Cliff Stamp wrote:Basically Yes and Yes.

In a bit more detail.

Back in the late nineties Alvin Johnson (custom knife maker - student of metallurgy) in comparisons of 1095 vs ATS-34 (Bos) noted that 1095 held an edge much longer. This wasn't just him talking about work he did (though it included that) people who used his knives reported it, often doing very detailed work (Mike Swaim) but also just being used by guys who didn't know anything about the steels and just did use the ones that didn't work as well (butchers, cowboys).

However even when harder, 1095 does not have the wear resistance of ATS-34 which is a very high wear stainless. Alvin argued from the ASTM standpoint that steels which were designed to have fine cutting edges were designed in a very particular way and it wasn't simply wear resistance it was the ability of the steel to keep a fine cutting edge due to the microstructure.

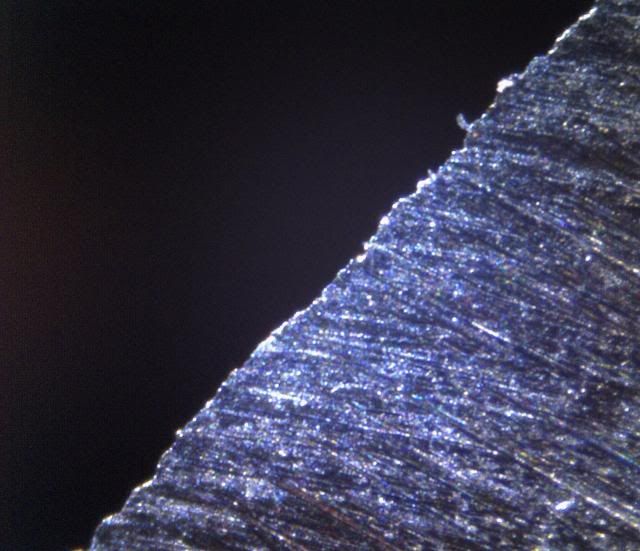

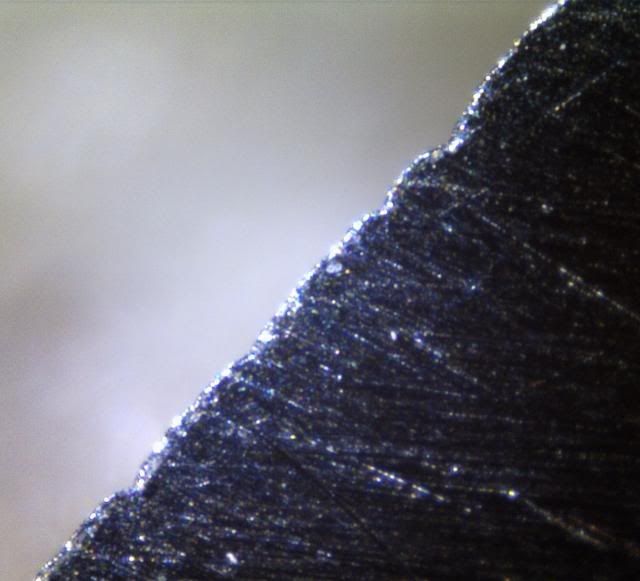

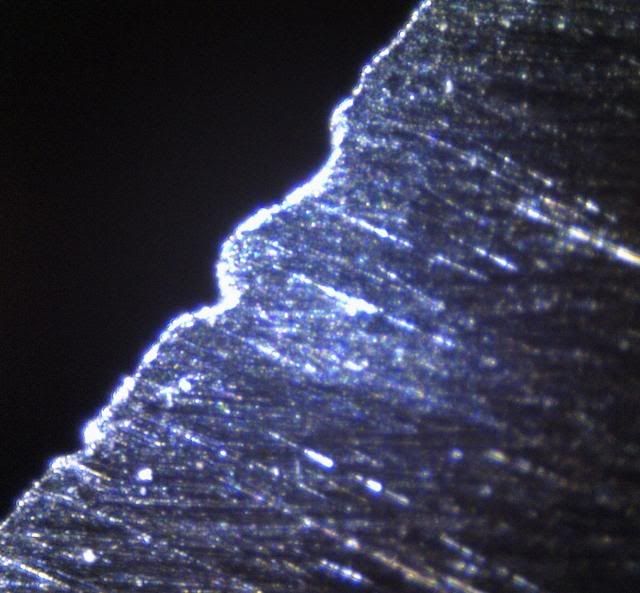

Skip ahead a decade or so and Roman Landes did a PhD thesis on the very subject and measured the ability of steels to stay stable (keep their shape) under micro-loads on the edge. He found that carbide volume directly reduced this stability and thus Roman will prefer to use steels like AEB-L, S1, and similar. He also has extreme geometries on his knives, how extreme, well this is a chopping knife :

"0.2-0,25mm and an angle of 20-25°total and it still breaks bones wo chips"

That is an edge of < 0.010"/12.5 dps on a chopping blade which cuts bones.

Now put that in comparison to the common thickness/angles being discussed usually here, and arguments that even things like cutting cardboard is abusive as it chips/damages edges.

In short, if you are looking to optimize cutting ability, durability, sharpness and edge retention at high sharpness you will end up with steels in the < 5% carbide volume (with ideal microstructure).

Now to be clear not everyone wants this and some people want (or are willing to tolerate) reduced cutting ability, durability, sharpness, ease of sharpening for edge retention at low sharpness in slicing cuts.

Like most things in steels and cutlery it is a balance of what you want and that is why there are always multiple steels. Even the people who make steels like AEB-L will make others. For example Sandvik makes :

-12C27M

Doesn't have the edge stability of 13C26 (AEB-L) but is much more corrosion resistant to the point it is dishwasher safe.

-19C27

Much more coarse carbide structure, designed to hold a low sharpness in slicing abrasive media

Except for the fact that we aren't talking about steels like AEB-L, 1095, ATS-34, S1, 12C27M etc here......

We are talking about K390 and CPM S110V and comparable steels that include K294 (A11) and CPM S90V, the steel that those two will be compared against at least by me in production knives keeping things apples to apples and fair (South Fork and CF Military, the 2 highest performing production knives I have seen so far based on my testing)

The A11 class of steels have an extremely high compression strength at high hardness and that allows them to be used in knives that are ground very thin with low edge angles and they will have excellent edge stability and do retain high levels of sharpness for good amount of time. They are very fine grained AND very wear resistant, the only drawback is they aren't stain resistant.

CPM S110V has some of the same traits as the A11 class of steels at high hardness.... Fine grained, high compression strength, holds a fine edge.... While being stainless to boot...

Now all of that will depend on the actual knives and how the steels are heat treated, tempered, final hardness range and or if they are CYRO treated or not just like any other steel.

It's not really good to make conclusions on steels based on performance of the steels that aren't at optimal HRC range for what the knives are designed for.

CPM S110V and K390 are a whole different world than most of the other steels that people are used to when prepared to provide optimal performance.

Now back to reality in that we are on the Spyderco forum and CPM S110V and K390 are being used in production knives so we will have to wait and see how they do in those knives before we make any real conclusions of how they perform.

We have to be objective here and fair to Spyderco by not jumping to conclusions before the knives have been tested because there are too many things that we don't know yet to draw any kind of conclusion or even guess.

Anyone can read a data sheet if they can read, but that doesn't really mean much when it comes to the actual knives, only in testing will the truth be found.