Swedge wrote:1. Do I start by cutting at right angles across the coarse stone? I tried that before, and while it worked great at dulling the edge, it didn't remover the burr.

A burr doesn't necessarily go away with one stroke. A stone isn't a magic eraser for a burr; a burr has to be ground or broken off. If you keep cutting straight into a stone, you're gonna get a flat spot where the bevels meet, and it'll take a long time to raise an edge. I recommend using the diamond stones I thought I heard you say you have, putting them in the 30˚ or 40˚ slots (whichever you're using), and instead of holding the knife straight up and down, hold it toward the stone a little bit for each side. This way you'll be sharpening the edge for sure and getting that nasty burr.

Again, it likely won't go away in one stroke.

Swedge wrote:3. How often should I be re-applying the Sharpie to check the bevel?

As soon as it goes away if you want to still know where you're sharpening. Eventually you should be able to see where you're sharpening even without the marker (different angles will look different in the light).

Swedge wrote:4. Do I alternate every stroke? Or do I start on the back (using the right-hand stone) and keep going until I feel a burr on the obverse edge?

Recently my idea of sharpening knives has changed because while sharpening, I notice that burrs just don't go away. So this is my new method:

Keep grinding one side until there is a very small amount of metal to go until you get to the edge. Switch to the other side and grind until you've almost gotten to the edge. Now do 1-1 each side until you get to the edge. This eliminates burr formation for me, or at least it makes burrs very easy to deal with when I make a micro-bevel.

Swedge wrote:5. When do I switch to the coarse stone?

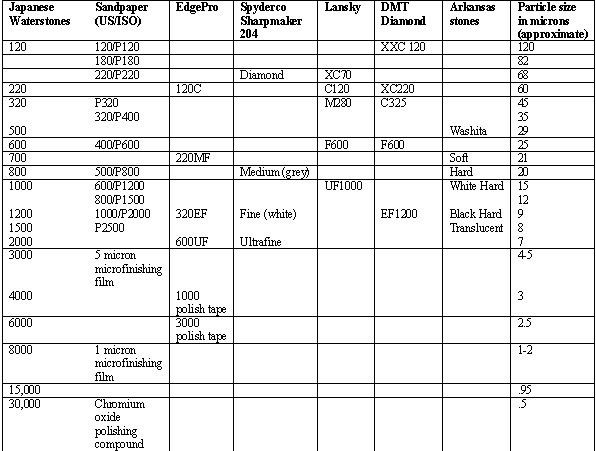

You mean from diamond to the brown? I suppose once you've gotten an edge raised with the diamond stones. Then you'll want to use the brown stones until the bevels look more polished uniformly throughout than before (when the scratches are finer).

Swedge wrote:Vampyrewolf, in the other thread, you refer to the "grey flats" as well as the "brown flats" and the "white flats." What stone is the grey one? Mine are brown and white.

I'm pretty sure "gray" and "brown" are the same. They're called "gray" by Spyderco, but they're actually more of a brown color. Kinda like how their waved Delicas and Enduras are called "gray FRN," but they're more blue than anything else

Swedge wrote:I have been learning to use less pressure, and I have been setting it on a table and standing up. And you're right, I can detect smaller burrs now.

Personally, I use moderate pressure when I'm profiling, and when I'm convinced I've got an edge and I just want to make things more uniform, I use light pressure. Then I switch stones (to a finer one), use moderate pressure, then when I'm finishing with it again, I use light pressure. And when I'm making a micro-bevel, it's light pressure all the way. That's just my way of doing things.

Swedge wrote:Does the burr look like a tiny, tiny wire along the edge?

Yes. A burr is also called a "wire edge."

vampyrewolf wrote:The first time might take 20-30 strokes to form a burr,

I dunno if I like that... That's kind of "textbook-ish." It all depends on the situation. When I was learning, I did all the "100, then 50, then 20, then 1-1" and all that kind of thing, but eventually I ditched all of that for my new rule: "It's done when it's done."

20-30 strokes is going to depend on the steel, the stones, the angle of the bevels currently, etc. If you want to form a burr, just grind until you feel one. If you want to minimize the burr, use the marker to see exactly when you get to the edge.

Anyway, the thing to remember is that you're NOT gonna get this over night; it's going to take practice! You must have patience, because even reprofiling jobs can take many, many hours...

Im not good at sharpening, even with a sharpmaker. How get your blade good can your blade with an edge pro system? - Bladeforums user

Has anyone really been far even as decided to use even go want to do look more like? - Some Online Meme