Calling all sharpening experts

Calling all sharpening experts

This is a bit of a spin-off from the Community Sharpening Journal thread. There was some discussion there a while back regarding fine edge retention, i.e. longevity of a shaving sharp edge, but nothing really conclusive. I've seen this discussed other places as well, and there are generally two groups.

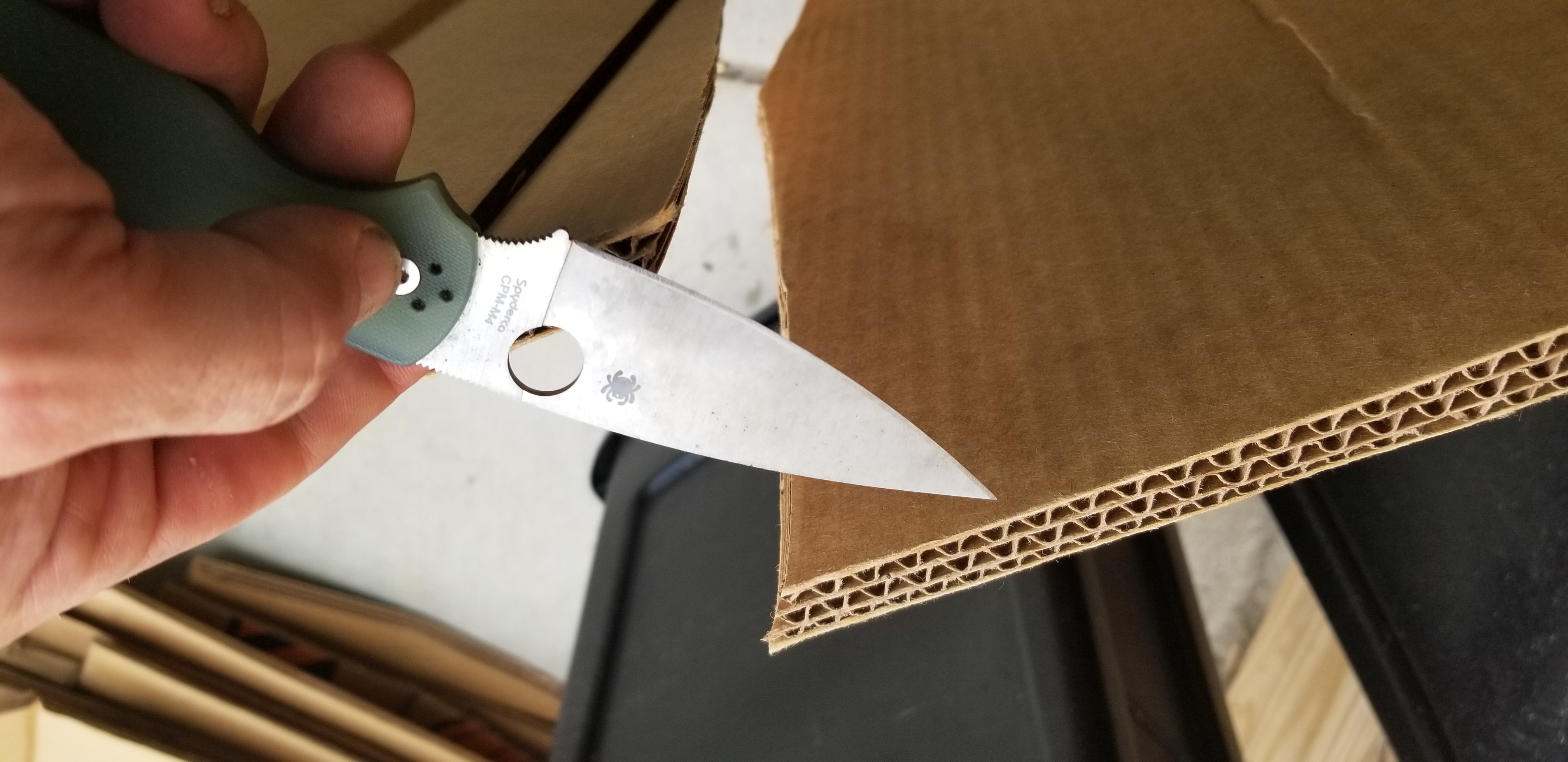

On the one hand, there are those of us who report a relatively rapid loss of shaving sharp edges -- mostly regardless or grit finish, angle, or blade steel -- when cutting through abrasive material like carboard. In my experience, these edges are easily brought back to shaving after a couple swipes on the Sharpmaker.

On the other hand, there are those who report a lasting shaving sharp edge when cutting through the same type of materal without the need for any kind of touch up to bring the edge back. @vivi has even mentioned he's able to retain shaving sharpness on plain edge H1 after cutting through a considerable amount of cardboard and was surprised that others of us haven't had the same experience.

So I'm really just hoping the experts who are getting this kind of excellent edge retention can offer the rest of us some tips and pointers as it relates to their sharpening process.

I will note that while this may be a burr issue, it would have to be a microscopic one, as I experience this with edges that have no traces of visible burr in low light with the naked eye or with 60x magnification.

On the one hand, there are those of us who report a relatively rapid loss of shaving sharp edges -- mostly regardless or grit finish, angle, or blade steel -- when cutting through abrasive material like carboard. In my experience, these edges are easily brought back to shaving after a couple swipes on the Sharpmaker.

On the other hand, there are those who report a lasting shaving sharp edge when cutting through the same type of materal without the need for any kind of touch up to bring the edge back. @vivi has even mentioned he's able to retain shaving sharpness on plain edge H1 after cutting through a considerable amount of cardboard and was surprised that others of us haven't had the same experience.

So I'm really just hoping the experts who are getting this kind of excellent edge retention can offer the rest of us some tips and pointers as it relates to their sharpening process.

I will note that while this may be a burr issue, it would have to be a microscopic one, as I experience this with edges that have no traces of visible burr in low light with the naked eye or with 60x magnification.

- WilliamMunny

- Member

- Posts: 2073

- Joined: Fri Jan 29, 2021 12:20 pm

Re: Calling all sharpening experts

I am no expert, but I will parrot what Larrin says, Edge Geometry has a huge impact on edge retention.

It may be a of work but if you bring down your factory edge of 17dps to under 14dps you will notice a large improvement in edge retention regardless of steel.

Obviously, this is only one part of edge retention, but it is a big one.

It may be a of work but if you bring down your factory edge of 17dps to under 14dps you will notice a large improvement in edge retention regardless of steel.

Obviously, this is only one part of edge retention, but it is a big one.

Endura AUS-8, Manix 2 S30V, Manix 2 LW MagnaCut, BBB 15V Manix 2, BBB 15V Para 3 LW, Alcyone BD1N, PM2 Micarta Cruwear, Native 5 Maxamet (2nd), Para 3 Maxamet (2nd), Magnacut Mule, Z-Wear Mule, REC Para 3 10V, Pacific Salt SE H2, Dragon Fly SE H2, Chaparral SE XHP, Shaman Burlap S90V, Bodacious SPY27, Manix 2 LW 15v, Sage 5 REX-121 LW.

Re: Calling all sharpening experts

Thanks for the feedback.WilliamMunny wrote: ↑Mon Jun 23, 2025 9:09 amI am no expert, but I will parrot what Larrin says, Edge Geometry has a huge impact on edge retention.

It may be a of work but if you bring down your factory edge of 17dps to under 14dps you will notice a large improvement in edge retention regardless of steel.

Obviously, this is only one part of edge retention, but it is a big one.

I run most of my knives around 14dps, though I've observed this with various angles from 13dps-17dps. So I think something else is at play besides the geometry.

Re: Calling all sharpening experts

As someone who shaves with a straight razor, I will point out there's a lot of range in the term "shaving sharp". I think in this context what most people mean is "this can remove some hair on my arm" rather than "this is suitable for shaving a face". So it's possible some people are just getting their blades sharper, and that lasts a bit longer before they consider it no longer "shaving sharp".

Re: Calling all sharpening experts

Here's what I think is going on.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

- WilliamMunny

- Member

- Posts: 2073

- Joined: Fri Jan 29, 2021 12:20 pm

Re: Calling all sharpening experts

Great, explanation, you're going to want to copy that answer to save to use again later.vivi wrote: ↑Mon Jun 23, 2025 11:03 amHere's what I think is going on.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

I would love to see a test of H2 at 10dps vs Maxamet at 20dps to see which held an edge longer. It would be a great way to show the power of geometry.

I also wanted to add a really hard strop works well for me. I have had good results with just a 12 micron diamond solution I recently got, paired with my custom hard rolled horse hide strops I made. With light pressure the apex doesn’t sink into the leather.

Endura AUS-8, Manix 2 S30V, Manix 2 LW MagnaCut, BBB 15V Manix 2, BBB 15V Para 3 LW, Alcyone BD1N, PM2 Micarta Cruwear, Native 5 Maxamet (2nd), Para 3 Maxamet (2nd), Magnacut Mule, Z-Wear Mule, REC Para 3 10V, Pacific Salt SE H2, Dragon Fly SE H2, Chaparral SE XHP, Shaman Burlap S90V, Bodacious SPY27, Manix 2 LW 15v, Sage 5 REX-121 LW.

Re: Calling all sharpening experts

Killer post V...

-

Scandi Grind

- Member

- Posts: 1213

- Joined: Wed Apr 06, 2022 6:37 pm

Re: Calling all sharpening experts

I typically don't have a hair shaving edge after breaking down five cardboard boxes with my VG-10 Endura. This is running a 320 grit edge using a 12 degree angle guide as reference, which may end up closer to 14 dps because of the angle of the primary bevel which gets set on the angle wedge. My edges start out being able to shave my fine, whispy arm hair with very light pressure, but not quite "take every hair it touches off" sharp, although I have managed that going to finer grits.

At first losing shaving sharpness that fast was a bit of a bother to me, considering I could do the same with my old S&W pocket knife that cost less than half as much, but then I realized something, which is that I never have to shave arm hair with my knife. Don't get me wrong, I understand why the question is being posed, and I think Vivi has probably left little for anyone to add if you really want to get the best edge possible.

However, I also think there is a certain practicality to realizing that an edge can cut all sorts of things really well even if it doesn't shave hair. My Endura currently only shaves somewhere along the last third of the tip, but it still glides through plastic wrap without hanging up, breaks down cardboard dandy, cuts smoothly through thick plastic packaging, slices through vines and bush branches great, and probably will continue to do so for months. And it still slices paper no problem (but that isn't something I ever need to cut either...). So while I am always looking to improve my sharpening method, I'm OK with my edge not staying shaving sharp if it still cuts the things I that I actually need to cut well.

On a side note, I also have not found stropping to work particularly well for me in general, but my experimentation is limited. I have had some sucess stroping very few strokes on balsa charged with diamond paste, but I only use it under certain circumstances. I figure if I practiced on it enough, the fact that it isn't soft should prevent rounding the edge pretty well, but I don't usually do 3 micron polished edges, so I have little reason to use it.

Something that I have found of possible interest though, is that stroping on paper backed by a hard surface seems like it might actually help finish off an edge after you are done on stones. It doesn't seem to steal any bite from coarse edges, but feels like it just gets a very slightly keener edge. I'm not sure if this is a sign of a invisible burr being removed, but I do check for burrs under 60x magnification. Still, micro burrs seem like they kind of would have to exist even past the perception of that manification. If you apex an edge, and you don't end on a stone as fine as one atom, some kind of burr seems like it would have to exist, so maybe the paper is interacting with that. Needs more testing though to convince me it is actually having a beneficial effect.

At first losing shaving sharpness that fast was a bit of a bother to me, considering I could do the same with my old S&W pocket knife that cost less than half as much, but then I realized something, which is that I never have to shave arm hair with my knife. Don't get me wrong, I understand why the question is being posed, and I think Vivi has probably left little for anyone to add if you really want to get the best edge possible.

However, I also think there is a certain practicality to realizing that an edge can cut all sorts of things really well even if it doesn't shave hair. My Endura currently only shaves somewhere along the last third of the tip, but it still glides through plastic wrap without hanging up, breaks down cardboard dandy, cuts smoothly through thick plastic packaging, slices through vines and bush branches great, and probably will continue to do so for months. And it still slices paper no problem (but that isn't something I ever need to cut either...). So while I am always looking to improve my sharpening method, I'm OK with my edge not staying shaving sharp if it still cuts the things I that I actually need to cut well.

On a side note, I also have not found stropping to work particularly well for me in general, but my experimentation is limited. I have had some sucess stroping very few strokes on balsa charged with diamond paste, but I only use it under certain circumstances. I figure if I practiced on it enough, the fact that it isn't soft should prevent rounding the edge pretty well, but I don't usually do 3 micron polished edges, so I have little reason to use it.

Something that I have found of possible interest though, is that stroping on paper backed by a hard surface seems like it might actually help finish off an edge after you are done on stones. It doesn't seem to steal any bite from coarse edges, but feels like it just gets a very slightly keener edge. I'm not sure if this is a sign of a invisible burr being removed, but I do check for burrs under 60x magnification. Still, micro burrs seem like they kind of would have to exist even past the perception of that manification. If you apex an edge, and you don't end on a stone as fine as one atom, some kind of burr seems like it would have to exist, so maybe the paper is interacting with that. Needs more testing though to convince me it is actually having a beneficial effect.

Last edited by Scandi Grind on Mon Jun 23, 2025 7:55 pm, edited 1 time in total.

"A knifeless man is a lifeless man."

-- Old Norse proverb

-- Old Norse proverb

-

Scandi Grind

- Member

- Posts: 1213

- Joined: Wed Apr 06, 2022 6:37 pm

Re: Calling all sharpening experts

Double post.

"A knifeless man is a lifeless man."

-- Old Norse proverb

-- Old Norse proverb

Re: Calling all sharpening experts

Some people's language tends to lean toward the hyperbolic.

I get three or four good shaves off a razor blade.

Stone Age people could scrape hair off a buffalo hide with a rock.

Can you manscape with a rock? No.

Can you shave your face with the knife you've been using to cut cardboard? Yeah... I don't think so.

- Fastidiotus

- Member

- Posts: 403

- Joined: Fri Nov 17, 2023 1:56 pm

Re: Calling all sharpening experts

Not discounting anyone here, there's obviously a disparity in natural talent in all art forms. Coupled with education and practice others will always excel beyond their peers. We can all get better but we can't all get best. Give me a lifetime of bricks and blades and I seriously doubt I'm ever replicating Cliff's video. Sometimes though on other sites you have to wonder how much is true and how much of it is like Instagram baddies making normal girls wonder why their real unedited lives don't compare.

Comparison is always the thief of joy. I spent a lot of time and disappointment chasing hair whittling sharpness on every knife, every steel, every time thinking I was surely achieving peak performance. Only to find that a quick and dirty coarse edge on my users always seems to out perform them. Although I do still put a mirror polish edge on my BD1N UKPK just because its so easy and fun. The sharpest it can be, and what stays the sharpest the longest in day to day tasks seem to be paradoxically at odds in my experience. Just ask is my knife cutting how I like? If not, you get to play around with angles and grits and that's the fun of it all. If you've done your homework and you put in the time practicing, the only secret to sharpening is find the way that makes you enjoy it.

Re: Calling all sharpening experts

@vivi Wow, it is indeed the skill I lack. I don't consider myself good at sharpening, I can do quite decent job but I wouldn't be able to sharpen H1 so it lasts such task you showed in the video. After 15 years of sharpening freehand and on Sharpmaker I still have a lot to learn I see. Great post, thanks a lot for sharing!

- Paul Ardbeg

- Member

- Posts: 1476

- Joined: Sun May 14, 2023 11:39 am

- Location: The Netherlands, EU, Earth

Re: Calling all sharpening experts

@vivi Really appreciate the elaborate feedback, i'm learning a lot from you guys! Will be checking out some of the videos from Cliff Stamp tonight.

MNOSD member #0052

***Memento mori, memento vivere***

-

RugerNurse

- Member

- Posts: 970

- Joined: Thu Apr 20, 2023 10:11 am

Re: Calling all sharpening experts

There was a video from BBB awhile back where he talked about people thinking knives should be capable of more than what is reality. We want a magic steel that can chop a nail in half without chipping. I’m guilty of that myself.

Quid hoc ad aeternitatem

- Steeltoez83

- Member

- Posts: 728

- Joined: Sat Aug 01, 2020 8:51 am

Re: Calling all sharpening experts

In January of 2023 I cut tested H1. I tried everything I could think of to get higher edge retention numbers. From 1k down to 80 grit. Nothing seemed to work. At the time I was putting my tickets into a big pile, but gravitated towards a grid pattern for 3rd party optional verification. I do remember the BTE being lower on my Pac-Man than other spyders.

For test purposes I use the denomination of front end sharpness as a moving metric for being able to bounce back after a workload was bestowed on the edge. I keep a thread for anyone curious how my samples test out. I use a slice motion in my test cutting also. How that's applicable to every day users is beyond my scope of understanding. How my method compares to arm hair shaving-i dont have a clue either. There are many reasons to pick a specific steel over others. Maximizing enjoyment should be center stage, and the paralysis by analysis needs to drift away imo.

For test purposes I use the denomination of front end sharpness as a moving metric for being able to bounce back after a workload was bestowed on the edge. I keep a thread for anyone curious how my samples test out. I use a slice motion in my test cutting also. How that's applicable to every day users is beyond my scope of understanding. How my method compares to arm hair shaving-i dont have a clue either. There are many reasons to pick a specific steel over others. Maximizing enjoyment should be center stage, and the paralysis by analysis needs to drift away imo.

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

-

RugerNurse

- Member

- Posts: 970

- Joined: Thu Apr 20, 2023 10:11 am

Re: Calling all sharpening experts

My PD1 Endura needed some work so I tried a 300 grit stone only. Worked to remove the burr and I did strop it lightly. It was able to slice paper towel easily. All off 1 stone. Curious to see how it does with other stuff and retention.

Quid hoc ad aeternitatem

Re: Calling all sharpening experts

I feel like I have asked before, but I don't really remember your answer... How are you measuring your angles?vivi wrote: ↑Mon Jun 23, 2025 11:03 amHere's what I think is going on.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

Reason I ask is because when I sharpen to angles as acutely as you're talking about, those types of edges have practically no edge stability unless they're very hard. I confirm my edge angles with a laser goniometer, and I just can't help but think that there's some kind of discrepancy between what you measure as 10dps versus what I measure as 10dps, though it seems like you account for things like creating micro convexity at the apex that most people don't consider so I doubt it's anything that simple, but it just seems strange and completely outside of my own experience. If I passed something like 1095 at 58HRC through cardboard at 10dps, it's going to end up rolled over and dented. Sort of at such a small level that it could only be seen as glinting under strong light, but certainly enough to make it unable to shave anymore.

But I think I need to revisit such acute geometries with some new-found wisdom...

Personally I feel like my issues with this were burrs. There seems to be a little bit of an impossibility to actually detect the smallest of burrs. I mean yeah, q tips, cotton balls, trying to feel for them, some of them are small enough to slip past any of that. I have even resorted to visually confirming the absence of burrs under very high magnification--like 120x magnification. Yet even if I do all of this to rule out the presence of a burr, I will often end up with a wire edge that's hair whittling sharp but just disappears after a few cuts into cardboard, regardless of coarseness.

What I finally found made the difference for me was using a micro-bevel. And I mean microscopic. It's gotta be barely visible to the naked eye as a mere glint, and be applied with only a few strokes at an elevated angle. If it's as wide as a hair is thick it's too big. I think rather than it creating a stronger apex, it's just a way to fully remove the weak metal of a a wire edge after deburring, but while still leaving it thin enough that it's about as imperceptible to whatever it's cutting as it is to the eye.

It's only been since I started doing this that basically any steel at any angle has retained shaving-sharp refinement through a significant amount of cardboard. I have only been trying it recently so I kind of need to catch up with years of impressions of other steels and geometries. I have been primarily experimenting with very hard and carbide rich steel to make these observations recently, but I have noticed it seems to help even with modest steels like 14C28N or ARPM9. It's such a wild difference... It's like if I had been watching a TV through the protective film for years and just finally figured out I needed to peel it off.

Re: Calling all sharpening experts

I measure blade angles by pressing the edge down into a block of wax, clay, soap or similar and measuring the impression left by the knife edge. never got around to ordering a goniometer.Mage7 wrote: ↑Wed Jun 25, 2025 1:01 amI feel like I have asked before, but I don't really remember your answer... How are you measuring your angles?vivi wrote: ↑Mon Jun 23, 2025 11:03 amHere's what I think is going on.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

Reason I ask is because when I sharpen to angles as acutely as you're talking about, those types of edges have practically no edge stability unless they're very hard. I confirm my edge angles with a laser goniometer, and I just can't help but think that there's some kind of discrepancy between what you measure as 10dps versus what I measure as 10dps, though it seems like you account for things like creating micro convexity at the apex that most people don't consider so I doubt it's anything that simple, but it just seems strange and completely outside of my own experience. If I passed something like 1095 at 58HRC through cardboard at 10dps, it's going to end up rolled over and dented. Sort of at such a small level that it could only be seen as glinting under strong light, but certainly enough to make it unable to shave anymore.

But I think I need to revisit such acute geometries with some new-found wisdom...

Personally I feel like my issues with this were burrs. There seems to be a little bit of an impossibility to actually detect the smallest of burrs. I mean yeah, q tips, cotton balls, trying to feel for them, some of them are small enough to slip past any of that. I have even resorted to visually confirming the absence of burrs under very high magnification--like 120x magnification. Yet even if I do all of this to rule out the presence of a burr, I will often end up with a wire edge that's hair whittling sharp but just disappears after a few cuts into cardboard, regardless of coarseness.

What I finally found made the difference for me was using a micro-bevel. And I mean microscopic. It's gotta be barely visible to the naked eye as a mere glint, and be applied with only a few strokes at an elevated angle. If it's as wide as a hair is thick it's too big. I think rather than it creating a stronger apex, it's just a way to fully remove the weak metal of a a wire edge after deburring, but while still leaving it thin enough that it's about as imperceptible to whatever it's cutting as it is to the eye.

It's only been since I started doing this that basically any steel at any angle has retained shaving-sharp refinement through a significant amount of cardboard. I have only been trying it recently so I kind of need to catch up with years of impressions of other steels and geometries. I have been primarily experimenting with very hard and carbide rich steel to make these observations recently, but I have noticed it seems to help even with modest steels like 14C28N or ARPM9. It's such a wild difference... It's like if I had been watching a TV through the protective film for years and just finally figured out I needed to peel it off.

Your experience with cardboard is very different than mine. I feel 100% confident I could reprofile a brand new full flat ground vg10 endura to 9 degrees per side using a guided system to ensure no convexity, and slice cardboard without any issues.

Something to keep in mind is cardboard varies a lot,more than arm hair probably. Single wall, double wall, triple wall....how heavily adhesive was applied to it, staples, and especially....how dirty is it?

either way, check out this post.

That was an M4 Native Chief sharpened to about 12 degrees per side initially then touched up at 15dps, still shaved sfter slicing up multiple very large triple walled pumpkin boxes.vivi wrote: ↑Fri Oct 20, 2023 1:07 pmYou know those thick cardboard bins 3 corrugated layers deep they ship pumpkins in? Broke down a few of those today with my Chief that we had in our back lot from a recent pumpkin carving competition.

Still scrape shaves despite using a pretty coarse finish and dulling it some since sharpening it.

What you describe as a microbevel is a real microbevel. A lot of folks that think they are using one are just using a compound bevel, going by pictures I've seen. Applying a microbevel is how you describe. For example, set a 10dps edge on a bench stone, and refine it until it shaves and you can't detect a burr. Then do exactly one stroke per side on the sharpmaker with very light pressure.

This does a few beneficial things. Like you observed it makes deburring much easier. It strengthens the weakest part of the knife blade, the apex. it also speeds up touching up the knife. If you don't go crazy doing a lot of strokes, you can touch up the knife a couple times using the microbevel angle before needing to reset the edge. If we use our example 10/15dps edge until it stops shaving, we can bring it back with a mere two strokes per side on medium rods at the 15dps microbevel angle without cutting performance suffering a noticeable amount. Of course after doing this a few times cutting ability will be affected, and that's when the bevel is reset to remove the microbevel.

One of the reasons I'm not wild about strops is I have a hunch they can be more or less bending burrs into a wire edge rather than cutting off steel and forming a crisp, strong V. I think strops may be applying edges to knives that are similar to when you bend a paperclip back and forth a few times. It'll be hard and sharp to the touch but using that edge will dull the knife pretty quickly. While grinding the edge off a stone instead of stropping it just cuts that steel off and exposes fresh steel. Like I said, just my hunch, I haven't done any serious controlled experiments with these thoughts.

- WilliamMunny

- Member

- Posts: 2073

- Joined: Fri Jan 29, 2021 12:20 pm

Re: Calling all sharpening experts

Strop question: What if you are using a diamond compound, like Gunny Juice on a strop? Would this not act the same as a fine stone? I have even seen compounds used own wood, like a paint mixing stick, that has little or no give, but the diamond compound embeds itself into the wood, much like a very stiff leather strop.vivi wrote: ↑Fri Oct 20, 2023 1:07 pmOne of the reasons I'm not wild about strops is I have a hunch they can be more or less bending burrs into a wire edge rather than cutting off steel and forming a crisp, strong V. I think strops may be applying edges to knives that are similar to when you bend a paperclip back and forth a few times. It'll be hard and sharp to the touch but using that edge will dull the knife pretty quickly. While grinding the edge off a stone instead of stropping it just cuts that steel off and exposes fresh steel. Like I said, just my hunch, I haven't done any serious controlled experiments with these thoughts.

It was always my understanding that the advantage of a strop was sharpening trailing edge as sharpening edge first develops more of a burr. Not that you can't do this on a stone.

Generally, start with a very sharp knife, when it starts to dull, I use a loaded strop to bring the edge back. After a few times when the knife is too dull for a strop to bring the edge back I then go to my Sharpmaker to make a micro bevel as you described. Once even the Sharpmaker can't really bring the edge back I go to my fixed system and start over resetting the edge. Years ago, every time I needed to sharpen my knife I would free hand it and nice stones. Worked great but it would shorten the knife's life as it just off way too much steel as it only needed a touch up, I know better now.

Endura AUS-8, Manix 2 S30V, Manix 2 LW MagnaCut, BBB 15V Manix 2, BBB 15V Para 3 LW, Alcyone BD1N, PM2 Micarta Cruwear, Native 5 Maxamet (2nd), Para 3 Maxamet (2nd), Magnacut Mule, Z-Wear Mule, REC Para 3 10V, Pacific Salt SE H2, Dragon Fly SE H2, Chaparral SE XHP, Shaman Burlap S90V, Bodacious SPY27, Manix 2 LW 15v, Sage 5 REX-121 LW.

- jasonstone20

- Member

- Posts: 111

- Joined: Tue Jan 06, 2015 5:29 pm

- Location: Portland, OR

Re: Calling all sharpening experts

I agree with Vivi, these are usually the main culprits of edges having poor edge retention.

One thing I would like to point out is that a coarse edge (#325 Diamond, Fine India) can get tree-topping arm hair sharp with sharpening proper technique. A few techniques that are extremely helpful are:

1) Crossing the scratch pattern: angle the knife at 45* on the stone, ei instead of pointing the point of the knife to the opposite edge of the stone, where the knife is perpendicular to the length of the stone, point the knife to the corner of the stone, so the knife edge is diagnol to the stone.

2) Micro-bevels: Use this to remove the burr and clean up the edge, use five very light passes per side.

3) Backsharpening: After micro-beveling, you can use five very light alternating passes to reset the edge angle to the original angle

4) Use Ultra-High Passes: Use one pass per-side, at an angle at >45* like at 65* to 75*, then backsharpen to the original angle

5) Use Super-Short Passes: When finally setting the edge bevel, use 5 alternating passes per side, super short, as in 1" inch long in length.

6) Use Magnification: When having a sharpening issue or problem, almost all of them can be solved with looking at the edge under magnification, I recommend having optics in the range of 10X, 30X and 90X, as well as a digital microscope, preferably one with a base so you don't have to hold the microscope and the knife, you can set the knife down and make adjustments to the knife position and to the microscopes focus and magnification. The one I found the most useful and easy to use and set up is $35 on Amazon: Elikliv 3.4" LCD Screen Digital Microscope

One thing I would like to point out is that a coarse edge (#325 Diamond, Fine India) can get tree-topping arm hair sharp with sharpening proper technique. A few techniques that are extremely helpful are:

1) Crossing the scratch pattern: angle the knife at 45* on the stone, ei instead of pointing the point of the knife to the opposite edge of the stone, where the knife is perpendicular to the length of the stone, point the knife to the corner of the stone, so the knife edge is diagnol to the stone.

2) Micro-bevels: Use this to remove the burr and clean up the edge, use five very light passes per side.

3) Backsharpening: After micro-beveling, you can use five very light alternating passes to reset the edge angle to the original angle

4) Use Ultra-High Passes: Use one pass per-side, at an angle at >45* like at 65* to 75*, then backsharpen to the original angle

5) Use Super-Short Passes: When finally setting the edge bevel, use 5 alternating passes per side, super short, as in 1" inch long in length.

6) Use Magnification: When having a sharpening issue or problem, almost all of them can be solved with looking at the edge under magnification, I recommend having optics in the range of 10X, 30X and 90X, as well as a digital microscope, preferably one with a base so you don't have to hold the microscope and the knife, you can set the knife down and make adjustments to the knife position and to the microscopes focus and magnification. The one I found the most useful and easy to use and set up is $35 on Amazon: Elikliv 3.4" LCD Screen Digital Microscope

vivi wrote: ↑Mon Jun 23, 2025 11:03 amHere's what I think is going on.

1. People use stupid geometries for their knives, to be blunt.

Cliff Stamp used to advocate for knife users to find their own optimal edge angle. His method was simple. Keep sharpening a given knife or cutting tool thinner and thinner, until the edge starts to fail while being used for the intended purpose of the tool. Sharpen it a degree or two thicker than the failure angle, or utilize a microbevel. I'm not aware of anyone here that does that.

I did do this. I found for my uses I could go below 10 degrees per side without a microbevel on VG10 & S30V & 8Cr Byrds and Spydercos and be totally fine cutting food, rope, cardboard etc. I did see some very, very minor chipping or rolling something when carving knotty seasoned wood, which led me to utilize microbevels. I've posted a zdp189 caly jr I reprofiled to full convex zero grind where this happened.

So when I talk about running 10-12 dps edges, despite those edges being twice as thin as the angle some people use, that's actually a good bit thicker than I need. I chose 10-12dps because it's quicker to apply than 8dps and gives me a little wiggle room in case of accidents. Chips aren't very severe even when I do something like accidentally chop into a rock while clearing briars from a camp site with my voyager xl.

17 degrees per side on a pocket knife is really inefficient and I simply can't fathom dropping hundreds to thousands on high performance knives and keeping the training wheels on. I've used this analogy a lot but to me it's like buying a nice sports car and keeping the tires at 20psi and running standard gas. It's leaving a lot of performance on the table for no good reason.

2. Burrs.

I think a lot of folks are leaving burrs on their knives when they sharpen them and they don't realize it. A freshly sharpened edge should feel completely the same on both sides if you run your thumb from spine to edge, it shouldn't catch your skin more on either side. You can do the same thing with a q tip, a strop or your pants and feel for a difference. I'm guilty of this too. Sometimes I'll do a quick touch up with my sharpmaker before I head out, and later on when I have my knife out for a job I'll check the edge and realize there's still a burr. You always want to finish with the lightest touch you can while still maintaining consistent contact with your sharpening media. I also suggest edge leading strokes because those produce less of a burr in my experience.

3. Over refinement

Most people run polished edges. The more polished an edge is, the worse the edge retention will be. 6,000 grit edges don't hold shaving sharpness any longer than 300 grit edges when slicing cardboard in my experience, and sometimes the opposite can even be true. Many folks have no idea what they're doing when they choose an edge for their knife. Lots of folks using 17-20dps high polish edges to slice cardboard with a 3" knife, which is really dumb. 10dps with a toothy edge would be at least twice as efficient with 4x the edge retention.

4. Using strops as a crutch

Many people are guilty of this one. Strops do two things that reduce edge retention: they thicken the apex by rounding it, and they polish away microserrations that aid in slicing edge retention. I have consistently found over the decades that my edges off stones last longer than my edges off strops. If I take two indentical knives sharpened the same way and dull them so they don't shave, then bring their edges back to equal feeling sharpness with a strop on the first and a fine ceramic stone on the latter, the second will outcut the first. That has been my experience.

5. Different standards

zhylas post is good. I use straight razors too, and even a razor that can catch hairs without contacting the skin can produce an uncomfortable shave. Personally, when I talk about a knife being able to shave, I mean it can remove hairs from my arm without significant pressure or having to use a certain technique. scrape shaving is the term I use for an edge that is barely able to remove arm hairs under any circumstance. clean shaving is one that'll effortlessly shave a patch with minimum pressure. hair whittling sharpness is just how it sounds - which is pretty much the minimum level of sharpness required for a truly comfortable shave.

Add to that the wide variety of hair thickness, oil content, racial differences etc., and it's a poor way to compare our edges honestly. BESS testers are a little better but not so great as measuring slicing sharpness, they're better for push cut sharpness testing.

6. Carelessness

People aren't always careful with their tools. In the thread about people breaking their pocket knife tips, a few people commented about slicing a material then banging their knife tip into a countertop or something. Why would you do that? I think everyone here is aware of the things that typically damages a knife edge, and the ways they can be damaged. Chop into metal or rocks, expect a chip. Cut into a staple in a box, expect a chip or roll. Slice a bone, expect a rolled edge. So.....here's an idea....don't do those things. Check for staples before breaking down boxes. Use thinner, sharper edges that require less force so you can control where your knife goes. never put a knife in a sink or dishwasher, period. scrape with the spine instead of the edge. don't pry. etc.

It's all about choosing the right edge. Go as thin as is practical for the tool, then optimize the grit based on how you're using it. Are you primarily slicing or push cutting? Most knife uses are slices, including cutting cardboard, so toothy makes more sense usually.

I could go even thinner on a Pacific Salt, and also regrind it to full flat on my belt sander, and make the one used in that video look like garbage.

"Gotta love living in 2019 baby, (63rc too soft on a production knife)"

--Shawn Houston

"I am still discussing issues of steels and performance at this stage."

--Cliff Stamp, May his memory be a blessing

"Cause geometry cuts, .....steel determines the level and the duration"

--Roman Landes

"Life is GOOD!"

--Stefan Wolf, May his memory be a blessing

--Ken Schwartz, May his memory be a blessing

"But in general, I'm all about high performance, Ergos, safety. That's why I've been accused of 'designing in the dark' "

--Sal Glesser

--Shawn Houston

"I am still discussing issues of steels and performance at this stage."

--Cliff Stamp, May his memory be a blessing

"Cause geometry cuts, .....steel determines the level and the duration"

--Roman Landes

"Life is GOOD!"

--Stefan Wolf, May his memory be a blessing

--Ken Schwartz, May his memory be a blessing

"But in general, I'm all about high performance, Ergos, safety. That's why I've been accused of 'designing in the dark' "

--Sal Glesser