oregon wrote:You sound like the voice of experience vw. So... lets see the scars or hear the war story (electricity vs vampyrewolf). Seriously, thanks for putting my feet onto the ground, no pun intended. I want to keep it fun for me and my next of kin who see me engrossed in using electricity and liquids for kicks.

oregon

car batteries are usually around 13.8VDC @ 650A, 8970W

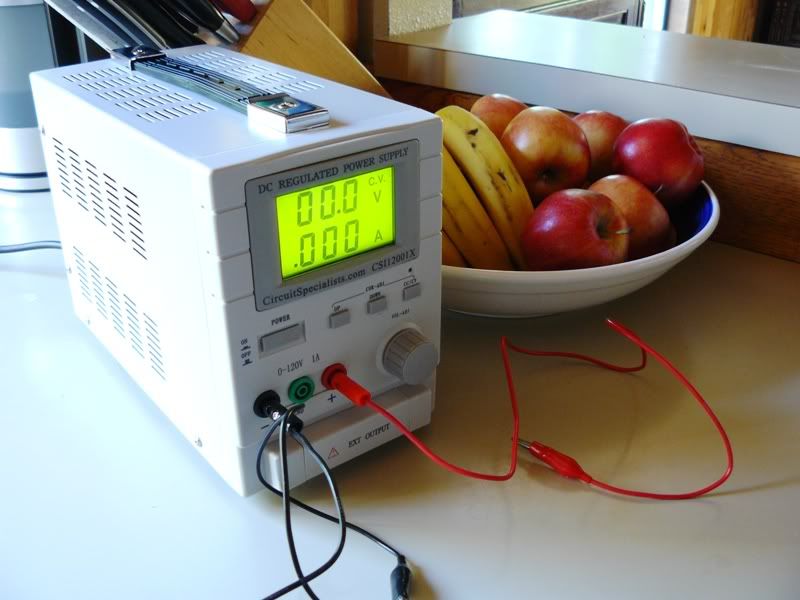

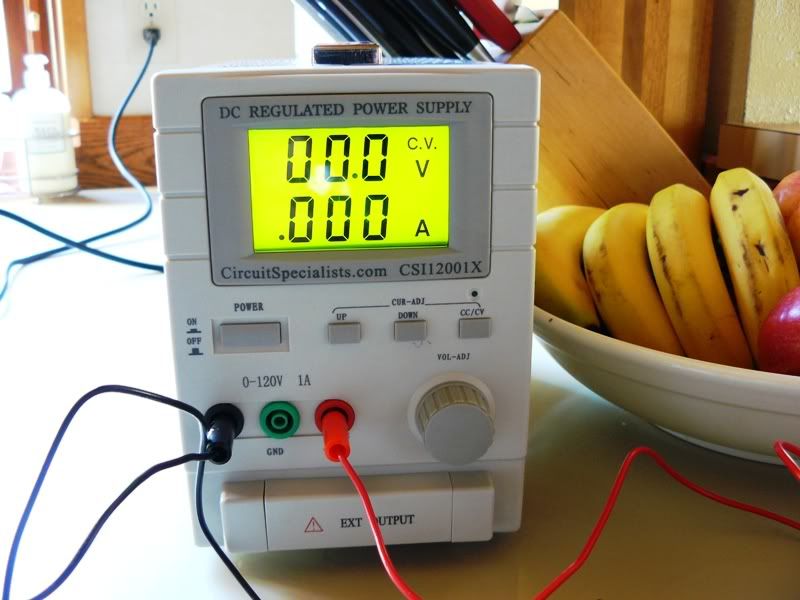

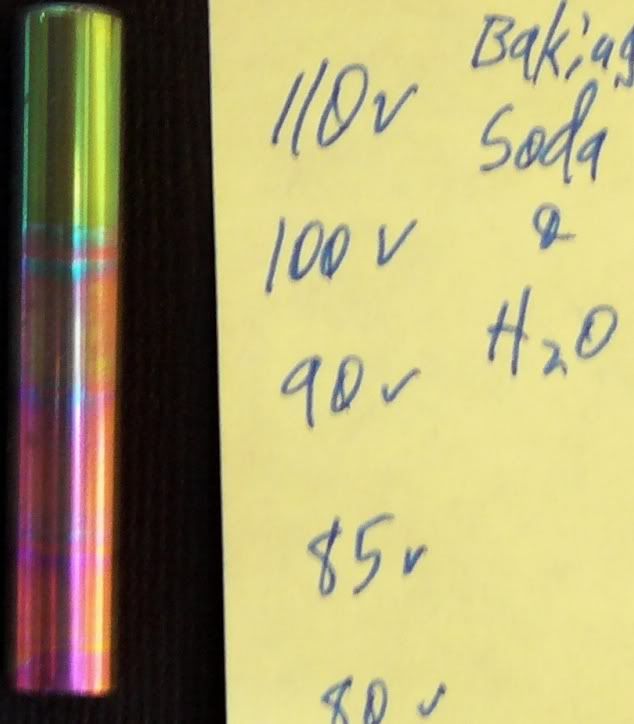

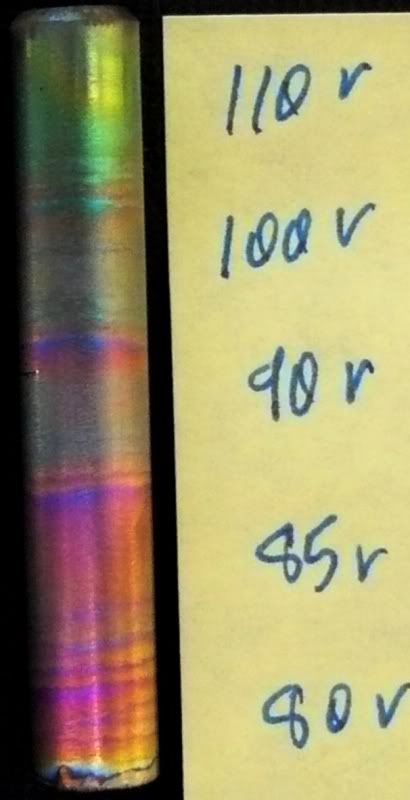

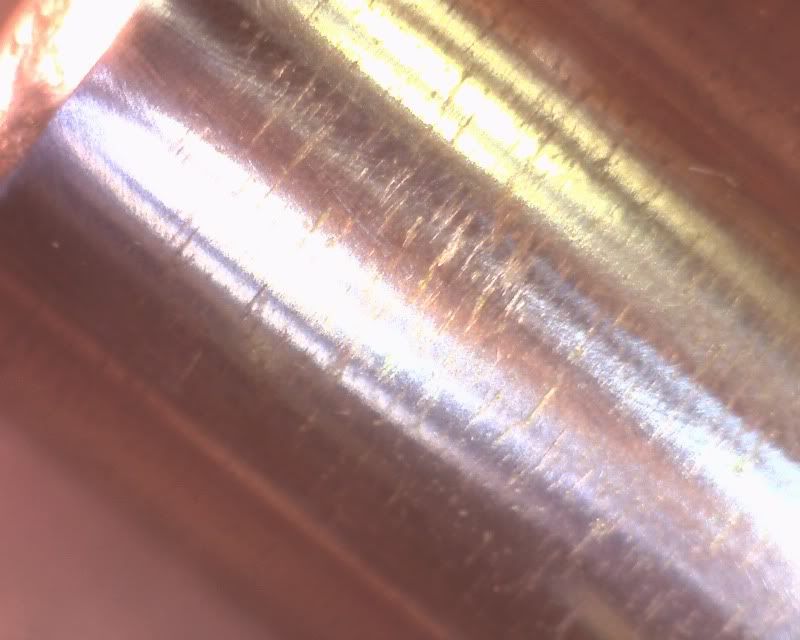

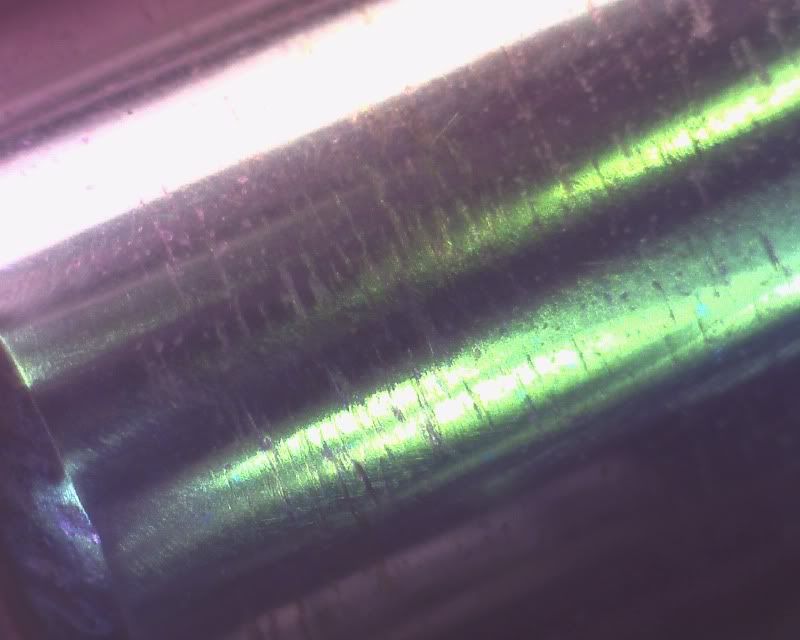

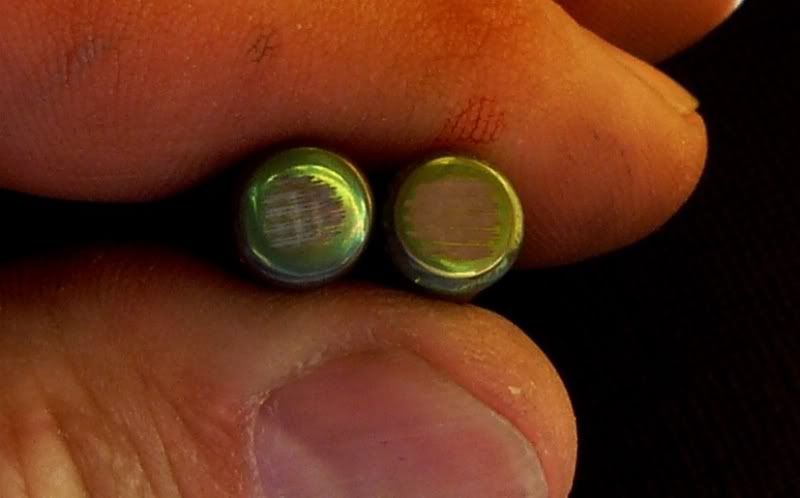

you're working with 120VDC @ 1A, 100W

I've played with a taser one of our techs made, 20kV @ ~5mA, 100W... I held it on my arm for a good 5min and watched it twitch :D left a red mark for a few days.

I've gotten a few good shocks working on my cars, even had a problem with the one that every now and then you had to short the batt to the chassis to get it to kick over.

I did more than enough vehicle work with a "live wire, dead wire" sense of electronics, using my fingers to tell me if I had power on a system... not going to count the times I've jerked my hand into something solid like that.

The real fun is working with 110VAC on household circuits. "Did you throw the breaker for this room?" "yep" BZZZZZT! "are you sure this plug is on that circuit?" "nope"... done THAT one a few times :rolleyes: Eventually you learn to take it across 2 fingers close together (preferably ones with thickened skin). 220VAC hurts.

The one shock that hurt like **** and actually left a mark?

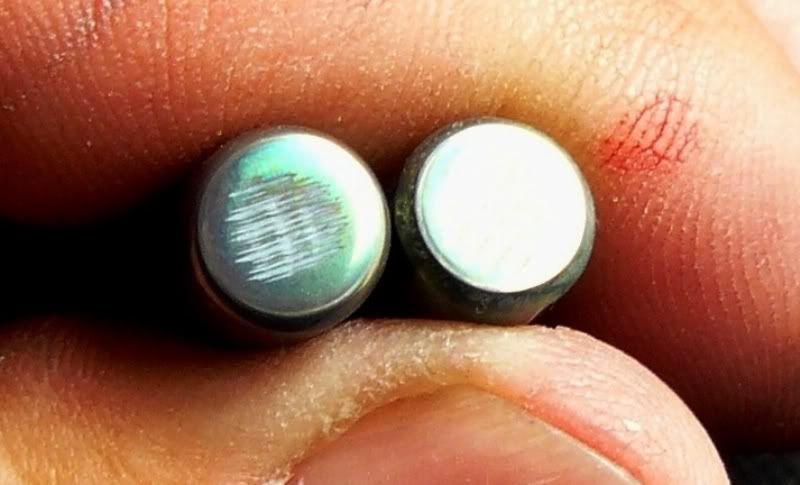

Went to work on a forklift, it doesn't power up. Reach around the tower to wiggle the power cable and ZZZZAAAAAAPPP :eek: Exposed wire on the harness was shorted to the chassis, but the floor wasn't grounding it so it had been an isolated cct. Had on combat boots with a good inch of rubber so I didn't do it when I stepped on. Took it across my arms and chest. THAT one hurt for a good hour and my arms didn't feel quite right for near a week.

Batt on that mofo weighed enough that we used a forklift to change it.

So the supply you're using to annodize is a toy. It might leave a mark if you put both leads on your arm, depending on how moist your skin in (dry will give a higher resistance and thus less current). Don't go purposefully touching both ends, but don't be afraid of touching both leads either.

We played with the 30V @ 2A (60W) supplies in my tech course, had a few people afraid to touch em while some of us would crank em up grab both leads between thumb and index and ask if it was even on (with both needles pinned on the far end).