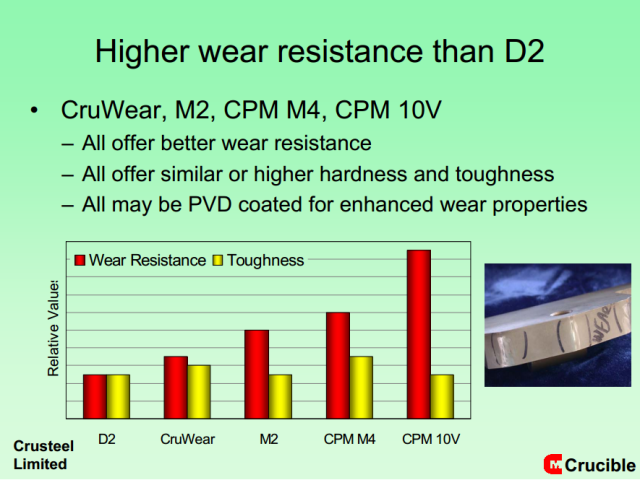

Here is an honest question, that chart is completely meaningless as there is no information onbdblue wrote:

I would like to see a few other steels on that chart for comparison- 3V, Elmax and even XHP.

-how the steels were hardened

-what exactly was measured

-the precision/accuracy

It isn't even said if the toughness and wear values are on the same hardening cycle of the steel.

There are many ways to measure a property and there are many ways to heat treat steels. Crucible used to be fond of doing something like comparing S90V to 440C and showing the adhesive wear resistance when S90V was hot tempered and 440C was cold tempered without cryogenics. This makes 440C look soft/weak and very low in abrasive wear resistance (as that is what you would think they would be showing but it isn't). It is only when you look at the patent data and see what was done and how the steels were hardened that you realize the data is very misleading.

Anyway, the question is why would that chart make you feel anything or why would you want to see more steels on it. There is no way to interpret it at all and most times, as with all marketing charts, the way data is presented is intentional to showcase the performance of some particular steel or steels. I could make up a chart right now with all steels on it with all material properties. If I didn't actually justify any of the numbers in a way which would make them meaningful then why would anyone pay attention to it.

That chart by the way looks like it comes from data in "ASM Specialty Handbook: Tool Materials", edited by Joseph R. Davis. That source has the charts with numbers, tells what way they are measured and there are other steels and other tests. They are not nearly as flattered to the PM steels. It shows for example that simple A2 is far tougher than all of them and all of those steels are actually very brittle and their C-notch toughness is comparable to the v-notch toughness of steels like S7. The hardening of the non-PM steels is also likely less than optimal as for example D2 is as low as 59 HRC in some of them as is likely not cold treated and tempered cold.