Wartstein wrote: ↑Fri May 05, 2023 11:36 pm

Pretty obvious, said often already, but I still want to make clear:

When wishing for more thin(ner) blade stock, of course it is clear that this just one of several factors that (can) enhance the cutting/slicing performance of a folder.

Grind angle, thickness behind the edge, blade height, tapering, "sharpness", and so on are important factors too.

Slicing is the sum of everything you put into a blade. All other things being equal, thicker blade stock is going to make a thicker wedge to push through material. If you managed to make a blade just 1 atom thick, it would still slice better if you managed to make it 0.5 atom thick.

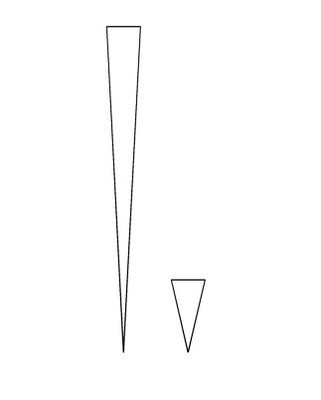

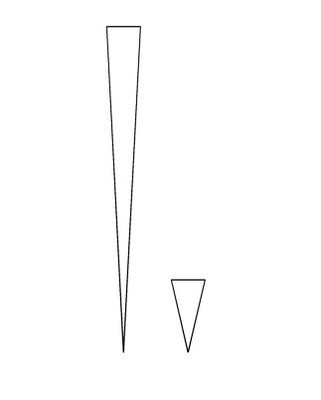

Blade height also has a huge impact on all this, which this pic should illustrate. Both wedges are the same "blade stock thickness" at the top and both are perfectly flat or "full flat grind" but it's not hard to imagine which is going to slice better.

Still, the problem of stock thickness still becomes an issue when material is rigid and doesn't separate around the blade, because eventually even a tall blade runs into the full stock thickness at the top and will start to wedge.

Blade grind is probably next in line. If you made them both hollow grind, it would make slicing easier up until... again...the full stock thickness hits the material you're cutting. When you have a low saber hollow grind you lose much of what a hollow grind can add because it doesn't have much room to transition into the spine, and you basically get a hollow wedge.

Thin blade stock alone won't get you there either if the edge bevel is 90 degrees inclusive and dull. You could have a blade that's only 0.25mm thick but if the edge is blunt then obviously it's not going to cut well (imagine a dull utility blade).

This topic to me is sort of like building a high performance engine. You need to match the parts to each other, they need to compliment each other. You can't just look at a catalog of parts and pick all the ones that seem like the highest performance and throw them all together. This is why back in the day when engines were carbureted, you couldn't just put a 1000cfm carburetor on your Ford 289 and expect it to magically make a bunch of power, it just doesn't work that way. In the same way you can put a super thin hollow grind and razor edge on a blade but it will only help so much if you start with a blade that's 10mm thick.

Of course all of this depends greatly on what you're cutting. I only used the rigid board as an example because it's something we all encounter and can cut to see this for ourselves and is a known rigid material.