'

please share your thoughts, and ask questions.

I first got a piece of wood, larger than the blade and made sure it was flat and the top is parallet to the bottom.

I then use the drill press and blade to align and drill the first hole, then insert a 3/16 dowel before drilling the second hole. I use the knife blank as a template to drill the second hole.

I then trace around the blank with a pencil and cut out a rough shape on the band saw.

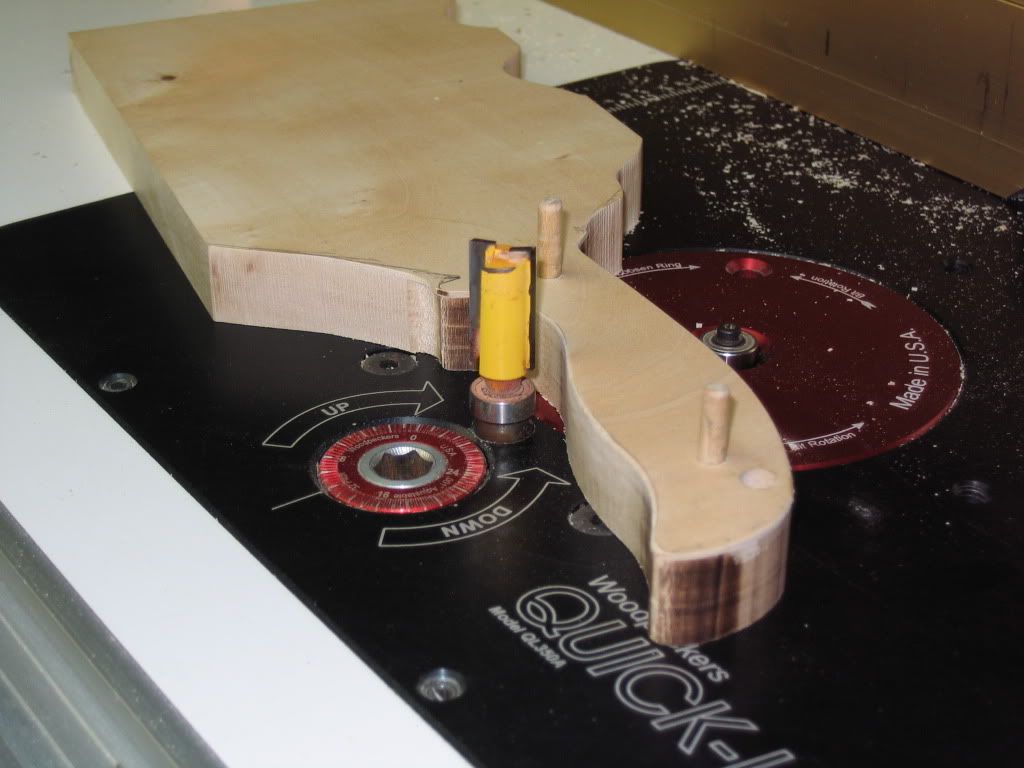

I then use a flush cut bit in the router to cut the template to match the knife blank.

The gap between the bearing and bit cause a lip to be left. I pull the pins out of the template and flip it over to cut this off.

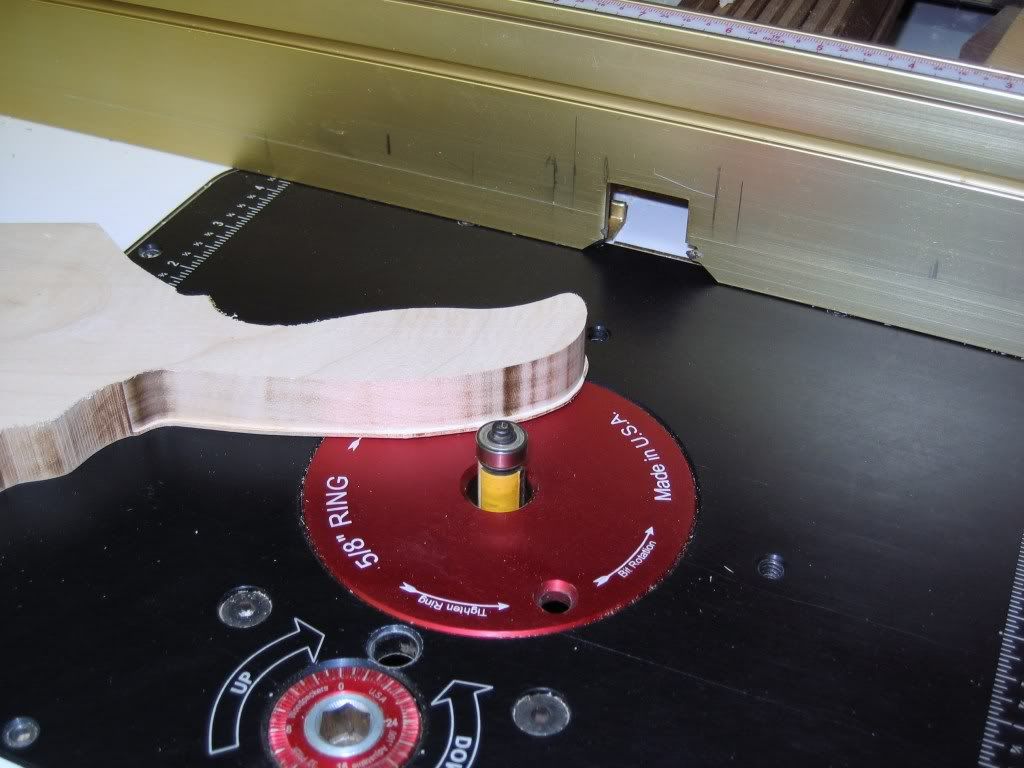

Template is now cut and matches the knife tang!!!!

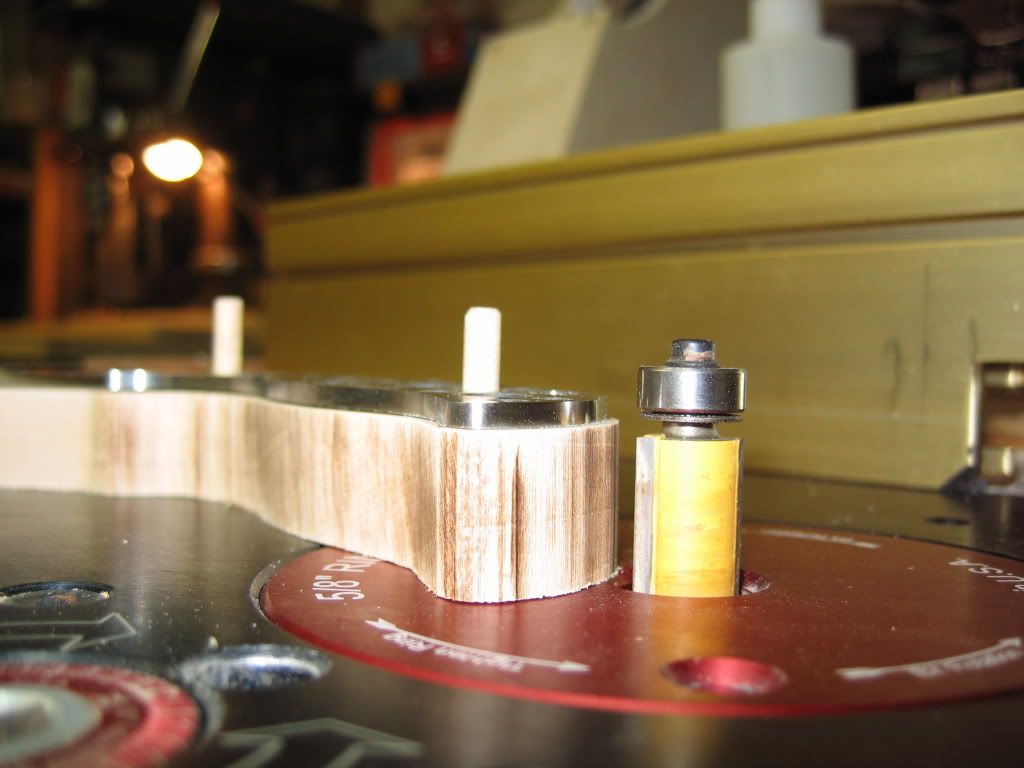

Last picture shows the template bit that is used to cut scales. The lower bearing rides on the template, and the upper blade cuts the scale.