What are the advantages of a "deep" blade?

What are the advantages of a "tall" blade?

What are the advantages (if any) of a "tall" or "deep" blade on a pocket knife, by which I mean, a larger-than-normal distance of steel between the edge and the spine?

For example, consider the LionSpy, Dialex Junior, Lum, or Rock Lobster as examples of "tall" or "deep" blades.

In culinary use, I can see the advantage: you can chop larger items and still keep your hand on the spine of the blade for control. And, they allow you to keep the on-spine hand comfortably clear of the action. I would also imagine their shallow wedging action to allow better slicing (provided it's flat ground, not saber ground).

But for pocket knife use...? It would curtail your cutting radius, and making peeling difficult.

Please school me on the advantages...I love the look of a tall blade...they look aggressive and powerful to me, but am puzzled regarding its actual functionality on a pocket knife. (Obviously you need both, but that's another topic...!)

For example, consider the LionSpy, Dialex Junior, Lum, or Rock Lobster as examples of "tall" or "deep" blades.

In culinary use, I can see the advantage: you can chop larger items and still keep your hand on the spine of the blade for control. And, they allow you to keep the on-spine hand comfortably clear of the action. I would also imagine their shallow wedging action to allow better slicing (provided it's flat ground, not saber ground).

But for pocket knife use...? It would curtail your cutting radius, and making peeling difficult.

Please school me on the advantages...I love the look of a tall blade...they look aggressive and powerful to me, but am puzzled regarding its actual functionality on a pocket knife. (Obviously you need both, but that's another topic...!)

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

- Minibear453

- Member

- Posts: 822

- Joined: Wed Jul 13, 2011 3:36 am

-

Drkknight614

- Member

- Posts: 438

- Joined: Sun Sep 04, 2011 12:12 pm

- Location: New York

Pretty much what you said. Also with a deep blade your more then likely going to have deep belly, which is good for many things, mostly known for skinning. How much youll do that with a folder is subjective, but belly isnt a bad thing either.Bolster wrote:What are the advantages (if any) of a "deep" blade on a pocket knife, by which I mean, a larger-than-normal distance of steel between the edge and the spine?

For example, consider the LionSpy, Dialex Junior, Lum, or Rock Lobster as examples of "deep" blades.

In culinary use, I can see the advantage: you can chop larger items and still keep your hand on the spine of the blade for control. And, they allow you to keep the on-spine hand comfortably clear of the action. I would also imagine their shallow wedging action to allow better slicing (provided it's flat ground, not saber ground).

But for pocket knife use...? It would curtail your cutting radius, and making peeling difficult.

Please school me on the advantages...I love the look of a deep blade...they look aggressive and powerful to me, but am puzzled regarding its actual functionality on a pocket knife. (Obviously you need both, but that's another topic...!)

Manix 2 DLC, Delica 4 FFG, Ladybug 3,County Comm H1 Ladybug 3 , Endura 4 FFG G10, C94 UKPK Leaf, Atlantic Salt, Military Camo DLC,Sage 1 Para 2 DLC, Delica 4.

-

Frapiscide

- Member

- Posts: 242

- Joined: Sun Apr 18, 2010 11:57 am

It makes it more gradual from the edge to the spine, making it easier for cutting. Would you rather cut with a quarter inch wide blade from 0 to 4mm thickness or one that's 1.125" wide?

dalstott wrote:When people have no ideas they invent words.

If you can not stun them with brilliance , then

baffle them with BS

Well, never. I might spread peanut butter but the chances of my dressing out a deer with my pocket knife are near 0%, especially given that I'm a vegetarian. Even if I weren't, I'd not use a pocket knife for the job.Drkknight614 wrote:Also with a deep blade your more then likely going to have deep belly, which is good for many things, mostly known for skinning. How much youll do that with a folder ...

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

I used to carry a pretty deep blade drop point knife. Then I bought my first expensive knife, a Benchmade with a clip point. I still remember the first time I went to spread chicken salad with it for lunch at work. That was the exact moment that I realized why there were different blade shapes and started to make informed opinions on what I do and do not like.

I love deeper blades. Spyderco's FFG leaf shaped blades are a home run in my opinion.

Grizz

I love deeper blades. Spyderco's FFG leaf shaped blades are a home run in my opinion.

Grizz

Well, from the discussion so far, seems that tall bladed knives have definite advantages for food preparation (but not peeling, for which they truly suck). Slicing, spreading, and skinning, good.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

Beyond what you already pointed out, and this of course doesn't necessarily benefit all of us, but if you consider a knife a weapon, then a taller blade will give a larger wound channel.

For me though it's about two things: 1, the grind almost always benefits from a taller blade. Consider two blades, one is .5 inch tall and the other is 2 inches tall, both are hollow grind...which do you think will be the better slicer if both are just as thick? 2, it gives longer knife life. A taller blade means you have that much more steel to sharpen over the years.

Of course, taller blades have drawbacks as well....that same comparison of the two hollow grind blades i mentioned...try to make a turn with both knives and see which one cuts easier....taller blades can be a real pain to cut turns with.

For me though it's about two things: 1, the grind almost always benefits from a taller blade. Consider two blades, one is .5 inch tall and the other is 2 inches tall, both are hollow grind...which do you think will be the better slicer if both are just as thick? 2, it gives longer knife life. A taller blade means you have that much more steel to sharpen over the years.

Of course, taller blades have drawbacks as well....that same comparison of the two hollow grind blades i mentioned...try to make a turn with both knives and see which one cuts easier....taller blades can be a real pain to cut turns with.

~David

Slicing all the way through a relatively rigid material is another plus. Many of us break down cardboard boxes from time to time and a tall, flat ground blade makes it a bit easier than a shorter one. That being said, for cardboard, a thinner blade always wins.

42 Spyderco fixed blades and counting...

The biggest impact it has is on aesthetics. Other advantages though would be tip strength, overall stability in cuts, and the ability to taper to a thinner edge while keeping overall spine thickness. Those are just hunches of mine.

Problems include generally a wider tip, less precise and lower penetration. Deep blades as you call them also tend to be wide in the pocket (Delica vs Sage).

Just generalizing of course as design philosophies can defy them.

Problems include generally a wider tip, less precise and lower penetration. Deep blades as you call them also tend to be wide in the pocket (Delica vs Sage).

Just generalizing of course as design philosophies can defy them.

- Dr. Snubnose

- Member

- Posts: 8799

- Joined: Sat Mar 05, 2005 9:54 pm

- Location: NewYork

+1....Doc :DEvil D wrote:Beyond what you already pointed out, and this of course doesn't necessarily benefit all of us, but if you consider a knife a weapon, then a taller blade will give a larger wound channel.

For me though it's about two things: 1, the grind almost always benefits from a taller blade. Consider two blades, one is .5 inch tall and the other is 2 inches tall, both are hollow grind...which do you think will be the better slicer if both are just as thick? 2, it gives longer knife life. A taller blade means you have that much more steel to sharpen over the years.

Of course, taller blades have drawbacks as well....that same comparison of the two hollow grind blades i mentioned...try to make a turn with both knives and see which one cuts easier....taller blades can be a real pain to cut turns with.

"Always Judge a man by the way he treats someone who could be of no possible use to him"

*Custom Avatar with the Help of Daywalker*

*Custom Avatar with the Help of Daywalker*

Sorry I have been calling this dimension "deep" and apparently it should be called "tall" so I'll go back and edit.

I've noticed some have said a stronger tip, but nobody's said a stronger overall blade. Does a tall blade not equate to overall strength?

I've noticed some have said a stronger tip, but nobody's said a stronger overall blade. Does a tall blade not equate to overall strength?

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

Thickness and form being equal, the taller blade is stronger, yes. However, blades are generally strong in the tallness dimension and weak in the thickness dimension. To get better lateral strength a gain in thickness is more effective than a gain in tallness, but adding steel will always make it stiffer and almost always stronger. The exception to stronger is if the thickness produces a stress riser that causes one portion to snap off under a stress.Bolster wrote:Sorry I have been calling this dimension "deep" and apparently it should be called "tall" so I'll go back and edit.

I've noticed some have said a stronger tip, but nobody's said a stronger overall blade. Does a tall blade not equate to overall strength?

- The Deacon

- Member

- Posts: 25717

- Joined: Fri Sep 24, 2004 10:33 am

- Location: Upstate SC, USA

- Contact:

IMHO, in this context, deep and tall, and wide and broad as well, are all interchangeable.Bolster wrote:Sorry I have been calling this dimension "deep" and apparently it should be called "tall" so I'll go back and edit.

I've noticed some have said a stronger tip, but nobody's said a stronger overall blade. Does a tall blade not equate to overall strength?

I think perhaps, like grind and overall shape, the advantages of any given one are often secondary to fashion and as much a matter of perception as reality. And, as with most things, the truth is that both wide and narrow blades have their good and bad points. To me, blade strength would be more closely related to thickness than to height, but the perception may be otherwise. There may be both more truth, and more perceived benefit, to it with Spyderco, because of the Spyderhole. OTOH, for any given thickness and length, a taller blade will be heavier and thus put the balance further forward. Some folks do prefer a blade heavy knife.

The real question is how much any of them matter in the context of a folder. Kitchen cutlery is somewhat more logical, you'll probably never see a wide bladed boning or fillet knife, or a narrow bladed cleaver.

Paul

My Personal Website ---- Beginners Guide to Spyderco Collecting ---- Spydiewiki

Deplorable :p

WTC # 1458 - 1504 - 1508 - Never Forget, Never Forgive!

My Personal Website ---- Beginners Guide to Spyderco Collecting ---- Spydiewiki

Deplorable :p

WTC # 1458 - 1504 - 1508 - Never Forget, Never Forgive!

I thought about this more and i really think it comes down to the grind vs. overall blade strength. The two compliment each other, and the height of the blade gives the ability to taper the grind over a further distance, which allows you to be thinner behind the edge while still keeping a thick spine. With a short blade height, if you want a thick strong blade and thin behind the edge, you'll end up with an abrupt wedge shape. Giving the blade some height (like with the leaf shaped blade) you can make that wedge more acute which will slice with less resistance but still retain strength at the spine. You just can't have a short blade that's also thick and also thin behind the edge and still get a blade that slices easily.

A good example would be the Centofante blades, particularly the Cento 4. Being a shorter height blade than most Spydies, and being hollow grind, if the blade was any more than 2mm thick it probably wouldn't slice very well, but being thinner steel takes away from that abrupt wedge behind the edge problem.

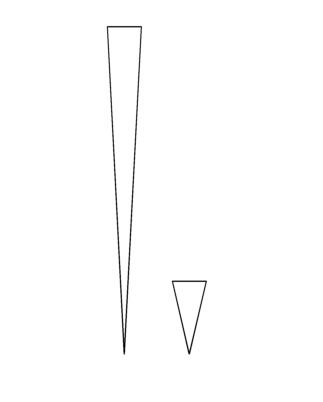

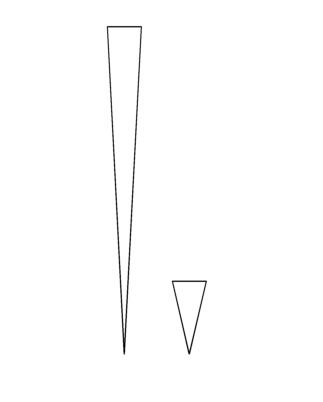

Here's a simple drawing to show what i mean. Both are the same width at the spine, but it's easy to see which is going to slice through cardboard with less resistance. If you have paintshop or photoshop, try it out yourself. Make a small triangle like the small one here, and then stretch the height upward, and you can watch the sides come closer together more acute as you get higher.

A good example would be the Centofante blades, particularly the Cento 4. Being a shorter height blade than most Spydies, and being hollow grind, if the blade was any more than 2mm thick it probably wouldn't slice very well, but being thinner steel takes away from that abrupt wedge behind the edge problem.

Here's a simple drawing to show what i mean. Both are the same width at the spine, but it's easy to see which is going to slice through cardboard with less resistance. If you have paintshop or photoshop, try it out yourself. Make a small triangle like the small one here, and then stretch the height upward, and you can watch the sides come closer together more acute as you get higher.

~David

-

Drkknight614

- Member

- Posts: 438

- Joined: Sun Sep 04, 2011 12:12 pm

- Location: New York

Agreed, and probably why some of those short blades are hollow grind and not ffg.Evil D wrote:I thought about this more and i really think it comes down to the grind vs. overall blade strength. The two compliment each other, and the height of the blade gives the ability to taper the grind over a further distance, which allows you to be thinner behind the edge while still keeping a thick spine. With a short blade height, if you want a thick strong blade and thin behind the edge, you'll end up with an abrupt wedge shape. Giving the blade some height (like with the leaf shaped blade) you can make that wedge more acute which will slice with less resistance but still retain strength at the spine. You just can't have a short blade that's also thick and also thin behind the edge and still get a blade that slices easily.

A good example would be the Centofante blades, particularly the Cento 4. Being a shorter height blade than most Spydies, and being hollow grind, if the blade was any more than 2mm thick it probably wouldn't slice very well, but being thinner steel takes away from that abrupt wedge behind the edge problem.

Here's a simple drawing to show what i mean. Both are the same width at the spine, but it's not easy to see which is going to slice through cardboard with less resistance. If you have paintshop or photoshop, try it out yourself. Make a small triangle like the small one here, and then stretch the height upward, and you can watch the sides come closer together more acute as you get higher.

Manix 2 DLC, Delica 4 FFG, Ladybug 3,County Comm H1 Ladybug 3 , Endura 4 FFG G10, C94 UKPK Leaf, Atlantic Salt, Military Camo DLC,Sage 1 Para 2 DLC, Delica 4.

Exactly, because making them hollow grind is the only way to make them thin behind the edge. Otherwise you would only be able to sharpen it at like 60+ degrees inclusive and it wouldn't be much of a slicer.Drkknight614 wrote:Agreed, and probably why some of those short blades are hollow grind and not ffg.

~David