Haha, I'm not worried. I was just curious about the numbers. :DAnkerson wrote:I wouldn't worry all that much over it. :D

Life is complicated enough to worry about things that aren't likely to happen and to over complicate things just because....

Kinda like I could win the lottery, but I am not going to count on it and start spending the money......

CPM S30V and hardning

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

If your S90V knife won't hold an edge in an impressive fashion you've got options: return it to the manufacturer with a polite note asking for some help, learn how to sharpen it, or auction it off. Somebody out there with a higher placebo index will be very happy with it! Their willingness to be the high bidder ensures that they'll think it holds an edge much better than their Granny's 1095 butcher knife.

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

I assume you're replying to me so let me assure you that I can sharpen reasonably well. Second of all, where I am, I can't ship out knives because there's an arbitrary rule in our airport. That's takes care of two of the options. Third of all, in my small city, I'm the only one who is into spydies.Fancier wrote:If your S90V knife won't hold an edge in an impressive fashion you've got options: return it to the manufacturer with a polite note asking for some help, learn how to sharpen it, or auction it off. Somebody out there with a higher placebo index will be very happy with it! Their willingness to be the high bidder ensures that they'll think it holds an edge much better than their Granny's 1095 butcher knife.

So what does that leave?

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

In general the variability you can expect in use is about 10:1 (900%). This is based on variability in materials, technique and initial sharpness. Given that the difference in those steels on a CATRA is about 40% the chance that you will see S90V outperforming S30V is slim in a one shot comparison because your variability is much larger than the difference.chuck_roxas45 wrote:Hhhmm, so what does all this mean in effect? Say I buy an S30V Para and an S90V para, what are the chances of my S30V holding an edge longer than the S90V if I just cut rope?

To put this in perspective, take a water balloon and throw it back over your shoulder into a crowd of 90 people. Four of them are wearing red shirts at random. Is it very likely you will hit one of the red shirt people? No, it is very likely that all you will see is scatter and no real patter as to who gets hit (i.e. the blades will just scatter about each other in performance).

However what happens over time if the same four red shirts are always there but everyone else changes at random. If you compare then a bunch of tosses you will see that in general the people that are red shirted tend to get more wet than a random person who comes and goes.

In general if you just do some cutting the difference in the cutting, the material, the initial sharpness, etc. all of it will make more of a difference than the steel. But over time, if you were to look at how often you sharpen for example, you would start to see a pattern develop.

Now if you take special care, you can reduce that initial population (the 90 people), but just remember that even a CATRA machine with jigged sharpening on their machince is at 10% (so there would be five people, four of them with red shirts).

(I am making some approximations in the above, rounding etc. to make the numbers a bit simpler, but they are all correct to first order precision).

- The Mastiff

- Member

- Posts: 6043

- Joined: Sun Jun 04, 2006 2:53 am

- Location: raleigh nc

Man, I don't like statistics.

Now the feeling a knife gives me on the stone, and how it cuts through stuff....that I understand. I let someone else do the science.

No offense meant there Cliff. Too much thinking takes the fun out of it for me.

Joe

Now the feeling a knife gives me on the stone, and how it cuts through stuff....that I understand. I let someone else do the science.

No offense meant there Cliff. Too much thinking takes the fun out of it for me.

Joe

"A Mastiff is to a dog what a Lion is to a housecat. He stands alone and all others sink before him. His courage does not exceed temper and generosity, and in attachment he equals the kindest of his race" Cynographia Britannic 1800

"Unless you're the lead dog the view is pretty much gonna stay the same!"

"Unless you're the lead dog the view is pretty much gonna stay the same!"

- chuck_roxas45

- Member

- Posts: 8797

- Joined: Wed Mar 03, 2010 4:43 pm

- Location: Small City, Philippines

So does all this mean that it's pretty much futile to get an s90v blade knife and expect more from it than from an s30v one over a period of time of use? If that's so then is getting an s30v one is also pretty much futile over a 8Cr13Mov one? Or do only the supersteels suffer from this variability? Or is the range of variability anything from the s90v level to 8Cr13Mov level? Does this also mean that in some cases 8Cr13Mov will outperform s90v?Cliff Stamp wrote:In general the variability you can expect in use is about 10:1 (900%). This is based on variability in materials, technique and initial sharpness. Given that the difference in those steels on a CATRA is about 40% the chance that you will see S90V outperforming S30V is slim in a one shot comparison because your variability is much larger than the difference.

To put this in perspective, take a water balloon and throw it back over your shoulder into a crowd of 90 people. Four of them are wearing red shirts at random. Is it very likely you will hit one of the red shirt people? No, it is very likely that all you will see is scatter and no real patter as to who gets hit (i.e. the blades will just scatter about each other in performance).

However what happens over time if the same four red shirts are always there but everyone else changes at random. If you compare then a bunch of tosses you will see that in general the people that are red shirted tend to get more wet than a random person who comes and goes.

In general if you just do some cutting the difference in the cutting, the material, the initial sharpness, etc. all of it will make more of a difference than the steel. But over time, if you were to look at how often you sharpen for example, you would start to see a pattern develop.

Now if you take special care, you can reduce that initial population (the 90 people), but just remember that even a CATRA machine with jigged sharpening on their machince is at 10% (so there would be five people, four of them with red shirts).

(I am making some approximations in the above, rounding etc. to make the numbers a bit simpler, but they are all correct to first order precision).

This blows my mind because if this is the case then there's been pretty much no advance in the knife metallurgy.

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

-

Henry - get both

- Member

- Posts: 211

- Joined: Wed Jan 04, 2012 9:32 pm

Hey Chuck, I feel for you being a knife enthusiast under those conditions. I was still having fun playing with the placebo effect.

To jump in here I'd comment that metallurgy is continually advancing, and that new applications are found for existing materials, but we are still the same fallible human beings that we've always been. Our manufacturing practices aren't perfect and our perceptions aren't perfect.

If you look at this another way, there are two ends of each probability bell curve and we seem to be more concerned about the small probability that there will be a perfect knife made of one alloy and a lousy knife made from another than we are grateful that we live in an age when folks have access to such an astounding variety of knives in the first place. A couple of the reasons Spyderco is as popular as it is are their willingness to innovate and their attention to detail. If they accidentally make a lousy knife they'll do right by you in the end. If you live somewhere that you can't ship a knife back for service you have my sincere sympathy.

To jump in here I'd comment that metallurgy is continually advancing, and that new applications are found for existing materials, but we are still the same fallible human beings that we've always been. Our manufacturing practices aren't perfect and our perceptions aren't perfect.

If you look at this another way, there are two ends of each probability bell curve and we seem to be more concerned about the small probability that there will be a perfect knife made of one alloy and a lousy knife made from another than we are grateful that we live in an age when folks have access to such an astounding variety of knives in the first place. A couple of the reasons Spyderco is as popular as it is are their willingness to innovate and their attention to detail. If they accidentally make a lousy knife they'll do right by you in the end. If you live somewhere that you can't ship a knife back for service you have my sincere sympathy.

- dj moonbat

- Member

- Posts: 1513

- Joined: Sat Mar 27, 2010 11:58 am

- Location: Sunny SoCal

I think the point is that with a sample size of 1 (one blade in each of the steels), you can't really say in advance what to expect. If, however, you've got a giant sample size of each steel, and you've stabilized the other variables, then you will expect to see more wear resistance out of the S90V sample, but less of other characteristics.chuck_roxas45 wrote:So does all this mean that it's pretty much futile to get an s90v blade knife and expect more from it than from an s30v one over a period of time of use?

"If you can't annoy somebody, there's little point in writing." — Kingsley Amis

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

In regards to high wear, yes you would expect to see a difference, but it will take some time and a decent volume of work.chuck_roxas45 wrote:So does all this mean that it's pretty much futile to get an s90v blade knife and expect more from it than from an s30v one over a period of time of use?

One of the most dramatic examples of differences I have seen was years back when I brought an S90V fillet blade (Wilson) with me fishing and when I got in to shore most of the guys were cleaning the fish (some splitting and some filleting). They noticed the blade and I gave it to them. The first guy reached to steel it right away without thinking, I encouraged him to use it until he needed to. It went down the line one person after another, no need to sharpen - yet each one of them was sharpening their own knives (420J2 class) multiple times.

Now what caused this effect :

1) The edge was much thinner and at a lower angle and had a high primary grind.

2) The initial sharpness was much higher.

3) The steel was about 10 points harder and much more abrasion resistant

Combining all of these with a high volume of work in very skilled hands made a very dramatic demonstration, too bad I did not have a video camera at that time. In short, the volume of fish cut was about 10X more with that blade than one of the others. But even then note it was not just the steel it was the other two factors as well.

Now if just one of those guys was unskilled and raked the edge of the knife across the edge of the table and hit a nail then the comparison would fail at that point. If I had not sharpener the S90V blade as well, if the edge was not so acute, etc., etc., etc. .

Steels are great, buy the best you can, but I don't buy Spyderco knives simply because of the steel but what they do with it. As just one example I have been measuring initial sharpness on blades for a long time and now have a pretty large and every expanding table. Out of the top 10 sharpest blades I have seen *eight* are from Spyderco (the other is a Dozier and a Deerhunter from A. G Russell).

Spyderco's also consistently come with :

-among the cleanest edge grinds

-little to no over heating of the edge

-the highest symmetry

If I gave an S30V knife and S90V knife to a friend I would have little confidence they would be able to tell them apart in use. But if I gave a friend a Spyderco folder and a random other folder I would bet heavily on which one would :

-be sharper

-cut better

-be easier to sharpen

-have easier opening/closing

-better ergonomics/security

etc. .

No.If that's so then is getting an s30v one is also pretty much futile over a 8Cr13Mov one? Or do only the supersteels suffer from this variability? Or is the range of variability anything from the s90v level to 8Cr13Mov level? Does this also mean that in some cases 8Cr13Mov will outperform s90v?

No.

Yes.

Yes.

Note 8Cr13MoV is superior to S90V in many ways :

-it is usually harder

-it is tougher

-it is easier to grind

-the edge is more stable (lower carbide volume)

S90V does have a significant increase in wear resistance but it isn't such a simple thing to say that makes a better knife steel. For example 52100 is praised by many knife makers but its wear resistance is low, it is easily exceeded by steels like 0.6C14Cr (AEB-L, 12C27, etc.). However they like it because :

-it is relatively tough

-it is easy to grind

-can be easily deferentially hardened (bit argument here if that is a good thing or not)

and it has "good enough wear resistance".

Knife metallurgy constantly advances, there are patents out on Ni based alloys which compared to S90V are :This blows my mind because if this is the case then there's been pretty much no advance in the knife metallurgy.

-are harder (62+ hrc)

-higher abrasive wear resistance

-better corrosion resistance

These are as recent as 2010. Of course these changes are small, on the order of 10% or so, but still if you are mass producing parts then a 10% increase in performance can mean a lot. Note that large manufacturing companies can operate on as little as a 1-3% margin so 10% is huge.

It takes a bit more than that.The Mastiff wrote: No offense meant there Cliff.

Koen Z wrote:Great tread. Learned a lot of it as someone studying Mechanical Engineering!

We will keep trying!

Don't forget the Advil and you will likely need bifocals from going blind looking at mountains of data that could be condensed down to much more manageable size in the end.

Some of those types are pretty smart with numbers, but they can't break it down so that a 14 YO can understand it because they over complicate it so much, usually much more than is really needed to explain it.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

I have suggested in the past that Spyderco do a fine edge line, or similar. A lot of the kitchen knife companies are putting out similar lines and marketing them as having "superior sharpness" as that is how everyone tends to describe cutting ability.Blerv wrote:I have a sudden urge to have my M4 Manix2 reground now :) .

I have been looking at the inexpensive kitchen knives lately and it isn't difficult to find one less than $10 with an edge under 0.010"/15 dps. This is just from increased pressure on cutting ability and a focus on Japanese vs Western knives.

The problem for Spyderco would be dealing with warranty issues with a 0.005"/10 dps/66 HRC (true tempered) M4 Paramilitary. If you realized what it was made to do it would be wonderful, if you tried to use it like a 0.025/20 dps edge then frustration and disappointment would ensue.

Cliff Stamp wrote:I have suggested in the past that Spyderco do a fine edge line, or similar. A lot of the kitchen knife companies are putting out similar lines and marketing them as having "superior sharpness" as that is how everyone tends to describe cutting ability.

I have been looking at the inexpensive kitchen knives lately and it isn't difficult to find one less than $10 with an edge under 0.010"/15 dps. This is just from increased pressure on cutting ability and a focus on Japanese vs Western knives.

The problem for Spyderco would be dealing with warranty issues with a 0.005"/10 dps/66 HRC (true tempered) M4 Paramilitary. If you realized what it was made to do it would be wonderful, if you tried to use it like a 0.025/20 dps edge then frustration and disappointment would ensue.

The interesting thing about that is the difference in performance in my Para 2 CTS-20CP (Carpenters vers of S90V) before and after I had the blade reground thin....

There was a 50% increase in performance going from .025" behind the edge to .009" behind the edge and that was at the same edge geometry (15 DPS) and finish.

So that difference would be even larger if I went to something like 10 DPS.

And larger again if I changed the edge finish to a more efficient semi polished like I normally use in testing compared to the high polished edge.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

It is easily 10:1 . Mike Swaim wrote about this in the late nineties on rec.knives, I reground a bunch of knives in 1998-2002 and showed how the performance in edge holding can change from 100 cuts into hemp to more than 2000 cuts into hemp and retain the same sharpness. Hence geometry/finish dominates steel easily : http://www.cliffstamp.com/knives/reviews/mel_sorg.html. Mel's was one of the earlier ones, I did a few before that, custom and production.Ankerson wrote:The interesting thing about that is the difference in performance in my Para 2 CTS-20CP (Carpenters vers of S90V) before and after I had the blade reground thin....

Lets put some pictures so people can see the difference between carbides at the edge:

Fine

Coarse:

(credit: Sandvik website)

Fine

Coarse:

(credit: Sandvik website)

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

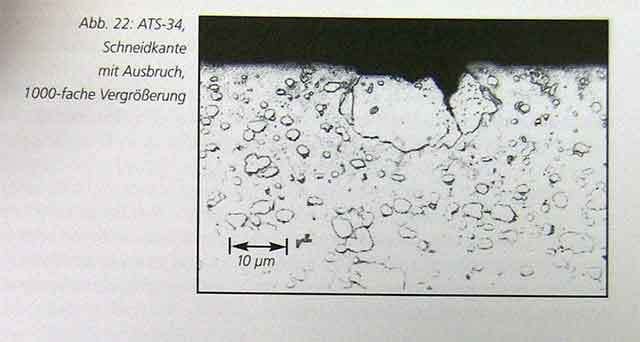

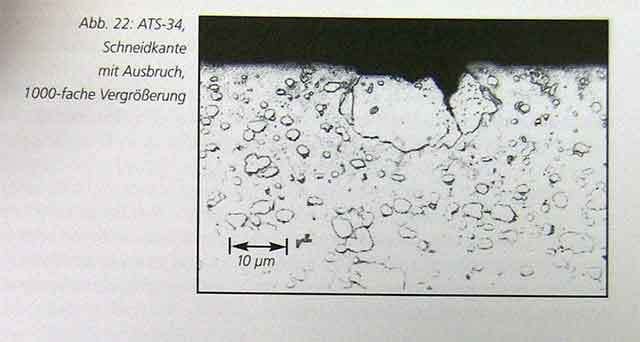

Here is a picture from Roman showing one of the problems with large carbide aggregates :

This is ATS-34, note the very large carbide which is just about to crack right out of the edge. These large carbides do not help the knife keep a high sharpness, in fact they lower it and reduce performance. But they do very well on CATRA style tests because they cut to a low sharpness and the edge has thickened by that point and the carbide stop tearing out.

This is again one of the main reasons where there is a lot of apparent contradiction as someone will take a steel like D2 and compare it to 52100 and see 52100 having better edge retention yet someone else will do the same thing (cut some rope/cardboard, or fish/game) and claim the exact opposite. There is no real contradition, all that is happening is one of them is interested in a very high sharpness and one of them in keeping a low sharpness.

This is ATS-34, note the very large carbide which is just about to crack right out of the edge. These large carbides do not help the knife keep a high sharpness, in fact they lower it and reduce performance. But they do very well on CATRA style tests because they cut to a low sharpness and the edge has thickened by that point and the carbide stop tearing out.

This is again one of the main reasons where there is a lot of apparent contradiction as someone will take a steel like D2 and compare it to 52100 and see 52100 having better edge retention yet someone else will do the same thing (cut some rope/cardboard, or fish/game) and claim the exact opposite. There is no real contradition, all that is happening is one of them is interested in a very high sharpness and one of them in keeping a low sharpness.

This is true in my own experience. Curiously, thinness behind the edge is often relegated to "ignore" status by many blade enthusiasts who prefer to focus primarily on Rockwell hardness, steel composition, degree of polish at the edge, and final bevel angle. All of these factors matter but thinness behind the edge makes a larger contribution to real world cutting ability than any of them! The common "paper cut" proves this point well on flesh.Cliff Stamp wrote:It is easily 10:1 . Mike Swaim wrote about this in the late nineties on rec.knives, I reground a bunch of knives in 1998-2002 and showed how the performance in edge holding can change from 100 cuts into hemp to more than 2000 cuts into hemp and retain the same sharpness. Hence geometry/finish dominates steel easily : http://www.cliffstamp.com/knives/reviews/mel_sorg.html. Mel's was one of the earlier ones, I did a few before that, custom and production.

Special thanks to Cliff and Jim for making this such an engaging thread.

Bill