Page 2 of 4

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Wed Oct 28, 2020 11:00 am

by Larrin

sal wrote: ↑Wed Oct 28, 2020 8:30 am

Thanx Larrin,

Very informative, as usual.

FYI, we have almost 5,000 lbs coming in different thicknesses.

sal

I hope it works out well!

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Wed Oct 28, 2020 11:05 am

by sal

Hi Larrin,

We'll see? The only real way to "know" a blade steel is to use it in "Real-World-Testing". While many don't care, there seems to be a growing number of Blade Afi's that do.

sal

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Wed Oct 28, 2020 11:23 am

by The Meat man

sal wrote: ↑Wed Oct 28, 2020 8:30 am

Thanx Larrin,

Very informative, as usual.

FYI, we have almost 5,000 lbs coming in different thicknesses.

sal

5,000 lbs of M398?? Wow that is a lot!! :eek:

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Wed Oct 28, 2020 2:16 pm

by Bill1170

5000 pounds! Spyderco must truly think this alloy has potential. I’m curious to see what they do with it.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Thu Oct 29, 2020 6:02 am

by legOFwhat?

Tucson Tom wrote: ↑Tue Oct 27, 2020 9:17 am

TomAiello wrote: ↑Mon Oct 26, 2020 7:35 pm

We definitely need an M398 Mule. :)

I was feeling relieved to see that this was a steel I could simply not get interested in. Until this comment came along .... :rolleyes:

Did somone say mule?

:D

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Thu Oct 29, 2020 7:19 am

by JRinFL

Well, based on Larrin's assessment, I won't be rushing out to get a knife in this steel. I'll withhold final judgment until actual knifes are made and tested, however.

Edited to add: Really "knifes"? I do know it is knives.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Fri Oct 30, 2020 1:03 am

by DDK

So if I read correctly, at 1 point higher on the HRC scale, s125v is barely outdone by m398 in toughness, while holding an edge for reasonably longer. I feel like at that higher end wouldn't more folks be interested in s125v? Also with lower carbide volume, it may be less tough, bit perhaps it will have better edge stability?

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Fri Oct 30, 2020 1:06 am

by DDK

At any rate, cpm-15v FTW

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Fri Oct 30, 2020 9:50 am

by JD Spydo

Bill1170 wrote: ↑Wed Oct 28, 2020 2:16 pm

5000 pounds! Spyderco must truly think this alloy has potential. I’m curious to see what they do with it.

I'm also very curious as to how it performs in full SE. I was pleasantly surprised when a good friend of mine showed me how good XHP was in full SE with two Cold Steel SE folders he got. I found it similar to 440V in SE and that steel has been one of my favorite SE steels for some time now.

It sounds to me like it might be a good steel for fixed blades in SE & PE both. But like Sal Said until you test in real world cutting jobs you never know until you do. But I've got a gut feeling that it would be another good SE blade steel.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Fri Oct 30, 2020 10:31 am

by Larrin

DDK wrote: ↑Fri Oct 30, 2020 1:03 am

So if I read correctly, at 1 point higher on the HRC scale, s125v is barely outdone by m398 in toughness, while holding an edge for reasonably longer. I feel like at that higher end wouldn't more folks be interested in s125v? Also with lower carbide volume, it may be less tough, bit perhaps it will have better edge stability?

S125V does not have more carbide volume than M398, it has a little bit less, hence why the S125V is a bit tougher when compensating for hardness (along with a bit smaller carbides). S125V is better for toughness-edge retention but worse for corrosion resistance. The M398 is probably also easier to sharpen when using aluminum oxide or ceramic abrasives. S90V has only slightly less edge retention than M398 while being significantly tougher.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Fri Oct 30, 2020 5:52 pm

by DDK

Larrin wrote: ↑Fri Oct 30, 2020 10:31 am

DDK wrote: ↑Fri Oct 30, 2020 1:03 am

So if I read correctly, at 1 point higher on the HRC scale, s125v is barely outdone by m398 in toughness, while holding an edge for reasonably longer. I feel like at that higher end wouldn't more folks be interested in s125v? Also with lower carbide volume, it may be less tough, bit perhaps it will have better edge stability?

S125V does not have more carbide volume than M398, it has a little bit less, hence why the S125V is a bit tougher when compensating for hardness (along with a bit smaller carbides). S125V is better for toughness-edge retention but worse for corrosion resistance. The M398 is probably also easier to sharpen when using aluminum oxide or ceramic abrasives. S90V has only slightly less edge retention than M398 while being significantly tougher.

Interesting! Thank you for the info. So a slight edge retention increase over s90v, and a large loss in toughness.. I'll still probably pass, but it's always good to have more new steel in the production market!

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Sun Aug 22, 2021 7:52 am

by XuZaX

so uh. Where are these m398 knives at. Would love a para 3.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 6:50 am

by Michael Janich

Dear XuZaX:

Welcome to the Spyderco forum.

Stay safe,

Mike

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 9:47 am

by JRinFL

Larrin wrote: ↑Fri Oct 30, 2020 10:31 am

DDK wrote: ↑Fri Oct 30, 2020 1:03 am

So if I read correctly, at 1 point higher on the HRC scale, s125v is barely outdone by m398 in toughness, while holding an edge for reasonably longer. I feel like at that higher end wouldn't more folks be interested in s125v? Also with lower carbide volume, it may be less tough, bit perhaps it will have better edge stability?

S125V does not have more carbide volume than M398, it has a little bit less, hence why the S125V is a bit tougher when compensating for hardness (along with a bit smaller carbides). S125V is better for toughness-edge retention but worse for corrosion resistance. The M398 is probably also easier to sharpen when using aluminum oxide or ceramic abrasives.

S90V has only slightly less edge retention than M398 while being significantly tougher.

Highlighted area is probably important to note.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 11:05 am

by Steeltoez83

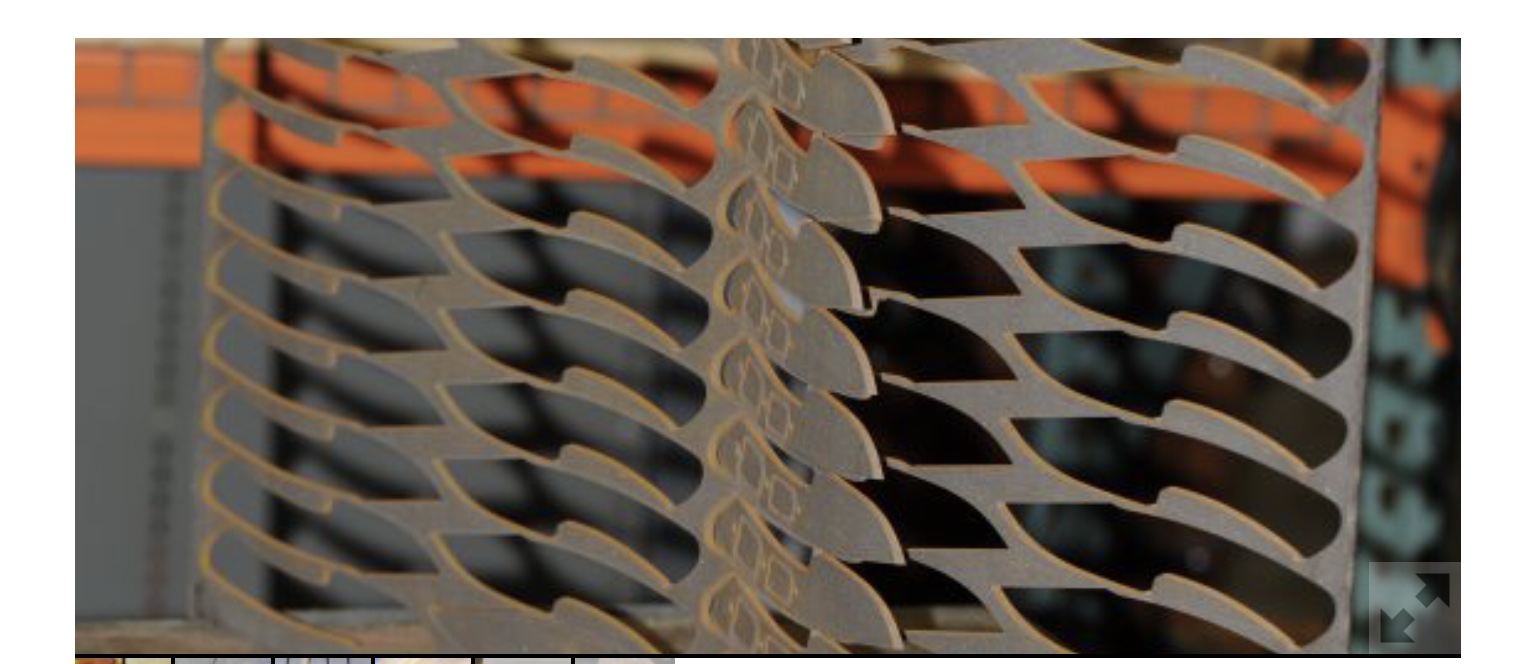

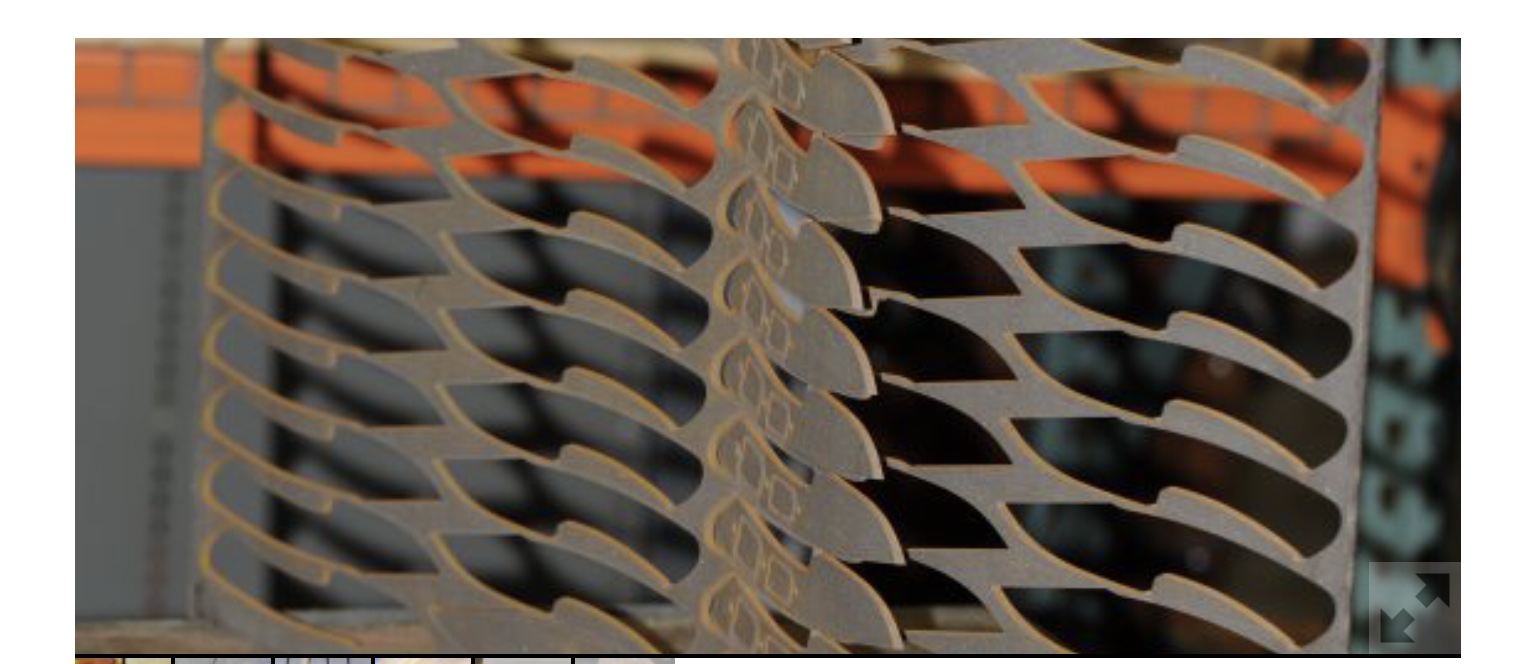

This is a custom trapper i bought from triple b in m398. I usually grab the other custom i own of his much more than this one truth be told. However this is a full handmade custom, so the heat treat, geometry, etc shouldnt be compared to production capabilities imo. I would like to do side by side comparisons to see how spyderco is heat treating this steel when the time comes. I will try to score a mule when possible if spyderco makes it. And i get the opportunity to purchase one before they sell out.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 11:10 am

by archangel

JRinFL wrote: ↑Mon Aug 23, 2021 9:47 am

Larrin wrote: ↑Fri Oct 30, 2020 10:31 am

DDK wrote: ↑Fri Oct 30, 2020 1:03 am

So if I read correctly, at 1 point higher on the HRC scale, s125v is barely outdone by m398 in toughness, while holding an edge for reasonably longer. I feel like at that higher end wouldn't more folks be interested in s125v? Also with lower carbide volume, it may be less tough, bit perhaps it will have better edge stability?

S125V does not have more carbide volume than M398, it has a little bit less, hence why the S125V is a bit tougher when compensating for hardness (along with a bit smaller carbides). S125V is better for toughness-edge retention but worse for corrosion resistance. The M398 is probably also easier to sharpen when using aluminum oxide or ceramic abrasives.

S90V has only slightly less edge retention than M398 while being significantly tougher.

Highlighted area is probably important to note.

Yeah, but still... give it to us, Sal.

Pretty please....

Great thread revival, XuZaX!

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 11:55 am

by kobold

I wonder what 5000 lbs yields in - lets say - PM2 blades. My rough guesstimate is about 15000 blades. Optimistic?

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Mon Aug 23, 2021 1:21 pm

by JRinFL

kobold wrote: ↑Mon Aug 23, 2021 11:55 am

I wonder what 5000 lbs yields in - lets say - PM2 blades. My rough guesstimate is about 15000 blades. Optimistic?

I'm fairly certain some is reserved for Sal's & Eric's matching Iron Man suits. The remainder will go to blades.

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Tue Aug 24, 2021 5:00 am

by Rp5

JRinFL wrote: ↑Mon Aug 23, 2021 1:21 pm

kobold wrote: ↑Mon Aug 23, 2021 11:55 am

I wonder what 5000 lbs yields in - lets say - PM2 blades. My rough guesstimate is about 15000 blades. Optimistic?

I'm fairly certain some is reserved for Sal's & Eric's matching Iron Man suits. The remainder will go to blades.

Should be Steel suits if anything...

Re: M398 Steel Testing – Edge Retention, Toughness, and More

Posted: Tue Aug 24, 2021 11:33 am

by standy99

I always wonder when I read these threads.

If laser cutting a sheet you loose 10% or more…..

And

If you just melted all the steel left over sheets from 10 different steels.

What would you get…

Larrin is this something that would be neat or would it even be possible to combine 10 different steels….