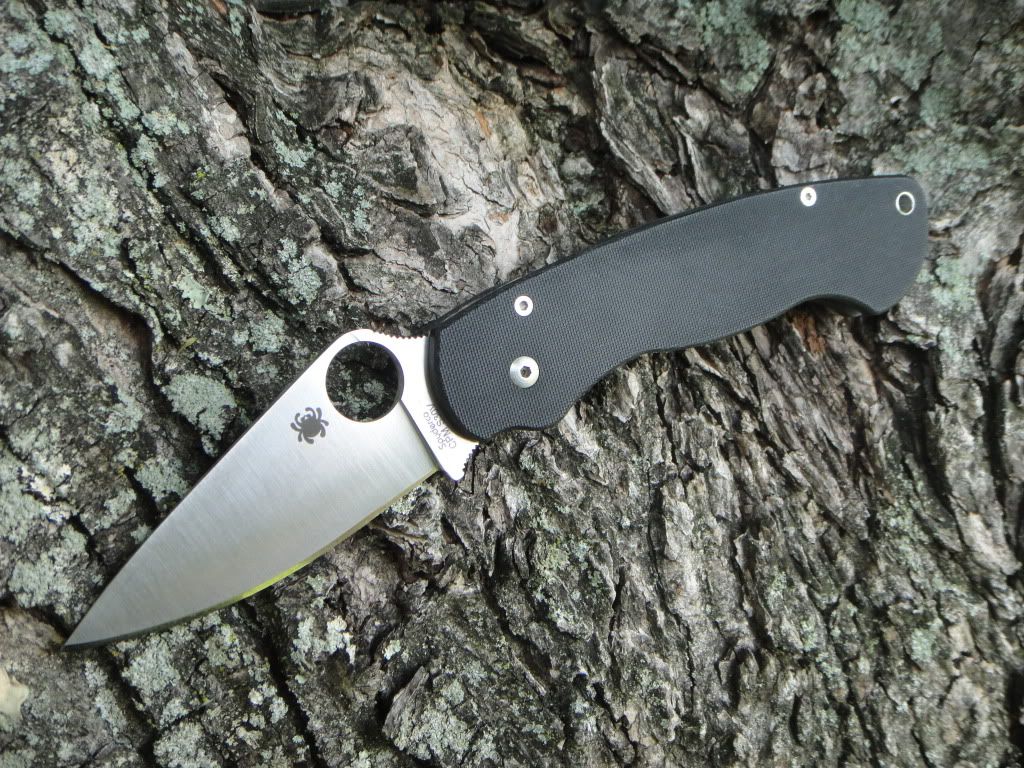

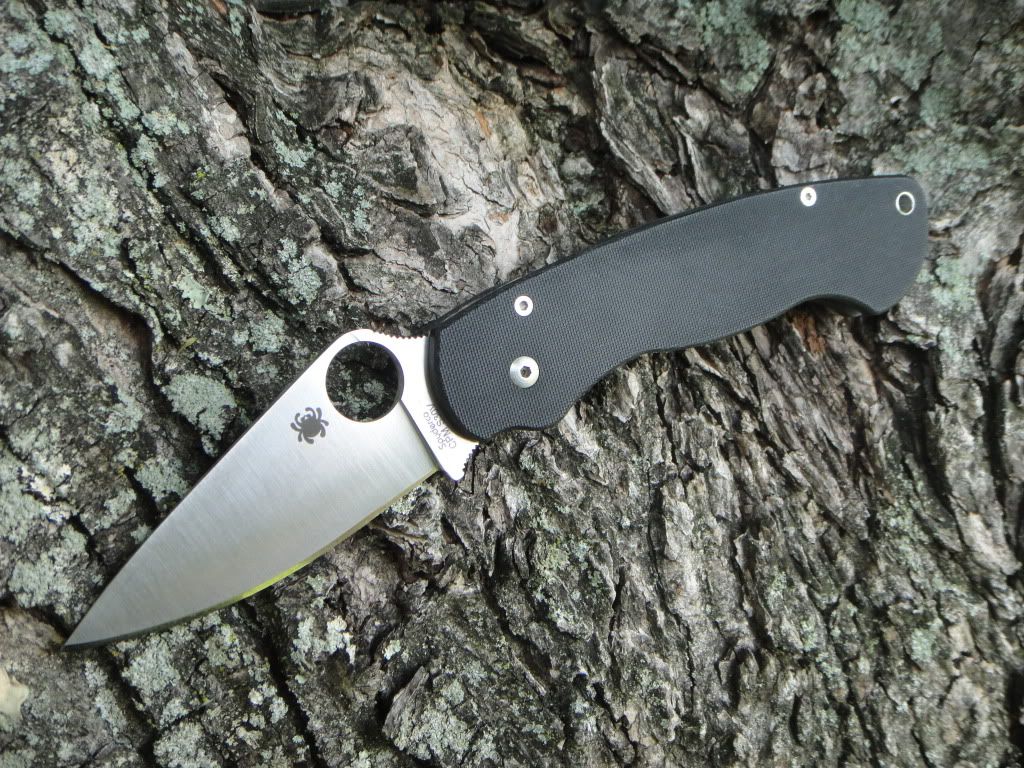

Paramilitary 2: Repairing a Broken Tip

Paramilitary 2: Repairing a Broken Tip

Well, I guess I finally “broke” in my PM2…I dropped it from waist level on to carpet. It was one of those slow motion moments where I watched it tumble to the floor. The knife landed tip down bouncing off the carpet. Unfortunately, about a half a millimeter of the tip broke off in the process.

My question is what’s the best way to fix it? I’ve got a Sharpmaker and my skill is good enough sharpen my Spydies almost as good as they were when new. However, I’ve never tackled a repair like this. It seems like sharpening the whole blade until the tip is repaired would waste to much metal. Or would it be best to just work on the tip? If so, would I use the Sharpmaker the same way I do when sharpening an entire blade? i.e., try to create a 30 degree back bevel at the point and then perhaps a 40 degree micro bevel?

Ironically, I just purchased the diamond rods for my Sharpmaker and a some lower grit Moldmaster stones from Congress Tools the day before.

Thanks for any tips. :)

Thomas

My question is what’s the best way to fix it? I’ve got a Sharpmaker and my skill is good enough sharpen my Spydies almost as good as they were when new. However, I’ve never tackled a repair like this. It seems like sharpening the whole blade until the tip is repaired would waste to much metal. Or would it be best to just work on the tip? If so, would I use the Sharpmaker the same way I do when sharpening an entire blade? i.e., try to create a 30 degree back bevel at the point and then perhaps a 40 degree micro bevel?

Ironically, I just purchased the diamond rods for my Sharpmaker and a some lower grit Moldmaster stones from Congress Tools the day before.

Thanks for any tips. :)

Thomas

Welcome thoffman, this forum is pretty cool :)

Ouch :eek: on your Para. Do try to look on the bright side, not much came off of the tip. With only .5mm mmissing you could probably get away with sharpening just the tip. Do you have a picture you could post??

Figured I'd post what happened to my Damascus Mule and how I recovered from that damage. In my case I took most of the material off of the top of the blade.

Good luck with the Para :)

Ouch :eek: on your Para. Do try to look on the bright side, not much came off of the tip. With only .5mm mmissing you could probably get away with sharpening just the tip. Do you have a picture you could post??

Figured I'd post what happened to my Damascus Mule and how I recovered from that damage. In my case I took most of the material off of the top of the blade.

Good luck with the Para :)

Charlie

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

-

KardinalSyn

- Member

- Posts: 1394

- Joined: Mon Nov 28, 2011 8:39 pm

- Location: Colombo, Sri Lanka

Feel bad reading about your mishap. I saw on another forum about how a Yojimbo2 was dropped and suffered a similar fate. Guess all that force getting concentrated at the tip causes the metal to "break".

Sorry I can't give you input on how to fix the tip. I am not that adept in that area nor do I know about the tools needed. Hope you find a solution.

Take care.

Sorry I can't give you input on how to fix the tip. I am not that adept in that area nor do I know about the tools needed. Hope you find a solution.

Take care.

:spyder: Centofante3 (C66PBK3), ParaMilitary2 (C81GPCMO), Endura4 (C10P), GrassHopper (C138P), Military (C36GPCMO), Perrin PPT (C135GP), Squeak (C154PBK), Dragonfly 2 Salt (C28PYL2), Military M390 CF (C36CFM390P), R (C67GF), ParaMilitary2 CTS-XHP (C81GPOR2), Tuff (C151GTIP), Ladybug & Perrin Street Bowie (FB04PBB)being the newest.

Same thing happened to me just from nicking some steel cable slightly while cutting some tape.

Such a delicate tip!

I originally fixed it with my Sharpmaker nicely. Concentrate on the tip mostly but also blend it in a bit too. Later, when I got my Wicked Edge, I reprofiled it a little nicer.

With such a small amount gone, I was still able to get a needle sharp tip again and it's likely stronger now. Use your coursest stones though, or you will be at it a long time.

Such a delicate tip!

I originally fixed it with my Sharpmaker nicely. Concentrate on the tip mostly but also blend it in a bit too. Later, when I got my Wicked Edge, I reprofiled it a little nicer.

With such a small amount gone, I was still able to get a needle sharp tip again and it's likely stronger now. Use your coursest stones though, or you will be at it a long time.

Keep those sharp tips coming Spyderco. I'd rather risk tip breakage. I wish the Endura still had a sharp tip!

Far better is it to dare mighty things, to win glorious triumphs, even though checkered by failure... than to rank with those poor spirits who neither enjoy nor suffer much, because they live in a gray twilight that knows not victory nor defeat.

Theodore Roosevelt

Theodore Roosevelt

If you have a Dremel, i would smooth down the spine until it hits the edge. If you bring the edge up to the spine, it's going to leave the tip sort of tanto-ish and take forever and a lot of sharpening to bring the tip back to a good point. If you bring the spine down you also won't lose any more edge length. I did this on purpose to shorten my old Paramilitary down to exactly 3 inches.

It's very subtle..if you start the transition on the spine high up enough, you probably won't even notice the change. I took about 3/16 or so off mine.

It's very subtle..if you start the transition on the spine high up enough, you probably won't even notice the change. I took about 3/16 or so off mine.

~David

wow that turned out really niceEvil D wrote:If you have a Dremel, i would smooth down the spine until it hits the edge. If you bring the edge up to the spine, it's going to leave the tip sort of tanto-ish and take forever and a lot of sharpening to bring the tip back to a good point. If you bring the spine down you also won't lose any more edge length. I did this on purpose to shorten my old Paramilitary down to exactly 3 inches.

It's very subtle..if you start the transition on the spine high up enough, you probably won't even notice the change. I took about 3/16 or so off mine.

http://i229.photobucket.com/albums/ee27 ... C00440.jpg

dbcad, that must have really hurt when tip broke on your Damascus Mule. Hurt just to see it! Thanks for the pictures. It helped to see the before and after.dbcad wrote:Do you have a picture you could post??

Figured I'd post what happened to my Damascus Mule and how I recovered from that damage. In my case I took most of the material off of the top of the blade.

Good luck with the Para :)

The broken part on mine is just on the "beveled" part of the tip, so I'm hoping I can still end up with a decent tip. (Tried to take pictures, but they didn't turn out very well.)

Thomas

Sanding barrels are your best bet. Use it on as low of a speed as you can get it done with so you don't heat up the blade. Use long gentile strokes from about an inch up the blade and be careful not yo press hard or you'll make dips and low spots. You wanna take off as little as you can on each pass so it blends in with the rest of the spine. You also wanna focus on keeping the bit square on the spine. You could probably get yours done with a sheet of sandpaper on a flat surface.thofmann wrote:I do have a Dremel. Which attachment/tool did you use? Great job on yours, I wouldn't have notice if had not pointed it out.

Thomas

~David

1/2mm is not much. Spydercos are generally pretty tippy and don't have to be that way unless you want it that way. If it were mine I would restore the tip to sharp and ignore the shape of the tip vs original. Not everyone has the right touch with a dremel, judge for yourself if you are comfortable with that.

thofmann, you might also consider sending it in to Spyderco, I seem to recall they offer minor repair/grinding of damaged blades for around $20/25? I know they don't offer *replacement* blades, but I thought I remembered seeing mention of grinding. At least that way you know they wouldn't damage the heat treat, and could probably get it looking pretty good.

Which Knife, A or B? get Both! (and C, D and E) :)

I would be willing to hook someone up with a repair before i let them spend $25 to fix a 1/2mm chip. I took off a good bit of steel off the tip of mine and the blade never even got hot. If you do it like i advised...make light sweeping passes, the blade is never under enough friction to get hot enough to damage the heat treat. You can do it with a cup of cold water nearby for good measure. If it's really that small i'd try sandpaper first.

Here's a pic of when i started mine, and i took off a good bit more than this from the spine in order to blend the trip up high enough so it didn't look as "Delica-ish" at the tip.

Here's a pic of when i started mine, and i took off a good bit more than this from the spine in order to blend the trip up high enough so it didn't look as "Delica-ish" at the tip.

~David

- mikerestivo

- Member

- Posts: 1090

- Joined: Fri Dec 25, 2009 10:19 am

- Location: Indiana

- phillipsted

- Member

- Posts: 3674

- Joined: Tue Oct 05, 2010 11:30 am

- Location: North Virginia

Thanks. It's a lot more obvious in person especially if you're familiar with the Para/Para 2. If you put them side by side, my Para almost has a leaf shaped blade because i contoured the tip that far up on the spine. Here's a shot of the flat part of the spine on a flat surface to show how much was taken off. It goes almost half way up the blade.mikerestivo wrote:Evil D - nice repair work. I can't tell that anything was done. I may have to send my knives south of the Ohio River to you if I ever break one...

~David

- defenestrate

- Member

- Posts: 2672

- Joined: Fri Sep 24, 2004 10:33 am

- Location: RTP NC area

- Contact:

Had the same thing happen to my Adventura and I am in the process of regrinding with a Dremel. Agreed it is far easier to do a good job grinding the spine to meet the edge. Mine is going to end up with a spear tip with a slight double edge just where covered by the handle, I think.

-

Happy, Happy, Happy! Peel, Peel, Peel!

Happy, Happy, Happy! Peel, Peel, Peel!

I have an old Aus 8 endura that had a broken tip from me prying a screen off a window open a long time ago. I sent it to spyderco and I was planning on spending $20 to have them reprofiled the blade, but they did it for free! Just had to pay $5 return shipping :D

I would try that if you aren't comfortable reprofiling yourself. If you are, get busy on those diamond stones :D

I would try that if you aren't comfortable reprofiling yourself. If you are, get busy on those diamond stones :D

-Ryan

-Techno, cruwear Mule, Dragonfly 2 FRN, Assist, Endura FRN ATS-55 SE, Endura SS aus-6 PE, Persistence(Wife's)

-Wicked Edge

-Techno, cruwear Mule, Dragonfly 2 FRN, Assist, Endura FRN ATS-55 SE, Endura SS aus-6 PE, Persistence(Wife's)

-Wicked Edge

-

chipdouglas

- Member

- Posts: 162

- Joined: Fri Oct 16, 2009 2:19 pm