The method is very similar :

-edge angle is 4-8 dps

-microbevel is 25 dps/600 DMT

-3/8" hemp cut on a 2" draw (alternate directions in subsequent cuts)

The sharpness was measured by cutting light cord under tension and using the length of draw to set the sharpness. Both 25 and 50 gram loads were used to allow measurement of high sharpness to decent precision as well as extended use to low stages of sharpness.

The force to cut the hemp can't be used to measure sharpness because of the very low precision and very high variability. To be specific this is the force used to cut the hemp (measured on a standard scale).

001, 4.5 lbs

003, 5.0 lbs

009, 5.0 lbs

021, 5.0 lbs

033, 5.0 lbs

045, 5.0 lbs

069, 5.0 lbs

093, 4.5 lbs

117, 5.0 lbs

The problem is that when the knife is fully sharp it takes a tiny amount of force to make the cut, the rest is just wedging. But the scale is at best +/- 0.5 lbs. Even if you have a more precise scale, just try to make a cut with less variability than that small amount.

Based on the fact that the knife starts to cut before the needle even moves I would estimate it takes on the order of 0.1 lbs to make the cut, this is the sharpness, the rest of the force is just wedging. However the minimum significant difference on the scale is 1 lbs. This means all sharpness reading between 100% of optimal and 10% of optimal show the same on the scale.

It is obvious that the sharpness of the knife is decreasing during the cutting, even if you ignore the thread cutting measurement. You can see the difference on paper, with checks on shaving, and even see the edge start to reflect light but the very poor precision of the scale prevents measurement. It is a simple matter of the math of significance of measurement.

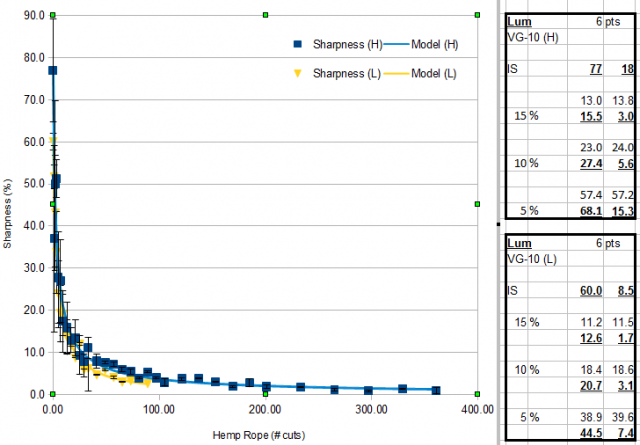

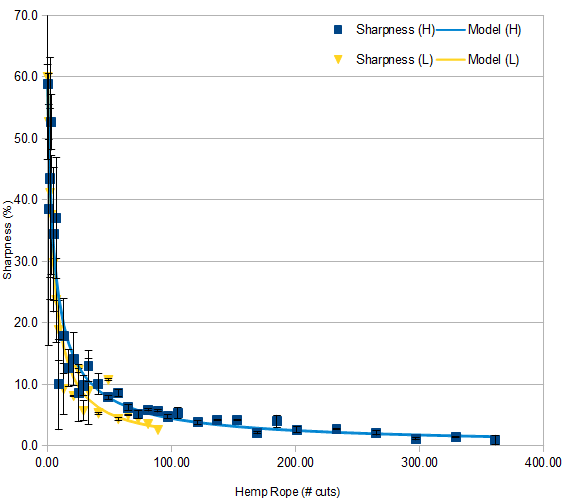

Here is the result of one run using the above measure of sharpness (the yellow is the 25 gram load, the blue is the 50 gram load) :

A few observations :

-as expected, follows the same pattern/curve as cardboard

-the 25 dps edge shows little deformation/chipping

Note that once the knife has entered that long plateau region the rate of blunting is very low and thus very high hemp counts can easily be produced. For example in the above it takes ~150 cuts to make a decrease of 1% of sharpness in that plateau region.

To clarify this is one run which is why the error bars (scatter) is so high, these will reduce significant as more runs are added and once 5-7 runs are completed the curves get very smooth and the scatter is much more contained.

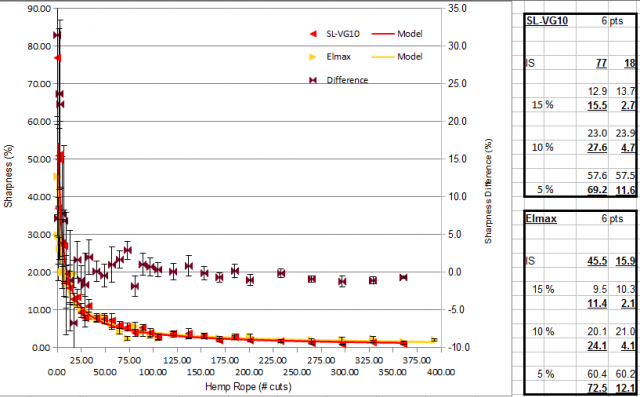

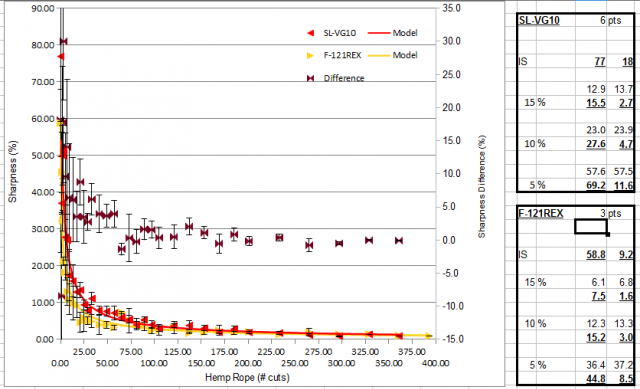

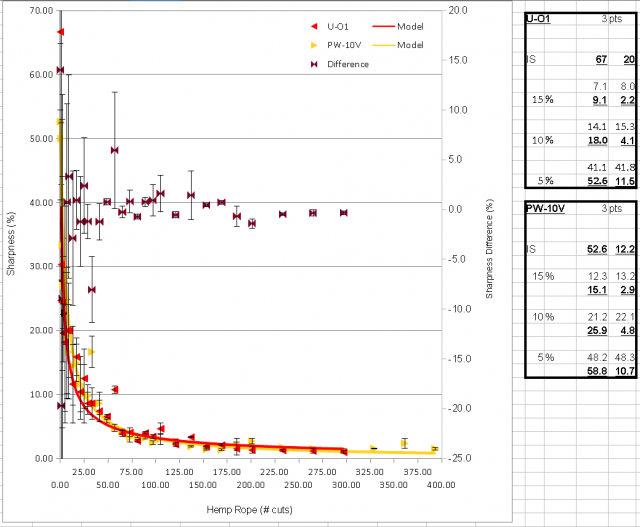

I also spent some time to write some code to allow comparisons, here is comparison of a O1 blade and a 10V blade :

It shows the plots with the high force measurement and also shows the difference in sharpness between the blades as cuts are made. Note how the sharpness difference gets very small as the cuts increase, it has to, this is just the nature of the curves.

Of course with one run it isn't possible to make anything but very coarse distinctions, it takes 3-5 runs to even see moderate differences in steels. This is just a consequence of how random errors propagate, in short they add up.