I would like to mainly focus on the performance of the knife and steel but I will try to give my impressions on the actual knife and design first. I was really pleased with the knife from the moment I opened the box. The knife really is a work of art. Two different blades with different locks put together seamlessly in such a small package. Pretty impressive! The build quality is excellent. Tight lockups on both blades and very smooth action. The knife has a very solid feel...I would almost term it "overbuilt". The (Knife) blade is quite thick for being so short and is fairly thick behind the edge. The thickness goes all the way to the tip too. This thing is not going to be a typical Spyderco "slicer". Between the thick blade, ti build and built in marlin spike which can double as a makeshift prybar, I would feel comfortable terming the tusk a small "hard use" knife.

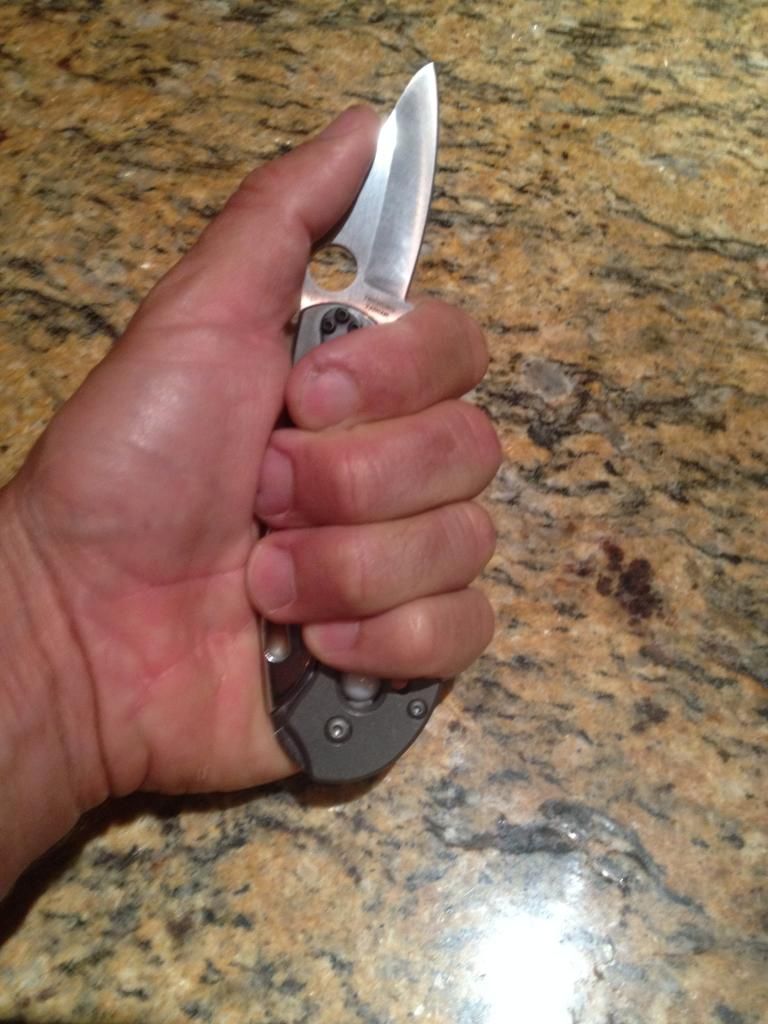

One additional note before getting into the performance review is on the ergonomics. I was blown away. Seriously, in the forward grip with finger in the choil and thumb on the spine this is one of the most comfortable spydies I have ever held. Fits my hand like a glove! That they were able to build such a radical design with dual blades and locking mechanisms without sacrificing anything ergonomically was quite an accomplishment. Color me impressed.

Ok, so I like the knife. Let's get on to what I have discovered in the last two weeks. First lets talk about corrosion resistance. I tried very hard to make this knife rust. I couldn't do it. I fished with it every day on my kayak so it was constantly soaking in saltwater for 4-5 hours a day. When I got home I would leave the knife in the sink, still salty, and would purposely not rinse it all day. After a week of this treatment there was no rust so I decided to step it up a notch. I have a center compartment in my kayak where I keep a few emergency supplies. It's not really watertight so there is always 1/4-1/2" of saltwater in the bottom of the tray. I left the knife in there during my fishing trips and would even leave it soaking in the heat and saltwater overnight. After 48 hours of this there was zero visible rust. Nothing. I can't say exactly what it would take to make it rust but I know that what I have done with it so far would cause any other stainless steel to be eaten up with rust. I am satisfied that I could have this steel on the ocean daily in extremely corrosive environments without any corrosion issues.

Now on to the edge retention part. I compared this steel pretty extensively against plain edged H1 and got some really interesting results. I'm going to give you the data but I'm not going to make you wade through it to get the answer. You want to know if it beat H1 in edge retention in my tests? Well, no, it did not beat it. It destroyed it. Not even close. Here's what I found.

The first few days I would bring the tusk and my PE Salt 1 to the cleaning table everyday to process fish. I would use them both for an equal number of cuts through meat, skin, scales and bone. I was very careful to give each one the same number of cuts on the same material using the same pressure. The results were obvious. The lc200 held both a shaving edge and a working edge MUCH longer than the h1.

Well, I knew I was going to have to provide you guys with better data than that (and I wanted to confirm the results I got on the fish) so out came the rope. I use these knives to do a lot of fish cleaning which sometimes involves high pressure cuts against fairly hard skin and bones so I wanted to try to mimic that kind of cutting. I chose a 3/8" dense nylon rope. This stuff is HARD to cut! I had both edges beveled at 30 with a 40* mb on the corners of the brown rods. Fairly coarse edges that would clean shave with no pressure against the skin. Even on the first cuts I had to use 15-17 lbs of pressure and a once forward, once back motion to make a clean cut. Tough rope. I also used an s30v Millie as a benchmark. Here's the results.

S30v:

10 cuts - After 10 cuts the steel was still very sharp. Little notable deterioration.

20 cuts - Steel had lost it's "hair popping" edge but would still easily shave in 1 pass

30 cuts - Less bite against thumb. Still shaves without "scraping" but takes two passes

40 cuts - Still shaving but started to require a bit more pressure on rope.

50 cuts - Starting to struggle more with rope. Will only scrape shave.

60 cuts - Still scrape shaving, but requires two passes.

70 cuts - Shaving same as 60 but slightly more pressure required on rope.

Lc 200n:

10 cuts - Still quite sharp. Very similar to s30v after 10

20 cuts - Still shaves without scraping but sometimes takes two passes.

30 cuts - Starting to struggle a bit with the rope. Still scrape shaves easily.

40 cuts - Increased pressure needed on rope but still scrape shaves easily. Similar condition to s30v after 60 cuts.

50 cuts - Still scrape shaving. Edge condition similar to s30v after 70 cuts.

60 & 70 cuts - I was able to finish out 70 cuts with the tusk, but by 70 cuts I was having to use quite a bit of pressure to make the cut. It should be noted that the lc200 would still scrape shave with some effort even after 70 cuts.

H1:

10 cuts - More dull than s30v after 70 cuts. Similar to lc200 after 70 cuts. Will barely scrape shave

20 cuts - Will only cut rope with extreme pressure and sawing. Will not scrape shave. Edge is dead.

That's it guys. Those are my results. I found them so surprising that I resharpened everything and performed the entire test again, only to get almost the exact same results. The h1 would always give up the ghost after about 15 cuts on this very tough rope.

Ok, I know this was a simple test and it wasn't performed in the most scientific of manners but the results were obvious. When cutting through hard material that requires a lot of pressure, PE h1 doesn't do very well at all. I already knew that from the fish cleaning I've done with it. I was quite surprised, however, by how well the lc200 n performed. I wish I had had a vg10 blade to compare it too. Given how well it held its own against s30v I suspect it would have fared even better against vg10. Maybe someone else can try that. I'm sure some of you are wishing that I had carried on with the lc200 and s30v to see how far they would go. I thought about it, but honestly by the time I stopped, all of the edges were well past the point at which I would have sharpened them. I had all the information I needed and I'm kind of lazy by nature so I stopped there.

Ok, before I leave y'all with all this info, let me add a couple of caveats. The rope used in this test is a very hard nylon fiber and probably presents unusual challenges to an edge because of the amount of pressure required. I am mentioning this because I remember a post Sal made where he mentioned that their testing showed lc200's edge retention similar to h1. That may be the case on certain mediums like cardboard but it certainly wasn't on the fish, skin, bones and rope that I tried it on.

Ok, I've got plenty more to say on the subject but this post is WAY too long already so I'll open it up to discussion.