chuck_roxas45 wrote:Spyderco aims it's s90v in around a range of 58-59 Rc and it's s30v at 58-60 Rc. so will there be any overlaps?

Yes, to clarify, lets assume :

1) both have been heat treated optimally

-austenization temp is minimal in time, and maximal in temperature

-at least 12% of chromium goes into solution

-fast quench (oil)

-cryo before temper

-temper to complete first stage tempering (low carbon martensite)

2) both have the exact composition as-spec'ed

3) the oven's (operators, etc.) are 100% without flaw

This will produce a near identical hardness in both and the same micro-structure the only difference being the carbide volume is much higher in S90V. In this ideal scenario :

-the will have similar compression resistance so the edges will dent / roll on a large scale the same, no advantage to either

-s30V will have better compression resistance on a micro-scale because it will have less carbide tear out, advantage to S30V for high sharpness edge holding

-S30V will have a higher toughness (25-28 ft.lbs vs 19 ft.lbs) and a much higher grindability in case damage has to be repaired, advantage to S30V

-S30V has a higher corrosion resistance (S30V shows a much higher tolerance to salt solution as compared to 440C but S90V can just equal it), advantage to S30V

-S90V has a higher abrasive wear resistance, as noted in the above that is about a 40% better CATRA score, advantage to S90V for cutting abrasive materials at a lot sharpness (CATRA stops when the blades are really dull)

Now the only advantage to S90V is in that one area and it is about 40% when tested on a machine which severely limits a number of factors some of which are actually superior in S30V (lateral loading on the edge, S30V would handle that better, again lower carbide volume).

Could a person see this difference - yes, but they would have to be doing controlled cutting and measuring sharpness and :

-the edges would need to be of a very similar angle

-same grit finish

-same initial sharpness

-consistent material

-consistent cutting (force, speed, etc.)

If any of those were not true then the performance of the blades could simply be dominated by that factor alone, i.e, if the S30V blade had a lower edge angle and/or a lower edge grit finish it would outlast the S90V blade anyway even if all of the assumptions are true (it would CATRA outlast it I mean, not just by hand).

To be very specific, if you gave me two of the blades, and one of them CATRA'ed 40% more than another could I tell them apart by hand. I am confident I could as long as I :

-had enough material to do a large sample cutting

-could measure the sharpness to at least 5% precision

-could do at least 3-5 runs to get an average

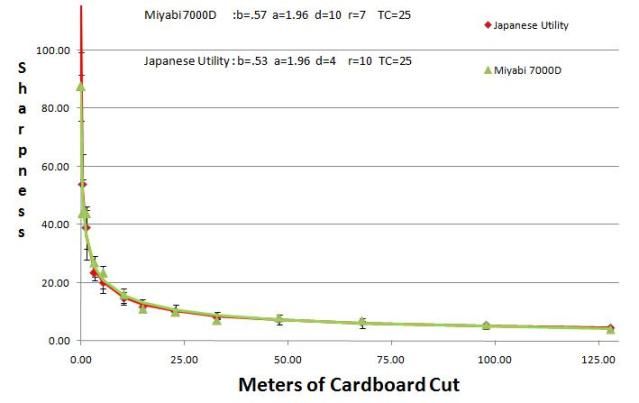

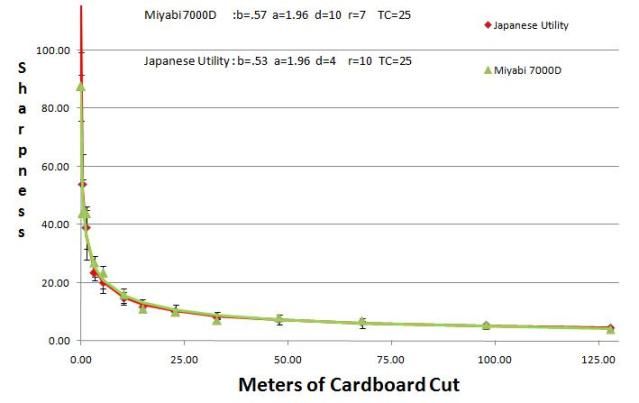

Note blunting is NONlinear, this means that if you cut to a low sharpness and were to double amount of material cut it could change the extent of dulling by as little as 2%. Just think about what that means when trying to compare blades - it is very difficult.

Just look how slowly the performance is changing at the 125 m mark. At this point the blades are at 5% of sharpness but they are changing so slowly I could double the material and barely see any difference. That means in order to determine how much material they can cut to a factor difference of 100% I need to be able to measure sharpness to a precision of 1%.

That isn't easy.

(I was going to run this out to 1000 m, just because I thought it would be amusing to cut a km of cardboard, but the problem was that I need a sample pool which is 10X larger, which means I need 250 KM of cardboard (I do ten runs with each blade) which I quickly figured out would fill my basement, thus I kept it down to about 0.1 KM).