[video=youtube;6Up6q6WiHXs]https://youtu.be/6Up6q6W ... ure=gp-n-y[/video]

Here's the box that gave up it's life for the cause (had a full size self propelled lawn mower in it...a grown man could curl up inside there...it's a big box).

The whole box and inside dividers are a very heavy weight double wall corrugated (C and A flute if I remember right..it's been a while

The aftermath (can you find the Manix?)

All together, I made 1990 cuts.

Some observations:

1. The sharpening choil. After about a dozen cuts, I immediately regretted the sharpening choil. I'm not sure why but that thing snagged on almost every cut. I've never had one snag as much as this one. I'm gonna have to sharpen the notch into a serration or something to correct this. After this I can't in good conscience recommend adding a notch on this knife. It could just be how I did it...who knows. As I've said before on this topic, I have several Spydercos that have them from the factory, and I've never had this issue so it may just be how I cut it...it is a little on the big side.

2. The FRN handle. Maybe it's just been a long time since I used a FRN handled knife this hard/long, but this thing was very rough on my hand. It isn't the knife itself, not the design or the ergonomics, it's all that texture and grip. Grip is a two way street...this knife is unlikely to slip out of your hand even if you're processing a deer and you're covered in blood and fat, but at the same time it's gonna leave an impression in your skin after a few hard spirited cuts. After a couple hundred cuts I put on a glove, which eliminated the hot spots except for my thumb when using saber grip, from pressing into the thumb ramp. If I had a need to use my knife this much on a regular basis (not sure who would), I would be very tempted to do a G10 blade swap, but I don't think this will be an issue for general purpose use.

(my hand was quite red in this pic but the camera didn't show it very well)

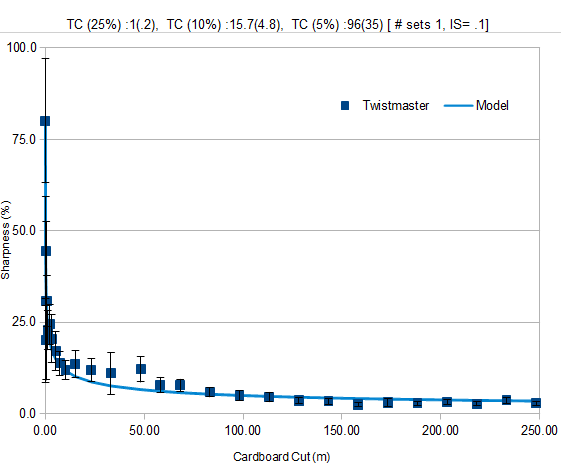

3. Edge retention. The edge is now what I would consider to be dull. It'll still slice cardboard, but when you look closely at the cut, it's pretty frayed and fuzzy looking. It'll probably go on cutting cardboard for a good number more cuts, but it won't slice printer paper at all. If you do it just right it'll sort of shred it's way through but not in a way that I would accept. The knife also wasn't freshly sharpened before this, so there isn't any real test data going on here, just me with some spare time and a big box that wouldn't fit in a trash can, and my own curiosity.

4. Lockup and pivot play. The lockup is still solid as a rock, and there isn't any side to side play at all. The blade does drop noticeably easier by gravity, so it definitely has broken in some.

5. Edge wear/damage. Nothing new here that Ankerson and others haven't told you, this one is mainly for Cliff Stamp! Yes Cliff, the edge did chip in this test, I think. Not much if at all, not enough that I can see it with my naked eye, but the edge feels "gritty" when running your fingernail down it. Micro chips? Call it what you will. I don't have a way to take good magnified macro shots (how do you guys do that anyway?) but looking at the edge under my 20x and 60x loupes, the edge looks more worn than chipped. There aren't any big nicks taken out of the edge that I can see even with the 60x loupe. The damage/wear is very uniform looking throughout the entire edge and the edge reflects like pretty evenly (meaning there aren't any single spots that are shinier/brighter than the rest of the edge, which would indicate a chip). You can tell me what you think this is, chips or whatever, maybe just typical wear from this kind of use? I can't see reflections from looking at the edge from the side when under light like I normally do when (what I would consider) a chip is present. At any rate, it still isn't anything even close to what I've experienced with other steels, including S30V and 20CP.

In the end, almost 2000 cuts through heavy double wall corrugated (now that I think of it, I probably made more than the extra 10 cuts when I broke the box down into smaller pieces to cut up, so it's really over 2k), and the knife was still making cuts. I was half tempted to look for other boxes to cut up, but honestly I just got plain old sick of cutting cardboard. Didn't break the blade off (lol), didn't get any blisters (though I may have if I hadn't put a glove on). I would still prefer this knife with solid G10 scales with the same minimalistic "8 shaped" liners that the FRN version has, but otherwise I couldn't be happier. Can you say "$100 cardboard conquerer"?