I use a Tormek T-8 and multiple methods via the tools that work with it. I feel pretty confident that I can say I get within 1-2 DPS precision which I feel is good enough.Deadboxhero wrote: ↑Thu Aug 24, 2023 9:22 pmWhat do you use?Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 7:29 pm

Are you certain of the edge angle? How exactly are you measuring the angle?

“Best” steels video with Larrin

- Traditional.Sharpening

- Member

- Posts: 285

- Joined: Thu Mar 02, 2023 12:29 am

Re: “Best” steels video with Larrin

- Deadboxhero

- Member

- Posts: 2178

- Joined: Tue Mar 01, 2016 4:35 am

- Contact:

Re: “Best” steels video with Larrin

Right on,Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 9:33 pmI use a Tormek T-8 and multiple methods via the tools that work with it. I feel pretty confident that I can say I get within 1-2 DPS precision which I feel is good enough.Deadboxhero wrote: ↑Thu Aug 24, 2023 9:22 pmWhat do you use?Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 7:29 pm

Are you certain of the edge angle? How exactly are you measuring the angle?

Some real talk for the other readers here. Not trying to offend anybody. Just sharing my experience.

Edge angles are not universal between all sharpeners.

Let me explain.

Sometimes, there can be some hidden convexity towards the apex *not the shoulder* that we can only see with a laser goniometer (if we could recognize the reflection pattern) or with a reflected light microscope looking at the side of the edge at the right angle.

Just because we aren't aware of it doesn't mean it doesn't have a vast effect on the differences in performance.

I find that hidden convexity is one of the biggest reasons why it's difficult for us all to be on the same page in the edge community when we talk about angles and specific properties of exact angles.

When we say convexity people only think about the convexity they can see at the shoulder not the convexity they can't see towards the apex.

If one person's 15° per side is hiding more convexity It's no secret that thicker geometry will always naturally create more durability then a less convex geometry. This is also at a consequence to the cutting edge retention and cutting ability.

Cutting ability and durability are completely inverse relationship.

So, there will be stark differences between a free hand convex ~15°, a jig system with flat stones ~15° and a wheel which creates a ~15° hollow bevel. Not including the deburring method which will also inherently always add some level of convexity at different degrees depending on the method, user skill along with the steel and HT itself.

Yes, we can have three people holding 15° per side but with widely varying levels of convexity hiding towards the apex, Yes, this can greatly depend on the sharpening method along with the deburring method.

This is why we have such widely varying experiences with durability and cutting ability, Even if everyone is supposedly holding the same angle.

So just saying what edge angle you're using is not universal? Yes, that will really depend on the method used and the tools used to objectively measure it, It is beyond using experience and instinct.

The reason why this concept is so important is because if we are trying to see differences between steel and heat treatment, geometry has to be ruled out first.

Because it's geometry, that is the most significant factor for cutting ability and durability.

Re: “Best” steels video with Larrin

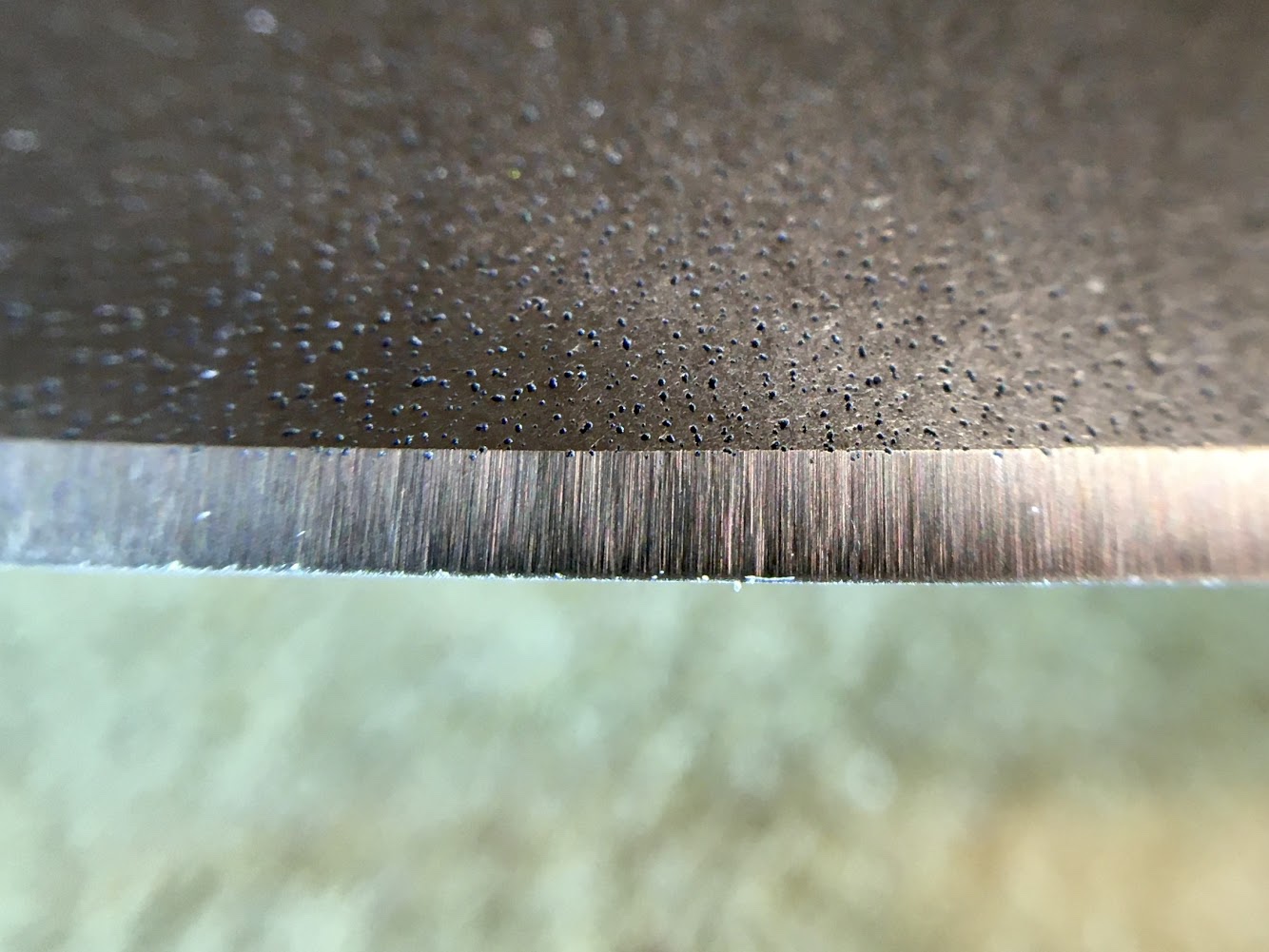

Triple B! Perhaps you know the answer - do you know why some of the 15V knives from seconds sale have little dots on them? Speckled, like a dusting of pepper.

Re: “Best” steels video with Larrin

I think it’s cool that talking about edge angles can be a shared interest on a forum like this.

Anyway, I just remembered that I thinned and convexed some old traditional knives I have. Thin stock, thin convex, and a small swedge, make for some nice cutting performance in a 2.5 inch blade. Not sure exactly how thin, but I could probably go thinner.

The serrated Z-cut does cut very well. So does the serrated blade in the CLIPITOOL Rescue.

One of the reasons I like Spyderco’s serrations is the lower inclusive edge angle from the factory.

It’s literally “halved” because of the chisel grind.

All of Spyderco’s edges seem to be that “hollow bevel”, which is something to keep in mind, like BBB is saying.

Some of my serrated Spydercos had or have bevels big enough to actually feel the hollow with my finger tip.

Even if you don’t change the factory angle, the edge you put on freehand or with guided flat stones will be significantly different from the factory edge geometry.

Anyway, I just remembered that I thinned and convexed some old traditional knives I have. Thin stock, thin convex, and a small swedge, make for some nice cutting performance in a 2.5 inch blade. Not sure exactly how thin, but I could probably go thinner.

The serrated Z-cut does cut very well. So does the serrated blade in the CLIPITOOL Rescue.

One of the reasons I like Spyderco’s serrations is the lower inclusive edge angle from the factory.

It’s literally “halved” because of the chisel grind.

All of Spyderco’s edges seem to be that “hollow bevel”, which is something to keep in mind, like BBB is saying.

Some of my serrated Spydercos had or have bevels big enough to actually feel the hollow with my finger tip.

Even if you don’t change the factory angle, the edge you put on freehand or with guided flat stones will be significantly different from the factory edge geometry.

rex121 is the king of steel, but nature’s teeth have been cutting for hundreds of millions of years and counting :cool:

- Deadboxhero

- Member

- Posts: 2178

- Joined: Tue Mar 01, 2016 4:35 am

- Contact:

Re: “Best” steels video with Larrin

First off,

It's not something unique to 15V or linked to HT.

It appears to be some type of error or artifact that may have occurred during stone washing but I'm simply speculating and could be wrong.

As to why it happened, I have no idea, I wasn't there to see what happened.

I think if cosmetic concerns are important, one should never, ever, ever buy a factory second.

Just slap an edge on it and use it up.imho

Re: “Best” steels video with Larrin

I just take a measurement of how high off the stone the spine is and use some trigonometry to work the angle out, but as Deadboxhero said, I'm sure there's probably some level of convexity since I don't use a jig or anything. I've still not got around to buying a laser goniometer to see what kind of tolerances I'm holding, but considering that most of the ones I've seen are advertised to measure within a +/- 2 degree tolerance, I don't assume I'm doing any better than that. So for example, if I hold the knife at what is supposed to be an 8 degree angle, I assume that I might have a very slight 10 degree micro-bevel on the very apex after I get done deburring. Generally speaking, though, I tend to try to visually confirm that I have not done that with a 160x pocket scope, so if I do leave a micro-bevel (which is probable) it's very micro.Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 7:29 pmAre you certain of the edge angle? How exactly are you measuring the angle? It can be difficult to get an accurate measure of this depending on how you are going about it. Did you measure the thickness behind the edge prior to working on it? I'd wager it was pretty thick there to start with and reprofiling made it worse plus every time you had to regrind the edge.

If the knife thickens out then you simply apply a transition bevel at the 'shoulder' where the primary/secondary grinds meet splitting the difference between the two. This is not terribly difficult or time consuming and can even be blended into a convex shape to improve cutting ability and reduce force applied to knife/apex.

Yeah, I have applied such a transition bevel to it several times over the years--we're talking around ten years and I don't know how many dozens of re-profiles. Amazingly, I had the foresight to write the thickness behind the edge when I first got it all those years ago, and even managed to remember where I put it. It was .027". I also added a transition bevel like you mentioned, and also blended into a convex long ago, so it's actually sitting at .025" at the ~15dps microbevel that's on it now. But if I measure at that point where the primary grind blends into that convex, it's more like .050".

Obviously I have heavily modified the spine and tip (was going for a mini-Nesmuk thing after I got overzealous grinding in a right angle on the spine to strike Ferro rods), so it's kind of hard to get an idea of how much I've reduced the width of the blade, but if you look at the plunge line on both knives it's pretty evident how much of the original blade I've ground off over time--basically enough to delete the choil. Even with the transitional bevel having thinned things down a bit, it's really not as slicey as it once was.

The thickness behind the ~10dps bevel on the unmodified 440C version is .030", and right behind the ~15dps microbevel it's .007". However, on the modified 1095 version, it's already at .030" halfway up the convex transitional bevel, and is .015" thick behind the microbevel.

Even now, with its current geometry, the edge apex has rolled on stuff like pressure treated wood. Also worth mentioning the bamboo I tested with was very dry and weathered. It was basically a worst case scenario kind of test case.

- Traditional.Sharpening

- Member

- Posts: 285

- Joined: Thu Mar 02, 2023 12:29 am

Re: “Best” steels video with Larrin

You are absolutely correct.Deadboxhero wrote: ↑Thu Aug 24, 2023 11:27 pmRight on,Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 9:33 pmI use a Tormek T-8 and multiple methods via the tools that work with it. I feel pretty confident that I can say I get within 1-2 DPS precision which I feel is good enough.Deadboxhero wrote: ↑Thu Aug 24, 2023 9:22 pmWhat do you use?Traditional.Sharpening wrote: ↑Thu Aug 24, 2023 7:29 pm

Are you certain of the edge angle? How exactly are you measuring the angle?

Some real talk for the other readers here. Not trying to offend anybody. Just sharing my experience.

Edge angles are not universal between all sharpeners.

Let me explain.

This is why I do not care for stropping or any sort of edge trailing passes on stones, etc. as I feel that the final step in the sharpening process where you bring out ultra sharpness is critical in regards to angle. I don't want to add a huge amount of micro bevel unless I actually intend to do this to support the apex for some reason. A lot of people will use the leather or composite honing wheels on the Tormek and I have never even used the one that came with my T-8. It hasn't even been oiled or loaded with abrasive. I have never mounted it and will likely keep it this way moving forward.

The reason being is that I prefer to simply elevate the angle by around 1 DPS and use very light passes and alternate sides for a few strokes to minimize the burr to a large degree. Then I turn off the machine (I have this tied to a surge protector and/or wall switch where I can be certain that no power will accidentally be fed to the machine and have an 'associate' of mine turn the drive wheel by hand very slowly, as in as slow as they can without having the wheel stop when I touch the blade to the stone. Alternating passes until the edge will shave very easily in both directions at the barest touch and pops hairs.

Re: “Best” steels video with Larrin

wise words from BBB and traditional.sharpening on this last page.

Kennbr34, I'll have to post my Izula to this thread at some point. My bevel is definitely wider than yours. I may have some convex edge action going on as BBB went into detail about, but I will definitely test mine on some local bamboo at some point.

Question - was it green bamboo or seasoned? I have both available.

Kennbr34, I'll have to post my Izula to this thread at some point. My bevel is definitely wider than yours. I may have some convex edge action going on as BBB went into detail about, but I will definitely test mine on some local bamboo at some point.

Question - was it green bamboo or seasoned? I have both available.

- Traditional.Sharpening

- Member

- Posts: 285

- Joined: Thu Mar 02, 2023 12:29 am

Re: “Best” steels video with Larrin

That was my suspicion and it would also not surprise met if it were rather small diameter pieces you were cutting, which actually really ramp up the pressure applied to the edge due to small contact area concentrating forces. I have some poles taken from the patch of bamboo at a relatives property and it's been seasoning in the garage for years now.

That is some seriously hard stuff at this point and with all the knots along the length combined with how thin it gets at the tip of the growth... it's not something I'd ever want to cut. My first wood cutting board was bamboo.... I had a bit of 'Little Did He Know' going on at that point in my knife journey. Didn't even bother sharpening the Farberware knife I used on it lol.

Re: “Best” steels video with Larrin

It looks like steel pitting and it happens also on my Maxamet blades.

8Cr13MoV:N690Co:VG10:S30V:S35VN:S45VN:Elmax:SPY27:H1:LC200N:4V:MagnaCut:CTS-XHP:204P:M390:20CV:Cru-Wear:Z-Wear:M4:Rex-45:10V:K390:15V:S90V:Z-Max:Maxamet

Re: “Best” steels video with Larrin

Yes, I usually grab seconds to either try something I'm not sure I'll like, or for users. For example, I'm a lefty, but I've never had a left-handed knife, so I picked up the lefty PM2 this seconds sale. Turns out, it makes me irrationally happy to fidget with a left handed knife! I think seconds are the perfect opportunity to really put a knife through the works. Thanks for the info.Deadboxhero wrote: ↑Fri Aug 25, 2023 12:08 amI think if cosmetic concerns are important, one should never, ever, ever buy a factory second.

Just slap an edge on it and use it up.imho

Re: “Best” steels video with Larrin

This. So much this.

I don't doubt it when people in this forum claim that LC200N can equal or even surpass S30V in edge-holding, but I think what's happening is that the ease of sharpening of LC200N means they are getting more consistent, and quite possibly more acute, edges on their LC200N knives compared to what they can get sharpening S30V. I think this is also what accounts for reports of H1's real-world performance far exceeding what its composition predicts on paper.

I have been able to get screaming-sharp, acute edges (~12°) on my Caribbean (LC200N) & my Lil' Temperance 3 Lightweight (VG10) with relative ease, and yes, I would say that their real-world edge-holding performance parallels or even exceeds that of my Sage 5 Lightweight in S30V that I keep at 20°. But I know that it's the geometry that gives them an edge (literally). If all things were equal geometry-wise, I don't doubt that their performances would rank the way Larrin's chart predicts, with S30V on top followed by VG10 & LC200N in third.

- salimoneus

- Member

- Posts: 361

- Joined: Sat Aug 13, 2011 8:52 pm

- Location: Colorado

Re: “Best” steels video with Larrin

That is absolutely not good in any way shape or form. Those air pockets are likely there throughout the entire blade stock, not just on the surface. They don't just appear during sharpening. I would be highly suspect of the durability of any blade that looks like that. Someone else said they have seen it on Maxamet blades, which could explain the very high rate of failure on those knives.

That being said, there's a reason some knives are sold as "seconds", usually not passing QC or having been returned due to defects. Sometimes you get a lot less than what you pay for with seconds.

That particular blade belongs in one and one one place, which is the recycle bin.

- dull&blunt

- Member

- Posts: 123

- Joined: Thu Mar 02, 2023 8:37 am

- Location: not too sharp nor pointy

Re: “Best” steels video with Larrin

^That's interesting. I recently got a Sage 1 in Maxamet in the seconds sale. the blade has only 3 tiny specs on it in a grouping.

I figured it was only on the surface, possibly a mistake during the finishing of the blade. But you believe such defects are homologous throughout the entire blade? That would seem to go against the Second's Sale policy of a safe/useable knife, if they're as brittle as ya are claiming.

I figured it was only on the surface, possibly a mistake during the finishing of the blade. But you believe such defects are homologous throughout the entire blade? That would seem to go against the Second's Sale policy of a safe/useable knife, if they're as brittle as ya are claiming.

Re: “Best” steels video with Larrin

I'm no metallurgist, but here's my 2 cents worth: I wouldn't worry too much about the bubbles being throughout the whole blade until I examined it more closely. If they are present in the bevel and/or along the spine, then I might relegate the knife to the pure-user category. Otherwise I'd ignore them.dull&blunt wrote: ↑Tue Aug 29, 2023 5:13 pm^That's interesting. I recently got a Sage 1 in Maxamet in the seconds sale. the blade has only 3 tiny specs on it in a grouping.

I figured it was only on the surface, possibly a mistake during the finishing of the blade. But you believe such defects are homologous throughout the entire blade? That would seem to go against the Second's Sale policy of a safe/useable knife, if they're as brittle as ya are claiming.

I predict the bubbles are not in the bevel or along the spine. What say ye?

- Deadboxhero

- Member

- Posts: 2178

- Joined: Tue Mar 01, 2016 4:35 am

- Contact:

Re: “Best” steels video with Larrin

This is the problem with forums, they rely on people that have the knowledge to dispute with people that spout nonsense.

If nobody disputes an outrageous claim or controversy then it must be true.

However, in some cases the people that have the information to shine some light on the subject are sometimes too exhausted and don't want to argue with nonsense. It can also be too confrontational and a waste of finite energy.

No,

there are no bubbles in the steel.

Most likely cause is a finishing error which led to some pitting with the most likely cause being a mistake happening somehow in tumbling.

Exact details? Unknown, none of us here were there.

That doesn't mean we get to make things up.

What is the exact cause of the pitting on that knife? How does this happen?

Don't know. I wasn't there. Sometimes you just have to be okay with not knowing.

Yes, it is an uncomfortable feeling to not have all the answers. Yes, it is natural for everyone to want to fill in the blanks to comfort themselves and others but the feelings of uncomfort from living in with the unknown should never overpower reality and truth.

Keep in mind, these aren't made one by one. They are made in very large batches, so mistakes in finishing can happen. A factory second by definition is a knife that is not up to QC standards that don't effect critical function.

No, pitting does not go through the entire blade, It doesn't take "rocket surgeon" to see that the edge bevel doesn't have holes.

No, not all the factory second knives had this finishing error.

No, none of the knives that were sold at major retailers had this issue.

No, It's not the heat treat or something Inherently connected specifically to this particular steel.

Yes, 15V is NOT a stainless steel so it will be more prone to corrosion and pitting like all carbon PM tool steels, It is a trade-off for the monster edge retention and ease of sharpening we can achieve.

Yes, use it, sharpen it, cut stuff with it, get it dirty then sharpen it again and again. Knives are meant to be used and sharpened away. If the finish isn't great then you got a free pass to use it up because when you use a knife, the finish is going to get run down regardless.

Yes, factory second is not a good representation of a fully finished product as it was intended to be in finish and presentation.

If nobody disputes an outrageous claim or controversy then it must be true.

However, in some cases the people that have the information to shine some light on the subject are sometimes too exhausted and don't want to argue with nonsense. It can also be too confrontational and a waste of finite energy.

No,

there are no bubbles in the steel.

Most likely cause is a finishing error which led to some pitting with the most likely cause being a mistake happening somehow in tumbling.

Exact details? Unknown, none of us here were there.

That doesn't mean we get to make things up.

What is the exact cause of the pitting on that knife? How does this happen?

Don't know. I wasn't there. Sometimes you just have to be okay with not knowing.

Yes, it is an uncomfortable feeling to not have all the answers. Yes, it is natural for everyone to want to fill in the blanks to comfort themselves and others but the feelings of uncomfort from living in with the unknown should never overpower reality and truth.

Keep in mind, these aren't made one by one. They are made in very large batches, so mistakes in finishing can happen. A factory second by definition is a knife that is not up to QC standards that don't effect critical function.

No, pitting does not go through the entire blade, It doesn't take "rocket surgeon" to see that the edge bevel doesn't have holes.

No, not all the factory second knives had this finishing error.

No, none of the knives that were sold at major retailers had this issue.

No, It's not the heat treat or something Inherently connected specifically to this particular steel.

Yes, 15V is NOT a stainless steel so it will be more prone to corrosion and pitting like all carbon PM tool steels, It is a trade-off for the monster edge retention and ease of sharpening we can achieve.

Yes, use it, sharpen it, cut stuff with it, get it dirty then sharpen it again and again. Knives are meant to be used and sharpened away. If the finish isn't great then you got a free pass to use it up because when you use a knife, the finish is going to get run down regardless.

Yes, factory second is not a good representation of a fully finished product as it was intended to be in finish and presentation.

Re: “Best” steels video with Larrin

Awesome thread. Some great info in here. Makes me want to go sharpen something.

Re: “Best” steels video with Larrin

I had a Manix with three marks on the show side close to the top of the blade. I think it is a mark from some type of device that holds the blade while they are working on it.dull&blunt wrote: ↑Tue Aug 29, 2023 5:13 pm^That's interesting. I recently got a Sage 1 in Maxamet in the seconds sale. the blade has only 3 tiny specs on it in a grouping.

I figured it was only on the surface, possibly a mistake during the finishing of the blade. But you believe such defects are homologous throughout the entire blade? That would seem to go against the Second's Sale policy of a safe/useable knife, if they're as brittle as ya are claiming.

Lc200n, s90v, magnacut, 20v, 204p, cruwear, s110v, 15v, cts-xhp

- Josh Crutchley

- Member

- Posts: 1395

- Joined: Wed Sep 30, 2020 2:44 am

- Location: Michigan

Re: “Best” steels video with Larrin

Here's a post showing the same issue on a Maxamet blade. You can see the voids stop just below the bevel transition.Coastal wrote: ↑Tue Aug 29, 2023 5:34 pm

I'm no metallurgist, but here's my 2 cents worth: I wouldn't worry too much about the bubbles being throughout the whole blade until I examined it more closely. If they are present in the bevel and/or along the spine, then I might relegate the knife to the pure-user category. Otherwise I'd ignore them.

I predict the bubbles are not in the bevel or along the spine. What say ye?

spoonrobot wrote: ↑Thu Apr 29, 2021 3:38 pmMaxamet does seem to have a propensity to have little tiny pits, this is from a new PM2. Pics are from a clip on macro lens, maybe 10x. The pitting is visible to the naked eye, which is why I looked closer.