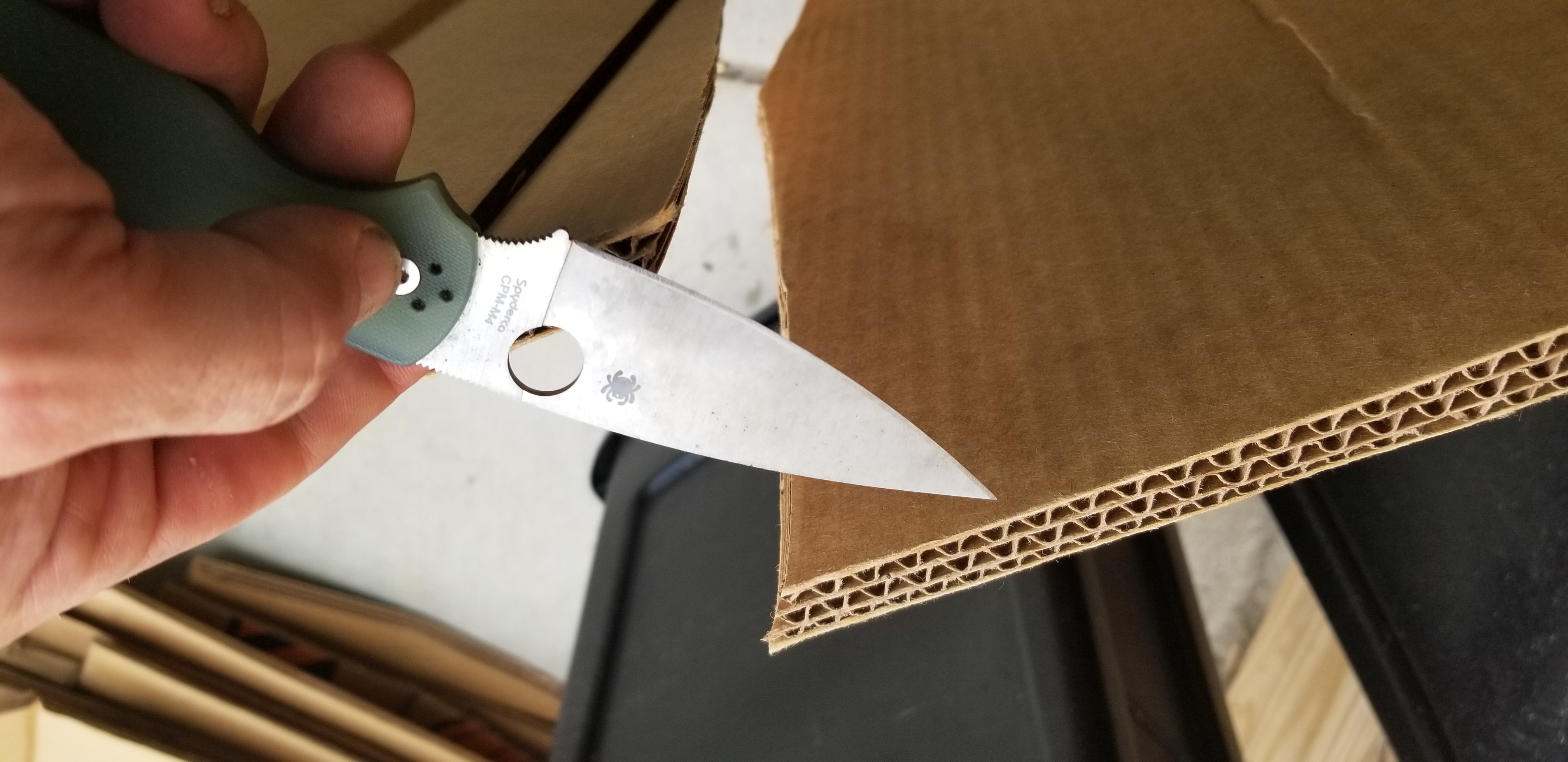

vivi wrote: ↑Wed Feb 12, 2025 6:39 amStrange results. I have no issues breaking down similar boxes with either PE or SE, going with or against the grain.Evil D wrote: ↑Wed Feb 12, 2025 5:04 amI recently came across one of the heaviest boxes I've seen that wasn't one of those watermelon/pumpkin gaylord boxes you see in stores, so of course I have to cut it up.

My Chief made short work of it, it barely felt heavier than a typical double wall box.

Now the wild part is, I actually CAN'T cut this with my Military 2, no matter how hard I push it's just wedged in there like I'm trying to cut through a hard wood branch. I cut at the same place at the same angle as the Chief.

Now before anyone says it, I know I can turn the knife 45 degrees and make this cut much easier, but I didn't have to do that with the Chief, you can see in those pics I made the same squared up cuts.

I'm no Eddie Hall but I'm not a weakling either, I'm really surprised by this. The Chief does have a thinner blade grind but not drastically different, so I'm not sure how much of this can be credited to serrations vs plain edge or if the Chief is really just that much slicier. I do also have a plain edge 4V Chief that I plan on getting out to see if it cuts any better.

I just tried again and I was able slice off a smaller piece if I hold the knife at an angle and really lean into it, but again this wasn't necessary with the Chief, you can even see by the glue marks on the Chief blade that I did more push cutting than slicing.

vivi wrote: ↑ You know those thick cardboard bins 3 corrugated layers deep they ship pumpkins in? Broke down a few of those today with my Chief that we had in our back lot from a recent pumpkin carving competition.

Still scrape shaves despite using a pretty coarse finish and dulling it some since sharpening it.

That's why I want to get my PE Chief out for comparison. Maybe it's the higher factory edge bevel on the Military? It's somewhere between 15 and 20 per side, it micro bevels on the 40 slots. I've reprofiled my 4V Chief too.