MT17P - Mule Team Fixed Blade featuring K390

P.S. Now that I'm getting closer and closer to ordering one of these before they're gone, can anybody tell me why the spyderco website lists Mule Team projects 1-13, then 15-17, but no Mule Team 14? In this forum, somebody said that in spyder bites it was indicated that #14 would be in CTS-204P (which somebody else said was like M390). But, I don't see any mule #14, or any Mule in CTS-204P. Thanks

IIRC...somewhere on this thread I believe someone posted that the Mule 14 was cancelled because they had some issue with it so it was never released. :) I am sure someone will correct me if I miss quoted! :DDunninLA wrote:P.S. Now that I'm getting closer and closer to ordering one of these before they're gone, can anybody tell me why the spyderco website lists Mule Team projects 1-13, then 15-17, but no Mule Team 14? In this forum, somebody said that in spyder bites it was indicated that #14 would be in CTS-204P (which somebody else said was like M390). But, I don't see any mule #14, or any Mule in CTS-204P. Thanks

I agree Ken. I use my Super Blue Caly in the kitchen all the time. And I have an 01 Kitchen knife. Having a patina on a knife doesn't hurt it's ability in the kitchen.kbuzbee wrote:ALL of my kitchen knives are non stainless /carbon steel. Old Fosters Bros, new Roselli, Opinel.... They work just fine.

Ken

I personally think some of the staining you see in the "show your patina" thread ( including my ownDunninLA wrote:I think the difference is that non-stainless high carbon steel develops a patina, and therefore a "uniform" staining that doesn't detract from its look. However, some of these exotics I've read, when they stain, they also pit, and it doesn't look good and also detracts from its function.

To each their own.

Not all those who wander are lost - J.R.R.T.

I don't believe it has been cancelled... just delayed. It has happened before. (I can't remember which ones specifically, but this certainly isn't the first time they didn't get released in numerical order...)sir_mike wrote:IIRC...somewhere on this thread I believe someone posted that the Mule 14 was cancelled because they had some issue with it so it was never released. :) I am sure someone will correct me if I miss quoted! :D

That is also my recollection of where that got left.mattman wrote:I don't believe it has been cancelled... just delayed. It has happened before. (I can't remember which ones specifically, but this certainly isn't the first time they didn't get released in numerical order...)

Not at all, most of the Mules have been in steels that Spyderco has already used. The goal is to provide a platform that takes all the other variables out of the equation and allows a relatively pure comparison of steels.DunninLA wrote:^ I don't know if it would make senseanymore to use CTS 204P in a Mule Team project since Spyderco already released the Southard in CTS-204p. Isn't the Mule Team project suppose to precede a release of a production knife using the same steel?

DunninLA wrote:^ I don't know if it would make senseanymore to use CTS 204P in a Mule Team project since Spyderco already released the Southard in CTS-204p. Isn't the Mule Team project suppose to precede a release of a production knife using the same steel?

not necessarily. for testing purposes, the edge geometry/thinness/length have much more to importance when comparing performance, so, by producing a Mule, the testing if the alloy can continue.

edited to add quote, as others posted in the meantime... :)

^ OK, thanks. I had misunderstood the purpose of the Mule Team releases.

Back to K390 -- I found this old thread in the Spyderco section of Bladeforums. Salimoneous was correct in his memory that he had read somewhere (see below) that K390 is similar in corrosive resistance to M4. http://www.bladeforums.com/forums/showt ... tary/page3 see post #57

-------------------------------

10-07-2011, 12:14 PM #57 OTK KnifeMaker / Craftsman / Service Provider

Just saw this thread after a buddy alerted me of it.

I've made a few out of K390 and minus corrosion resistance it is probably the highest performing blade steel out there. It is super wear resistant ...way more than s90 but the big difference is toughness. It is much tougher than 10v or the high vanadium stainless. Corrosion is about like M4.

Also at bladeforums.com, Phil Wilson reported on K390, indicating that after he dressed a couple of mule dear, and left the blade uncleaned, it developed a patina, but no rusting or pitting. He then cautions against using K390 in wet climates, or salt water. http://www.bladeforums.com/forums/showt ... st10060601

-----------------

10-03-2011, #22 Phil Wilson

I can give some feedback on K390 based on one finished knife that I now have in my kit. I took it on a recent Mule deer hunt in Utah and it saw most of the duty from field dressing to cutting and trimming to vac pack in the freezer on two Mule deer. ... I was concerned about corrosion resistance. So far the blade has a slight patina and no rust or pits. I left it “as is” after field dressing the last deer on the trip home just to see what would happen. ----------

So, bottom line, I can live with patina, but not rusting or pitting, so I'm now leaning toward purchasing the K390 mule, assuming any are left tomorrow, and using it a few times in the kitchen.

Back to K390 -- I found this old thread in the Spyderco section of Bladeforums. Salimoneous was correct in his memory that he had read somewhere (see below) that K390 is similar in corrosive resistance to M4. http://www.bladeforums.com/forums/showt ... tary/page3 see post #57

-------------------------------

10-07-2011, 12:14 PM #57 OTK KnifeMaker / Craftsman / Service Provider

Just saw this thread after a buddy alerted me of it.

I've made a few out of K390 and minus corrosion resistance it is probably the highest performing blade steel out there. It is super wear resistant ...way more than s90 but the big difference is toughness. It is much tougher than 10v or the high vanadium stainless. Corrosion is about like M4.

Also at bladeforums.com, Phil Wilson reported on K390, indicating that after he dressed a couple of mule dear, and left the blade uncleaned, it developed a patina, but no rusting or pitting. He then cautions against using K390 in wet climates, or salt water. http://www.bladeforums.com/forums/showt ... st10060601

-----------------

10-03-2011, #22 Phil Wilson

I can give some feedback on K390 based on one finished knife that I now have in my kit. I took it on a recent Mule deer hunt in Utah and it saw most of the duty from field dressing to cutting and trimming to vac pack in the freezer on two Mule deer. ... I was concerned about corrosion resistance. So far the blade has a slight patina and no rust or pits. I left it “as is” after field dressing the last deer on the trip home just to see what would happen. ----------

So, bottom line, I can live with patina, but not rusting or pitting, so I'm now leaning toward purchasing the K390 mule, assuming any are left tomorrow, and using it a few times in the kitchen.

I wa curious, so I checked over at Spydiewiki, and MT08 and MT09 were skipped, then went back to after the release of MT10.mattman wrote:I don't believe it has been cancelled... just delayed. It has happened before. (I can't remember which ones specifically, but this certainly isn't the first time they didn't get released in numerical order...)

http://www.spydiewiki.com/index.php?title=MT_Mule_Team

Hey All and Especially Sal,

Been lurking here almost 6 months, reading the info etc. Then, secretly, I got my first Spyderco (didn't want my Cold Steels etc to know), then another .... and another. Well it's time to come out of the closet: I bought 2 Mules and I'm glad!!! My Recon 1 will probably never open right for me again but at 6.8 ozs it probably will never see my pocket again either. All 3 of my Spydys together don't add up to 6.8 ozs.

Just wanted to share the joy and say thanks to all, especially Sal, for all the help these last few months. Now I have to go back to thinking about my Mules. Later Guys

Been lurking here almost 6 months, reading the info etc. Then, secretly, I got my first Spyderco (didn't want my Cold Steels etc to know), then another .... and another. Well it's time to come out of the closet: I bought 2 Mules and I'm glad!!! My Recon 1 will probably never open right for me again but at 6.8 ozs it probably will never see my pocket again either. All 3 of my Spydys together don't add up to 6.8 ozs.

Just wanted to share the joy and say thanks to all, especially Sal, for all the help these last few months. Now I have to go back to thinking about my Mules. Later Guys

your making me curious now, I think you need to share a picture of ur collection :DYotee wrote:Hey All and Especially Sal,

Been lurking here almost 6 months, reading the info etc. Then, secretly, I got my first Spyderco (didn't want my Cold Steels etc to know), then another .... and another. Well it's time to come out of the closet: I bought 2 Mules and I'm glad!!! My Recon 1 will probably never open right for me again but at 6.8 ozs it probably will never see my pocket again either. All 3 of my Spydys together don't add up to 6.8 ozs.

Just wanted to share the joy and say thanks to all, especially Sal, for all the help these last few months. Now I have to go back to thinking about my Mules. Later Guys

-Spencer

Rotation:

Gayle Bradley 2 | Mantra 1 | Watu | Chaparral 1 | Dragonfly 2 Salt SE

Rotation:

Gayle Bradley 2 | Mantra 1 | Watu | Chaparral 1 | Dragonfly 2 Salt SE

- xceptnl

- Member

- Posts: 9000

- Joined: Mon Feb 21, 2011 6:48 pm

- Location: Tobacco Country, Virginia

- Contact:

Welcome to the forum and I agree with Holland, we need to see this collection.Yotee wrote:Hey All and Especially Sal,

Been lurking here almost 6 months, reading the info etc. Then, secretly, I got my first Spyderco (didn't want my Cold Steels etc to know), then another .... and another. Well it's time to come out of the closet: I bought 2 Mules and I'm glad!!! My Recon 1 will probably never open right for me again but at 6.8 ozs it probably will never see my pocket again either. All 3 of my Spydys together don't add up to 6.8 ozs.

Just wanted to share the joy and say thanks to all, especially Sal, for all the help these last few months. Now I have to go back to thinking about my Mules. Later Guys

*Landon*sal wrote: .... even today, we design a knife from the edge out!

Here's a copy and paste of a test I did between 10V and K390. In no way is it super accurate but it gives you an idea of what they can do

I gathered up 10 boxes and cut each in half to make sure each knife cut the same boxes. I also added whittling of some aspen I had laying around to test toughness and observe for any edge chipping.

Each knife was sharpened to 9micron using diamond PSA on my EP at 25deg inclusive. Both push cut phone book paper with ease before starting the test.

Just to be clear, this is a steel comparison. I'm not comparing makers :)

Both are nearly identical in respects to alloy makeup and design but there are some subtle differences…

K390 at 63rc FFG (Loveless style blade by David Williamson (OTK)

Carbon: 2.45%

Chromium: 4.15%

Cobalt: 2.00%

Molybdenum: 3.75%

Tungsten: 1.00%

Vanadium: 9.00%

Knife Specs:

Blade length: 3.5in

Spine thickness: .114in

Width: 1.2in

Behind the edge: .014

10V at 64rc FFG (EDC by Big Chris)

Carbon: 2.45%

Molybdenum: 1.3%

Chromium: 5.25%

Vanadium: 9.75%

Knife Specs:

Blade length: 3.55in

Spine thickness: .130in

Width: 1.1in

Behind the edge: .014

And now on to the pics…

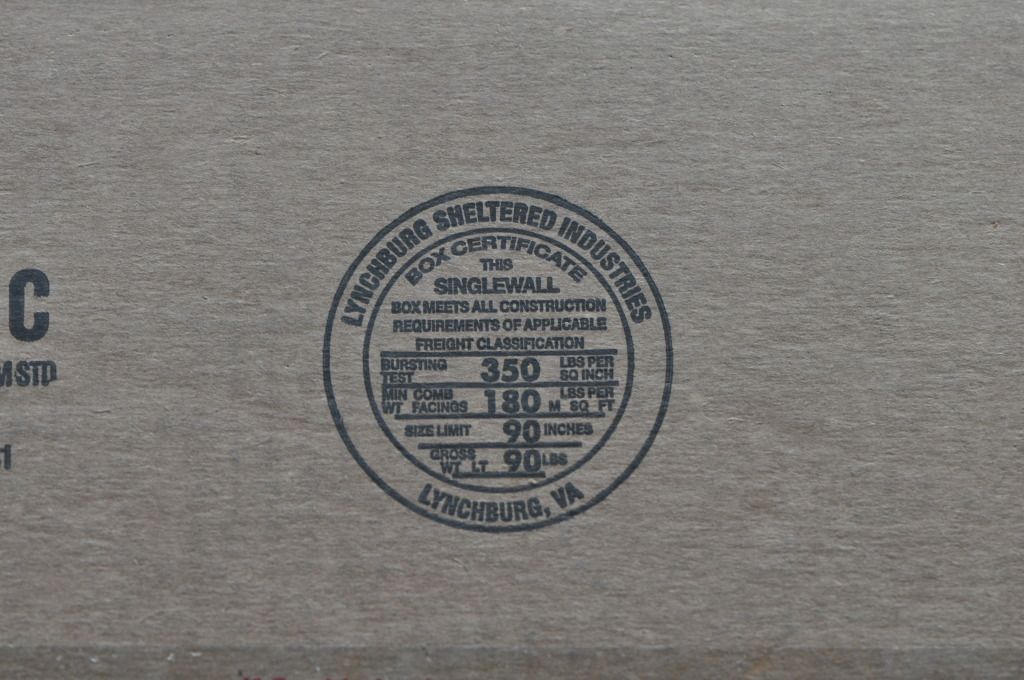

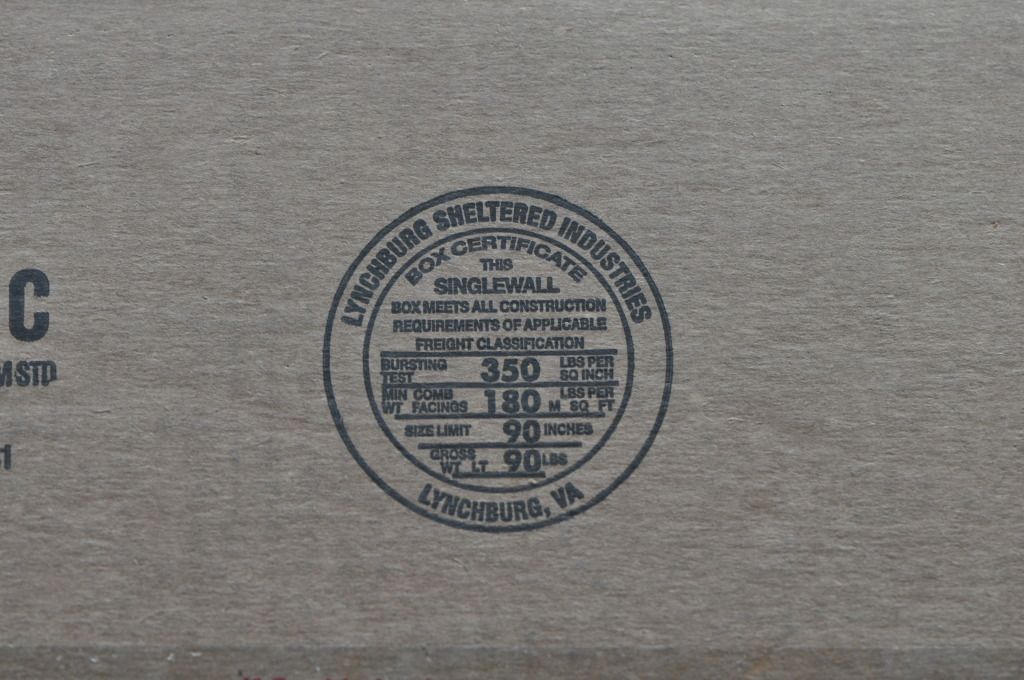

Some of the cardboard I used. This stuff is TOUGH!

And the aftermath…

I gathered up 10 boxes and cut each in half to make sure each knife cut the same boxes. I also added whittling of some aspen I had laying around to test toughness and observe for any edge chipping.

Each knife was sharpened to 9micron using diamond PSA on my EP at 25deg inclusive. Both push cut phone book paper with ease before starting the test.

Just to be clear, this is a steel comparison. I'm not comparing makers :)

Both are nearly identical in respects to alloy makeup and design but there are some subtle differences…

K390 at 63rc FFG (Loveless style blade by David Williamson (OTK)

Carbon: 2.45%

Chromium: 4.15%

Cobalt: 2.00%

Molybdenum: 3.75%

Tungsten: 1.00%

Vanadium: 9.00%

Knife Specs:

Blade length: 3.5in

Spine thickness: .114in

Width: 1.2in

Behind the edge: .014

10V at 64rc FFG (EDC by Big Chris)

Carbon: 2.45%

Molybdenum: 1.3%

Chromium: 5.25%

Vanadium: 9.75%

Knife Specs:

Blade length: 3.55in

Spine thickness: .130in

Width: 1.1in

Behind the edge: .014

And now on to the pics…

Some of the cardboard I used. This stuff is TOUGH!

And the aftermath…

10V edge

K390 edge

Both performed exceptionally well which I expected

If I learned anything from this test is that if anyone uses these steels to a point where the really need a good sharpening I salute you.

In case you guys missed this http://www.spyderco.com/forums/showthre ... post871435

sal wrote:The one I tested on the handle was 62/64.

sal

~David

I was up at SFO yesterday picking up the new Mule and they mentioned that the CTS 204P had some production issues and are now just laying in wait. Hopefully they will still be released at some point, I love that steel in the Southard package.mattman wrote:I don't believe it has been cancelled... just delayed. It has happened before. (I can't remember which ones specifically, but this certainly isn't the first time they didn't get released in numerical order...)

Lobo.joe

:spyder: Manix 2, native, native 5, dragonfly g10, sage 2, sage 4, delica, endura, caly 3 Damascus, caly 3.5, nearly all para 2, CF military, techno, superleaf, tenacious

:spyder: Manix 2, native, native 5, dragonfly g10, sage 2, sage 4, delica, endura, caly 3 Damascus, caly 3.5, nearly all para 2, CF military, techno, superleaf, tenacious