I used a Lansky diamond system to reprofile the edge of the blade I'm photographing now. From the factory it was slightly higher than the 17 degree setting on the sharpener. The opposite side matched 17 degrees well. I used coarse, medium and fine diamond stones with a quick finish with a black hard Arkansas hone (1200 grit, maybe?)

Not sure how this could be useful other than looking at edge quality, but it's always fun seeing stuff larger than life :)

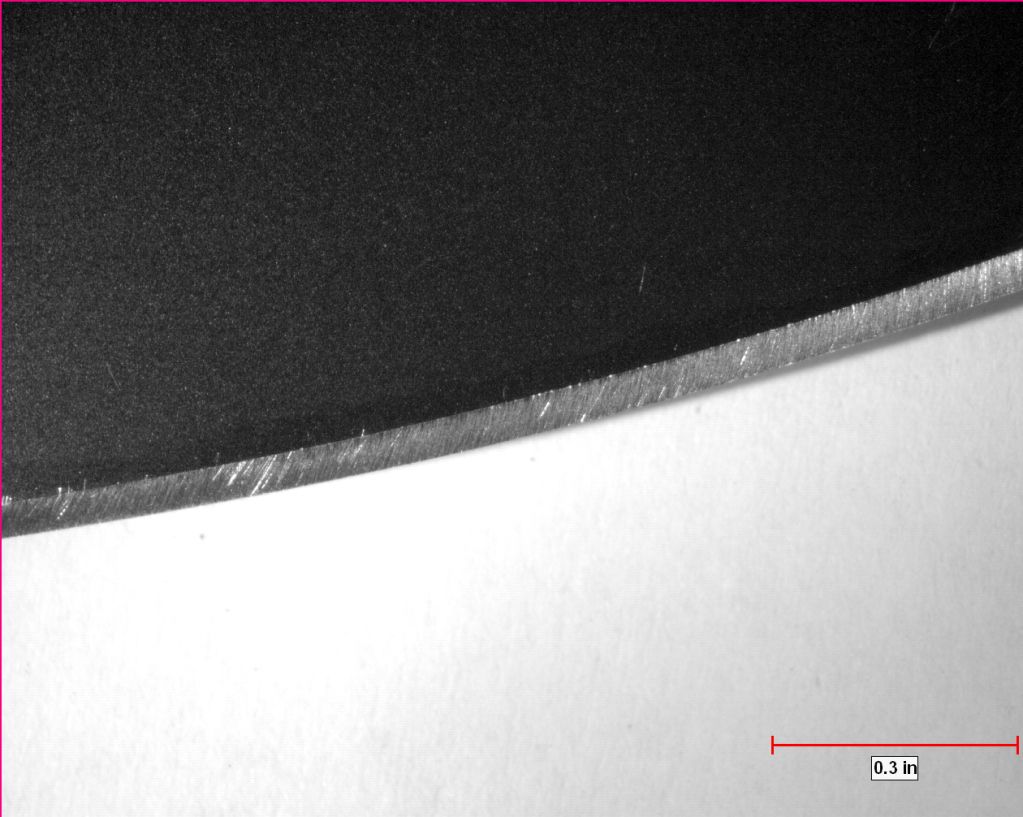

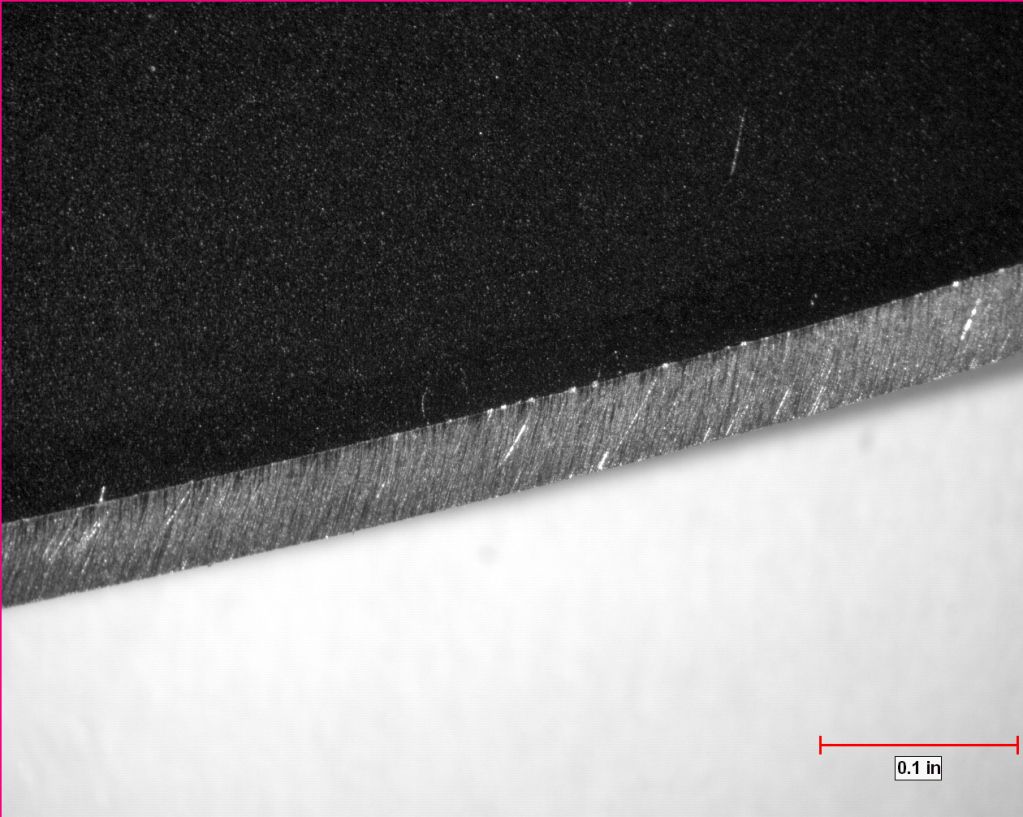

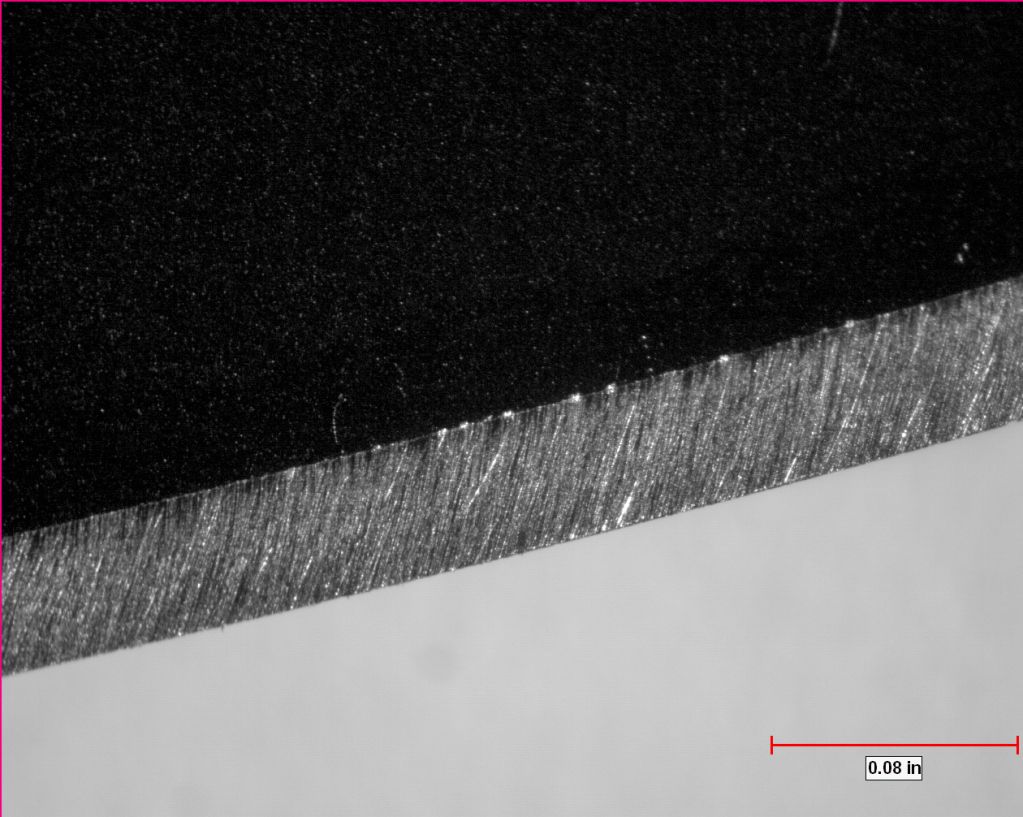

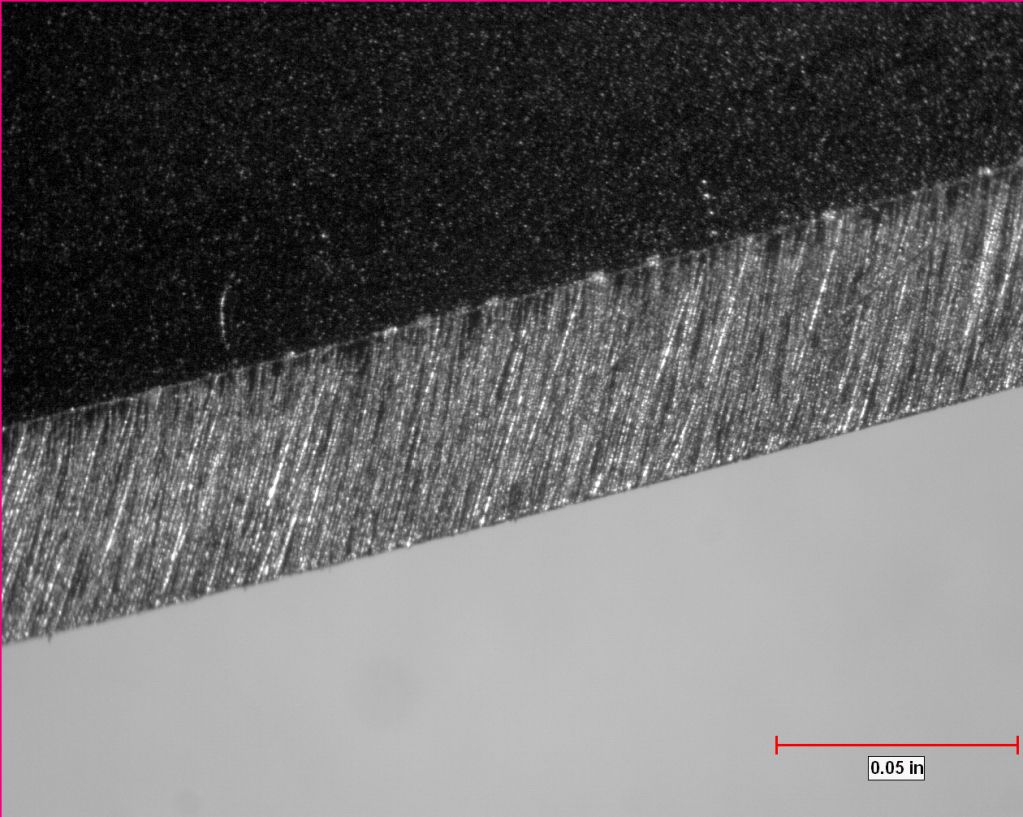

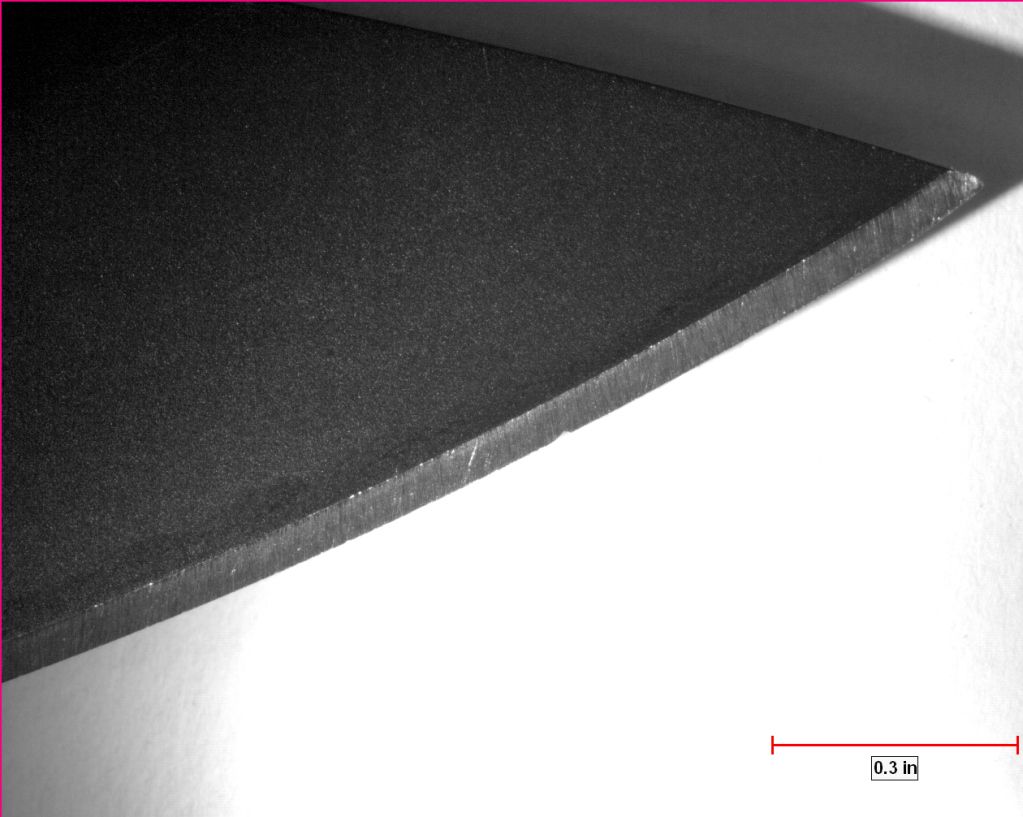

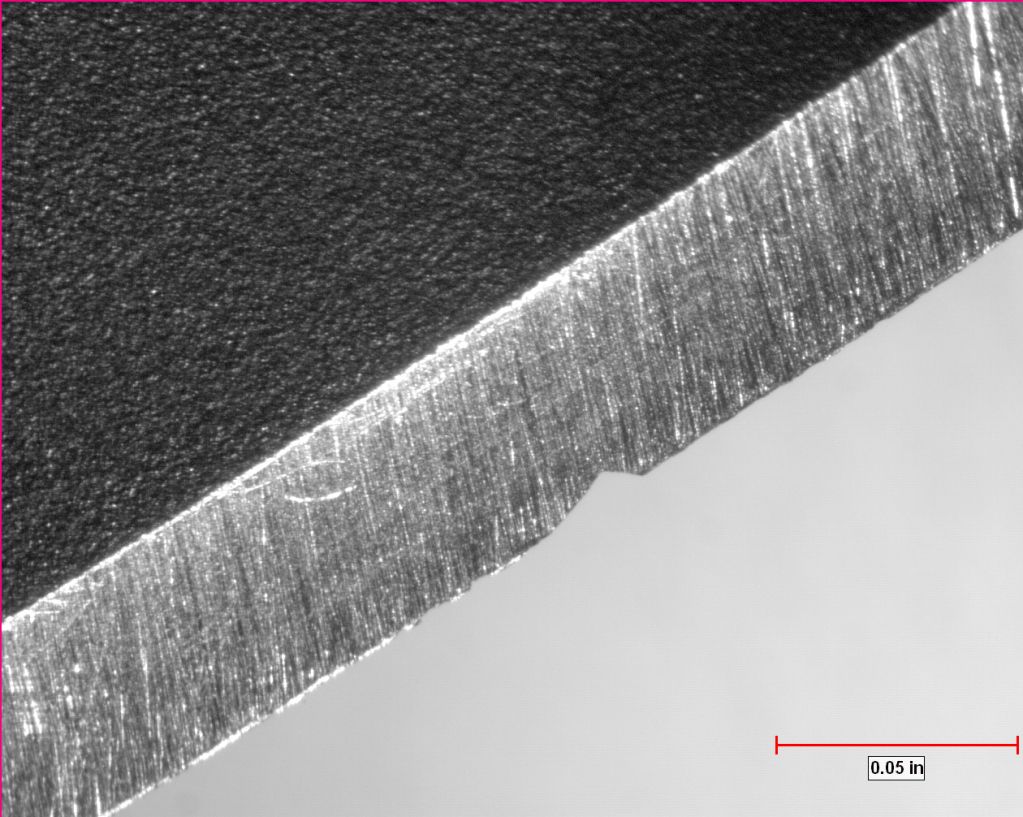

1, 22 - Manix 2, 154CM, hollow ground and 17° Lansky-sharpened

35 - Dodo, S30V, factory hollow ground

43, 44 - Manix 2, M4, factory full flat ground

45 - Mule MT13, Elmax, factory full flat ground

68, 69 - Bark River Little Creek, A2, convex ground and touched up on the black and green strops

83 - Manix 2, M4, Lansky diamond system and black and green strops, 17° and 20°

94, 95 - Washington state quarter

96 - Caly3, ZDP189/420J2, flat ground, Lansky diamond system and black and green strops, 17°

97 - Caly3, ZDP189/420J2, same as above but with 25° micro bevel

99 - Lansky coarse diamond stone

100 - Lansky medium diamond stone

101 - Lansky fine diamond stone

102 - Lansky black hard Arkansas hone

122 - Reynolds aluminum foil

137 - Manix 2, 154CM, sharpened with Edge Pro Apex

143 - Manix 2, 154CM, after cutting white pine and cardboard

159 - Manix 2, 154CM, after cutting white pine and cardboard, edge-on view

160 - Ritter RSK Mk1, M2HS, factory edge

Here's a picture of the setup:

The stereo microscope is 10-63x magnification with a B/W camera, and the metallograph to the left will go from 50-1000x. I really want to make a jig that'll hold the blade's edge parallel to the lens so I can get some closer pictures.

Some pictures, starting at 10x:

25x:

40x:

63x:

It amazes me how bad little flaws look at 63x. Here's a good example:

10x:

63x:

I did appreciate how the light found where my edge needed a little more work.

Mods, not sure if this qualified as a general thread or should be in the pictures section. Please move if it belongs in the other!