8Cr13Mov vs VG-10 test

8Cr13Mov vs VG-10 test

8Cr13Mov vs VG-10 test

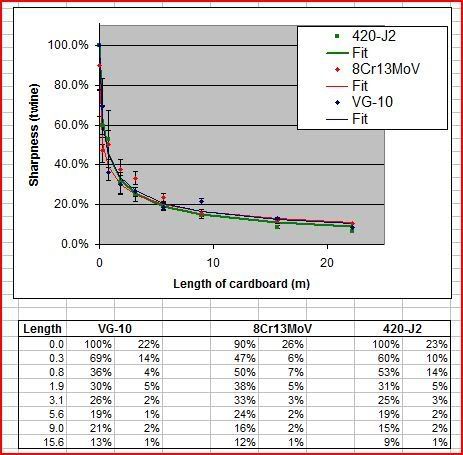

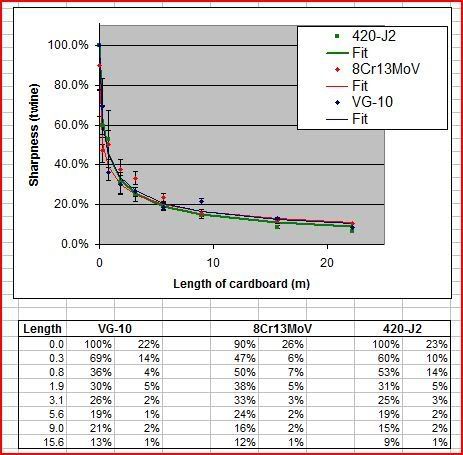

I saw this post from December 2007 on CutleryScience, comparing the edge retention of 8Cr13Mov (byrd meadowlark) to VG-10 (delica). Ignore the first two graphs - they were done with the knives unsharpened and/or at different angles of sharpening. The interesting graphs are in the last post at the bottom of the page, where the knives are sharpened to the same angle and cut through 40 meters of cardboard.

They found no significant difference between the two in terms of edge retention. Many comments I find on Google regarding 8Cr13Mov portray it in a negative light, calling it "cheap" and "not preferable". Where does this come from?

They found no significant difference between the two in terms of edge retention. Many comments I find on Google regarding 8Cr13Mov portray it in a negative light, calling it "cheap" and "not preferable". Where does this come from?

- tonydahose

- Member

- Posts: 6277

- Joined: Thu Jan 19, 2006 7:56 am

- Location: Chicago

- Contact:

looks like spyderco got the heat treatment right in china...interesting thread. i am glad to see that the byrds are holding their own, they are the gateway drug to the highly addictive spydercos :D .

WTC #1444 Always Remember

Need info on a particular :spyder:, just click here

My knives

Spydie count: a few:D

Need info on a particular :spyder:, just click here

My knives

Spydie count: a few:D

420J is as good as VG-10?

Interesting graphs. The third graph is the important one for this discussion (since the fourth attempts to remove edge stability as a variable, whereas users seldom ever purposely reduce edge stability!).

In the third test, not only is there little difference between VG-10 and 8Cr13Mov, but there is also little difference between VG-10 and the 420J found in the $2 knife.

So this graph is saying that the VG-10 Delica has virtually no edge retention advantage over either the 8Cr13Mov 'Lark, or the 420J Winchester.

So why don't I just buy cheap 420J knives?

In the third test, not only is there little difference between VG-10 and 8Cr13Mov, but there is also little difference between VG-10 and the 420J found in the $2 knife.

So this graph is saying that the VG-10 Delica has virtually no edge retention advantage over either the 8Cr13Mov 'Lark, or the 420J Winchester.

So why don't I just buy cheap 420J knives?

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

- Michael Cook

- Member

- Posts: 4383

- Joined: Fri Apr 01, 2005 9:44 pm

- Location: People's republic of Madison

- Contact:

We are not buying 420J Winchesters probably because we are snobs. :o :o :o :D :D :DBolstermanic wrote:

So why don't I just buy cheap 420J knives?

"People sleep peaceably in their beds at night only because rough men stand ready to do violence on their behalf"

My top choices Natives5, Calys, C83 Persian

My top choices Natives5, Calys, C83 Persian

-

MANIXWORLD

- Member

- Posts: 1144

- Joined: Thu Sep 27, 2007 2:51 pm

- Location: South Africa Capetown

Something For Everyone

These results have something for everyone, whatever your opinion of 8Cr13Mov.

If you like 8Cr13Mov, you can use this data to say, "It's as good as VG-10."

If you hate 8Cr13Mov, you can use this data to say, "It's as bad as 420J."

If you like 8Cr13Mov, you can use this data to say, "It's as good as VG-10."

If you hate 8Cr13Mov, you can use this data to say, "It's as bad as 420J."

- malice4you

- Member

- Posts: 186

- Joined: Wed Jun 13, 2007 2:14 am

- Location: NJ

Based off my limited use of a FRN Cara Cara vs my daily user VG10 blades, I've gotta say that the 8Cr13MoV holds up very well, it seems to be a tad softer when cutting things I shouldn't cut, but otherwise I wouldn't hesitate to use it. In a situation where it's more likely to get damaged or lost, I'd have no problem carrying a 8Cr13MoV blade over a more expensive spyderco, especially since I've gotten the Cara Cara to be about as sharp as any knife I own with "better" steel. I've found it to be far superior to my H1 blade.

I'd say the Byrd line is clearly a great value for the price, and I will be picking up a flight, raven, crossbill, tenacious, and likely another cara cara in the future...

I'd say the Byrd line is clearly a great value for the price, and I will be picking up a flight, raven, crossbill, tenacious, and likely another cara cara in the future...

Sporting 61 Spydercos in G-2, AUS-6, 8CR13MoV, ATS-55, H-1, VG-10, CPM-S30V, N690Co, ZDP-189/420J2, ZDP-189, AUS-10, and 52100.

- dialex

- Member

- Posts: 9169

- Joined: Fri Sep 24, 2004 10:33 am

- Location: Campina, Romania, Europe, Terra

- Contact:

This was a nice one, thanks for the smile :)Wharnie wrote:These results have something for everyone, whatever your opinion of 8Cr13Mov.

If you like 8Cr13Mov, you can use this data to say, "It's as good as VG-10."

If you hate 8Cr13Mov, you can use this data to say, "It's as bad as 420J."

The mind commands the body and it obeys. The mind orders itself and meets resistance.

:spyder: :spyder: :cool: :spyder: :spyder: I don't own a Bryd knife, and it is because of the blade steel :spyder: I guess I shouldn't judge a book by it's cover, ha....? Maybe someday, when my (S)pyder)wiss account is active again, and I've got'n my UKPK, I might give a Bryd a go :cool: :D

:spyder: :spyder: :cool: :spyder: :spyder: "Spyderco...does a pocket good":spyder:

Spyderco Rocks!!!! "A wise man once said all knives were created equal...Obviously, he meant Spydercos''

As of 1-29-08, I am a proud member of Knife Rights!

Spyderco Rocks!!!! "A wise man once said all knives were created equal...Obviously, he meant Spydercos''

As of 1-29-08, I am a proud member of Knife Rights!

-

yablanowitz

- Member

- Posts: 7261

- Joined: Sun Apr 09, 2006 2:16 pm

- Location: Liberal, Kansas

Okay, I'll bite. All you all kidding, or did you really miss the point of that test completely? :confused:

First of all, although it was marked as 420J on the charts, the third steel was identified only as "stainless". While I conceed that 420J IS stainless (and a good candidate given the price of the knife), I must point out that 420V is also stainless, as are many others. Without analysis, there is simply no way to know for certain what that steel actually is.

Second, there was no mention of any hardness testing being done on any of the blades. So what? So it only shows that the Byrd with a heat-treat within specs was about as good as a Spyderco with a heat-treat within specs. That could mean that 8Cr13MoV with an ideal heat treat is as good as VG-10 with a merely acceptable heat-treat. It may not even mean that much.

The point being made is that sub-optimal sharpening can negate the advantages of premium steels. While I agree with that point, even that was not really demonstrated, since the third steel was unknown and could have been a premium steel as well (although I admit it isn't likely).

First of all, although it was marked as 420J on the charts, the third steel was identified only as "stainless". While I conceed that 420J IS stainless (and a good candidate given the price of the knife), I must point out that 420V is also stainless, as are many others. Without analysis, there is simply no way to know for certain what that steel actually is.

Second, there was no mention of any hardness testing being done on any of the blades. So what? So it only shows that the Byrd with a heat-treat within specs was about as good as a Spyderco with a heat-treat within specs. That could mean that 8Cr13MoV with an ideal heat treat is as good as VG-10 with a merely acceptable heat-treat. It may not even mean that much.

The point being made is that sub-optimal sharpening can negate the advantages of premium steels. While I agree with that point, even that was not really demonstrated, since the third steel was unknown and could have been a premium steel as well (although I admit it isn't likely).

I don't believe in safe queens, only in pre-need replacements.

All Steels Are The Same...It's Just Marketing Hype

As other posters have pointed out, the test under discussion doesn't really distinguish among the tested steels. If you relied on this test alone, you should be just as happy with 420J as with 8Cr13Mov as with VG-10. You should be just as happy with a $2 knife as a $200 knife, regarding edge retention.

This implies that super-steels such as VG-10 are little more than marketing hype. It implies that modern powder metallurgy is a sham, producing edge retention for cutting twine that's really no better than 420J. Do you buy that argument?

The problem is, these results fly in the face of lots of other tests that find dramatic differences in edge retention among various steels. And they fly in the face of the experience of thousands of users. I think there'd be relatively few users who would say their 420J knives holds up as well as their VG-10 knives under use. (If anyone DOES believe that, please contact me. I have many 420 knives I'd like to trade you for your VG-10 knives.)

Don't get me wrong, I like data, and I appreciate these tests, but I don't think a single test is sufficient to jump to the conclusion that "All steels are pretty much equal in terms of edge retention."

Although I do agree with Cliff's larger point, that the condition of the edge overwhelms any difference in steels. In other words, if you have to choose between a sharp 420J knife and a dull ZDP-189 knife, take the sharp 420J every time.

I guess another lesson to derive from this test is: your Sharpmaker is even more important than your fancy super-steel in providing you with long-lasting cutting satisfaction.

This implies that super-steels such as VG-10 are little more than marketing hype. It implies that modern powder metallurgy is a sham, producing edge retention for cutting twine that's really no better than 420J. Do you buy that argument?

The problem is, these results fly in the face of lots of other tests that find dramatic differences in edge retention among various steels. And they fly in the face of the experience of thousands of users. I think there'd be relatively few users who would say their 420J knives holds up as well as their VG-10 knives under use. (If anyone DOES believe that, please contact me. I have many 420 knives I'd like to trade you for your VG-10 knives.)

Don't get me wrong, I like data, and I appreciate these tests, but I don't think a single test is sufficient to jump to the conclusion that "All steels are pretty much equal in terms of edge retention."

Although I do agree with Cliff's larger point, that the condition of the edge overwhelms any difference in steels. In other words, if you have to choose between a sharp 420J knife and a dull ZDP-189 knife, take the sharp 420J every time.

I guess another lesson to derive from this test is: your Sharpmaker is even more important than your fancy super-steel in providing you with long-lasting cutting satisfaction.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

-

yablanowitz

- Member

- Posts: 7261

- Joined: Sun Apr 09, 2006 2:16 pm

- Location: Liberal, Kansas

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 1:23 pm

- Location: Earth

- Contact:

That isn't the main point I was trying to make which was that the steel itself is often not the dominant factor and that it is more important how you sharpen a knife than picking a particular steel. You can see what you are looking for in other work done, such as on the CRK&T knives and others where I have shown the effect of edge geometry and finish. Possibly the most striking example was on the Mel Sorg blade where I took a knife all the way up to a 2000+ cut on hemp rope by adjusting the finish and edge geometry. I did dozens of such comparisons years ago.yablanowitz wrote:In my opinion, the data would have been more meaningful if each steel had been plotted against itself to show the effect of the changes in initial sharpening on edge retention. After all, that is what he said he was testing.

Then you are not really reading what is written nor what I have said nor referenced on steels. If you really are going to look at what I post in such a manner I would really prefer that you don't. What I write is meant for those who want to understand and learn about steels, if you just want to be told what to buy in an oversimplified fashion then please look somewhere else. If you ask me in an email about what steel is best for edge retention then there are a half a dozen questions you need to answer before I can begin to give you some information.Bolstermanic wrote:If you relied on this test alone, you should be just as happy with 420J as with 8Cr13Mov as with VG-10. You should be just as happy with a $2 knife as a $200 knife, regarding edge retention.

The reality, as in MEASURED FACT, supports that the edge stability of VG-10 and high carbides steels is very low, yes, actually lower than steels such as 420HC, AUS-6A. And yes, this means that they will go blunter slower, i.e., stay sharper longer than high carbide steels such as VG-10 at a high polish and low angle. Again, MEASURED FACT, in a lab with published papers in peer reviewed journals and this is actually about 50 years old now, not new.This implies that super-steels such as VG-10 are little more than marketing hype. It implies that modern powder metallurgy is a sham, producing edge retention for cutting twine that's really no better than 420J. Do you buy that argument?

As for the rest, no it doesn't say that and in general I don't imply much of anything, if I think something is a sham I just say it. For example I think that it is marketing hype that high carbide steels are classified as superior uniformly and that is a sham. But hardly ever maker/manufacturer does it. Some are quote clear that low carbide steels have their strong points as well, it just depends on what you want in a steel.

No they don't, again, science is on my side, I have the guys with the PhD's and journal articles supporting my work. I take what I do seriously, even though this is just a hobby, it is treated seriously.The problem is, these results fly in the face of lots of other tests that find dramatic differences in edge retention among various steels. And they fly in the face of the experience of thousands of users.

I would ask you how many of those "thousands of users" actually take the time to note the effect of edge geometry, initial sharpening and how many are actually MEASURING anything - how many are taking into account the placebo effect?

Actual MEASURED data from material engineers like Verhoven will classify AUS6A as a superior blade steel than 154CM (420HC superior over VG-10). If you want to debate the results I am open to it, but let us stick to the facts. Now again, superior is only meaningful when the specific criteria is noted, in general saying one steel is superior to another is hype, you have to be a lot more specific to be meaningful.

I have done a lot more than one test, and I would never make the bottom statement.Don't get me wrong, I like data, and I appreciate these tests, but I don't think a single test is sufficient to jump to the conclusion that "All steels are pretty much equal in terms of edge retention."

Yes, I stated this clearly, there is significant variant among performance, I showed this by doing the same work with a bunch of S30V and ZDP-189 knives and showing the performance overlapped. Now take those knives and give them in pairs to consumers and what happens. Now add to this different sharpening skills and different initial geometries, you will get whole factors of performance differences. There is also a lot of math here, and how you actually look at it will make a difference. For example one knife at 8% initial sharpness is actually 25% sharper than a knife at 10% initial sharpness but a user could never actually tell the difference by cutting with the knife so are the knives the same or does one have a significant advantage? if you are selling the material then you say one, I will give you the numbers and let you decide.yablanowitz wrote: Second, there was no mention of any hardness testing being done on any of the blades. So what? So it only shows that the Byrd with a heat-treat within specs was about as good as a Spyderco with a heat-treat within specs. That could mean that 8Cr13MoV with an ideal heat treat is as good as VG-10 with a merely acceptable heat-treat.

It is possible that they decided to but a steel which costs 10x the retail price of the knife, but really that isn't going to happen. I have done such work with known low carbide steels before, AUS-4/6A and 420J2. I know the behavior of such steels, the do not have the same blunt response as a high end steel nor do they have the same behavior in sharpening. It is fairly easy to do a pure wear test, I have meant to do this for sometime. I have picked up a cheap 200x digital microscope so I will do this in the future.The point being made is that sub-optimal sharpening can negate the advantages of premium steels. While I agree with that point, even that was not really demonstrated, since the third steel was unknown and could have been a premium steel as well (although I admit it isn't likely).

-Cliff