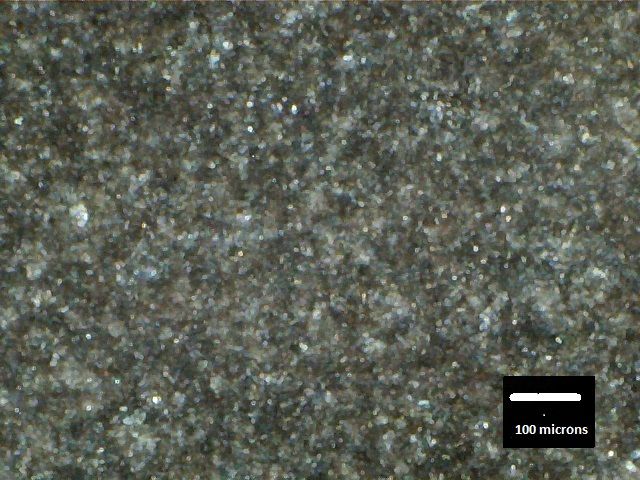

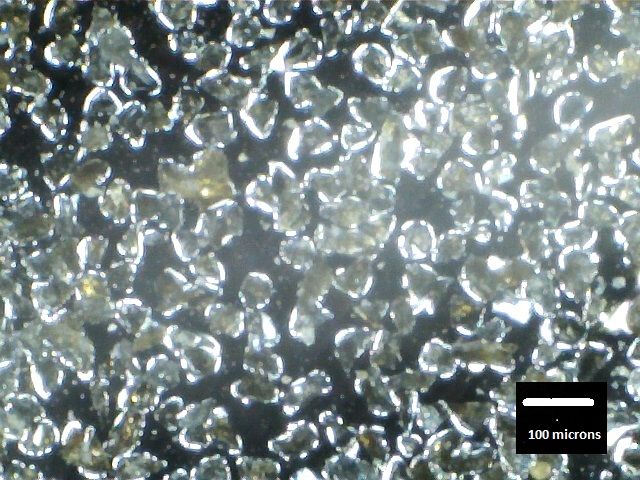

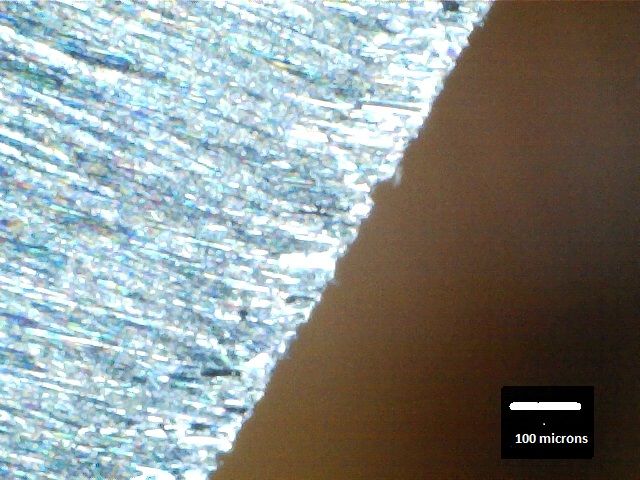

This is a high magnification shot of the surface of a medium rod, the scale is in the picture (credit to Clay Allison for convincing me to stop being so lazy and to put it in there). Here is the CBN rods at the same magnification :

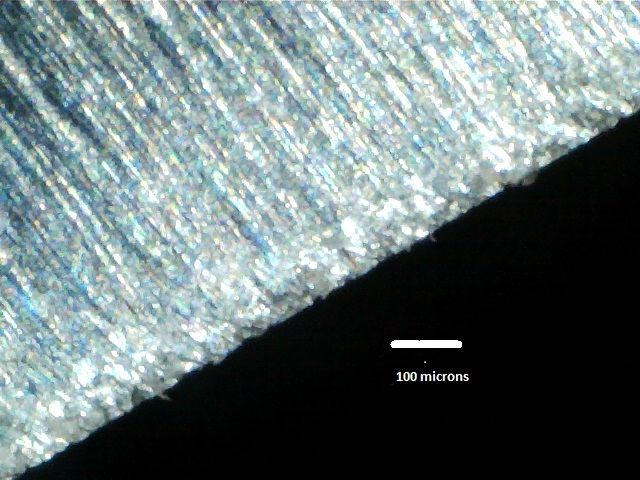

The grit size difference is obvious, you can even measure the exact grit size of the CBN as you can just see the grains clearly. Note as well they are fairly evenly distributed and not subject to extreme mass clumping. This is confirmed if you just feel the rods, they are rough yes, but they are not highly irregular.

Note as well that the 400 mesh or sieve rating appears to be correct as the particles are of the order of 40 microns which is the approximating micron rating for 400 mesh.

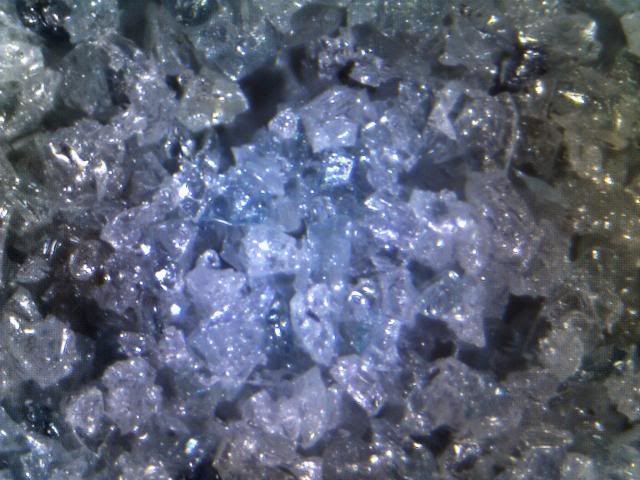

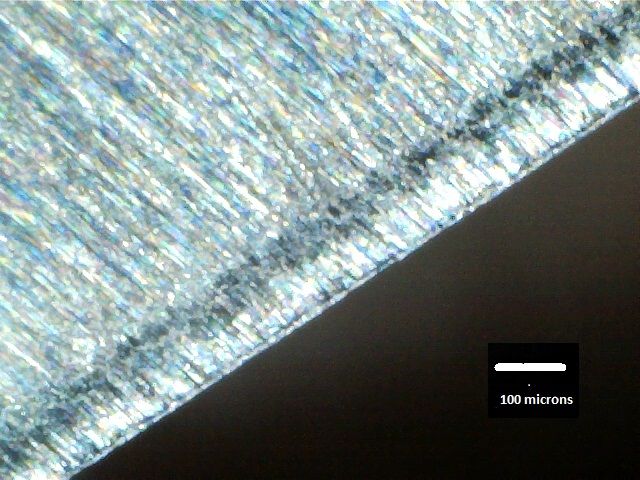

For reference, here is a 240X SPS-II waterstone :

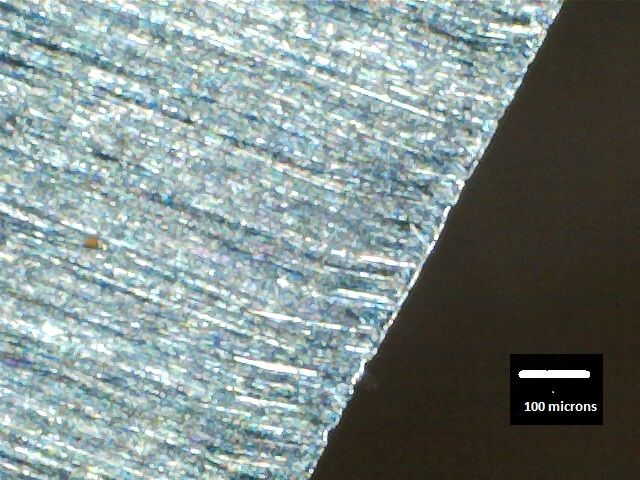

This is the edge on a Mora #1260 (the number doesn't mean anything, it is just the model number) which is 1095 at 58-59 HRC (as spec). It has been flattened and the edge apexed with a Bester 700 grit waterstone, using the hone-to-dry method to maximize the edge finish. Note the :

-uniform scratch pattern

-even edge line

-small irregularities

I then cut the edge off by making three slices into the same stone to mill a flat on the edge. This is the result of just 10 passes per side on the CBN :

The edge is brought to an apex immediately and will slice newsprint but won't shave and the edge has some pieces knocked out of it as would be expected. Here is the result of 6 more passes which are done using ultra-light honing (5-10 grams) on the CBN rods :

Note the edge is refined and now it will shave, but it is really coarse, even a wet shave isn't likely to be comfortable. I cut the edge off again (same process, 3 cuts into the 700 grit Bester) and just for comparison apexed it with the medium rods. This time it took 130 passes per side :

The edge is significantly more polished and shaves well and does all the things you expect from the Spyderco medium rods (3-finger sharpness test passes readily). Note that the bevel now is about 0.1 mm side and you can see it by eye.

As another comparison, to see if you could jump from the CBN right to the medium rods I cut the edge off again (same process, three passes into the 700 grit bester) and then apexed the edge with the CBN rods. As the edge was much thicker/wider now it took 30 passes per side to apex.

(I don't have the diamond rods, if I did I would have interjected them here).

I then switched to the medium rods. After 10 passes per side there was a significant difference in finish, after 30 passes per side it was back to the Spyderco medium rod finish. To clarify now, I am working on a very narrow bevel, it is still only about 0.1 mm or so wide.

In short :

-the rods are fairly coarse, a 400 mesh/grit rating is a decent approximation to the type of finish

-they cut much faster than the medium rods

-in order to jump from the CBN to medium rods the bevel would have to be very narrow

-the edge from the CBN rods can be sharp, it isn't just shaping only

-the abrasive is well distributed

A immediate recommendations / observations :

-use the CBN rods to set the relief only, use the medium rods as the micro bevel

If the diamonds are inbetween then you could use them. If you try to polish the CBN bevels with just the medium rods you are likely going to be at it awhile. I will measure this later.

In regards to issues, there is only one :

There were a couple of points where the surface was rough enough to snag the edge. Do not, and this is critical, try to resolve this by just grating the edge hard against the rods, this will just tear the grit off the surface. For the first sharpening use the highest carbide knife you own which is fairly dull (or that you want to reset the angle). Work it light and slow and this will even out any of the coarse spots.

(the reason that you do not want to use a low carbide knife is because it will be cut much easier which means much deeper and you could just pull out the high spots and you want to wear them down rather than just pull them off or crack off a large piece)

If there is any thing in particular of interest just let me know.