Reprofiling CPM Cru-Wear

Reprofiling CPM Cru-Wear

SUCKS.

That is all.

Ok no really, I seem to recall this steel supposedly being easier to sharpen than S110V, but I swear it seems almost worse. Granted, I'm removing a lot of steel to correct what has to be the worst factory bevel I've ever seen from Spyderco, but still it's VERY slow going even with an 80 grit Moldmaster stone. In fact for some reason it even seems like my 220 grit Shapton Glass stone cuts it better. I spend about 60 seconds making passes and then have to lap and brush the 80 grit clean because it's clogging so fast.

Figured I'd take a break to complain. Also Tropic Thunder is back on Netflix, hilariously stupid movie lol.

That is all.

Ok no really, I seem to recall this steel supposedly being easier to sharpen than S110V, but I swear it seems almost worse. Granted, I'm removing a lot of steel to correct what has to be the worst factory bevel I've ever seen from Spyderco, but still it's VERY slow going even with an 80 grit Moldmaster stone. In fact for some reason it even seems like my 220 grit Shapton Glass stone cuts it better. I spend about 60 seconds making passes and then have to lap and brush the 80 grit clean because it's clogging so fast.

Figured I'd take a break to complain. Also Tropic Thunder is back on Netflix, hilariously stupid movie lol.

~David

Re: Reprofiling CPM Cru-Wear

Pics or it didnt happen

Re: Reprofiling CPM Cru-Wear

Which knife David?? I have a Millie and a Manix with Cruwear. Both edges from Spydie are really nice and even......and SHARP!! I've just been maintaining the factory edge.

What was the reason for re profiling??

Just curious.

Joe

What was the reason for re profiling??

Just curious.

Joe

Re: Reprofiling CPM Cru-Wear

I'll have before and after pics once it's done.Spydergirl88 wrote:Pics or it didnt happen

Yeah I was surprised at how bad it was. I believe this knife came from back when bevels were cut by hand instead of by the robot arm thing.palonej wrote:Which knife David?? I have a Millie and a Manix with Cruwear. Both edges from Spydie are really nice and even......and SHARP!! I've just been maintaining the factory edge.

What was the reason for re profiling??

Just curious.

Joe

~David

Re: Reprofiling CPM Cru-Wear

The worst part isn't so much that the bevels are uneven, but that the edge is so far off center because of it. One side is well above 15 degrees but the other side is seriously close to 60 degrees, it's practically a chisel grind. So while one side was relatively easy to grind and get down to 15 degrees, the other side is taking forever because I had to cut into the shoulder so deep to bring it back down to 15 degrees, and then I have to grind the other side down until the edge is centered again. I probably shouldn't blame the steel so much because this would suck on VG10.

~David

Re: Reprofiling CPM Cru-Wear

Very interesting. I would expect it to be easy, relative to some of the more wear resistant steels. I just reprofiled my 52100 Millie, and it took longer than I expected (the non-presentation side was pretty obtuse). Though I am doing it using the SM diamonds.

I need to reprofile my Cruwear PM2. The factory bevel on it isn't great. Presentation side looks to be around 15dps, while the other side looks closer to 20. I've found the bevels on recent Spydies that are sharpened robotically to be more inconsistent and uneven than when they used to be sharpened by hand. But maybe I'm just getting poor examples.

I need to reprofile my Cruwear PM2. The factory bevel on it isn't great. Presentation side looks to be around 15dps, while the other side looks closer to 20. I've found the bevels on recent Spydies that are sharpened robotically to be more inconsistent and uneven than when they used to be sharpened by hand. But maybe I'm just getting poor examples.

Re: Reprofiling CPM Cru-Wear

Lol, just found this thread.

I nagged David for a while to look at my Cruwear Manix and he eventually folded, sucker! :D

Maintaining the factory bevel was ok for a while, but it really was bad. I've joked that the edge bevel must have been ground late on a Friday afternoon. I wanted to reprofile it to improve the cutting performance and ease of maintenance. Figured someone with a good jig system would likely do a much cleaner job on it than I could by hand.

Sounds like I'm going to owe Evil D a big jug of SunnyD or something once he's finished. Thanks again man!

I nagged David for a while to look at my Cruwear Manix and he eventually folded, sucker! :D

Maintaining the factory bevel was ok for a while, but it really was bad. I've joked that the edge bevel must have been ground late on a Friday afternoon. I wanted to reprofile it to improve the cutting performance and ease of maintenance. Figured someone with a good jig system would likely do a much cleaner job on it than I could by hand.

Sounds like I'm going to owe Evil D a big jug of SunnyD or something once he's finished. Thanks again man!

:spyder:

Re: Reprofiling CPM Cru-Wear

Lol it's coming along. The longest part of these jobs is the very end when you have that teeny sliver of the old bevel left and haven't quite reached the apex. You're grinding so much metal per pass it just gets slower and slower the closer you get but it's getting close.

~David

Re: Reprofiling CPM Cru-Wear

Well, the deed is done.

I can tell you with no ego, this is my finest sharpening job. If on your journey, you should encounter God, God will be cut.

Seriously though, once the profile work was done, I'm super impressed with how this steel takes an edge. It definitely whittles hanging hair and push cuts phone book paper. It has that "sticky" feeling when you pluck hair off your arm.

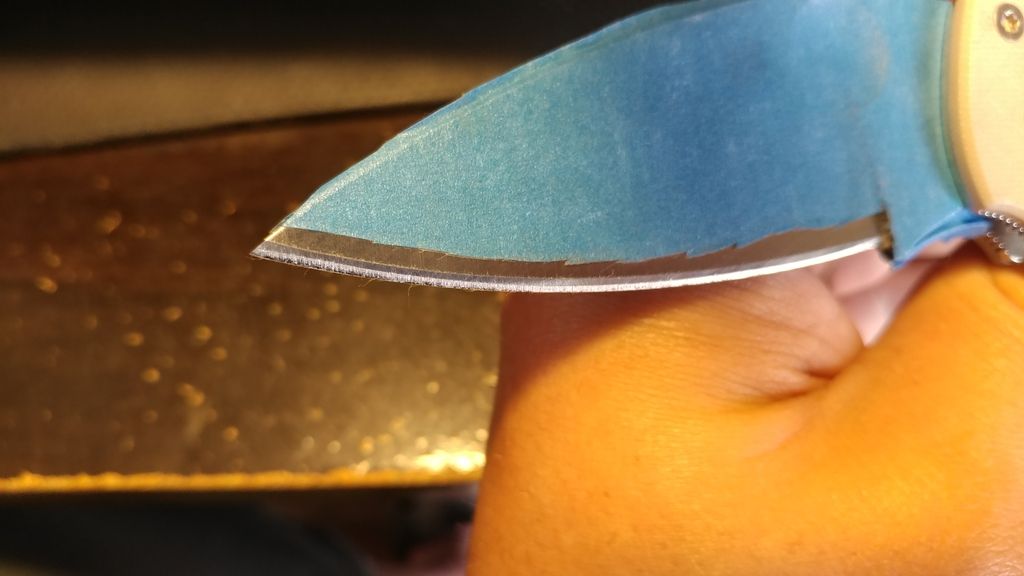

Here's what I started with.

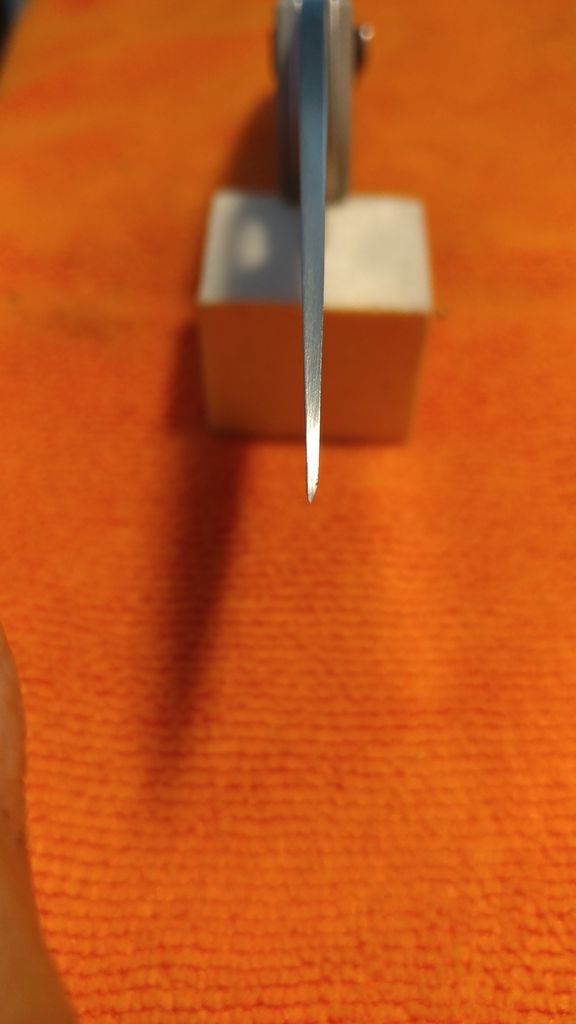

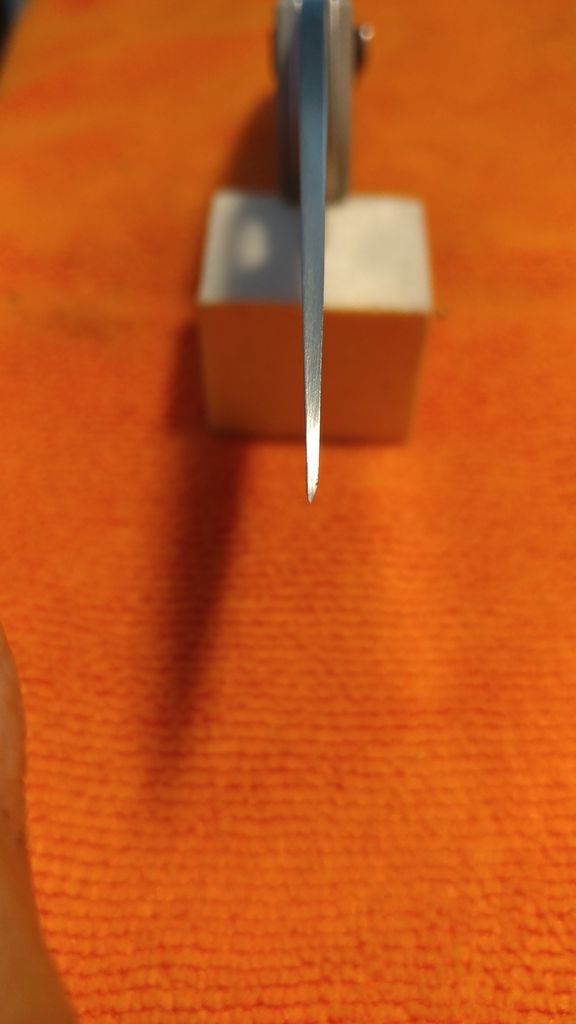

Look at how uneven that tip is..

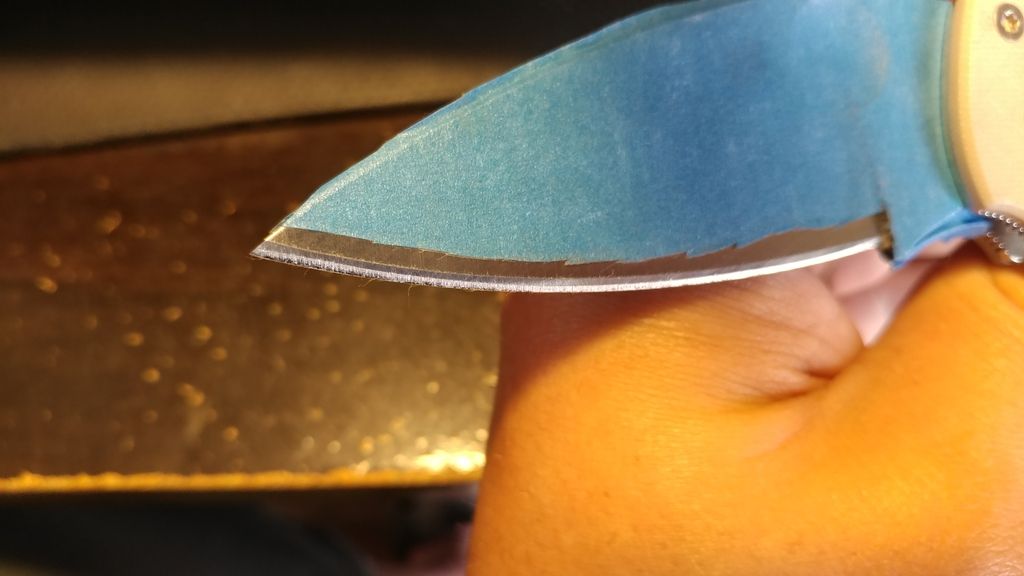

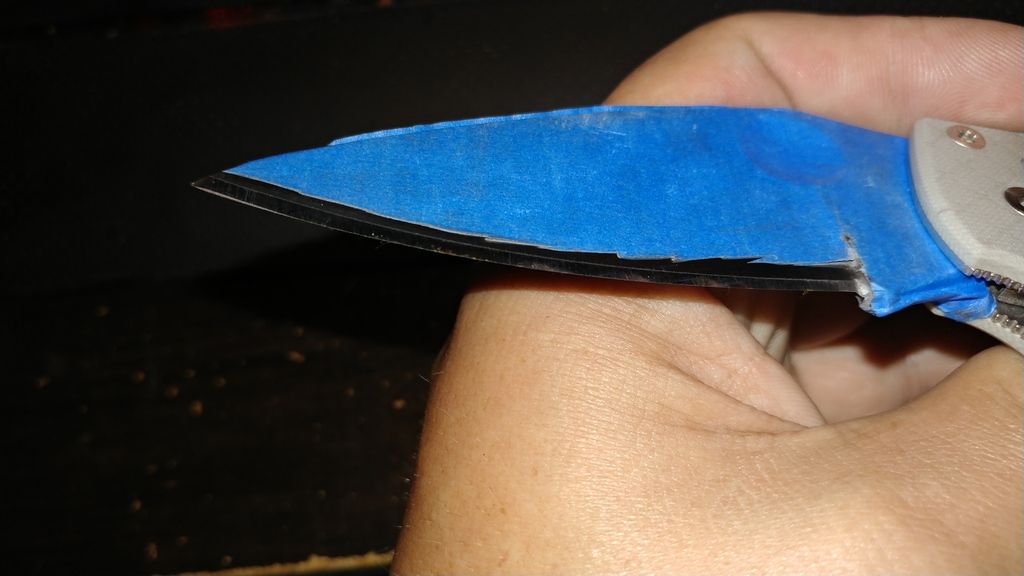

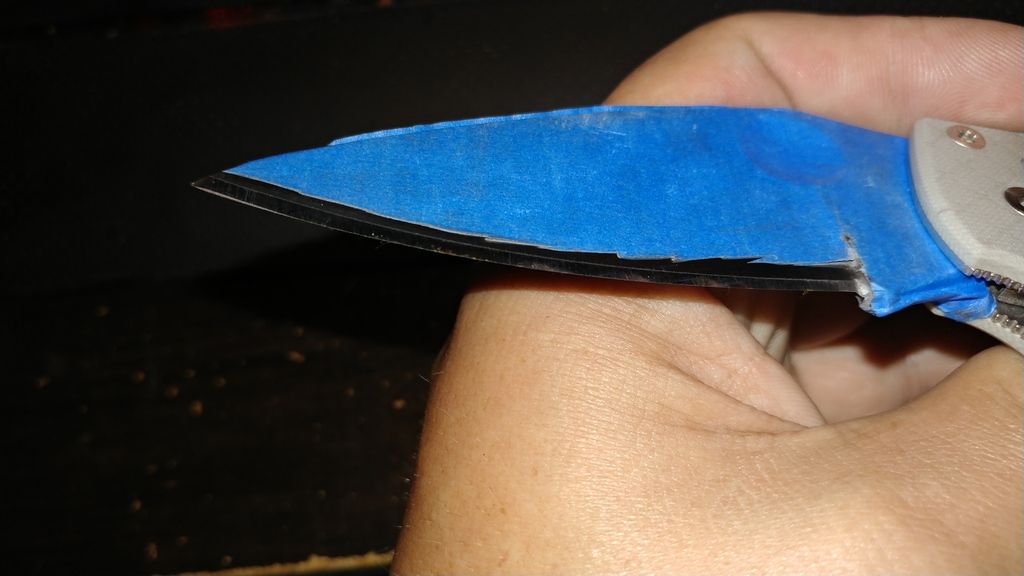

Taped up and ready for action..

First couple passes with marker so you can see how uneven the bevels were. The back side wasn't all that bad and just a little steeper than 15 degrees, but the presentation side was seriously well north of 60 degrees. It may look like the presentation side is a low angle because of how wide the bevel is, but it's only wide like that because it's ground way over past the center of the blade. The back side was probably in the neighborhood of 20 degrees or so and apart from having to move the edge over to the center of the blade it didn't take much work to get it down to 15 degrees.

Progress was slow..

Especially this wee little bit at the tip. I was ready to throw this knife across the room at this point lol.

Here's the finished product. I wasn't sure what Nate wanted as far as edge finish so I just went with 600 grit on the bevel like I do my own knives and then micro beveled with the Sharpmaker at 40. This 600 grit Moldmaster gives a really creamy satin scratch pattern that I really like.

Now she has a nice clean even V tip.

I can tell you with no ego, this is my finest sharpening job. If on your journey, you should encounter God, God will be cut.

Seriously though, once the profile work was done, I'm super impressed with how this steel takes an edge. It definitely whittles hanging hair and push cuts phone book paper. It has that "sticky" feeling when you pluck hair off your arm.

Here's what I started with.

Look at how uneven that tip is..

Taped up and ready for action..

First couple passes with marker so you can see how uneven the bevels were. The back side wasn't all that bad and just a little steeper than 15 degrees, but the presentation side was seriously well north of 60 degrees. It may look like the presentation side is a low angle because of how wide the bevel is, but it's only wide like that because it's ground way over past the center of the blade. The back side was probably in the neighborhood of 20 degrees or so and apart from having to move the edge over to the center of the blade it didn't take much work to get it down to 15 degrees.

Progress was slow..

Especially this wee little bit at the tip. I was ready to throw this knife across the room at this point lol.

Here's the finished product. I wasn't sure what Nate wanted as far as edge finish so I just went with 600 grit on the bevel like I do my own knives and then micro beveled with the Sharpmaker at 40. This 600 grit Moldmaster gives a really creamy satin scratch pattern that I really like.

Now she has a nice clean even V tip.

~David

Re: Reprofiling CPM Cru-Wear

Great job!

Re: Reprofiling CPM Cru-Wear

Nicely done and thank you for sharing!

My ZDP-189 Delica had a horrible edge when it came to me. Nothing like that but it needed a good bit of grinding. It was a chore indeed. That was my first experience with a harder steel. I have a lot of respect for the work you did here!

My ZDP-189 Delica had a horrible edge when it came to me. Nothing like that but it needed a good bit of grinding. It was a chore indeed. That was my first experience with a harder steel. I have a lot of respect for the work you did here!

- farnorthdan

- Member

- Posts: 4409

- Joined: Wed Apr 02, 2014 11:32 pm

Re: Reprofiling CPM Cru-Wear

That looks real good David, good on you helping a brother out. I've had a few come like that and know how much work it is to get right. You've come a long way since that M4 Manix2 :D

Happy to be part of this great forum and group of down to earth spyderco addicts, Thanks Sal and gang.

My Grails: Lum Tanto folder sprint, Sprint Persian(red), Captain, Manix 2 (M4), SB MT, PM2 M390, CF dodo, Manix2 (CF S90V),Manix2 XL S90V, Zowada CF Balance Rassenti Nivarna, Lil' Nilakka, Tuff, Police 4, Chinook 4, Caly HAP40 52100 Military, S110V Military, Any/All PM2 & Military sprints/exclusives I can get my grubby hands on :) :spyder: :) :spyder: :)

"We may look curious, homely, whatever, but we'll never be called unusable or undependable."

My Grails: Lum Tanto folder sprint, Sprint Persian(red), Captain, Manix 2 (M4), SB MT, PM2 M390, CF dodo, Manix2 (CF S90V),Manix2 XL S90V, Zowada CF Balance Rassenti Nivarna, Lil' Nilakka, Tuff, Police 4, Chinook 4, Caly HAP40 52100 Military, S110V Military, Any/All PM2 & Military sprints/exclusives I can get my grubby hands on :) :spyder: :) :spyder: :)

"We may look curious, homely, whatever, but we'll never be called unusable or undependable."

- WireEdge Roger

- Member

- Posts: 926

- Joined: Mon May 18, 2009 11:25 am

- Location: Indiana

Re: Reprofiling CPM Cru-Wear

Looking excellent! Wow

That M4 Manix, oh boy, I remember those pics.

That M4 Manix, oh boy, I remember those pics.

Re: Reprofiling CPM Cru-Wear

Yeah. I think Nate mentioned doing this knife at least a couple years ago and I avoided it for that very reason. It was fresh on my mind the whole time.

~David

Re: Reprofiling CPM Cru-Wear

Woo-hoo!

That seriously looks FANTASTIC!!! :eek:

Thank you so much brother. I'm stoked! That Manix is going to spend a lot less time in the box now.

I remember the M4 Manix pics as well lol, but that was a long time ago and I figured it was a lesson that wouldn't need to be learned twice. I knew you would do a great job with it and it looks like my expectations were exceeded.

In case I didn't say it enough: Thank you, thank you, thank you!

That seriously looks FANTASTIC!!! :eek:

Thank you so much brother. I'm stoked! That Manix is going to spend a lot less time in the box now.

I remember the M4 Manix pics as well lol, but that was a long time ago and I figured it was a lesson that wouldn't need to be learned twice. I knew you would do a great job with it and it looks like my expectations were exceeded.

In case I didn't say it enough: Thank you, thank you, thank you!

:spyder:

Re: Reprofiling CPM Cru-Wear

I picked up the Chef Knives to Go diamond stones. They were rediculously good priced.

http://www.chefknivestogo.com/edprolowgrpl.html

The finer one is fine enough to use a knife right off of it.

*edit* I don't even touch the Edge Pro stones that came with it.

http://www.chefknivestogo.com/edprolowgrpl.html

The finer one is fine enough to use a knife right off of it.

*edit* I don't even touch the Edge Pro stones that came with it.

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

Re: Reprofiling CPM Cru-Wear

Donut wrote:I picked up the Chef Knives to Go diamond stones. They were rediculously good priced.

http://www.chefknivestogo.com/edprolowgrpl.html

The finer one is fine enough to use a knife right off of it.

*edit* I don't even touch the Edge Pro stones that came with it.

I had the Atoma's and in the end felt they were a total rip off unfortunately. They wore out in less than 3 years and for $75 each they were not worth it. The best thing about them was that they didn't need lapping and were always flat, it's too bad they didn't wear longer. I wish the Shapton stones came in grits lower than 220, but for the most part the Moldmasters usually cut through anything.

~David

Re: Reprofiling CPM Cru-Wear

Thanks for the details and pics evil dave, not a lot of info especially regarding reprofiling of cruwear. I was thinking of getting myself a para2 in cw, but now im having second thoughts

Re: Reprofiling CPM Cru-Wear

It just depends on how much reprofiling you have to do. If the bevel were even to start out with it wouldn't be any more difficult to maintain than S90/110V/Maximet/ZDP or any other hard high wear steel. My only question would be how tough it is and how it stands up against chipping and rolling, because those will be deciding factors in how often you have to do this sort of thing. But, my favorite stainless is S110V so I'm used to this sort of thing, I guess the point of this thread was that I was expecting it to be easier than it was. If you've ever worked with S90/110V and were able to reprofile that, I don't think this steel is any different. I don't think I would use this experience as the benchmark of what to expect when getting a knife in this steel unless you intend to grind the edge bevel way down.npad69 wrote:Thanks for the details and pics evil dave, not a lot of info especially regarding reprofiling of cruwear. I was thinking of getting myself a para2 in cw, but now im having second thoughts

Another thing I would consider if this were my knife is having it reground. 99% of the difficulty in fixing this bevel was because these knives are ground pretty thick behind the edge, which means a wider bevel, which means removing a lot more metal to reach an apex. If this blade were ~.010 behind the edge it would have been significantly easier to reprofile.

~David

Re: Reprofiling CPM Cru-Wear

Re: Reprofiling CPM Cru-Wear

Home again! One more pic:

This seriously made my day. It is wicked sharp too, atom-splitter. :)

-Good thought on the reprofile and how the size of the bevel impacted your work. I've thought about that as well, but either way I would've wanted to have the edge fixed first. Post reprofile it's ~.025" behind the edge most of the way and thickens up to ~0.03" near the tip. It is pretty a pretty stout grind, but I plan to use this as is for a while and see how it goes. I have a lot of really thin blades as well if I need one.

This seriously made my day. It is wicked sharp too, atom-splitter. :)

-Good thought on the reprofile and how the size of the bevel impacted your work. I've thought about that as well, but either way I would've wanted to have the edge fixed first. Post reprofile it's ~.025" behind the edge most of the way and thickens up to ~0.03" near the tip. It is pretty a pretty stout grind, but I plan to use this as is for a while and see how it goes. I have a lot of really thin blades as well if I need one.

:spyder: