So lets get right to initial impressions.

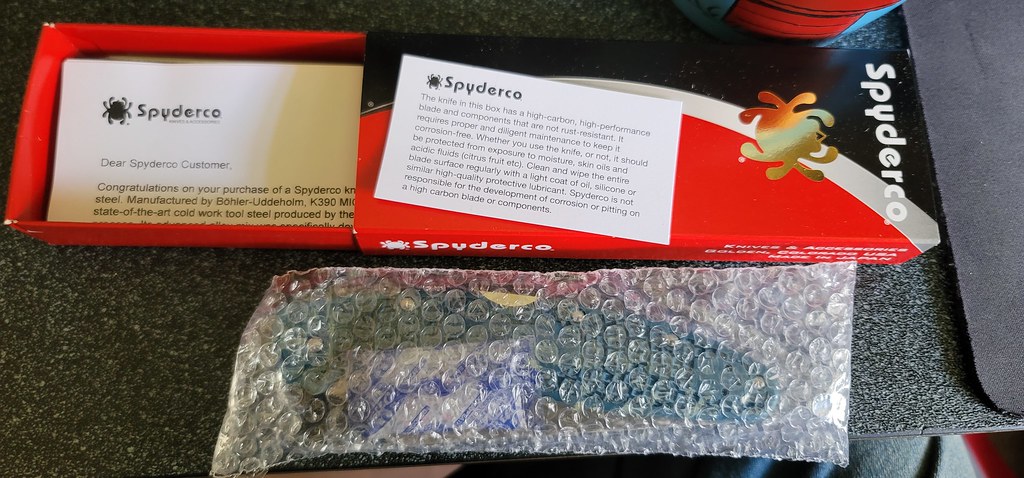

Right out of the box, we have a pretty interesting note from Spyderco about not letting it rust. Also of note is a silica packet inside the baggie, and the whole blade is covered in a grease or oil of some sort. When I first looked at it, some spots of the blade almost looked like they were patinaed already but it's just the grease. You have to consider the potential for knives like this to sit on warehouse shelves for who knows how long and potentially rust, so it's smart that they slather them down before shipping.

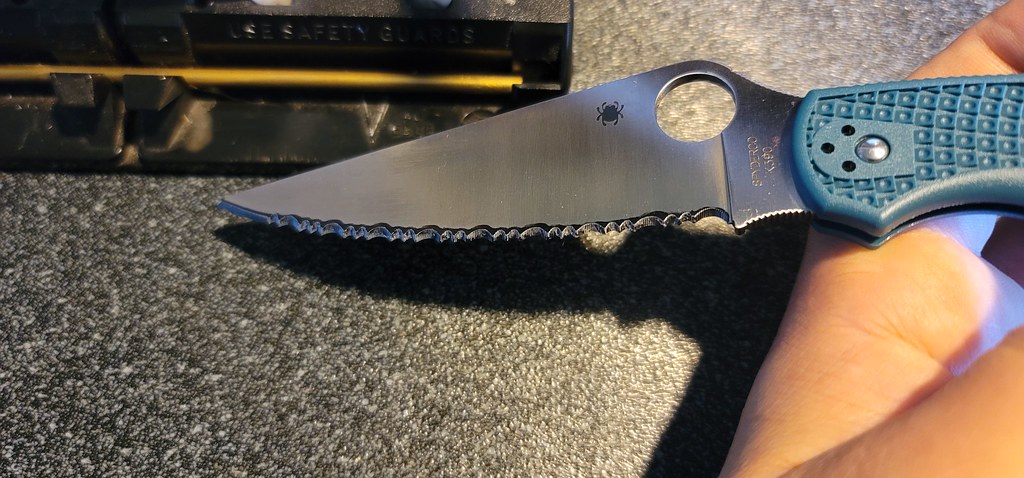

Aaaaaand then I noticed the blade is super duper off center:

Ok.....don't panic...

A quick note about knife construction and blade centering, as I understand it.

These knives have what I (respectfully) see as a somewhat obsolete construction method. What I mean is, it uses a "pin and screw" construction holding the whole thing together where one side of the handle has a dome head pin with a screw that threads into it from the opposite side. This was very common 20 or so years ago with Spyderco but has since largely been replaced on a lot of models (especially in Golden it seems) with "screw/pin/screw" style construction where each side of the handle has a screw threading into a center pin much like you see with most pivot pins. What you tend to get with this (again, as I understand it...maybe Sal can verify this) is it's VERY easy to throw the parallel balance of the scales/liners/blade off when assembling the knife and if a very careful torque sequence isn't followed while tightening the screws, everything is basically warped and that causes the blade to not be centered.

Here I've got each side of the blade laid down on a flat cutting board

As far as I can tell the blade is not warped/uneven ground at least as close as my eyeballs can tell.

So here's how you center up the blade. Loosen all the scale screws and in really bad cases even the pivot screw (I didn't need to with this one) and hold the knife in your hand in such a way that you can "flex/bend" the knife and you'll see that depending on which way you flex it, you can move the blade centering around:

Then, while holding/flexing it this way, tighten down all the scale screws. I usually work from the center of the handle outward. There is probably a proper torque sequence for this much like an engine's cylinder head but this worked for me.

If nothing else even if your blade is a wee bit warped, you can do this and center the blade tip up enough to not make yourself crazy over it.

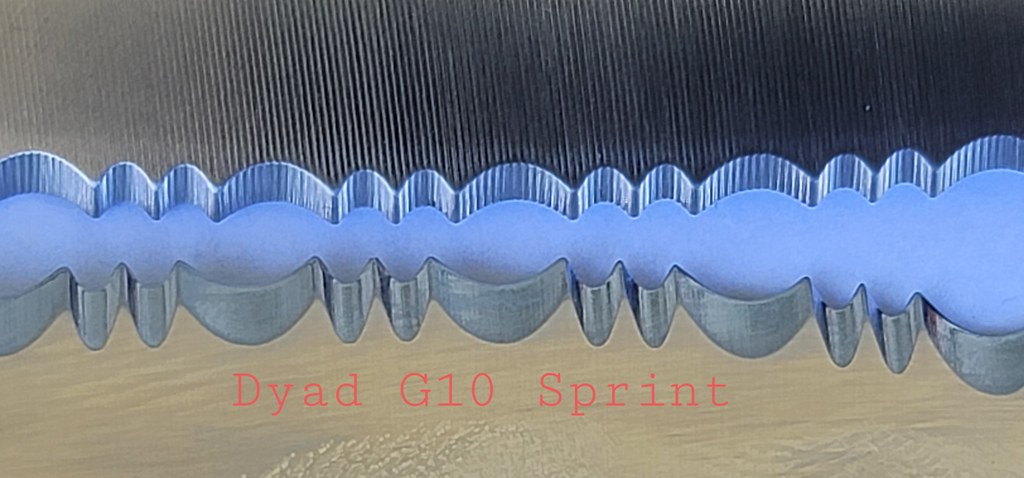

Serration grind comparisons

I'll add to this part of the post as I can with other knives. The problem I have is that almost all of my other SE knives have been reprofiled, so it's hard to give you a fair side by side comparison. Here are some shots next to a factory grind Police OG.

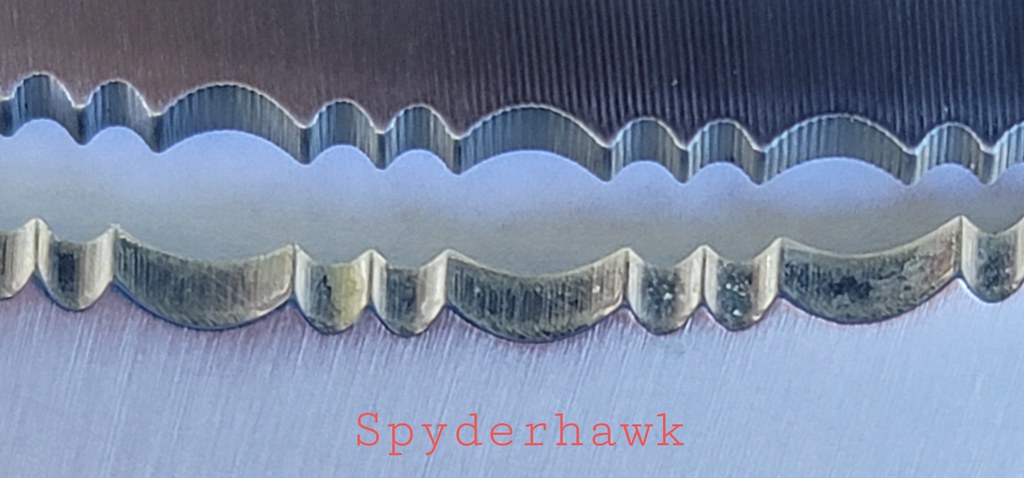

Police 4 on top, Police OG on bottom:

Right out of the gate I can tell you the blade grind is pretty thin, obviously thinner than that low hollow Police OG, but I'll have to see if I can figure out about what the serration grind angle is. You can see that it's a good bit shorter in height which could be due to the thinner behind the edge thickness of the blade grind or due to a much steeper serration angle grind (hopefully not that). We'll see.

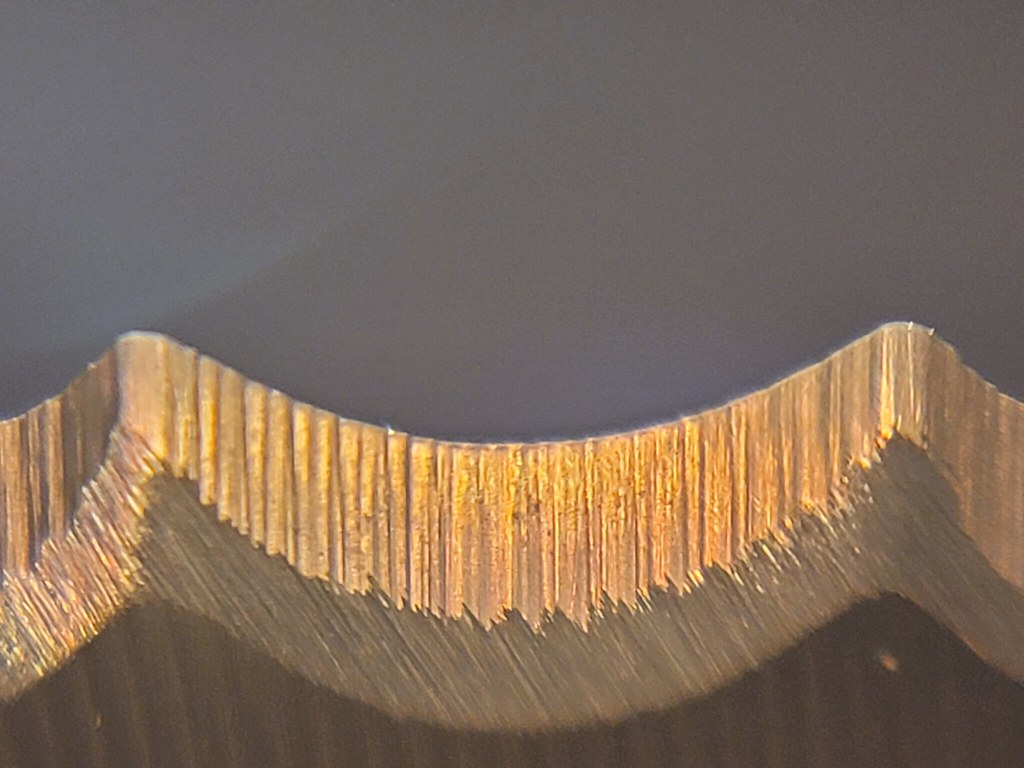

What about those grind lines in the serrations though? I really would love to see how these are ground, I don't think they came off a grinding wheel because they are absolutely perfect and insanely uniform in shape. The whole bevel is so even from start to finish, this has to be done by a robot or CNC or something (now that I look closer, I see the Police OG has those line in the serrations too but not as visible...on the P4 you can even feel them with your fingernail). Again, maybe Sal can chime in with a little info here because I've never seen serrations ground like this. They're somewhat short in length, maybe even a bit shorter than the Police OG. Shorter length serrations can be good or bad depending on what you like, shorter length does mean there's more of them in a given blade length.

Police 4 on the top in all of these pics:

Behind The Edge Thickness

Well, I suck with calipers so take this with a healthy spoonful of salt, but I'm seeing around 0.53mm at the top of the points between the scallops and about 0.65mm at the top of the scallops. The Police OG measures in at 0.78mm at the points and 1.40mm atop the scallops. They measured about the same all along the blade, at least as accurately as my shaky hands can manage. And again, I'll dig out some other knives that have factory bevels and see if I can get some more numbers to compare but I don't have much and I think the ones I have are much older models that may not tell us much. Someone with a factory bevel grind Caribbean get us a measurement to compare to this.

I'll leave ya'll with that for now. Time to go cut some stuff