GRIFFIN HAWKS wrote:To finish I used various micro-files [to smooth the holes],

150-600 sandpaper[to remove edges and make a rough polish],

and good old French's Golden Mustard ,)

I made my own formula for a Mustard etch.

Mix 4oz of COKE, 2 teaspoons of gun bluing paste (can get it in a tube, but the liquid can be used. May have to experiment with that, tho. Maybe start with a tablespoon), and two tablespoons of plain old yellow mustard. Depending on the steel, and how deep you want the etch to be, 2-5 coats.

Be sure to degrease the steel. Even alcohol will work for that, or brake cleaner.

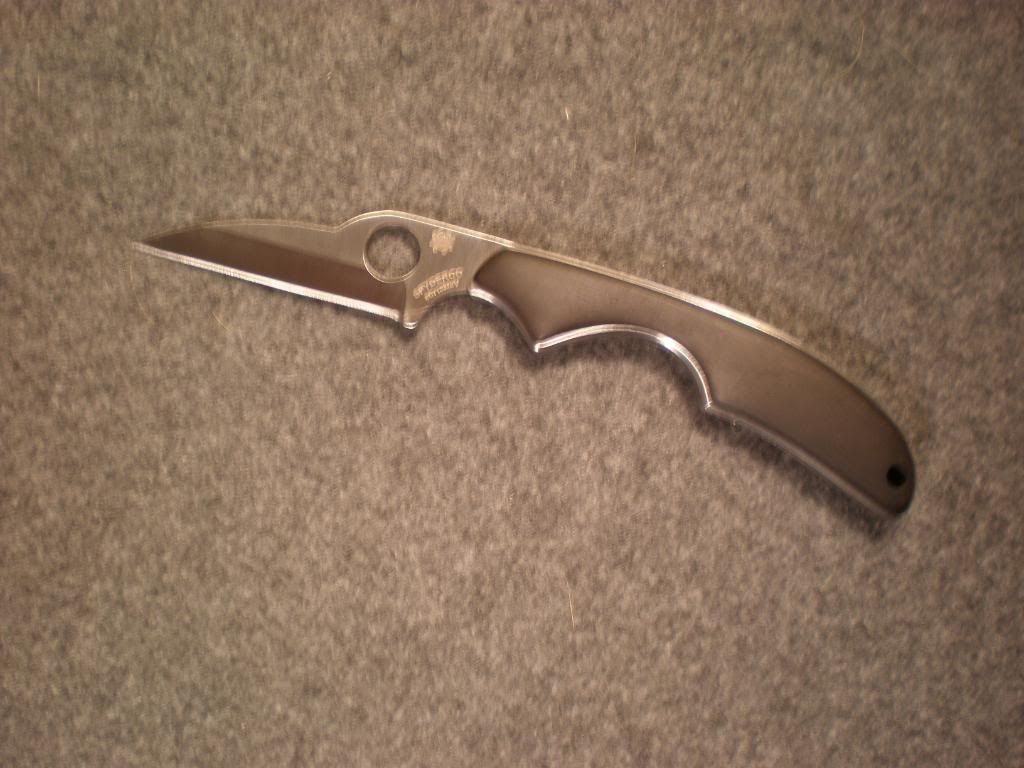

Apply each coat with a SPONGE, don't rub, blot. Let sit until dry. Then just clean off the junk with some 000 steel wool and hot water. Use the steel wool VERY lightly as you don't want to buff the finish, just get the junk off. Dry the steel, then repeat until you get the desired etch. Then let sit, not touching anything, overnight, then lightly buff with the steel wool. Here is a pic. The blade is actually 440C Stainless! So when people tell you you cant etch Stainless, here's the proof.

Gotta remember that this is a RUST (oxidation) finish, but when it's done, it actually makes the finish even MORE rust resistant (like bluing does for gun steel). But until it's finished... well let the steel wool sit a while and you will see what I mean.