sal wrote:.......

When you go out in the "bush" for a "walkabout", we'd like you to want to carry one of our hawks. I'd like to want to carry one myself. Light, very effective, easy to use and transport. (in a suitcase for a trip to hike or camp).

.......

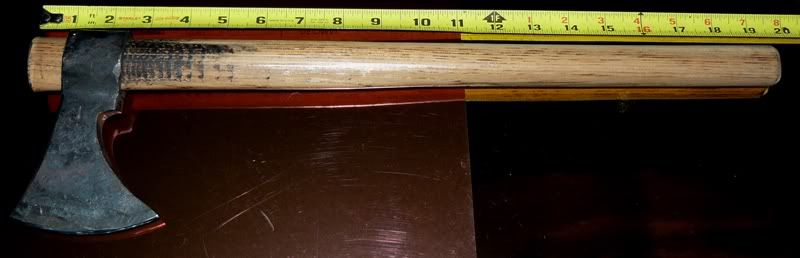

I have been thinking about the tomahawk in the past few weeks, and if you want to take the hawk with you to the bush it indeed has to be light and easy to transport.

Very effective and easy to use makes it a little more complicated because you need kenetic energy while chopping. While practicing for Bladesports NLD I learn something about chopping and control.

Kenetic energy = 0.5 x mass x speed²

So speed is much more inportant for your results than the mass of the hawk. I think a small head with a relative long and light handle will work, the classic pattern.

I think the best shape for this hawk is thin and convex. Thick enough to chop with, but thin enough to cut good. It must be possible to whittle wood with it. There are enough axes made to cut sheet metal. The Spyderco hawk will not be made for that.

By the way, I don't think SE will work :D

Materials? Hmm that’s not easy. Carbon steel and wooden handle will work very good, but there are so much hawks like that. A Syntetic handle and a tough modern steel? CPM 3V or M4? You need very thick stock , that will cost a lot. And such steels are not very forgeable I think…

Sal, how will it be produced? Forged? Cast? Machined?