Edge retention slicing cardboard (15 dps, x-coarse DMT)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Video commentary : https://youtu.be/4tzyA6u1RGE" target="_blank

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Thanks, Cliff. Your observations square with my own experience and our hunches about the effects of ergonomics are similar, too. As a builder, I'm a huge fan of good ergonomics, preferring a fatter, longer handle even with short blades.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Cliff, after watching your video, it almost seems we should be starting a "cardboard forum" to discuss the wonderful nature of this lowly material...... I do appreciate your dedication to testing, technique & statistical analysis, but I'm sure glad I'm not doing the testing.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

David Boye was one of the first makers whose work I used which showed a strong interest in handle design, Phil Wilson as well. The most extreme position I have seen is Dan Keffeler. If you are interested in ergonomics you really need to look at his work. He really worked on the design of his handles based on experience in competition cutting and how the grip has to support force transfer. I have one of his custom pieces and it makes a lot of knives that I thought had nice handles suddenly appear not so nice any more.Bill1170 wrote:As a builder, I'm a huge fan of good ergonomics, preferring a fatter, longer handle even with short blades.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

It might seem odd on a few counts, but I have to cut it up anyway for recycling. If you want to make paper from it then it has to be fine shredded to soak, plus for burning those rolls I do work very well. The only extra work is really all the counting, but it is something I enjoy anyway.noseoil wrote:... I'm sure glad I'm not doing the testing.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Just watched the vid, and I do think it's an interesting conversation, so thanks for posting. One comment and one question:

In the video, you mentioned disregarding a result as a potential source of a tester getting an erroneous stark difference between two steels. One thing you didn't mention in the video, but I believe you've mentioned before, is using an arbitrary stopping point, which could also cause you to draw erroneous conclusions. I guess this could also be filed under cognitive bias, in that the tester expects a certain steel to cut longer, so they cut longer with it. Just wanted to mention that.

For the question, since I haven't seen you mention this anywhere, do you think that the curvature of the blade (belly) plays a role in these trials at all? Obviously, cardboard is relatively thin, and it looks as though those knives have somewhat similar edge geometry, but would you expect to start to see a difference if you compared say a Yojimbo and a Dodo?

In the video, you mentioned disregarding a result as a potential source of a tester getting an erroneous stark difference between two steels. One thing you didn't mention in the video, but I believe you've mentioned before, is using an arbitrary stopping point, which could also cause you to draw erroneous conclusions. I guess this could also be filed under cognitive bias, in that the tester expects a certain steel to cut longer, so they cut longer with it. Just wanted to mention that.

For the question, since I haven't seen you mention this anywhere, do you think that the curvature of the blade (belly) plays a role in these trials at all? Obviously, cardboard is relatively thin, and it looks as though those knives have somewhat similar edge geometry, but would you expect to start to see a difference if you compared say a Yojimbo and a Dodo?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Yes, and even if it appears to be well determined if you look at the strong nonlinear response to blunting it becomes obvious that the precision required here is extreme to draw even coarse conclusions.tvenuto wrote:One thing you didn't mention in the video, but I believe you've mentioned before, is using an arbitrary stopping point, which could also cause you to draw erroneous conclusions.

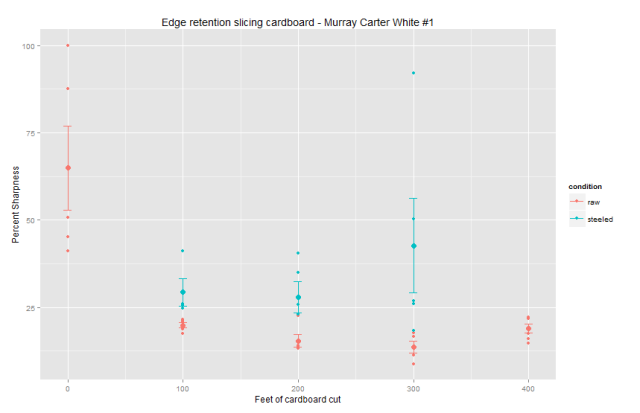

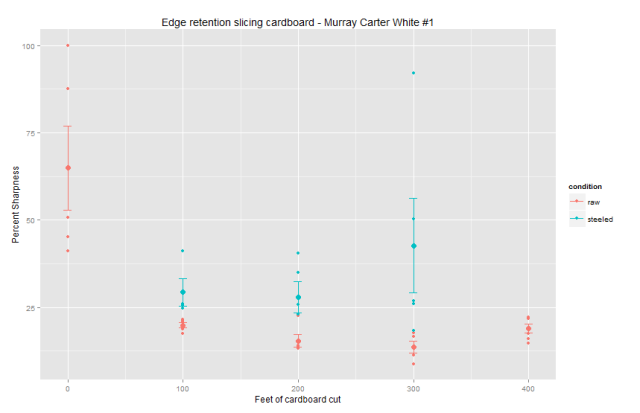

This is Ian's data, if you look at the scatter, there is no significant difference between 100, 200, 300 and 400' of cardboard as it is all in the tail. As a rough guideline, to even see a difference of 2:1 in material (or 100%) you need to have a precision on the order of 1% of sharpness.

No as the cutting is all done with the straight section, or concentrated on it greatly anyway as I use a 2" section of edge. In general, very general, the belly will increase the strength of the edge as it will allow the knife to slide/glance over something it hits and can't cut through. Hence in general the straight portion tends to be more easily damaged. But this is only true in an absolute sense as the belly often gets harder contacts anyway as people cut with it on things like plates and such which just smash the edge down directly.For the question, since I haven't seen you mention this anywhere, do you think that the curvature of the blade (belly) plays a role in these trials at all?

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Most days I can't tell if you are one of the scientists who is reporting accurate information or one who sees if he can get people to believe crazy information.

Why it's it, in your tests, that the cheapest steel always performs the best? Why does it seem that people's perception is opposite your results?

I admit that I don't have much experience with Sandvik/AEB-L, and I wish I did. I like testing to see if my results are in line with other results.

Why it's it, in your tests, that the cheapest steel always performs the best? Why does it seem that people's perception is opposite your results?

I admit that I don't have much experience with Sandvik/AEB-L, and I wish I did. I like testing to see if my results are in line with other results.

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I don't think that is accurate, in this comparison for example k390 had the highest edge retention however the difference wasn't statistically different which is simply to say the data isn't strong enough to say it isn't random. Similar for example in the ongoing hemp run, the current maximum performance is from an Elmax blade : http://www.cliffstamp.com/knives/reviews/hemp.html" target="_blank .Donut wrote: Why it's it, in your tests, that the cheapest steel always performs the best?

In general what blade does the best/highest in regards to steel is going to depend on what you are doing with it. 440C has much higher wear and corrosion resistance than S7, similar strength and far less toughness/ductility. Hence it might do better on cardboard, worse on chopping, much worse on digging. These will also be effected by the edge angle, grit finish and how they are sharpened.

As for other claims, it is to be expected there are differences as there are differences in method. In general you don't listen to someone because of who they are or what they say, you listen because the justification can support the claims. Is what they have done the type of thing which would generate a true conclusion, it is in general consistent when other claims, is there a metallurgical basis to support it?

Making claims is easy, here is one :

"A Chris Reeve Sebenza in S35VN has the most awesome performance of any knife every made."

That claim however is vague and can't really be interpreted and there is no justification given at all so it can be ignored just as easily as it was made. The interesting thing is when two people who appear to be doing reasonable things, which would appear to generally produce reasonable results, and who in general make consistent statements - have a disagreement over findings.

Now the fun really begins as you have to sort out the difference in method to find out where the disagreement is originating. As long as the other party is willing to discuss what they did in detail then it is always possible to sort out these conflicts. I have done it many times. If the other part isn't interested, well they don't have any justification then and can be again easily ignored.

This assumes that you accept science as a method to generate knowledge. If you want to reject that of course you can do many things, flip coins for example to decide which claim it true, look to the stars, consult the magic 8-ball, or if all else fails then ask the great Oz. The great thing about an empirical view though is that it doesn't need you to believe it to be true for it to generate results unlike something like astrology which really does.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

So, using the same testing method that Jim uses gives similar results.

Are we saying that the higher carbide steels have a greater variation of performance and greater variation of results? The lower costing steels are more consistent performing?

It's sort of hard to read those charts. Since you are showing the variation, do I go by the top of the bars for the fluke result or do I go by the bottom of the bars for being a consistent result?

I agree on the Sebenza thing, different people are looking for different things in knives. Just as the opposite people who think a knife that is practically a pry bar has the most awesome performance of any knife ever made.

Are we saying that the higher carbide steels have a greater variation of performance and greater variation of results? The lower costing steels are more consistent performing?

It's sort of hard to read those charts. Since you are showing the variation, do I go by the top of the bars for the fluke result or do I go by the bottom of the bars for being a consistent result?

I agree on the Sebenza thing, different people are looking for different things in knives. Just as the opposite people who think a knife that is practically a pry bar has the most awesome performance of any knife ever made.

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

There is a whole lot of troll in this post. Where did he say the cheapest steel performed the best? Since he didn't say this, your assumption of why people's perceptions are the opposite of Cliff's test results makes no sense.Donut wrote:Most days I can't tell if you are one of the scientists who is reporting accurate information or one who sees if he can get people to believe crazy information.

Why it's it, in your tests, that the cheapest steel always performs the best? Why does it seem that people's perception is opposite your results?

What you are probably trying to say is... Why do people think the most expensive steels perform the best and the cheapest steels perform the worst? The answer to that would most likely be that most people have been conditioned to believe that if something is more expensive then it it must be better than its cheaper counter part.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I don't think it was the intention in this case. It has to be kept in mind that there are some people who don't read everything I write (shocking) and perception of what I say can sometimes be a bit less than ideal as I often am not the clearest in explaining something as a have a habit of saying things which often only make sense if you know what I know.Chum wrote: There is a whole lot of troll in this post.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

In regards to rope cutting on a scale, I did a fair amount of this early on. I stopped when I discovered that blunting was nonlinear and then figured out the equation behind it. The reason I stopped using the scale as a measure of sharpness was that it was too coarse and I could not determine the stopping point.

In particular, if you look at the review of the Mel Sorg D2 hunter, you can see that the force required to cut the hemp on the 100'th cut is not significantly different than the force on the 1000'th cut. How could I compare anything if the measurements showed that anywhere between 100 and 1000 cuts was the same sharpness, the spread in the results is simply too large.

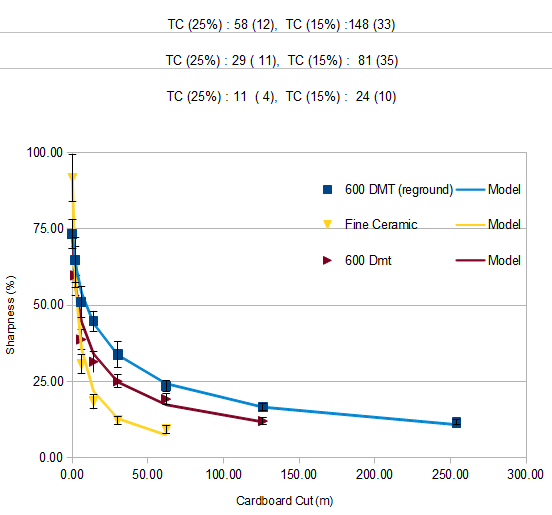

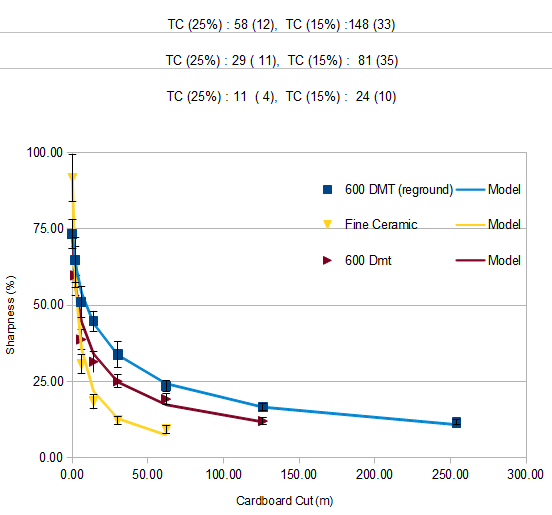

I spent a bit of time then figuring out how to measure sharpness with enough precision to map out the behavior and then do a bunch of comparisons. A year later I had basically settled on a method and was producing results like this :

This shows the increase in edge retention due to angle and grit, and has a much higher precision of measurement. I have changed a few things since then (2001) but the basic method is mainly the same.

vs a low carbide steel, AEB-L :

The white parts are the carbides.

Now draw a few lines at random on those images, pretend they are the apex line of the sharpened knife. Now look at the lines and see in the high carbide steel you can have much more variation in the composition of that line, how many of those big chunks it hits. In the AEB-L one it will always hit a bunch of small chunks. Hence in general you get much more consistent performance out of lower carbide steels, or in particular, less segregated steels.

To be clear this is not my argument, the first person I saw make it was Roman and he has the direct measured data to support it, it is in his book based on his PhD work. He also suggested an excellent demonstration which is to print them off, take the sheets and just fold them and look at the edges they produce in the fold lines. It should be clear then that the steel with the high carbide volume and aggregates can cluster/clump at the edge.

The bars (orange and blue) on the top graph are the median results they tell the result that you would expect to get most of the time and in general the value the results will cluster around. The black vertical lines show the spread, or the amount you expect to see the results change from one trial to the next. Here are the actual edge retention numbers :

420 : 4.7 +/- 1.8

VG-10 : 7.1 +/- 2.8

k390 : 9.9 +/- 2.3

M4 : 6.8 +/- 2.3

So k390 was the largest value, had the highest edge retention, but the scatter is +/- 2.3 meaning it will tend to be between 7.6 and 12.2. If you look at VG-10 then that will tend to between 4.3 and 9.9 . As these ranges over lap then you just see them scatter around each other.

In the bottom graph, the stacked chart, each slice shows a run. If you look at the 420 one you can see that while it is in general made from thinner slices, some of them are thicker than some of the slices on the k390 one which means in some of the trials it was ahead of the k390 one.

Again though, to be clear, I did this intentionally without random sampling to show this exact influence. Now I knew cardboard was not consistent, but I did not know how much and this is a measure of it. From the statistics I posted above you can conclude that cardboard can vary as much as 10:1 even if it is the same general type.

In particular, if you look at the review of the Mel Sorg D2 hunter, you can see that the force required to cut the hemp on the 100'th cut is not significantly different than the force on the 1000'th cut. How could I compare anything if the measurements showed that anywhere between 100 and 1000 cuts was the same sharpness, the spread in the results is simply too large.

I spent a bit of time then figuring out how to measure sharpness with enough precision to map out the behavior and then do a bunch of comparisons. A year later I had basically settled on a method and was producing results like this :

This shows the increase in edge retention due to angle and grit, and has a much higher precision of measurement. I have changed a few things since then (2001) but the basic method is mainly the same.

The data in the above doesn't show that but in general I would expect that to be true. I think it is fairly simple to understand if you just think about how an apex forms and look at these two picture of a high carbide steel, ATS-34 :Donut wrote:

Are we saying that the higher carbide steels have a greater variation of performance and greater variation of results? The lower costing steels are more consistent performing?

vs a low carbide steel, AEB-L :

The white parts are the carbides.

Now draw a few lines at random on those images, pretend they are the apex line of the sharpened knife. Now look at the lines and see in the high carbide steel you can have much more variation in the composition of that line, how many of those big chunks it hits. In the AEB-L one it will always hit a bunch of small chunks. Hence in general you get much more consistent performance out of lower carbide steels, or in particular, less segregated steels.

To be clear this is not my argument, the first person I saw make it was Roman and he has the direct measured data to support it, it is in his book based on his PhD work. He also suggested an excellent demonstration which is to print them off, take the sheets and just fold them and look at the edges they produce in the fold lines. It should be clear then that the steel with the high carbide volume and aggregates can cluster/clump at the edge.

I posted a few, one of mine and one of Ian's, if you mean mine :Since you are showing the variation, do I go by the top of the bars for the fluke result or do I go by the bottom of the bars for being a consistent result?

The bars (orange and blue) on the top graph are the median results they tell the result that you would expect to get most of the time and in general the value the results will cluster around. The black vertical lines show the spread, or the amount you expect to see the results change from one trial to the next. Here are the actual edge retention numbers :

420 : 4.7 +/- 1.8

VG-10 : 7.1 +/- 2.8

k390 : 9.9 +/- 2.3

M4 : 6.8 +/- 2.3

So k390 was the largest value, had the highest edge retention, but the scatter is +/- 2.3 meaning it will tend to be between 7.6 and 12.2. If you look at VG-10 then that will tend to between 4.3 and 9.9 . As these ranges over lap then you just see them scatter around each other.

In the bottom graph, the stacked chart, each slice shows a run. If you look at the 420 one you can see that while it is in general made from thinner slices, some of them are thicker than some of the slices on the k390 one which means in some of the trials it was ahead of the k390 one.

Again though, to be clear, I did this intentionally without random sampling to show this exact influence. Now I knew cardboard was not consistent, but I did not know how much and this is a measure of it. From the statistics I posted above you can conclude that cardboard can vary as much as 10:1 even if it is the same general type.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Another conclusion that I'm beginning to draw here is that my strong preference towards stainless in folders is a reasonable position to take. Not that anyone has to justify their preferences, but it's nice to know that it comes from accurate intuition. Namely, it appears that for what you give up in corrosion resistance, you don't get a commensurate increase in edge retention. At least that's from comparing VG-10/M4/K390 in this test. I've never experienced a gross (as in: large) blade failure of any kind, so it would seem I'm not wanting for yield strength or impact toughness either.

So given that I carry, use, and sharpen my knives, the main properties I should be concerned with are: edge retention, corrosion resistance, and ease of sharpening. This is assuming I have the minimum required strength/toughness not to break my knives, which is a good assumption from available steels hardened by Spyderco. I'm really just kind of thinking out loud here (if this can even be done via the written word), with the thought that it might explain some people's strong preference for stainless folding knives.

So given that I carry, use, and sharpen my knives, the main properties I should be concerned with are: edge retention, corrosion resistance, and ease of sharpening. This is assuming I have the minimum required strength/toughness not to break my knives, which is a good assumption from available steels hardened by Spyderco. I'm really just kind of thinking out loud here (if this can even be done via the written word), with the thought that it might explain some people's strong preference for stainless folding knives.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I don't think it is possible to justify a preference, though you could argue it isn't consistent at most. In regards to stainless, like most things, often times the conclusions being reached are less than ideal because too many things change and the conclusion is hit/miss. For example what is one of the most common things you hear about stainless "That is just hard to sharpen - give me a good old carbon steel any day!" . If you ask what was used then you tend to find what is being compared is ATS-34 vs O1 or similar. In that case it isn't stainless that is the issue, is is a very high carbide steel vs a low carbide one. If you compared 10V (which isn't stainless) to AEB-L (which is), then the conclusion completely reverses.tvenuto wrote:Another conclusion that I'm beginning to draw here is that my strong preference towards stainless in folders is a reasonable position to take.

For makers/manufacturers, stainless steels can be difficult to harden. A steel such as 1084 can be hardened with very basic methods and extremely advanced methods, while refining it, don't make a dramatic difference. However trying to harden 440C with a torch and a magnet isn't really the same thing. Can it be done - well yes, but that steel has to get a lot hotter than non-magnetic and it has to be held there. Now compare a torch hardening of that with a modern oven, and then add to it a deep quench (beyond room temperature) and the difference increases again.

One of the biggest issues with steels like 13C26/AEB-L is that properly hardened they make it hard to argue for something like O1, 1095, White, etc. unless you get them with extremely hardening cycles (ultra-fine grain, near maximal hardness). In a real practical sense, those stainless steels offer the same hardness as those 1% carbon steels, have the same apex stability, a small improvement in wear resistance and on top of all of that - they are stainless. But all of those facts aside, I still have White steel knives - I believe that is just my inner weeaboo.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Yeah, I didn't mean to troll. It just seems like every time I look at the results, I ask myself WTF?

That's good info. The stacked bars should give a better average of the performance.

The problem it looks like you were seeing is that you're approaching 0% sharpness. :)

That's good info. The stacked bars should give a better average of the performance.

The problem it looks like you were seeing is that you're approaching 0% sharpness. :)

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Yeah, the interesting thing is sharp isn't really what a lot of people think in regards to extent. If I ask you for example how much time would it take for someone to run 100m for it to be considered fast there is a well known reference for that. It is so well known that most people, or at least people into sports, would answer very quickly that ~10-12 seconds is fast. If the person runs track they might tend to focus more on lower numbers and it could even be under 10 seconds. Similar if you go into a gym and ask people how much is a strong squat then you can get a well defined cluster of numbers.

However just take a look around and see what people think is a sharp knife? If knife can slice photocopy paper it is at < 1% of optimal sharpness (in regards to slicing aggression). Now to some people that seems a little odd, but if that is all you have seen in terms of sharpness then that becomes the norm. But just ask anyone who sharpens knives, who owns some kind of sharpening system if they would consider the ability to slice a piece of rigid paper as being sharp, most people would sharpen blades before they even fall to that level of sharpness. Now there is a practical question of how much is needed, how does this influence edge retention/durability, etc. . These are all useful and practical questions. Do you really need a knife to shave hair above the skin, to push cut newsprint to be able to use it? Well no, just like you don't really need some kind of "optimal" edge retention. In many cases we are discussing things to the far right of what is practical as we are interested in them is all.

However just take a look around and see what people think is a sharp knife? If knife can slice photocopy paper it is at < 1% of optimal sharpness (in regards to slicing aggression). Now to some people that seems a little odd, but if that is all you have seen in terms of sharpness then that becomes the norm. But just ask anyone who sharpens knives, who owns some kind of sharpening system if they would consider the ability to slice a piece of rigid paper as being sharp, most people would sharpen blades before they even fall to that level of sharpness. Now there is a practical question of how much is needed, how does this influence edge retention/durability, etc. . These are all useful and practical questions. Do you really need a knife to shave hair above the skin, to push cut newsprint to be able to use it? Well no, just like you don't really need some kind of "optimal" edge retention. In many cases we are discussing things to the far right of what is practical as we are interested in them is all.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I think most people like a good working edge that lasts a very long time.

That's why we gravitate towards better / super steels.

That's about all I have used for many years now. And am sure I am not alone.

Most days its S90v or M390. Just a couple personal favorites that come in knives I really like.

That's another issue, getting the blade steel in the knife you want.

I have been working in that direction for many moons now. And it keeps me going............ :D

That's why we gravitate towards better / super steels.

That's about all I have used for many years now. And am sure I am not alone.

Most days its S90v or M390. Just a couple personal favorites that come in knives I really like.

That's another issue, getting the blade steel in the knife you want.

I have been working in that direction for many moons now. And it keeps me going............ :D

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

All steels blunt like that, it is the nature of the mechanism.MCM wrote:I think most people like a good working edge that lasts a very long time.

I am not sure when/who started the ideal that high carbide steels hold a "working edge" in that it is a property that they have exclusively. It is often linked to the "carbides" but there is nothing that allows the kind of behavior attributed to them. Yes, it is true that carbides in steel resist wear, how much and to what extent depends on the size of the carbides vs the size of the abrasive grit (if the carbides are much smaller they have very little effect at all), but wear is only one factor in blunting and carbides are only a small volume in steels even in high carbide steels.

Here is some data from Ian on White steel, which is a pure carbon steel, no alloy carbide, cementite volume will be 5-10% depending on the exact grade and hardening :

Note that it initially loses sharpness rapidly and then settled into a long tail where further changes are very slow. All steels have this behavior because it is due to several physical laws which are quite simple in nature. They are for example things like the more you bend a piece of steel the more force it takes to keep bending it. The more an edge wears the more work it takes to wear it to the same amount again.

One way to understand this would be to imagine digging a hole in your yard. Initially the change in your yard is very dramatic and anyone could notice each time you made a shovelful removing sod, throwing dirt on the grass and making the hole, if it rained you would see the hole fill up with water. At the start each one of these changes is very dramatic to the fresh lawn.

That is like using a freshly sharpened edge, even small changes will be obvious as the percentage difference is very large and we see things in percents / relative differences.

But now imagine that hole is large, and you have made 1000 shovelfuls. Now make one more, can you see the difference in the size of the hole, can anyone? Why is this so different than the first shovel which made a dramatic difference as they both are the exact same amount of work done / dirt moved? It is because the percentage change it makes is very small.

This is like making a cut after already doing 1000 cuts with a knife, the percentage change is very small compared to the first cut even though the work is the same. Thus with any knife the edge loss behaves in a strongly nonlinear way and all knives, all steels hold that "working edge" as they have to, it is just due to the laws of physics.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I think it depends on what people think sharp is, that will vary greatly depending on who one talks to.MCM wrote:I think most people like a good working edge that lasts a very long time.

That's why we gravitate towards better / super steels.

That's about all I have used for many years now. And am sure I am not alone.

Most days its S90v or M390. Just a couple personal favorites that come in knives I really like.

That's another issue, getting the blade steel in the knife you want.

I have been working in that direction for many moons now. And it keeps me going............ :D

We have to remember we are all a very small part of the world as knife guys.

For a lot of people that use kitchen knives sharp means they can cut what's needed in the kitchen and as most of us know one heck of a lot of those knives are dull, but they still cut what they need so they work.

How many of us have seen knives that people carry that are bone butter knife dull?

I would guess a lot of us have over the years.

For me once an edge starts to lose bite it needs a touch up. :)