Started to work on homemade kydex Enuff sheath

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

Started to work on homemade kydex Enuff sheath

Well, dissatisfied as I am with the stock sheath for the Enuff (I love the knife, though), I finally mustered the fortitude to start an attempt at making a homemade kydex sheath for it (late Sunday night 6/9/13).

I've managed to upload it to Photobucket, but honestly the Photobucket iPhone app is a total piece of useless junk, and the website simply doesn't work right with iOS, so managing to get the photo posted here is not an easy thing to do and I haven't been able to make it work. I'll probably have to wait until I can take my laptop computer somewhere to use wifi (lacking it at home).

Anyway, the project got sort of complicated, but I'll explain that later, and it'll make more sense when there are photos to accompany the explanation anyway.

Keep watching this space.

I've managed to upload it to Photobucket, but honestly the Photobucket iPhone app is a total piece of useless junk, and the website simply doesn't work right with iOS, so managing to get the photo posted here is not an easy thing to do and I haven't been able to make it work. I'll probably have to wait until I can take my laptop computer somewhere to use wifi (lacking it at home).

Anyway, the project got sort of complicated, but I'll explain that later, and it'll make more sense when there are photos to accompany the explanation anyway.

Keep watching this space.

"Within this frame an ocean swells -- behind the smile -- I know it well..."

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

I should mention that I'm not finished yet. I have shaping and smoothing to do, and then I have to see about adding the belt clip from the Enuff's sheath or maybe the Teklok off my Moran Featherweight.

(As an aside, I think that there has never been a stock kydex sheath as smooth and refined and snug/secure as the one that came with the Moran Featherweight. That thing is a work of art, and really makes me "SMH" at the dismal cop-out that is the Enuff stock sheath.)

(As an aside, I think that there has never been a stock kydex sheath as smooth and refined and snug/secure as the one that came with the Moran Featherweight. That thing is a work of art, and really makes me "SMH" at the dismal cop-out that is the Enuff stock sheath.)

"Within this frame an ocean swells -- behind the smile -- I know it well..."

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

I bought a replacement sheath for my Perrin Street Bowie from Mike Sastre at RiverCity Sheaths. Nice sheath. I don't have an Enuff but it sounds like you have similar problems to my Bowie. Dulled the knife making it unusable. Spyderco said it was user error????peacefuljeffrey wrote:Anyone else made or bought a replacement sheath for an Enuff?

Jeffrey, once you load the picture to photobucket, select the picture and click on the i/info button on the bottom right. Then copy/paste the img code here. Did it with my PM2 pics this morning on the regrind thread.

Click here to zoom: Under the Microscope

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

- Mike Sastre

- Member

- Posts: 419

- Joined: Fri Sep 24, 2004 10:33 am

- Location: Hamilton, Ohio USA

- Contact:

I've been meaning to make some sheaths for the Enuff series, but have been a little too busy lately. I'll see if I can squeeze some time in to do so.

Mike

http://www.RiverCitySheaths.com

"Kitchen Kydex" DVD sets available. http://rivercitysheaths.com/dvd.html

http://www.RiverCitySheaths.com

"Kitchen Kydex" DVD sets available. http://rivercitysheaths.com/dvd.html

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

Finally got the sheath done!

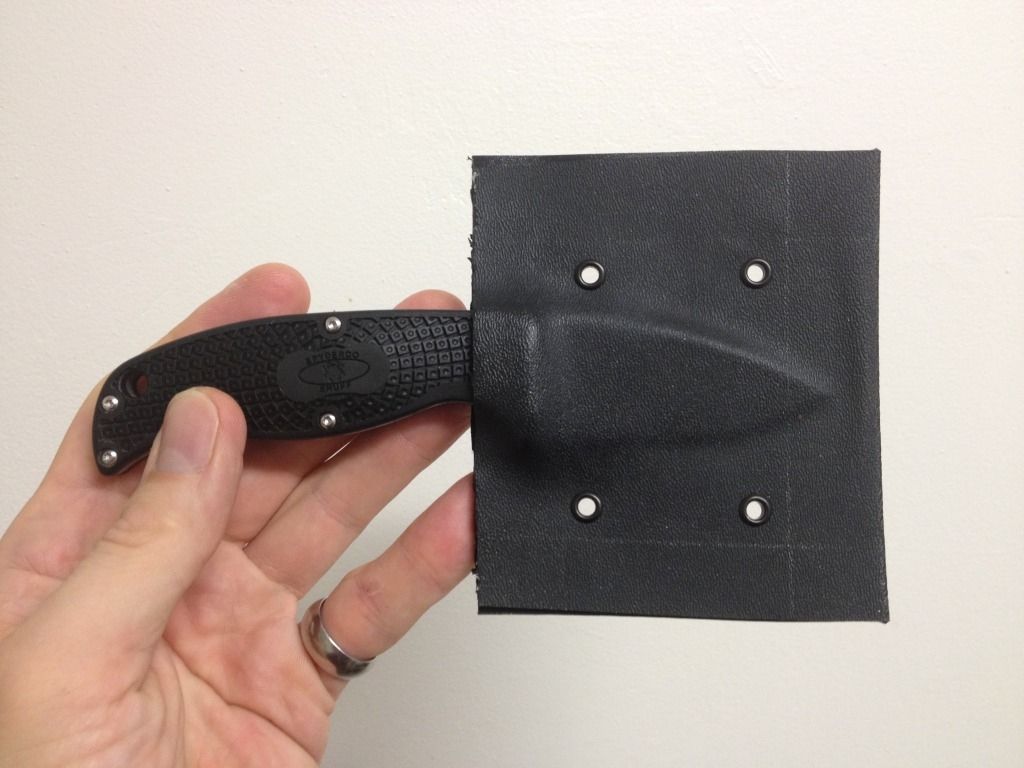

On Monday afternoon I finished molding and then sanding my homemade kydex sheath for my Enuff. On Sunday night I had done the basic cutting of the kydex and some of the heating and shaping, and then I did the riveting.

Here's the thing (and you can see in the photos): the finished sheath has four rivets. When I first started the sheath, I had six rivets. But I found (and this isn't the first time it's happened) that the two rivets closest to the opening were too close to the opening, and that prevents there being enough length of kydex to flex open and admit the knife.

I was pretty dismayed. I had already invested a good bit of time by that point. So I attempted to salvage the project, and I ended up succeeding. I cut off the top part of the sheath with the top two rivets and -- for the first time ever, tried to see what would happen if I heat-formed the sheath with the rivets already in place. I used to think that it wouldn't work. Now I know better.

I heated the four-riveted sheath with my heat-gun and slid the knife into it, and using a combination of foam pads and suede-gloved fingertips, formed it to the knife. Here's what it looked like at that point.

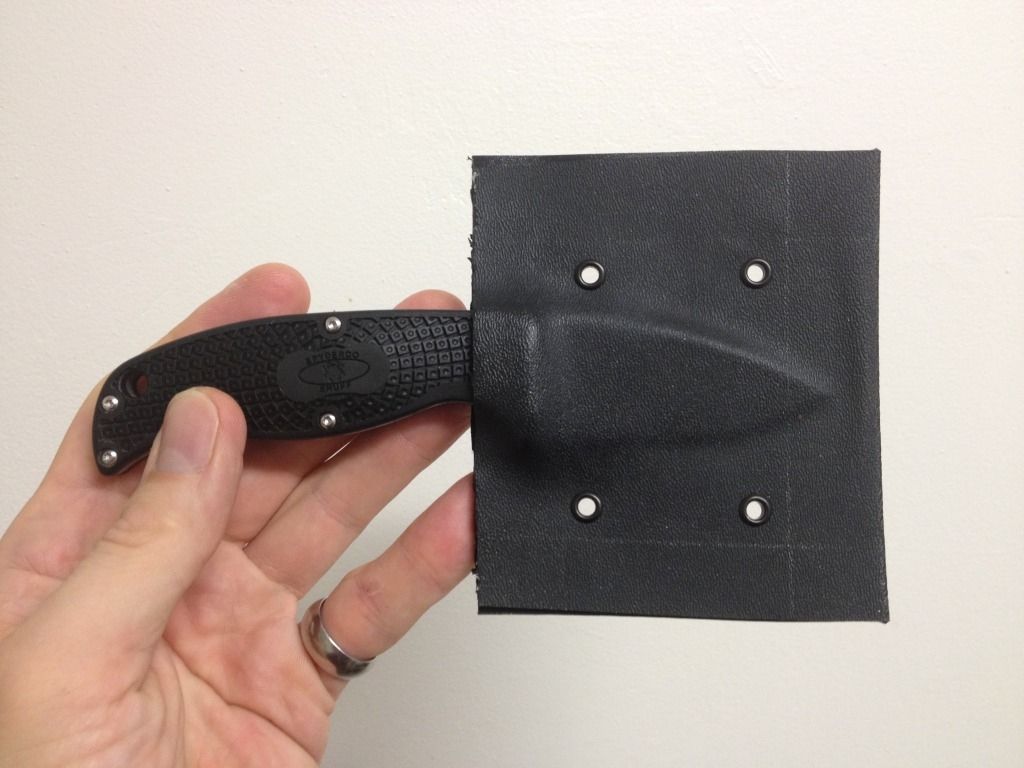

On Monday, I proceeded with cutting away excess, sanding edges, and then adjusting the fit and tightness. I am a fiend for tight-retention kydex. Rattling is not acceptable. Easy withdrawal is not acceptable.

So it took a good few hours (since I'm not an expert, and I am working with a very under-equipped kit and workspace) to get the fit correct. At that point, I did a little more sanding, and then took the Tek-Lok clip from my Moran Featherweight and drilled a couple of holes and attached that.

Here is the result. It is a very serviceable sheath, holds the knife nice and tightly, is a little bit of a challenge to re-sheathe, but that's ok with me. It rides comfortably on my hip. The little curved dips beside the knife on the left and right have purpose. The one on the blade side is there to help the tang of the blade make it inside (it's really a carve-out to open up the aperture). The one on the spine side is there for thumb pressure to help unsheathe the knife.

The flat of the blade has taken on some scratches from the sheath. I can live with that.

I am planning on getting this professional-grade foam kydex press as soon as I can, because it will make this kind of project about 500% easier and quicker. Click for link to Kydex press

Here's the thing (and you can see in the photos): the finished sheath has four rivets. When I first started the sheath, I had six rivets. But I found (and this isn't the first time it's happened) that the two rivets closest to the opening were too close to the opening, and that prevents there being enough length of kydex to flex open and admit the knife.

I was pretty dismayed. I had already invested a good bit of time by that point. So I attempted to salvage the project, and I ended up succeeding. I cut off the top part of the sheath with the top two rivets and -- for the first time ever, tried to see what would happen if I heat-formed the sheath with the rivets already in place. I used to think that it wouldn't work. Now I know better.

I heated the four-riveted sheath with my heat-gun and slid the knife into it, and using a combination of foam pads and suede-gloved fingertips, formed it to the knife. Here's what it looked like at that point.

On Monday, I proceeded with cutting away excess, sanding edges, and then adjusting the fit and tightness. I am a fiend for tight-retention kydex. Rattling is not acceptable. Easy withdrawal is not acceptable.

So it took a good few hours (since I'm not an expert, and I am working with a very under-equipped kit and workspace) to get the fit correct. At that point, I did a little more sanding, and then took the Tek-Lok clip from my Moran Featherweight and drilled a couple of holes and attached that.

Here is the result. It is a very serviceable sheath, holds the knife nice and tightly, is a little bit of a challenge to re-sheathe, but that's ok with me. It rides comfortably on my hip. The little curved dips beside the knife on the left and right have purpose. The one on the blade side is there to help the tang of the blade make it inside (it's really a carve-out to open up the aperture). The one on the spine side is there for thumb pressure to help unsheathe the knife.

The flat of the blade has taken on some scratches from the sheath. I can live with that.

I am planning on getting this professional-grade foam kydex press as soon as I can, because it will make this kind of project about 500% easier and quicker. Click for link to Kydex press

"Within this frame an ocean swells -- behind the smile -- I know it well..."

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

I'm looking forward to getting the press (when I have the spare cash) and another Tek-Lok and do a sheath for my Benchmade Nimravus Cub, because its stock sheath works ok but it's the type that has the annoying thumb snap on a web strap. It'll be sweet wrapped in kydex. ...

I also have a Swick and I've never really liked its neck sheath, so I'll eventually do a new one for that, too.

I also have a Swick and I've never really liked its neck sheath, so I'll eventually do a new one for that, too.

"Within this frame an ocean swells -- behind the smile -- I know it well..."

nice! that pro kydex press is nice but i found a way to avoid spending that kind of cash for one though - unless you'll be doing lots of sheaths. here's a kydex tutorial i wrote awhile back that might be useful to some: http://jungletraining.com/forums/showth ... ex-sheaths.

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

I like the practical tips that you give in your tutorial. Experience is a great teacher. As you can see above, I ran into the "rivets too close to the opening" problem at the early stage of this sheath, and had to make a radical design change in order to salvage the project. Happily, it ended up working out.

"Within this frame an ocean swells -- behind the smile -- I know it well..."

- peacefuljeffrey

- Member

- Posts: 1192

- Joined: Wed Jun 07, 2006 11:42 am

You scratched your knife?!?JV3 wrote:nice! that pro kydex press is nice but i found a way to avoid spending that kind of cash for one though - unless you'll be doing lots of sheaths. here's a kydex tutorial i wrote awhile back that might be useful to some: http://jungletraining.com/forums/showth ... ex-sheaths.

yup, one of many mistakes i learned - get all the sanding done, rinse the kydex thoroughly and rivet it last. no biggie - i have a 2nd cts-xhp that's still new. i'll probably scratch that one next when i try my hand with leather sheaths or diy handles, haha.mattman wrote:You scratched your knife?!?