Serrata : Stewart Ackerman

Posted: Thu Feb 06, 2014 6:57 pm

This knife has generated considerable interest due to the material which is 440C but used in an as-cast state :

-http://www.cliffstamp.com/knives/forum/read.php?5,24899

-http://www.cliffstamp.com/knives/forum/ ... p?20,24447

-prototype : http://spydercollector.wordpress.com/20 ... n-serrata/

-the makers version : http://www.spyderco.com/forums/showthre ... l-thoughts

-maker website : http://ackermancustomknives.com/

Compared to the Temperance 2, it isn't a small knife. A few specifications :

-0.215" blade stock

-full flat grind, 3.5 dps primary grind

-0.03" edge bevel, 14.5 dps (checked on the 15 dps Sharpmaker, catches immediately)

Blade is :

-220 grams (neutral balance)

-4 5/8" blade

-4.5" handle

-2.5" distal taper

The handle is full functional length, however almost 1" of the blade is not sharpened at the base - this isn't obvious from the side pictures. To be clear I mean it isn't apexed, it is 1 mm wide at the base and gradually thins until it is apexed about 1" from the choil.

Handle is :

-0.97 to 1.2" wide

-0.58 to 0.72 " thick

Very stable in hand, due to the large difference in width vs thickness, no chance of it rolling, however the edges are very square, barely broken, the pressure is obvious even in a tight grip. Front of the handle/top is also sharp so thumb over ramp and pinch grips can hit sharp points.

Initial sharpness is solid but not extreme :

-shaves, but requires force against the skin/slight

-slices newsprint well, no push cut, does a 45 degree zipper cut

-110-130 grams to push cut espirit thread

-0.25 to 0.45 cm to slice bergia spinning thread under a 40 gram load

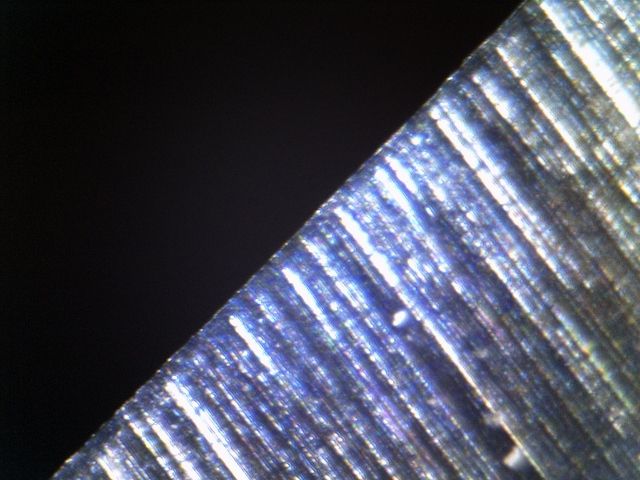

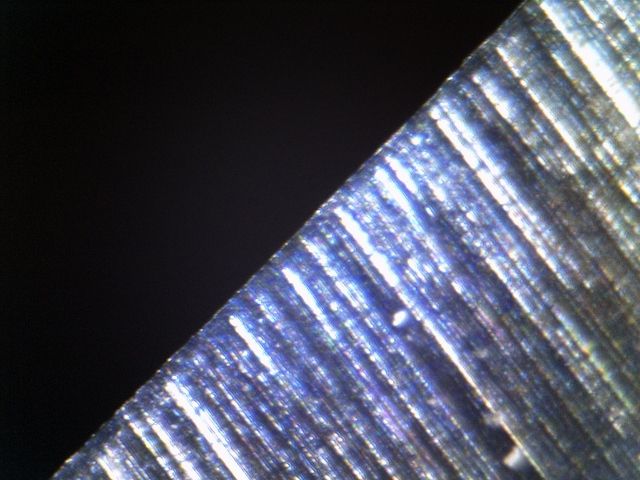

Initial edge 50X magnification :

-coarse shaping grit

-nice buff job, not rounded out

Cutting ability is moderate to high :

3/8" hemp

-push cut, 34-36 lbs

-2" draw, 14-15 lbs

A few materials :

-slices cords well

-plastics, thin and thick

-foams

Light wires were ok :

Twenty cuts into light cord (tv cable, charger cable, etc.) only had one issue and that was when the knife twisted.

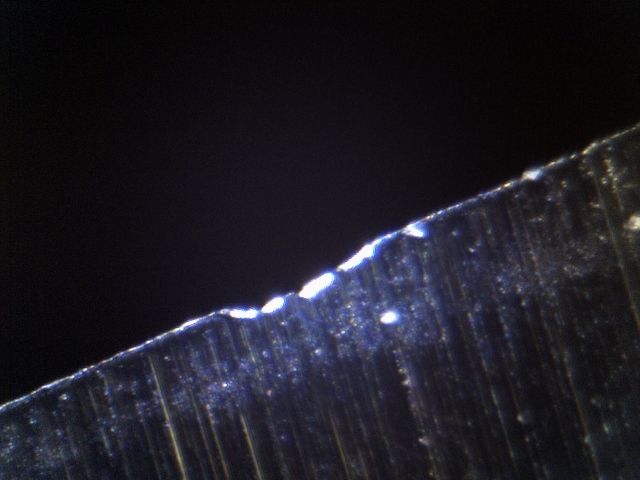

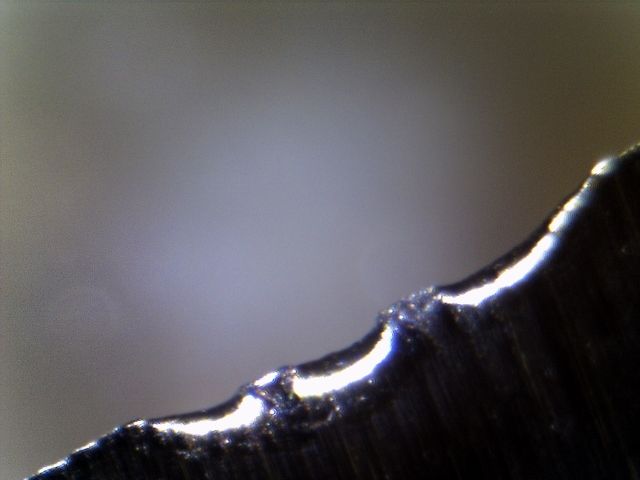

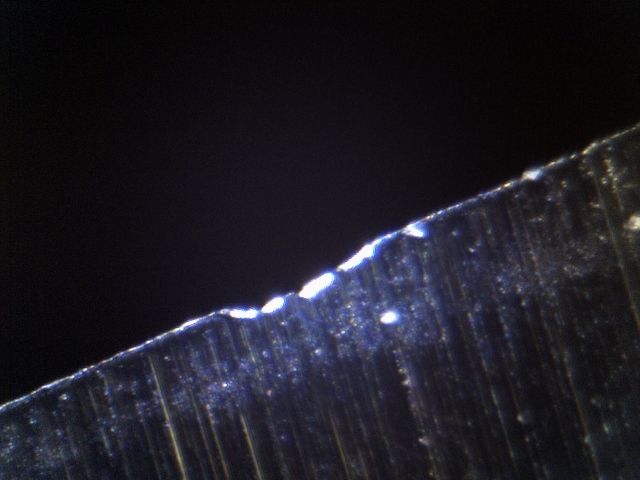

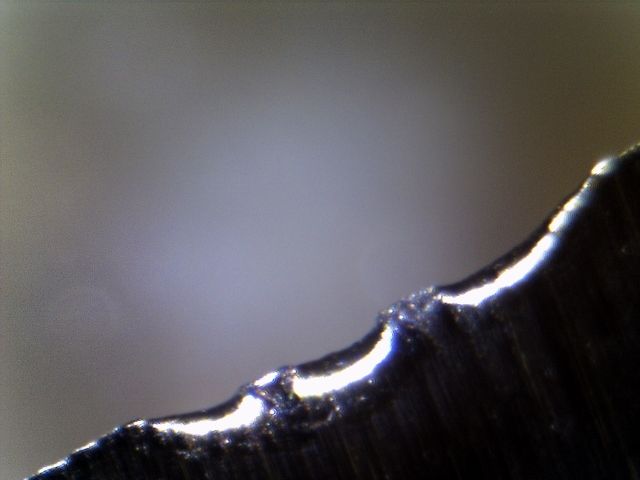

However heavier cable was an issue (CAT-5) :

It would not cut the core, the edge buckled.

These are both 100 slices into hardwood, light force 10-20 lbs. This is mainly dependent on edge angle (assuming the blade is sharp and there are no issues with ergonomics/security or leverage which there are not). The difference in wood shaving thickness is obvious and just shows the edge angle ratio (10/15).

However with heavier cuts into softer wood the performance equalizes and it can cut as well as the Mora :

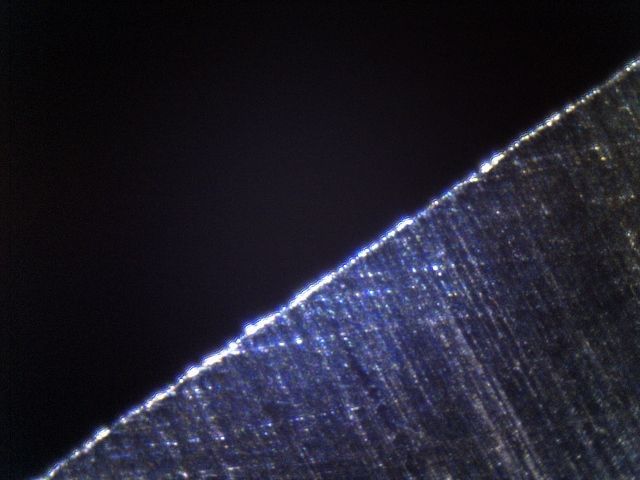

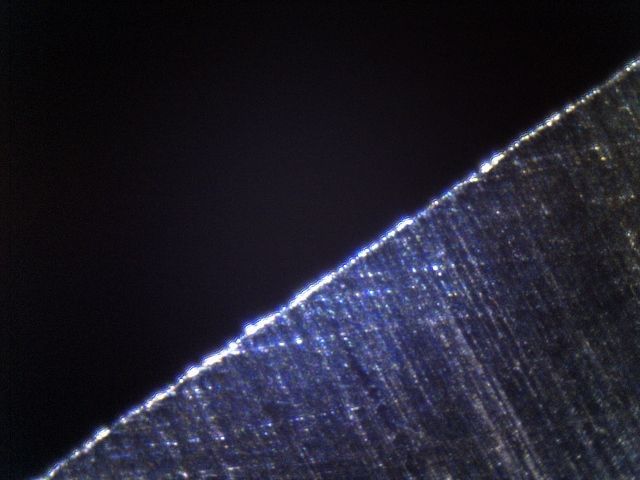

The edge aside from the damaged wire areas :

No issues, no reflection of light.

I cut the edge off then :

-10 pps with a 700 bester, light micro-bevel, apex immediately

-20 pps with a 600 DMT, easily shaved, very sharp (< 0.1 cm on the bergia / 40 gram load)

A few side observations / comments :

-as always Spyderco gives credit, Boye is mentioned in the pamphlet (Stewart is also vocal Boye was an influence)

-the very thick spine poses some interesting questions about scope of work

-there was mention of this as a bushcraft knife (silly label) but the spine is broken/chamfered

This looks interesting to use.

-http://www.cliffstamp.com/knives/forum/read.php?5,24899

-http://www.cliffstamp.com/knives/forum/ ... p?20,24447

-prototype : http://spydercollector.wordpress.com/20 ... n-serrata/

-the makers version : http://www.spyderco.com/forums/showthre ... l-thoughts

-maker website : http://ackermancustomknives.com/

Compared to the Temperance 2, it isn't a small knife. A few specifications :

-0.215" blade stock

-full flat grind, 3.5 dps primary grind

-0.03" edge bevel, 14.5 dps (checked on the 15 dps Sharpmaker, catches immediately)

Blade is :

-220 grams (neutral balance)

-4 5/8" blade

-4.5" handle

-2.5" distal taper

The handle is full functional length, however almost 1" of the blade is not sharpened at the base - this isn't obvious from the side pictures. To be clear I mean it isn't apexed, it is 1 mm wide at the base and gradually thins until it is apexed about 1" from the choil.

Handle is :

-0.97 to 1.2" wide

-0.58 to 0.72 " thick

Very stable in hand, due to the large difference in width vs thickness, no chance of it rolling, however the edges are very square, barely broken, the pressure is obvious even in a tight grip. Front of the handle/top is also sharp so thumb over ramp and pinch grips can hit sharp points.

Initial sharpness is solid but not extreme :

-shaves, but requires force against the skin/slight

-slices newsprint well, no push cut, does a 45 degree zipper cut

-110-130 grams to push cut espirit thread

-0.25 to 0.45 cm to slice bergia spinning thread under a 40 gram load

Initial edge 50X magnification :

-coarse shaping grit

-nice buff job, not rounded out

Cutting ability is moderate to high :

3/8" hemp

-push cut, 34-36 lbs

-2" draw, 14-15 lbs

A few materials :

-slices cords well

-plastics, thin and thick

-foams

Light wires were ok :

Twenty cuts into light cord (tv cable, charger cable, etc.) only had one issue and that was when the knife twisted.

However heavier cable was an issue (CAT-5) :

It would not cut the core, the edge buckled.

These are both 100 slices into hardwood, light force 10-20 lbs. This is mainly dependent on edge angle (assuming the blade is sharp and there are no issues with ergonomics/security or leverage which there are not). The difference in wood shaving thickness is obvious and just shows the edge angle ratio (10/15).

However with heavier cuts into softer wood the performance equalizes and it can cut as well as the Mora :

The edge aside from the damaged wire areas :

No issues, no reflection of light.

I cut the edge off then :

-10 pps with a 700 bester, light micro-bevel, apex immediately

-20 pps with a 600 DMT, easily shaved, very sharp (< 0.1 cm on the bergia / 40 gram load)

A few side observations / comments :

-as always Spyderco gives credit, Boye is mentioned in the pamphlet (Stewart is also vocal Boye was an influence)

-the very thick spine poses some interesting questions about scope of work

-there was mention of this as a bushcraft knife (silly label) but the spine is broken/chamfered

This looks interesting to use.