Sandvik Steel Spydercos?

- araneae

- Member

- Posts: 5506

- Joined: Wed Aug 09, 2006 10:10 pm

- Location: A lil more south of the Erie shore, Ohio

I have been happy with opinels in 12c27mod. Those knives are so thin that they slice like a razor blade and hold an edge rasonably well. I have a feeling they could be run a little higher than Opi does them, but I am happy with the steel.

So many knives, so few pockets... :)

-Nick

Last in: N5 Magnacut

The "Spirit" of the design does not come through unless used. -Sal

-Nick

Last in: N5 Magnacut

The "Spirit" of the design does not come through unless used. -Sal

Here is the testing done by a maker, of course, all credit to him.

DvdM wrote:The kiln takes about 45 mins to stabilise at 1060degC.

Once at temperature the stainless foil package is inserted and timing of the soak cycle is started once the temp is back up at 1060degC, soak time for 4mm thick blade is 12mins.

After 12 mins the envelope is removed with pliers and the blade dipped into the quench oil to get the blade temp down to 600degC within 2 mins for the martensitising to take place. Normally I get the blade to the oil within 4 seconds since the process is well rehearsed and tools ready.

When the blade hits the oil is goes into vapor blanket stage, the oil is boiled into gas around the blade so does not come into contact with the blade, it is important to agitate the oil by raising and lifting the blade. Then, the second the oil stop vaporising around the blade the blade must be kept perfectly still else unnecessary warping will take place. The cue is when you stop hearing boiling bubbles. This takes about 6 seconds depending on blade thickness.

When the blade is out of the oil and you're just able to touch it by bare hand it is checked for warping on a marble slab then gently tapped with a rubber mallet on a wooden block to straighten it. If you wait longer than 5mins the steel will be so hard it will shatter if you try to correct a warp.

From here the blades go to the deep freezer to chill to -20degC. During this time the kiln is cooled down to 175degC for the tempering process, then the blades go in for 2 hours in this case of 14C28n Sandvik. I'm going for a hardness of 60HRC. For 58HRC it will be 225degC for 2 hours and for 56HRC 350degC for two hours.

The blades are now hardened and tempered, all black/grey again so now the final grind can start:

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

Continued:

DvdM wrote:Final grind done, blades all shiny again:

With the final grinding done I started wondering just how tough this new Sandvik steel is. I opted for a rather hard blade at 60HRC, especially for the size of the blades. Puma go as low as 56HRC on their broad bladed knives, remember, the larger the knife the more leverage you have and the harder the steel the more brittle it is. Then I recall Miles telling of a chef's knife he dropped and it broke in two! Now since one of these knives is for Miles I decided to do the chop test to put my mind at ease. I took a 7mm piece of scrap round bar from old burglar proofing and a heavy hammer and marked the spot where I'm about to abuse the blade so I'll know where to look for damage. I proceeded to hammer away at the blade spine with the rod on my cute little anvil:

After the first blow the blade was more than halfway through the 7mm round bar, the blade did not shatter and the cutting edge did not chip:tanks:

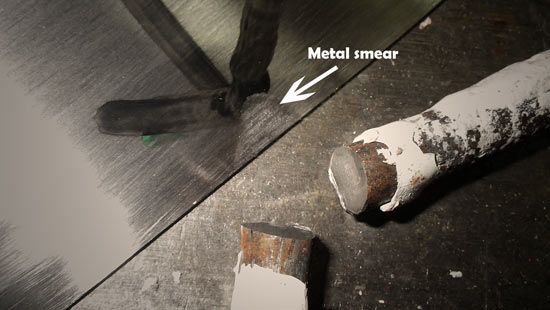

Two more blows severed the rod and I checked the blade for damage....NONE, not where the hammer struck nor at the cutting edge, all I could see was a smear of mild steel on the cutting edge.

..and not as much as a dent or mark on the spine where the hammer struck:

I will with confidence split a marrow bone or chop a branch off a tree with this 14C28n chef's knife and at 60HRC it's going to keep a keen edge for a while and more :D Miles can also shorten table legs in his kitchen if he wishes.

So next up is the sandblasting, stay tuned...

DvdM wrote:Mathinus I'm impressed with the elasticity of this steel at high hardness. I replaced my EDC blade with a piece of this steel a while ago because the original blade was badly worn through 4 years of constant sharpening. My EDC really gets abused since I don't feel sorry for it and the blade is holding up very well and keeps an edge through wood scraping work, opening tins, cutting cloth to name but a few abuses. I'll do a thread soon on the Kershaw Vapor with 'revised blade'. No better way to test steel as to put it on an EDC you don't feel sorry for.

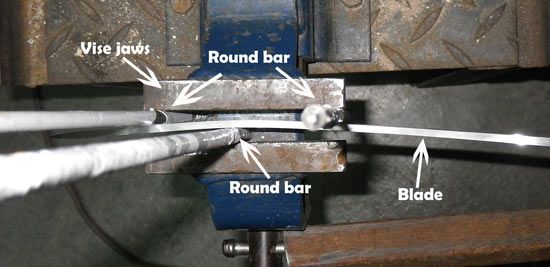

Here's a pic of the bend test of the 14C28N, clamped between round bar in the vise, the vise is then cranked with a pipe extension wearing leather apron, gloves and eye protection in case the blade fails. These broad chef's knife blades showed no sign of deformation after testing when checked again on the marble slab, they returned to straight after my test. My point is that the blade should give enough without snapping for the user to feel he's bending it before it breaks. Bad hardening and tempering will see the 'accidental' snapping of a work blade before the user was even aware he was abusing it. My tests are worst case scenario.

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

From Sandvik:

Sandvik 14C28N is the latest development in Sandvik's range of knife steels. Optimized chemistry provides a top grade knife steel with a unique combination of excellent edge performance, high hardness and good corrosion resistance.

This new grade matches the previous highest achievable hardness without affecting the microstructure. Blade re-sharpening is therefore easy. At the same time, edge stability in terms of microchipping and edge folding or rolling is also good.

With a recommended hardness range of 55-62 HRC, Sandvik 14C28N is ideal for knife applications which place very high demands on edge sharpness, edge stability and corrosion resistance such as chef's knives, pocket knives, hunting and fishing knives.

Like most of Sandvik's knife steel grades, Sandvik 14C28N is fineblankable enabling efficient production.

Hardening program for 14C28N

http://www.smt.sandvik.com/en/products/ ... g-70c-95f/

As I said before, I am biased to Nitrogen containing steels :)

Sandvik 14C28N is the latest development in Sandvik's range of knife steels. Optimized chemistry provides a top grade knife steel with a unique combination of excellent edge performance, high hardness and good corrosion resistance.

This new grade matches the previous highest achievable hardness without affecting the microstructure. Blade re-sharpening is therefore easy. At the same time, edge stability in terms of microchipping and edge folding or rolling is also good.

With a recommended hardness range of 55-62 HRC, Sandvik 14C28N is ideal for knife applications which place very high demands on edge sharpness, edge stability and corrosion resistance such as chef's knives, pocket knives, hunting and fishing knives.

Like most of Sandvik's knife steel grades, Sandvik 14C28N is fineblankable enabling efficient production.

Hardening program for 14C28N

http://www.smt.sandvik.com/en/products/ ... g-70c-95f/

As I said before, I am biased to Nitrogen containing steels :)

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

Well now, if you're talking 3V or cruwear kind of toughness...That's also quite interesting to me. :)

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

Sal,sal wrote:

... the best steel Sandvik makes that we could use in our knives?

19C27 is a nice steel for wear, however you have used MBS-26 and are using CTS-BD1 which are the same steel from different manufacturers.

14C28N would be a nice steel to use but it has to be clear what it offers and what it does not.

It does not have an advantage over VG-10 for long term sharpness at moderate to high angles and low to moderate grit finishes.

Thus 14C28N will not fare as well in CATRA style tests which are popular.

However it has :

-very high grindability

-exceptional ease of sharpening

-high toughness (for a stainless)

-optimal edge stability

It is thus best suited for knives :

-which demand precision cutting (low thickness/angle and high polish)

-are used roughly and need to minimize damage and maximize ease of restoration

-high versatility in sharpening, can even be worked readily with natural stones

It is however extremely critical that the HT is done so as to produce these qualities which means :

-oil (or plate)

-below room temperature quench (no snap temper)

-hot and fast soak (with a pre-equalize)

If you don't do these you will end up with a blade which is :

-about 56 HRC

-large amounts of non-martensite phases

and it will :

-feel gummy and be difficult to sharpen

-have low edge stability

and you now have a blade which will just perform poorly across the board and only really has one positive which is that you can file sharpen it.

The only real question is do you want to adjust the soak/temper to achieve the maximum hardness/corrosion resistance (62/63 HRC) or to get 59/60 HRC and have a higher toughness.

That is just a matter of seeing what blend of properties you want.

- Johnnie1801

- Member

- Posts: 2219

- Joined: Sat Apr 26, 2014 10:29 am

- Location: Europe

Sorry to resurrect an old thread but I was just wondering if Spyderco are still interested in using Sandvik steels in any future projects?

Currently enjoying Spyderco's in - S30V, VG10, Super Blue, Cruwear x4, CTS XHP, S110V x2, M4 x3, S35VN, CTS 204P x2, S90V, HAP 40, K390, RWL34, MAXAMET, ZDP 189, REX 45

Jon

Jon

- xceptnl

- Member

- Posts: 9000

- Joined: Mon Feb 21, 2011 6:48 pm

- Location: Tobacco Country, Virginia

- Contact:

I second these thoughts. I have had enjoyable results with 14C28N and would be interested in trying the 19C27.Invective wrote:According to them the highest wear resistant steel they have is 19C27.

http://www.smt.sandvik.com/en/products/ ... vik-19c27/

Having tried their 12C27, 13C26, and 14C28N, I especially liked their 14C28N in the Kershaw Skyline platform. Took a great edge and seemed to hold it longer than the VG-10 on my Endura.

edit: didn't see the date of the OP, but my comment still stands. I would like to know if a Sandvik steel is one of the Mules already in the lineup that Sal previously mentioned.

*Landon*sal wrote: .... even today, we design a knife from the edge out!

- Johnnie1801

- Member

- Posts: 2219

- Joined: Sat Apr 26, 2014 10:29 am

- Location: Europe

I think 14C28N would work really well in a Manix configuration but I would be happy to see it used in anything Spyderco make. I'm very happy with the Sandvik steels I have used, I just hope we will see it on a Spyderco knife in the near future.

Currently enjoying Spyderco's in - S30V, VG10, Super Blue, Cruwear x4, CTS XHP, S110V x2, M4 x3, S35VN, CTS 204P x2, S90V, HAP 40, K390, RWL34, MAXAMET, ZDP 189, REX 45

Jon

Jon