Page 4 of 4

Re: Making a Mule Handle (step-by-step)

Posted: Fri Apr 15, 2022 3:42 pm

by Ramonade

Xplorer wrote: ↑Fri Apr 15, 2022 2:11 pm

Ramonade wrote: ↑Fri Apr 15, 2022 1:48 pm

.. but I might still be able to produce something i'd be proud of. ..

Looks to me like you're definitely going to have a beautiful handle you can be proud of.

Congrats on picking up the new grinder! I started out with a 1x30 (American measurements

) grinder as well. I used my 1x30 grinders for years, and with practice and a few little modifications I was even able to produce some really good knives on those grinders. You can do a lot with that tool! Hopefully you have a supplier near you that offers a good selection of belts. There are an extremely wide variety of belts (alum. oxide, ceramic, even diamond) and grits available for your grinder.

Thanks, I'm willing to put in the hours ^^.

Thanks, I became really acquainted with the Imperial system trying to find something for the Mules ! I'm used to traditionnal french fixed blades, it's mostly a twig and some 3 or 4 mm brass pins. It was super hard to find some 3/16" drill bits and 1/4" counterbore, had to order from Finland.

For now on I only have aluminium oxide belts, but in a pretty great variety. I'm in the countryside so the hardware stores are not that specialized. I'm near the old center of knife making in France so it won't be hard to find a good supplier, if they managed to keep their business open...

Edit : i polished the front part, even if I'll most definitely change its shape later on. It will be part of thinning the handle, so the finish wont change much, and ill be able to access it without the blade getting in the way.

Re: Making a Mule Handle (step-by-step)

Posted: Tue Apr 19, 2022 10:40 am

by Bolster

IMO the best scales are those that relieve the area near the blade, as you have done. Good work on the forward chamfer.

Re: Making a Mule Handle (step-by-step)

Posted: Tue Apr 19, 2022 3:55 pm

by Ramonade

Thanks ! I've tried two designs on my test scales, and I didn't really like how bring everything along the plunge lines looked like.

Re: Making a Mule Handle (step-by-step)

Posted: Thu Jun 02, 2022 2:46 pm

by BearShark44

Wow... late to the Mule Team game, but making a handle sounds fun.

Huge thanks to this thread and the original poster for the detail and photographs.

Kudos

Re: Making a Mule Handle (step-by-step)

Posted: Thu Jun 02, 2022 4:34 pm

by Xplorer

BearShark44 wrote: ↑Thu Jun 02, 2022 2:46 pm

Wow... late to the Mule Team game, but making a handle sounds fun.

Huge thanks to this thread and the original poster for the detail and photographs.

Kudos

I'm glad you found it. Helping people that are new to Mules get started on their first handle is what it's here for.

I hope you build yourself a Mule handle and show it off here when you're done.

Re: Making a Mule Handle (step-by-step)

Posted: Fri Jun 03, 2022 9:04 am

by JRinFL

With the new Spy27 Mule 2 releasing soon, I think we will see more attempt to put on their own handles on a blade that is more readily replaceable.

Re: Making a Mule Handle (step-by-step)

Posted: Sat Jun 04, 2022 5:25 pm

by Ramonade

JRinFL wrote: ↑Fri Jun 03, 2022 9:04 am

With the new Spy27 Mule 2 releasing soon, I think we will see more attempt to put on their own handles on a blade that is more readily replaceable.

I'm impatient to see that ! I get that putting your own handle on a precious and unique blade might scare some people. I might try to do a screw-in set of scales next, but almost everyone uses epoxy to make them, if you mess up it can be a pain to retrieve the blade.

I know I'll take advantage of the Spy27 Mule. I bought two MC Mule to gift my first knife to my father, but since there might be a 1 per home limit on the next ones, I'm happy there's a production Mule to rely on for gifts. I'm slowly converting my surroundings with Spyderco, and more generally good blades

Re: Making a Mule Handle (step-by-step)

Posted: Mon Jun 06, 2022 11:47 am

by Xplorer

Ramonade wrote: ↑Sat Jun 04, 2022 5:25 pm

JRinFL wrote: ↑Fri Jun 03, 2022 9:04 am

With the new Spy27 Mule 2 releasing soon, I think we will see more attempt to put on their own handles on a blade that is more readily replaceable.

I'm impatient to see that ! I get that putting your own handle on a precious and unique blade might scare some people. I might try to do a screw-in set of scales next, but almost everyone uses epoxy to make them, if you mess up it can be a pain to retrieve the blade.

I know I'll take advantage of the Spy27 Mule. I bought two MC Mule to gift my first knife to my father, but since there might be a 1 per home limit on the next ones, I'm happy there's a production Mule to rely on for gifts. I'm slowly converting my surroundings with Spyderco, and more generally good blades

I think it would be great if someone would post pics here of the process they use for making a removable handle. I can add that to this tutorial and will get around to it sooner or later, but I'm going to be moving in about 2 months and I won't have time to do that sort of thing until after I move and set up my new shop.

Ultimately there are not many differences. Once the hardware is chosen, the holes simply need to accommodate the hardware and the counter-bore for the head of the hardware needs a little more room than you would give a corby. The accuracy of the depth of the counter-bore is a little more important in this case, but otherwise it's almost the same process.

If anyone is going to build a removable handle soon, please take pics and share them here.

I'm also planning to post is "how to make a leather sheath" thread soon. But, again..my time is very limited right now.

Re: Making a Mule Handle (step-by-step)

Posted: Mon Jun 06, 2022 11:55 am

by Ramonade

I just need to see how to procure myself some hardware (I'll certainly use the one on the Spyderco G10 handle kit) and see what counterbore I need. If everything is going ok, I'll make one during June or early July.

I'll make sure to take pictures at every steps this time ! (I tried to do it for the three first handles, but I got carried away and barely have any pictures

)

Re: Making a Mule Handle (step-by-step)

Posted: Mon Jun 06, 2022 1:06 pm

by Xplorer

There's a wide range of hardware possibilities available from the usual knife making supply sources. There's also a lot of personal preference involved in choosing what to use. It will be easiest if the hardware choice doesn't require you to enlarge the holes in the tang. That's something most people will want to avoid.

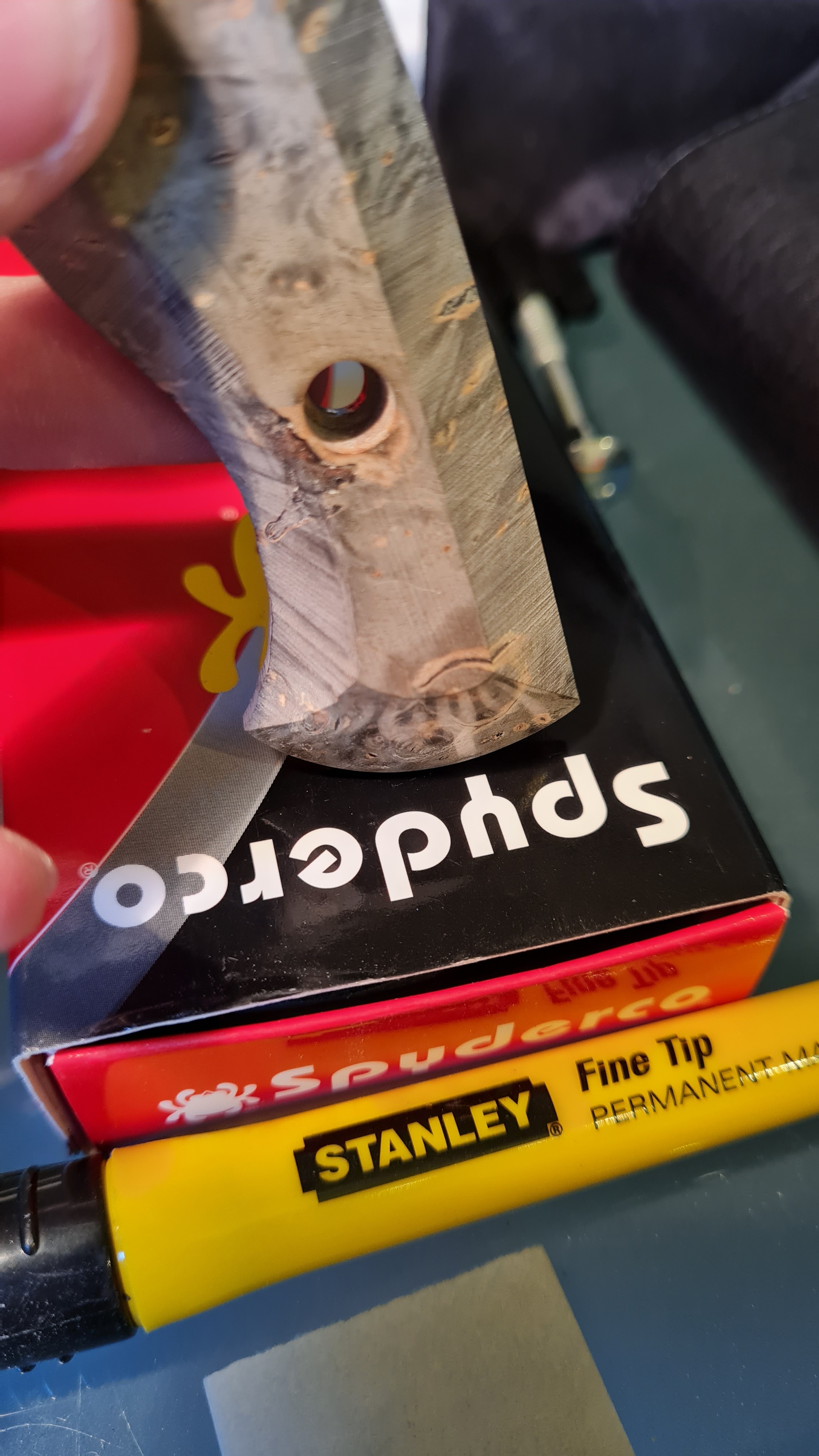

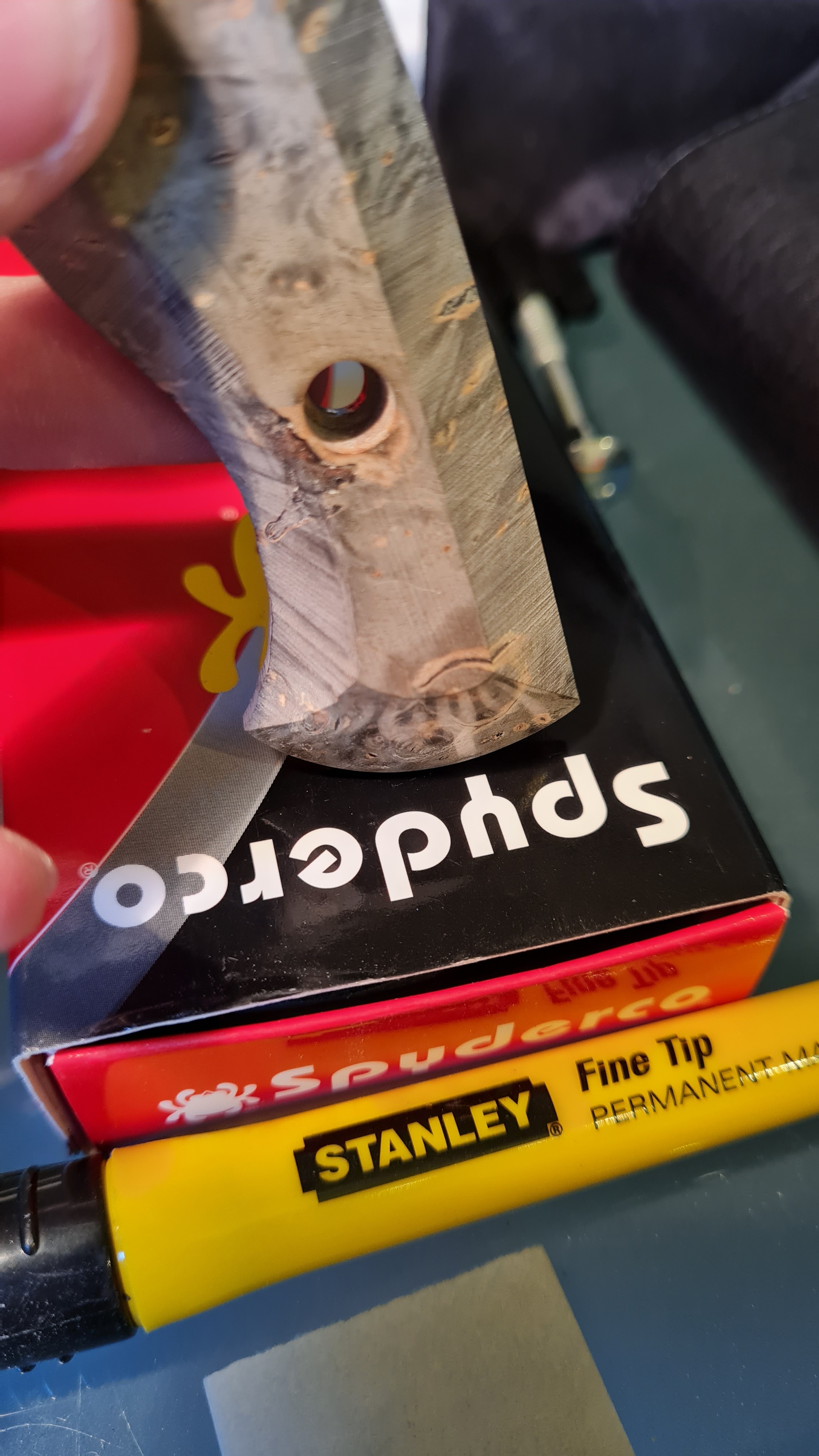

Here's small (folder size) hardware with 1/8 threaded shafts inside that I've been abusing on a prototype for a couple of years now. I wanted to see if using only 2 small pieces of hardware would be strong enough. It proved to be quite strong.

What I used in the pics above are some of the smallest and most basic examples. You can find many, many sizes and variations. In addition to looking up knife handle hardware, search for knife pivots (often sold as 3 piece sets) and chainring bolts for more options.

Re: Making a Mule Handle (step-by-step)

Posted: Mon Jun 06, 2022 2:23 pm

by Ramonade

Thanks, I'm still scouring the Internet to find french (or EU) shops that carry the hardware needed. Ironically, I've found the kind of counterbore you showed me on a french website. It is not tungsten carbide, but has the same dimensions. I'm gonna try it !

As far as pivot, they mostly are titanium, sold by piece and pretty expensive. I'll keep searching

I've found some, but it's not actual pivot, one end has a Torx print but there's only one actual screw, like on this pic :

They seem to be badly labelled, as both knife pivots and chicago screws

Re: Making a Mule Handle (step-by-step)

Posted: Sun Jun 12, 2022 9:46 am

by Ramonade

Little update : I'm working on the RWL34 Mule, and was planning to make it screw construction.

However, I was talking to my uncle and father while doing it, and I messed up on some steps (3 or 4 times total, necessitating a lot of troubleshooting and work arounds to make this handle work).

I am going to finish this one, wich will be epoxy'd on. I'm gonna make a strict checklist / protocol to be sure that everything is pitch perfect, and then I'll start to make a screw construction handle for the K390 Mule

It'll take a bit of time.

Re: Making a Mule Handle (step-by-step)

Posted: Mon Nov 28, 2022 9:31 am

by standy99

Great tutorial…needs to be bumped up for newer Mule owners..

Give it a go.

Re: Making a Mule Handle (step-by-step)

Posted: Wed Aug 23, 2023 8:47 pm

by Bolster

Bump for new folks looking for info re hafting a mule.

Re: Making a Mule Handle (step-by-step)

Posted: Thu Aug 24, 2023 8:30 pm

by legOFwhat?

Would be nice if this and a couple others could be stickied?

) grinder as well. I used my 1x30 grinders for years, and with practice and a few little modifications I was even able to produce some really good knives on those grinders. You can do a lot with that tool! Hopefully you have a supplier near you that offers a good selection of belts. There are an extremely wide variety of belts (alum. oxide, ceramic, even diamond) and grits available for your grinder.