

- Joined: Sat Jul 22, 2017 11:07 am

- Location: Between Broome and Cairns somewhere

Re: The Mule Thumb Ramp

I knew that Sal, misplaced Aussie smart ar$e comment.sal wrote: ↑Thu Apr 06, 2023 9:01 pmBolster wrote: ↑Tue Apr 04, 2023 12:06 pm

Yeah, good point. Though to be fair, Sal asked for the poll.

Does CQI apply to mules?

TTFulltimer wrote: ↑Tue Apr 04, 2023 11:32 amScales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see

Clever, and looks maximum comfortable.

As Bolster stated, I did ask for the poll.

sal

I'm happy with the mules as they are. Have grown on me so ramp and nub are just part of the Mule experience.

Im a vegetarian as technically cows are made of grass and water.

Re: The Mule Thumb Ramp

I could live without it altogether. If I ever get around to making my own scales I'm going to look into making a back spacer that fills that area in and blends it in with the spine of the handle.

~David

-

JRinFL

- Member

- Posts: 6149

- Joined: Wed Nov 18, 2015 10:30 am

- Location: Unfashionable West End of the Galaxy (SE USA)

Re: The Mule Thumb Ramp

Removing the hole or making it smaller would allow more room for people to adjust the ramp to their liking, though I do understand the need to keep it for trademark reasons.

"...it costs nothing to be polite." - Winston Churchill

“Maybe the cheese in the mousetrap is an artificially created cheaper price?” -Sal

Friends call me Jim. As do my foes.

M.N.O.S.D. 0001

- Tucson Tom

- Member

- Posts: 1641

- Joined: Tue Mar 28, 2017 10:19 pm

- Location: Somewhere in Arizona

Re: The Mule Thumb Ramp

Thanks to TTfultimer for the tip on the $14 sheath, I tracked down what looks like the item in question and will give it a try.

Re: The Mule Thumb Ramp

I like the ramp and the mules as they are too. Doesn’t mean they couldn’t be better but I like them both.

-

TTFulltimer

- Member

- Posts: 111

- Joined: Wed Feb 01, 2023 12:25 pm

Re: The Mule Thumb Ramp

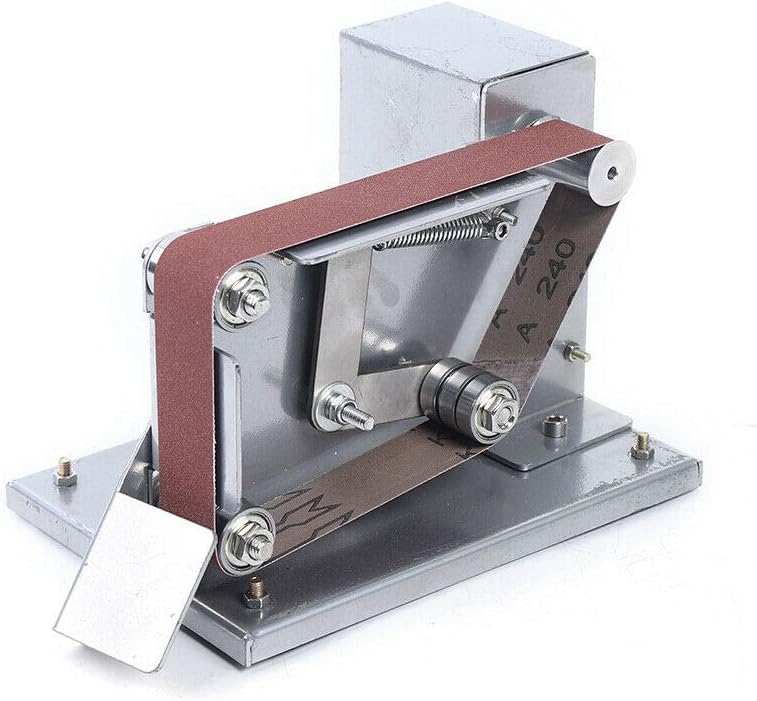

I travel full time so have limited space and weight carrying capability. What I found to use for these smaller wood projects.defenestrate wrote: ↑Thu Apr 06, 2023 4:20 pmVery nice work! I don't have much space or gear but I'd definitely like to make a decent handle soon.TTFulltimer wrote: ↑Tue Apr 04, 2023 11:32 amScales made with my ideal ramp, gap filled with sanding dust/epoxy mix. If you look closely at the top view you can see the filler. I make all my mules with that handle shape as I intend to do some serious stabbing and I do not want my hand to move forward. I use a $14 Ottoza sheath from Amazon

Japanese pull saws, adjustable frame coping saw, small drill press, small table saw, small belt sander, and small oscilating spindle sander.

Just a crotchety old curmudgeon who has seen a thing or two

-

burlyspyder

- Member

- Posts: 87

- Joined: Sat Feb 25, 2017 11:09 am

Re: The Mule Thumb Ramp

This has always bothered me and I have evolved my scale design to make it comfortable. You can see my solution in my other threads. It's essentially just extending the scales to widen/extend the ramp. I also like to have the scales extend a tiny bit above the ramp to give an index/reference point for blade control.

MT; Z-max, Z-wear, Magnacut, SRS13, Rex76, M398, T15, K294, ZDP-189, HIC, AEB-L, SPY27, 15v

Other: D2, White#1, Blue#2, SuperBlue, VG-10, 204P, 20cv, s30v, s35vn, s45vn, s90v, HIC, TC71

- Traditional.Sharpening

- Member

- Posts: 293

- Joined: Thu Mar 02, 2023 12:29 am

Re: The Mule Thumb Ramp

Actually just recently got my first Mule(s) and have to say I'm not a fan of the hole on a fixed blade along with the ramp it produces. I get it's a visual cue to their folders but there's no added function there so it's not adding value other than aesthetics and adding a potential snag point to the knife. I haven't used it enough to say if that actually happens though.

The real issue I take with it is that it causes the Boltatron sheath to have a functional sticking point when you draw the knife. Perhaps the sheath was designed to 'catch' there on purpose to aid retention but if it was done for this it does not give a consistent release tension as wiggling the knife as it comes out can cause it to sneak by the snag point easily if it turns.

The real issue I take with it is that it causes the Boltatron sheath to have a functional sticking point when you draw the knife. Perhaps the sheath was designed to 'catch' there on purpose to aid retention but if it was done for this it does not give a consistent release tension as wiggling the knife as it comes out can cause it to sneak by the snag point easily if it turns.

- Tucson Tom

- Member

- Posts: 1641

- Joined: Tue Mar 28, 2017 10:19 pm

- Location: Somewhere in Arizona

Re: The Mule Thumb Ramp

It works for me. It is fine. It has never bothered me.

Re: The Mule Thumb Ramp

Traditional.Sharpening wrote: ↑Fri Apr 07, 2023 6:55 pm...not a fan of the hole on a fixed blade ...

I take your point. However, if you ever have need to turn your mule into a spear tip (which is possible if an outing goes wrong) you'd be glad for the lashing point the hole gives.

On your other point: I also had problems with the hole when making my own Kydex sheath. As you say it added a "pinch point" that aided retention, but it also meant the Kydex nub it created nearly scraped off the Spyder logo with the friction from only a couple dozen sheathings and unsheathings. And that was with clean Kydex; imagine what happens after the sheath has been on the trail for a week or two. So I cut a dowel the width of the blade and inserted it into the hole when making the replacement sheath. That worked. I much prefer no sheath "indent" at the hole.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

Re: The Mule Thumb Ramp

Do you mean the octagon handle solution? I don't see any other mule handle photos than that. But yes, making a tang of the mule handle, and then adding a large octagonal handle, would obscure the thumb ramp. I don't think you ever posted a final photo of your project, however.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

-

TTFulltimer

- Member

- Posts: 111

- Joined: Wed Feb 01, 2023 12:25 pm

Re: The Mule Thumb Ramp

I trimmed the sheath just a bit, and use a lanyard on the knife.Tucson Tom wrote: ↑Fri Apr 07, 2023 8:48 amThanks to TTfultimer for the tip on the $14 sheath, I tracked down what looks like the item in question and will give it a try.

Just a crotchety old curmudgeon who has seen a thing or two