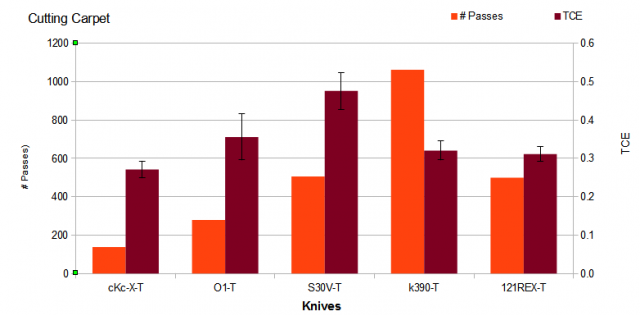

Knives :

-Kyley Harris fixed blade, cKc-X (steel not released)

-Ozark Tradition Knifeworks EDC, k390 / 64 HRC

-Spyderco Paramilitary, S30V

-Uddopukko/Enzo, O1

The method :

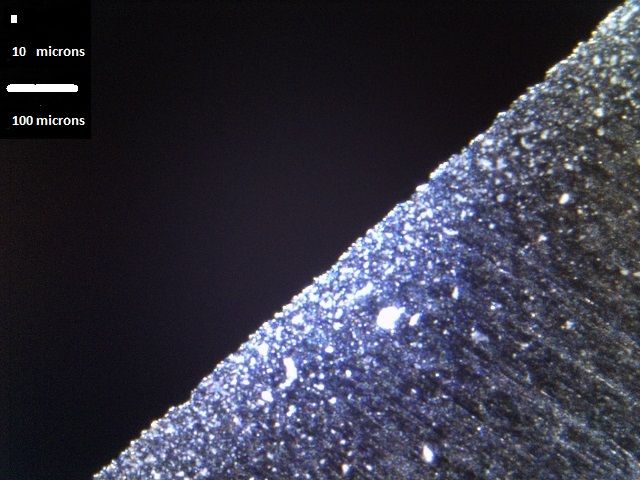

-all knives zero ground to a very light convex, edge bevel starts to increase curvature at ~0.010"/6.5 dps

-15 dps micro bevel, 600 DMT

-carpet cut with a 2" section of blade, cuts were 2" deep

-cuts were made through random selection on the same section of carpet

-blinding was used (the individual measuring the sharpness didn't know how many cuts were made)

-sharpness was measured in multiple different ways (35 g/Bergia, 500 g/heavy jute, 2" slice on 3/8" sisal, visual inspection, etc.)

-126 slices were made, four rounds of each to produce average / total values

-a Naniwa Superstone 400 was used to reset the edge, pressure on the stone was 0.4 to 0.8 psi

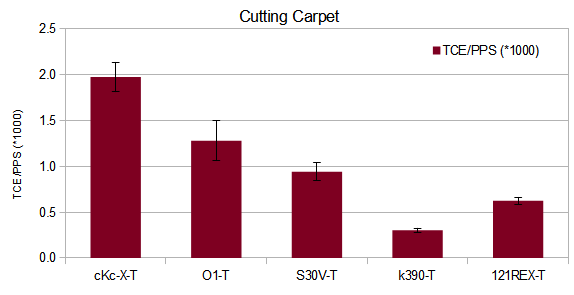

The results :

-final sharpness was ~1.5% of optimal

-cuts on 3/8" sisal at this point were ~10/11 lbs

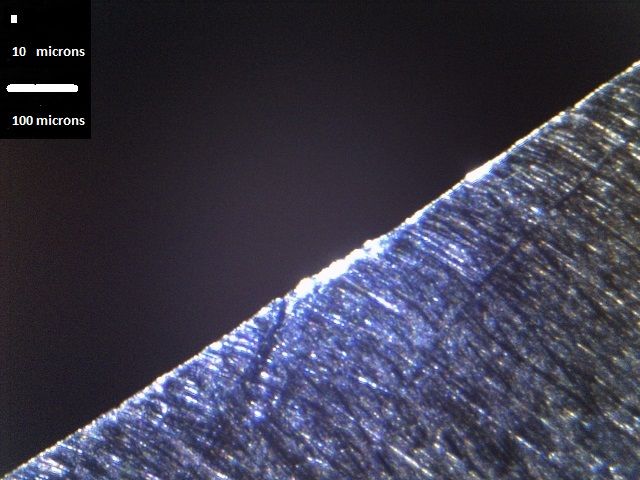

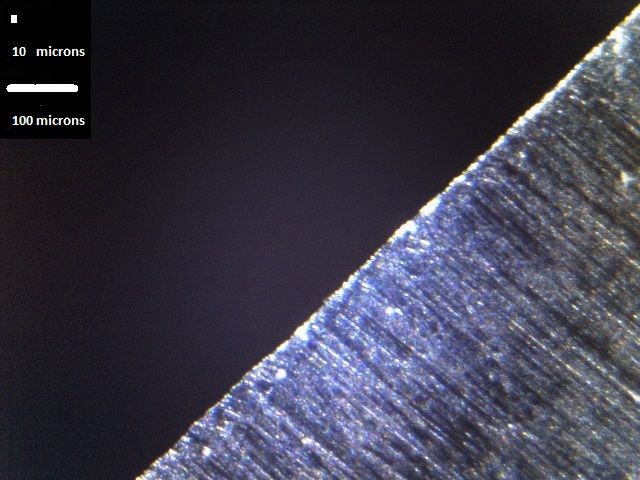

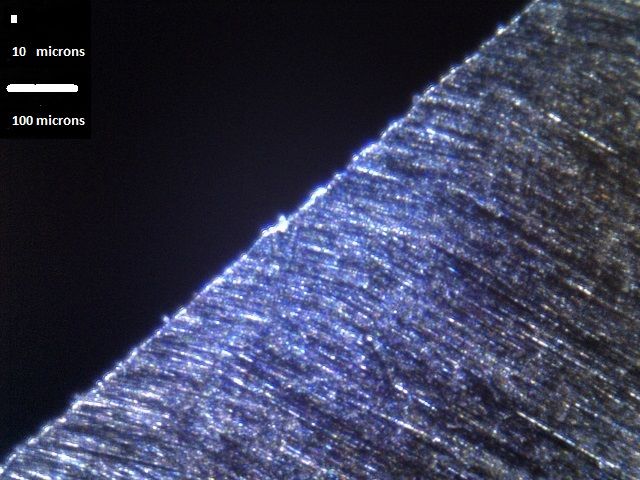

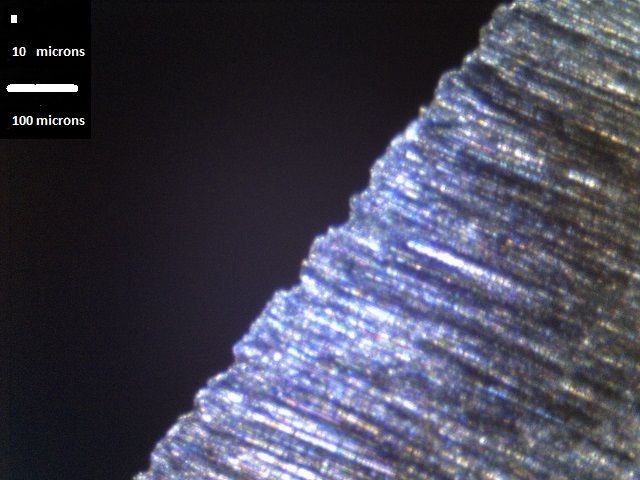

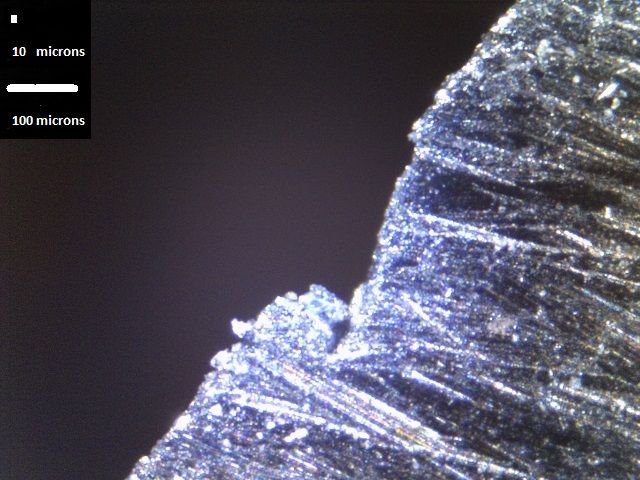

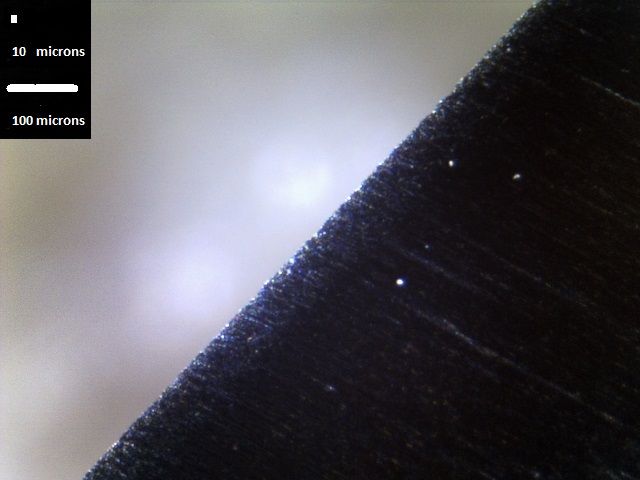

-all edges showed a reflection of light (the amount decreased in the order of the list below)

-the edge retention was much closer than the resharpening times (# passes)

In some detail :

- cKc-X : TCE :0.27 (2), PPS (total) : 550

- Uddo/O1 : TCE 0.36 (6), PPS (total) : 1115

- Paramilitary/S30V TCE (1.5%) : 0.48 (5), PPS (total) : 2025

- OTK/k390 : TCE 0.32 (2), PPS (total) : 4250

The PPS count is the number of passes needed on the waterstone, it is the total of four runs. The TCE is a measure of edge retention, it is calculated as :

sum = amount of material cut (in meters) * sharpness (as a percentage)

It basically is a weight average of the sharpness during the cutting, the higher the TCE the stronger the edge retention. In this case the final sharpness was very low, ~1.5% thus the TCE is for extreme cutting, this would be like cutting a km of cardboard and thousands of cuts of hemp/sisal.

Comments :

The results are fairly straightforward aside from the k390. It had an acid treatment to force a paina (from the maker), I think I am still seeing some effects of that. I have some more carpet left and I am considering :

-doing a few more runs to get more precise values

-do a super long runs with a couple of blades to extreme low sharpness (<0.5%)

-check a couple of more UHC steels

-try a different angle/edge finish (25 dps/mxf DMT)

The last three are more interesting as I think they will show different relative performance ratios.