h-1 steel

- polyhexamethyl

- Member

- Posts: 258

- Joined: Tue Mar 12, 2013 11:01 pm

- Location: Austria

- captnvegtble

- Member

- Posts: 1058

- Joined: Tue Oct 06, 2009 10:20 am

I own a lil' matriach and a Tasman. They're very different knives in a number of different ways (besides the steel being different). The serrations on the matriach are less aggressive making it more suitable for EDC. The curvature on the lil' matriach is also less pronounced and I find the little bit of "belly" on lil' matriach by the handle to be useful for EDC tasks. The internal liners on the matriach also make the knife feel more substantial and balanced in hand. Even though I LOVE H1 serrations, if I had to pick one, I'd probably pick the lil' matriach over the Tasman, but I suppose it depends what you'd be using it for.BAL wrote:Hey Blerv, just curious, how do you mean. I have debated either a Tasman or

Large Matriarch. Thanks

Hi BAL,BAL wrote:Hey Blerv, just curious, how do you mean. I have debated either a Tasman or

Large Matriarch. Thanks

Sorry that was probably confusing. They are all terrific tools but IMO the bi-directional FRN combined with the hourglass clip is a bit more sophisticated. That and the liners do cut down on flex a bit while offering 4-way mounting options.

If someone likes the volcano grip FRN (it sure is better than most) the Tasman offers a terrific lightweight package that is durable for anything someone could throw at it.

-

Commendatore

- Member

- Posts: 275

- Joined: Mon Mar 05, 2012 1:39 pm

- Location: Austria

I use H1 for EDC though being hundreds of miles away from the sea. Having a reliable, non corroded edge in my pocket is a great feeling. I rather don`t soak my knives with oil as swallowing that stuff when food is cut won`t please me. Using edible oil makes all kind of dirt stick to the knife, don`t want that either.

No lubricant will stay right at the very ege when the knife is used, with H1 I don`t need it.

Soft steel which scratches easily? Hey, my keys do all the stonewash-finish I like :D

Lightweight folders without liners are fine for most of my cutting needs.

No lubricant will stay right at the very ege when the knife is used, with H1 I don`t need it.

Soft steel which scratches easily? Hey, my keys do all the stonewash-finish I like :D

Lightweight folders without liners are fine for most of my cutting needs.

Wow I have a head ache.I asked for that one.the way he writes it up in the catalog makes it seem wonderful and rust proof steel but he doesn't compare it to other steels .I live on the ocean also that is why I asked everythink rusts here and I was wondering why it wouldn't be on more knives seeing a couple of posts on rust on the forum.but if it doesn't hold a edge like the others I am glad I got serrated I only like serrated when surf fishing any way.thanks guys

-

mrphotoman

- Member

- Posts: 82

- Joined: Sun Mar 17, 2013 10:17 am

-

GoodEyeSniper

- Member

- Posts: 400

- Joined: Wed Feb 08, 2012 10:32 am

I haven't oiled a carbon steel blade like 1095 or Case's CV in years, let alone stainless.... that whole issue is vastly overblown...Commendatore wrote:I use H1 for EDC though being hundreds of miles away from the sea. Having a reliable, non corroded edge in my pocket is a great feeling. I rather don`t soak my knives with oil as swallowing that stuff when food is cut won`t please me. Using edible oil makes all kind of dirt stick to the knife, don`t want that either.

No lubricant will stay right at the very ege when the knife is used, with H1 I don`t need it.

that said I'm shopping for a knife in H1. Because of the handles and design, not the steel, though.

You are correct. Work hardening and cold working are the same thing. Heat undoes the effects of work hardening. Grinding doesn't produce the kind of plastic deformation needed for work hardening, except for a thin layer under the ground surface, which can be severely deformed to be sure. However, for through hardening of an edge, something else is happening. Case hardened and nitrided steel is very hard, for a few microns of depth.noseoil wrote:Correct me if I'm wrong, but my understanding is that "work hardening" occurs as a result of the cold-forming process. This could be from cold-rolling at the mill, or stamping for a shape from die-forming. I know that the SE Salt has a higher edge hardness than the PE, so my question is, does this come from a stamping (forging?) process used to manufacture the blades "in house" once materials are delivered? I would think that both types of blades come from the same material stock but are treated differently during the manufacturing process. Thanks.

The solubility of nitrogen in steel is low at room temperature. It forms nitrides and carbonitrides. I'm still digging to find out how it increases stain resistance. It's out there somewhere. The Germans used nitrogen steels in WWII when Chromium was in limited supply.

My comparison testing shows H1 PE to hold an edge comparable to 420 steel used by RADA Cutlery, which I like.

I have a question no one has asked before. How much of a problem is burning the edge on H1 when power sharpening? I have a Salt 1 and need to fix the tip. The last 1/16" is acting very soft. I have considered using my belt sander to fix it. I am wondering if it could have been overheated from the factory sharpening, and how likely I am to over heat it myself if I sharpen it on the belt sander?

There are different perspectives to consider here. How often do you use your knife and are you good at sharpening? If you do both a lot then a steel that doesn't hold an edge forever but sharpens very easily and is extremely tough means it wont chip and will be a breeze to maintain. The more I think about it, I could go for a bushcraft style knife in H1...it would take a beating and be easy to sharpen and you'd never have to worry about rust while you're out in the elements. Also remember that VG10 may be the "vanilla" steel these days but the fact that H1 measures just below it in edge retention doesn't mean H1 is a terrible steel. I would still rate it above many other steels and put it at the very least above the Chinese steels that come in the value line knives, and then the rust free part is an added bonus. You should search for some of Cliff Stamp's videos on You Tube about it. He also has some threads here. Probably the biggest plus aside from being rust proof is how crazy tough it is.endgame wrote:Wow I have a head ache.I asked for that one.the way he writes it up in the catalog makes it seem wonderful and rust proof steel but he doesn't compare it to other steels .I live on the ocean also that is why I asked everythink rusts here and I was wondering why it wouldn't be on more knives seeing a couple of posts on rust on the forum.but if it doesn't hold a edge like the others I am glad I got serrated I only like serrated when surf fishing any way.thanks guys

All SE all the time since 2017

~David

~David

"I have a question no one has asked before. How much of a problem is burning the edge on H1 when power sharpening? I have a Salt 1 and need to fix the tip. The last 1/16" is acting very soft. I have considered using my belt sander to fix it. I am wondering if it could have been overheated from the factory sharpening, and how likely I am to over heat it myself if I sharpen it on the belt sander?"

Is this a plain or serrated edge? I'm wondering because the SE is deemed to be much harder at the edge and wonder about the tip if it was broken. The closer to the edge, the harder the metal and is the converse true?

Is this a plain or serrated edge? I'm wondering because the SE is deemed to be much harder at the edge and wonder about the tip if it was broken. The closer to the edge, the harder the metal and is the converse true?

Yes, in my experience the converse is true. Despite a very high edge hardness on my SE Pacific Salt, I was able to easily drill a 1/4" hole through the blade near the spine just forward of the opening hole, with a solid carbide twist bit. A HSS bit would not bite, but the carbide drilled it like butter.noseoil wrote:"I have a question no one has asked before. How much of a problem is burning the edge on H1 when power sharpening? I have a Salt 1 and need to fix the tip. The last 1/16" is acting very soft. I have considered using my belt sander to fix it. I am wondering if it could have been overheated from the factory sharpening, and how likely I am to over heat it myself if I sharpen it on the belt sander?"

Is this a plain or serrated edge? I'm wondering because the SE is deemed to be much harder at the edge and wonder about the tip if it was broken. The closer to the edge, the harder the metal and is the converse true?

For comparison, I did the same thing to a VG-10 Endura. The carbide bit that drilled the H-1 wouldn't bite and I had to use a special carbide spade bit for high Rockwell metals, the process was anything but easy, and the steel chipped on exit despite being backed by an aluminum block. I should have used steel to back it up. VG-10 at 60 HRc is the hardest metal I've ever drilled and I was grateful not to shatter the blade or the drill. It made a terrible sound, even with plenty of cutting fluid.

Aha, the PE version! I'm glad I sent for a SE knife, but it does sound like the edge is the hardest area of these blades. I'm reading more about the steel, but it still sounds like a bit of a changeling with respect to hardness. Still wondering about the manufacturing process and edge formation on the SE version. There must be some extra plastic deformation during manufacture which is happening at the edge on the SE which isn't causing the plain edge to gain as much hardness. Truly a weird steel for hardness. Wonder if it would make a good Katana if it was forged instead of tempered at the edge?

It would probably be really bad for a sword. I haven't seen toughness charts but don't think it could even compare to something like 3V, T10 even crude steels like 1060 or 5160. Like not even on the same spectrum.noseoil wrote:Wonder if it would make a good Katana if it was forged instead of tempered at the edge?

Unfortunately in the world of toughness if it isn't up to par the blade becomes two pieces. Slightly more dramatic than simply not holding an edge as well. :)

H-1 seems incredibly tough to me, to the point where its strength or edge holding is the weaker link for a sword application. I remember that photo of a Salt folder blade bent to a sharp 90 degrees (plastic deformation) without breaking.Blerv wrote:It would probably be really bad for a sword. I haven't seen toughness charts but don't think it could even compare to something like 3V, T10 even crude steels like 1060 or 5160. Like not even on the same spectrum.

Unfortunately in the world of toughness if it isn't up to par the blade becomes two pieces. Slightly more dramatic than simply not holding an edge as well. :)

- polyhexamethyl

- Member

- Posts: 258

- Joined: Tue Mar 12, 2013 11:01 pm

- Location: Austria

Here is a quote.polyhexamethyl wrote:do you've a link to that picture?

cgmblade wrote:Very cool link. Thanks for posting.

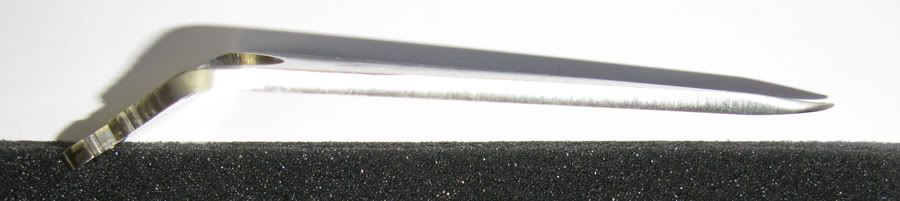

These are photos of an H1 blade tested by Spyderco showing that the blade bends instead of breaking.

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

I read a long time ago about a knife maker (can't for the life of me remember who) that was testing 3V in a vice by bending a blade 90 degrees and it didn't break. Still, the fact that this blade bent as far as it did and didn't break even with having the thumb hole there is pretty amazing. What I really wonder though is how was this test done....was the knife together and was there a pivot in place or was the blade in a jig/press? I ask because I bet the tang would break long before it reached the stresses that bent that blade that far. Either the tang would break or the pivot pin would rip out of the FRN, especially since there aren't any liners.

All SE all the time since 2017

~David

~David