SE MagnaCut Testing Thread

Re: SE MagnaCut Testing Thread

Serrated salts are edc perfection. Light, stout, grippy frn, and blades that slice and dice.

Re: SE MagnaCut Testing Thread

Finally got around to taking this one apart this morning and there were a couple surprises that differ from my older February 2017 production Maxamet model.

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

Next I noticed that instead of the typical D shaped end of the pivot bushing like we see on a lot of other models, this one has a hexagonal head that seats tightly into the FRN scale.

I immediately got curious about my Maxamet Native, because I didn't remember seeing this. I looked back on my pics and noticed I didn't take the pivot all the way off on that knife. I can't remember if the thread locker stopped me from being able to or if I just didn't bother.

Here's that old pic...

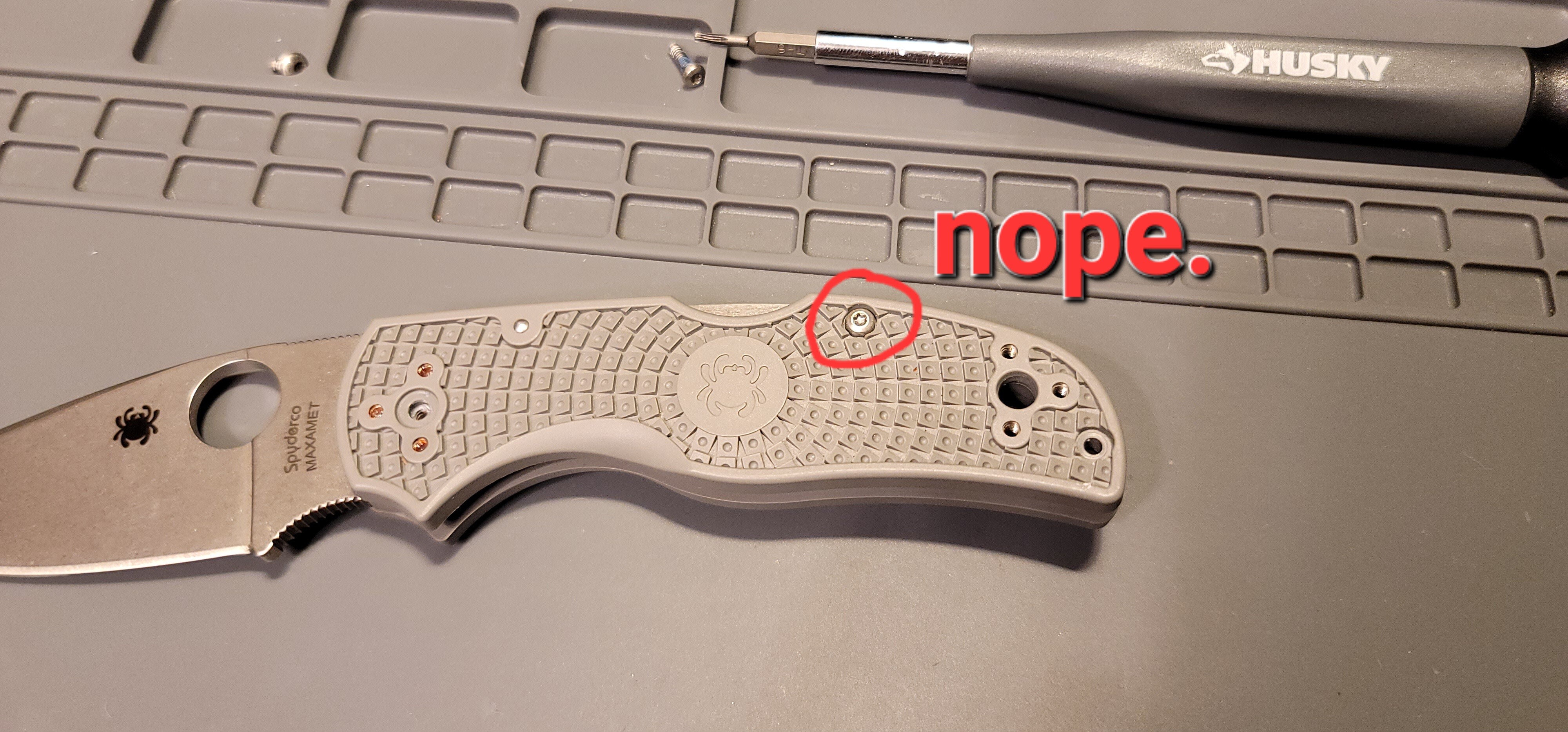

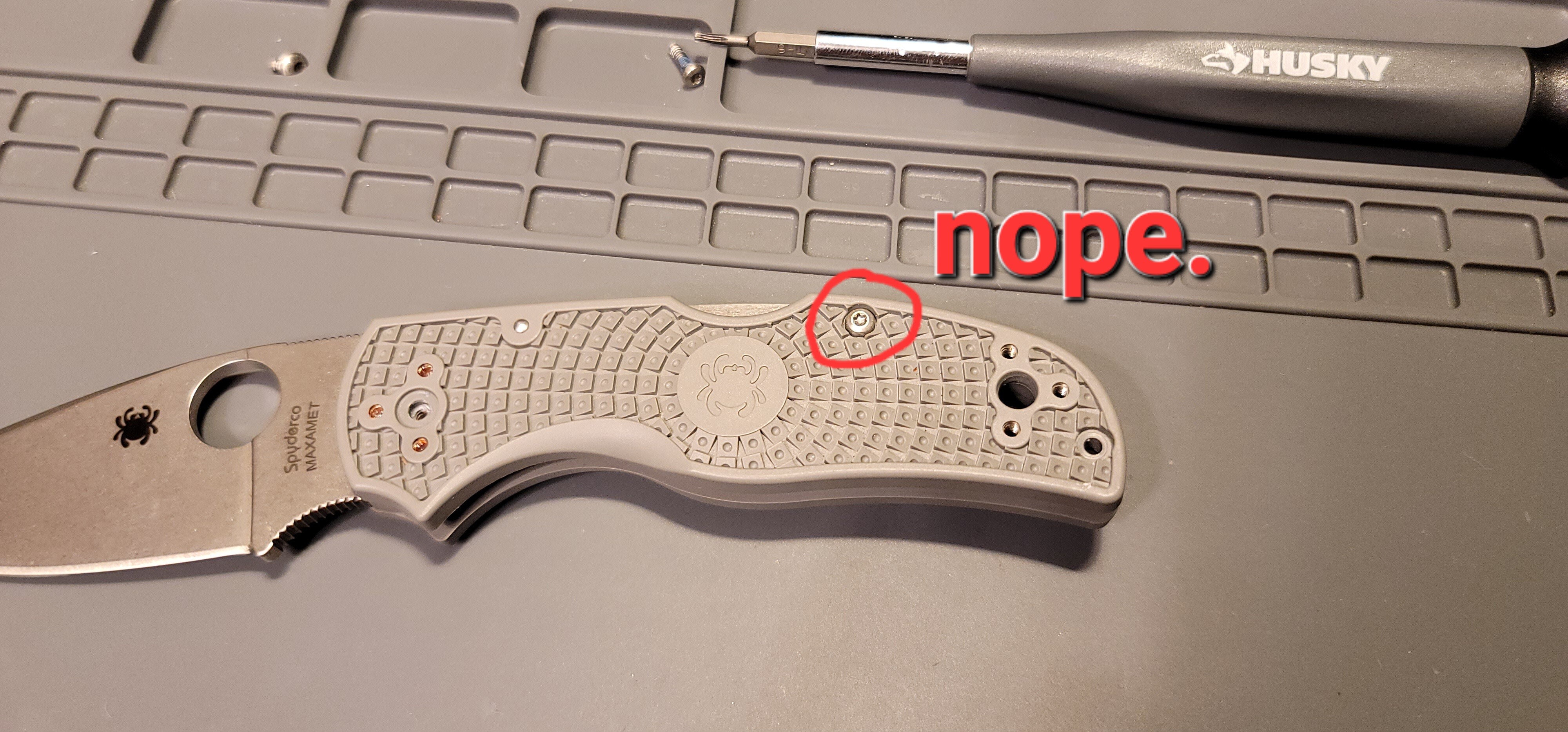

So I figured I'd take it apart again and check but...

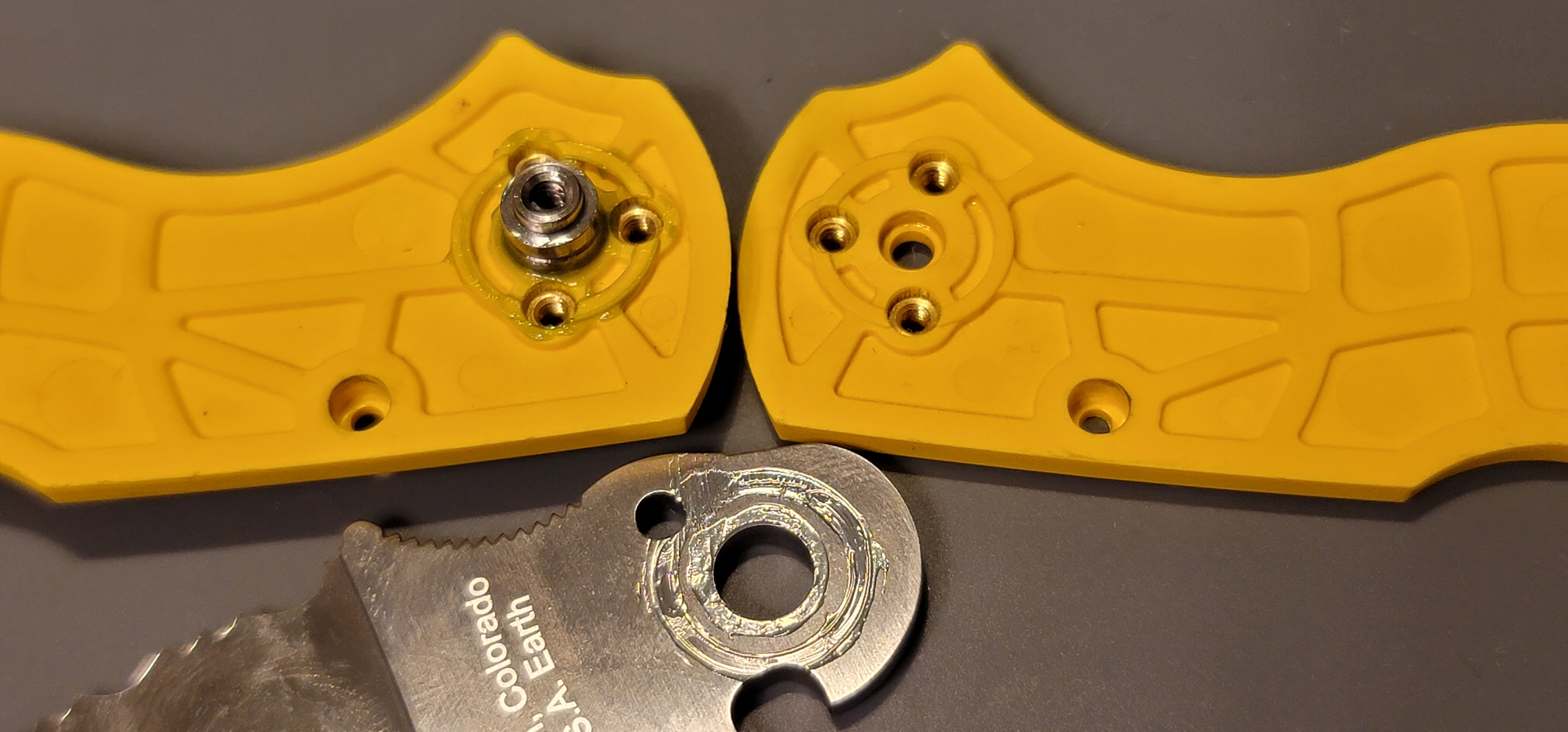

That screw just spins in place, because the embedded female screw anchor thing has broke loose from the FRN. This is my fault I suppose because I did use blue thread locker on this knife, but strangely enough it came with red thread locker (I remember posting about that when I first got it) so I'm a bit surprised about this. I'm not sure if Spyderco can even fix this, the screw would need to be drilled out and then a new female anchor epoxied into the FRN or something. Oh well, this knife just became pinned construction for me. I would highly recommend against using thread locker on these body screws or the clip screws, you're much better off losing a screw than the screw being stuck.

Anyway. The action is pretty great on this knife. The opening force isn't quite as pleasant as a Rock Jumper, requiring a lot more force to open, but it's quite smooth and the blade drops super easily when you press the lock.

One thing I used to do a lot was polish the lock ramp and tang but this one was polished at the factory. This may not be a new or recent thing they're doing but I know I've needed to do this on other models (Seki models). The lock bar head itself is also quite smooth so it isn't chewing up the tang ramp. Again this is something I've seen on other Spyderco back locks. The Golden folks seriously make the best back lock in the catalog.

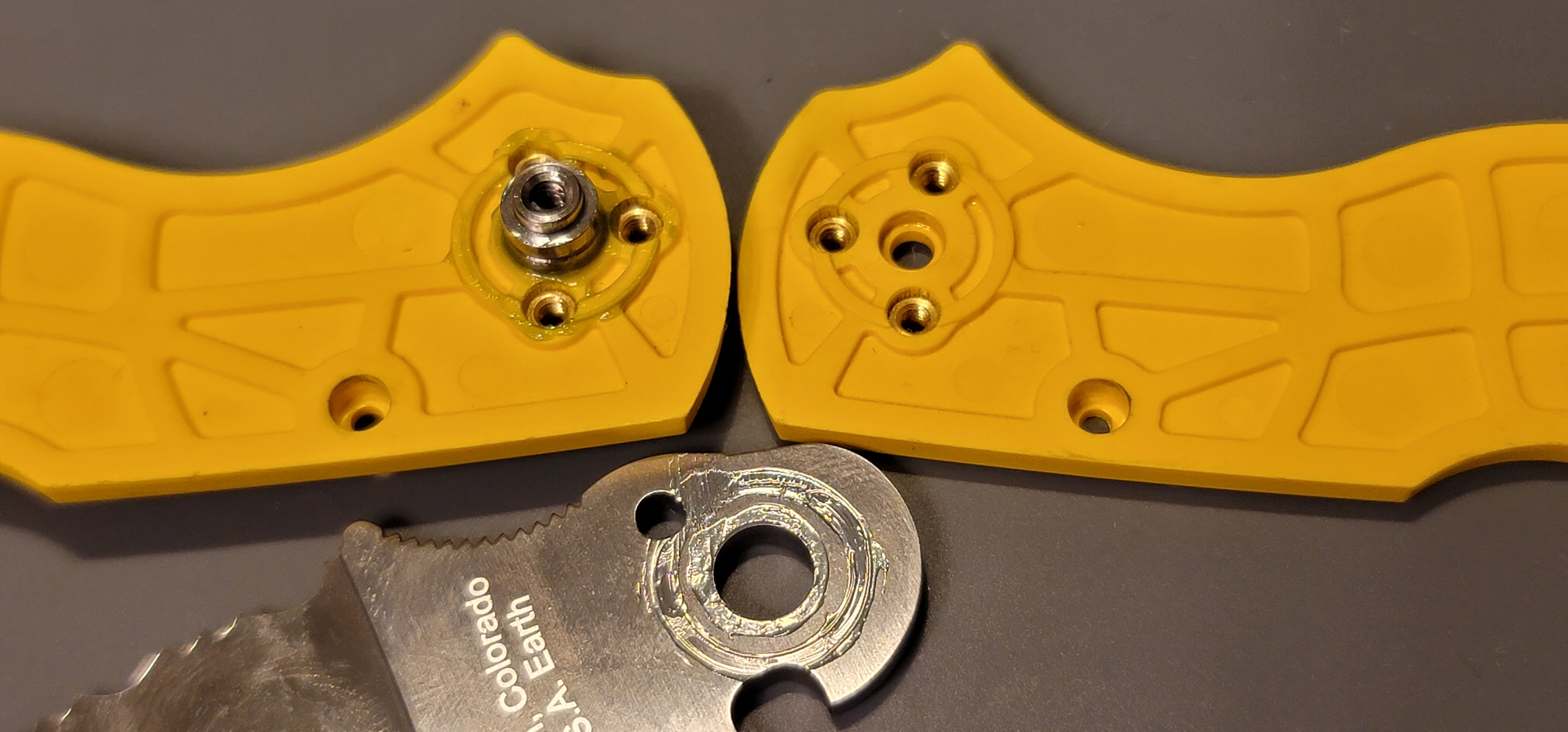

One thing I really like about these knives, that I think more people (particularly you anti-FRN G10 peeps) should appreciate it the way they mold these extra large "washers" into the scales. The end result here is a larger washer surface than you get with real washers and it goes a long way in making the pivot tighter. Considering these are linerless molded scales without washers, it really is impressive how accurate the molds come out and how good the resulting lock up is.

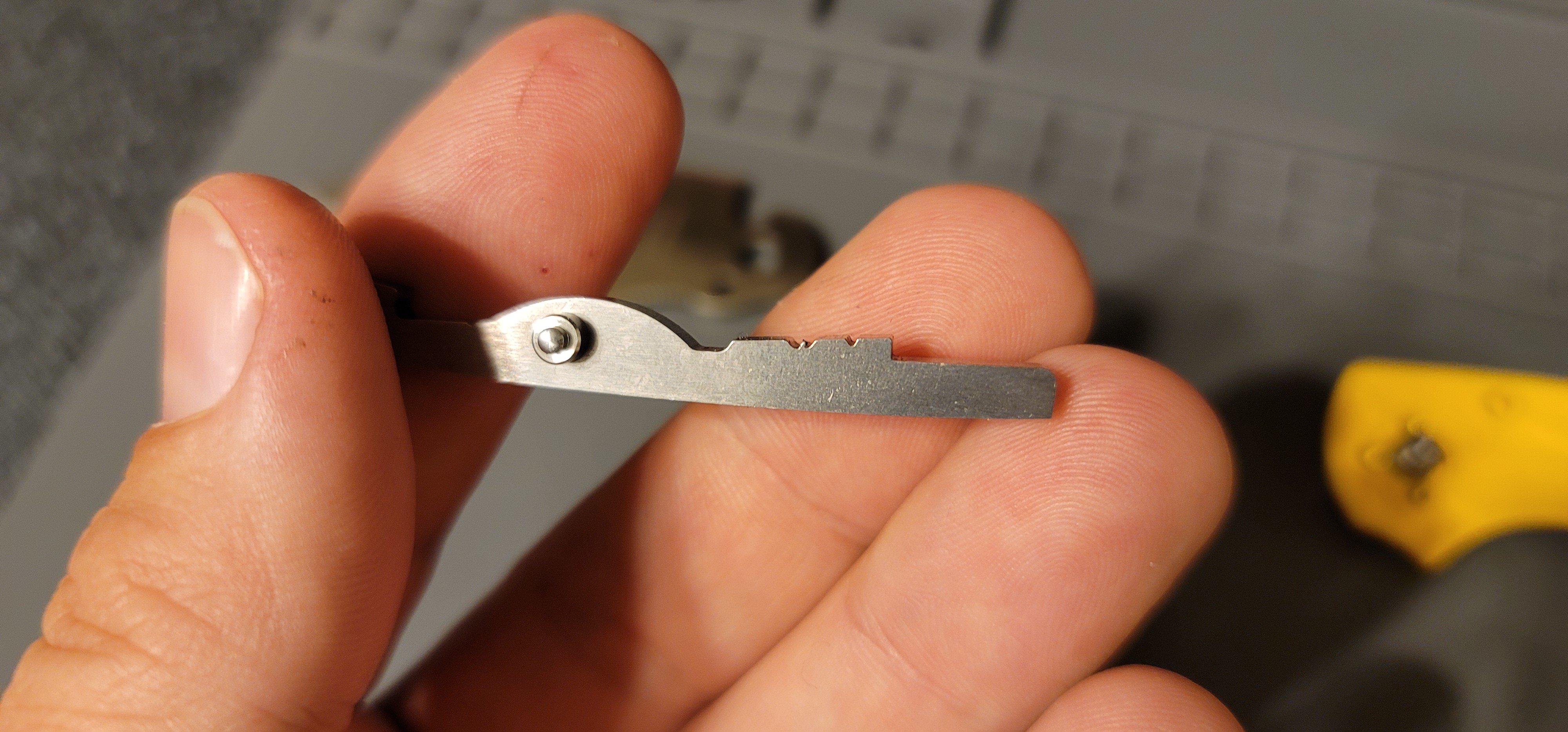

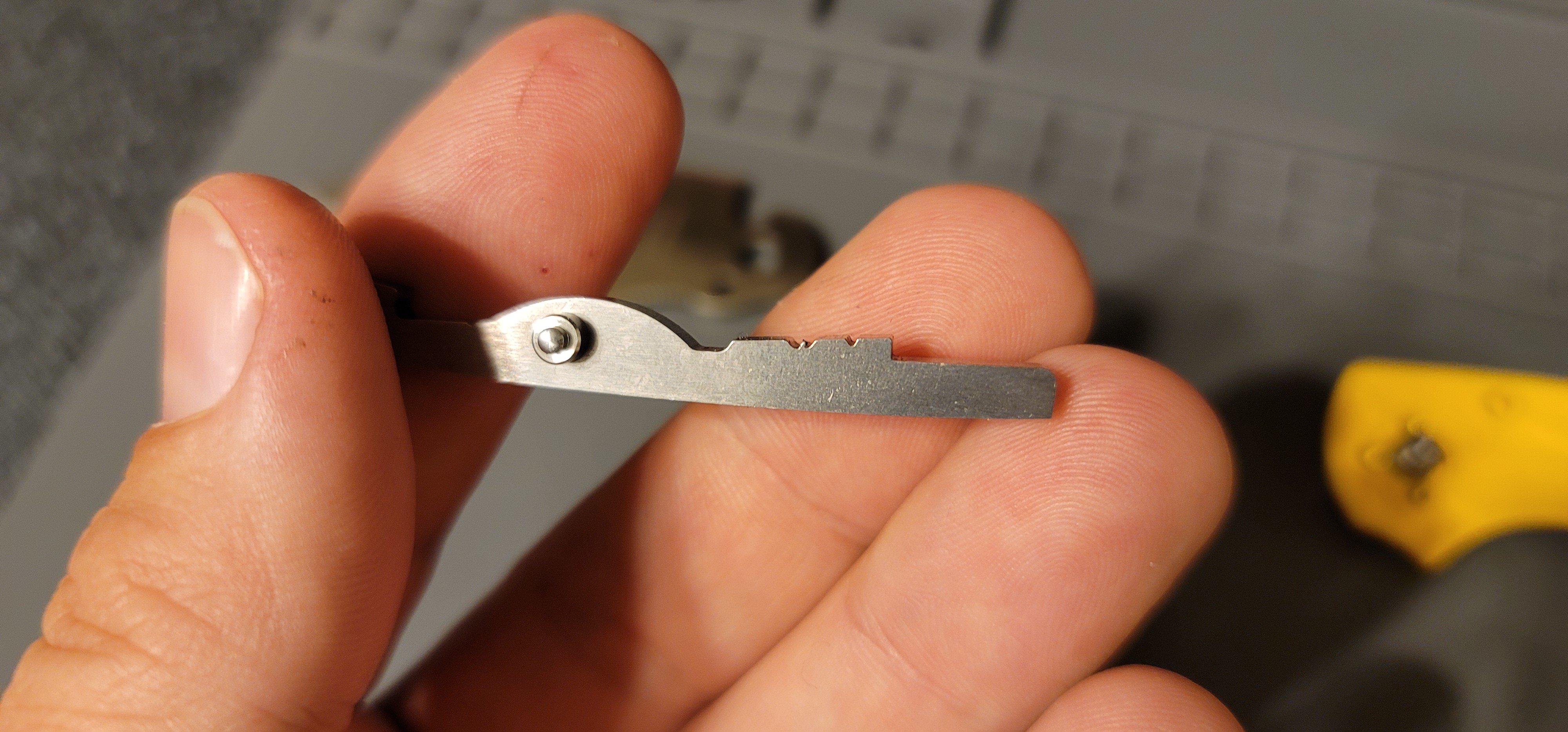

Another unusual thing I noticed are these weird grooves or cuts or whatever in the lock bar, and as much as they look like they might be a hidden screwup that you might not even notice, these marks are very similar to the marks on the Maxamet in the above pic so they certainly aren't blemishes. They probably have something to do with how the lock bar is cut out, but it's a weird little detail.

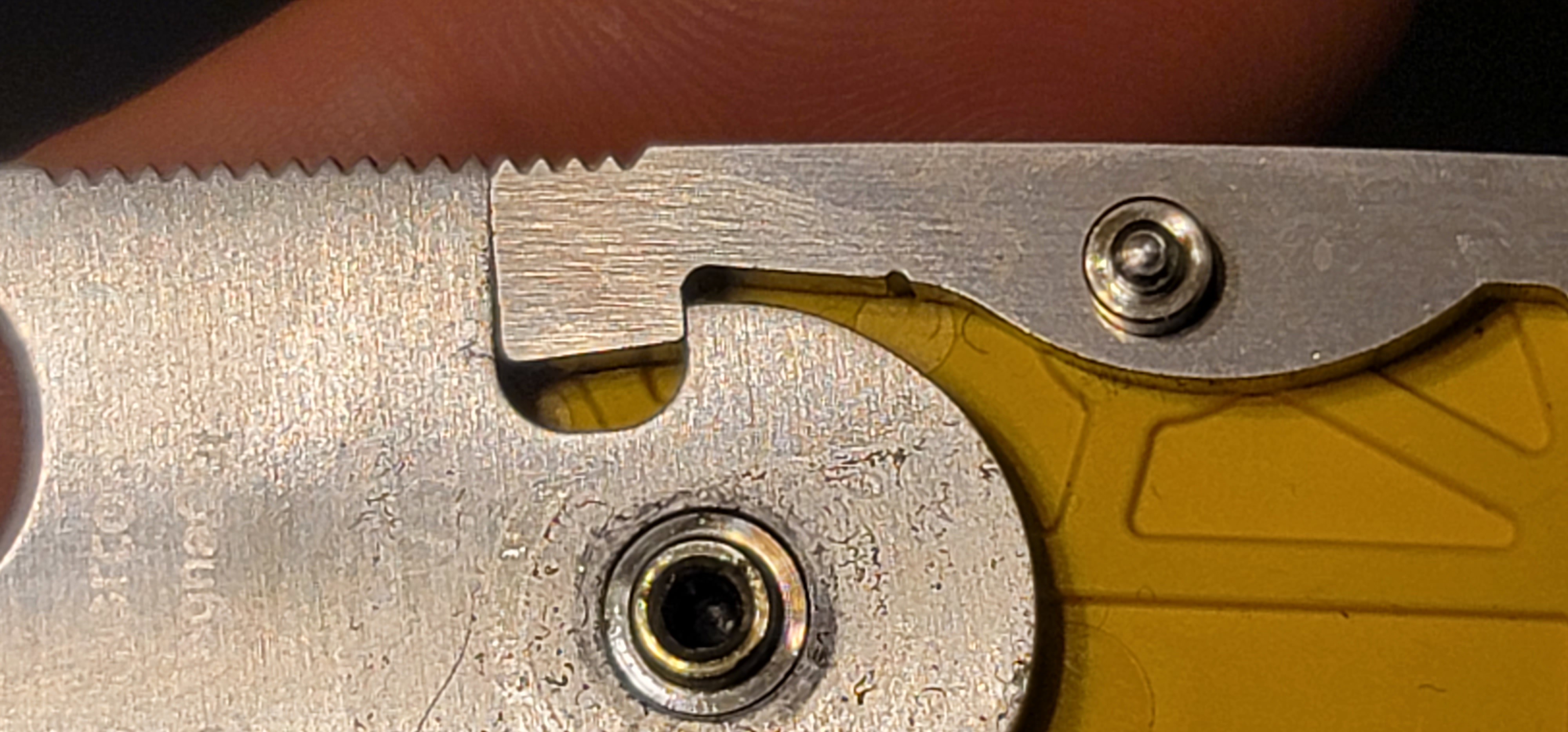

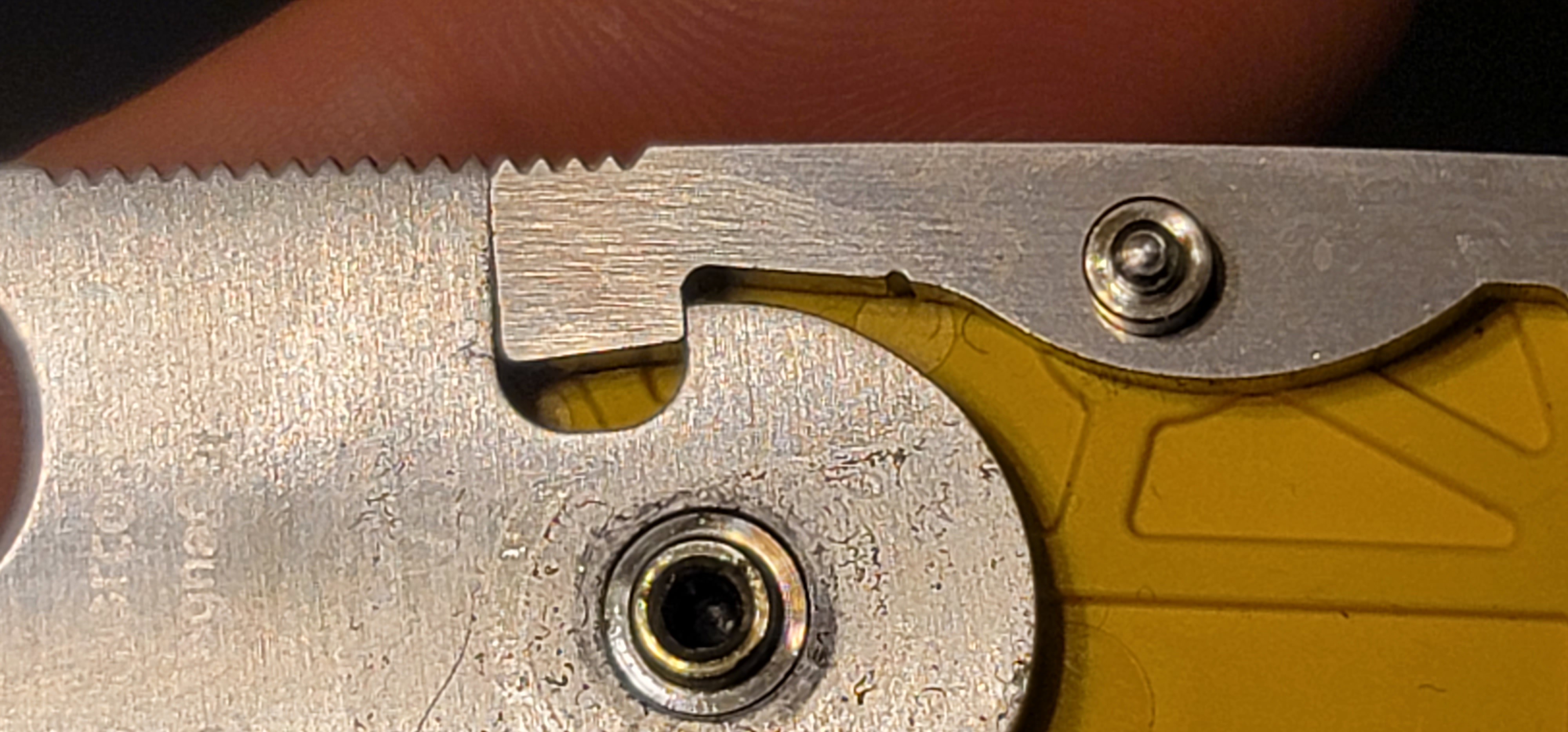

This knife has a pretty healthy amount of lock engagement too. This has been a concern for some of us when we see back locks where just the corner edge of the lock bar is engaging with the tang.

Something I think is often overlooked with back locks is how the lock bar also does effectively the same job as a back spacer and/or stop pin, and if you look at that pic you can see how much contact area there is between the blade tang and lock bar at this spot here...

And keep in mind that the blade stock thickness is 3.2mm and the lock bar itself is probably a teeny bit thicker, which added to that contact area I mentioned above plus the extra large molded washers all combine to really minimize side play in the pivot without the need to crank down the pivot screws.

And if anyone is wondering this knife was born in December of 2022. No idea what the C stands for.

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

Next I noticed that instead of the typical D shaped end of the pivot bushing like we see on a lot of other models, this one has a hexagonal head that seats tightly into the FRN scale.

I immediately got curious about my Maxamet Native, because I didn't remember seeing this. I looked back on my pics and noticed I didn't take the pivot all the way off on that knife. I can't remember if the thread locker stopped me from being able to or if I just didn't bother.

Here's that old pic...

So I figured I'd take it apart again and check but...

That screw just spins in place, because the embedded female screw anchor thing has broke loose from the FRN. This is my fault I suppose because I did use blue thread locker on this knife, but strangely enough it came with red thread locker (I remember posting about that when I first got it) so I'm a bit surprised about this. I'm not sure if Spyderco can even fix this, the screw would need to be drilled out and then a new female anchor epoxied into the FRN or something. Oh well, this knife just became pinned construction for me. I would highly recommend against using thread locker on these body screws or the clip screws, you're much better off losing a screw than the screw being stuck.

Anyway. The action is pretty great on this knife. The opening force isn't quite as pleasant as a Rock Jumper, requiring a lot more force to open, but it's quite smooth and the blade drops super easily when you press the lock.

One thing I used to do a lot was polish the lock ramp and tang but this one was polished at the factory. This may not be a new or recent thing they're doing but I know I've needed to do this on other models (Seki models). The lock bar head itself is also quite smooth so it isn't chewing up the tang ramp. Again this is something I've seen on other Spyderco back locks. The Golden folks seriously make the best back lock in the catalog.

One thing I really like about these knives, that I think more people (particularly you anti-FRN G10 peeps) should appreciate it the way they mold these extra large "washers" into the scales. The end result here is a larger washer surface than you get with real washers and it goes a long way in making the pivot tighter. Considering these are linerless molded scales without washers, it really is impressive how accurate the molds come out and how good the resulting lock up is.

Another unusual thing I noticed are these weird grooves or cuts or whatever in the lock bar, and as much as they look like they might be a hidden screwup that you might not even notice, these marks are very similar to the marks on the Maxamet in the above pic so they certainly aren't blemishes. They probably have something to do with how the lock bar is cut out, but it's a weird little detail.

This knife has a pretty healthy amount of lock engagement too. This has been a concern for some of us when we see back locks where just the corner edge of the lock bar is engaging with the tang.

Something I think is often overlooked with back locks is how the lock bar also does effectively the same job as a back spacer and/or stop pin, and if you look at that pic you can see how much contact area there is between the blade tang and lock bar at this spot here...

And keep in mind that the blade stock thickness is 3.2mm and the lock bar itself is probably a teeny bit thicker, which added to that contact area I mentioned above plus the extra large molded washers all combine to really minimize side play in the pivot without the need to crank down the pivot screws.

And if anyone is wondering this knife was born in December of 2022. No idea what the C stands for.

All SE all the time since 2017

~David

~David

- Spicy Suplex

- Member

- Posts: 237

- Joined: Mon Nov 15, 2021 11:14 am

- Location: SoCal

Re: SE MagnaCut Testing Thread

I've seen the letter notation after the date on my Golden blades as well, always figured it was a Batch number for the month, seems to be just A, B, or C from my limited experience.

Re: SE MagnaCut Testing Thread

Great series of photos and explanations, thanks!!

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

Re: SE MagnaCut Testing Thread

Yeah there is a case to be made that Brother David should be an official "Spokesperson" for the Great Spyder Factory. He's got my vote to be sure.

I'm just glad that people are starting to take this subject of blade steels for serrated blades more seriously. Because PE & SE are two completely different animals all together.

I've always found it strange that many blade steels that most people tend to ignore in many cases turn out to be great for full SE blades. AUS-8, ATS-55 and VG-10 are all great examples.

I'm really high on this "Magnacut" blade steel for SE. It may be like VG-10 in that it would be great for both edge types.

- Josh Crutchley

- Member

- Posts: 1394

- Joined: Wed Sep 30, 2020 2:44 am

- Location: Michigan

Re: SE MagnaCut Testing Thread

I've been using it for a lot of casual stuff, nothing too picture worthy but so far I'm really loving it. I feel pretty confident in expecting it to not have any real downsides, it almost seems like VG10 on steroids.

All SE all the time since 2017

~David

~David

Re: SE MagnaCut Testing Thread

You've got a valid point because in some ways the two blade steels are comparable i.e. Magnacut and VG-10. Because with my limited experiences I do believe both steels are great for both edge types. In my experience that is the exception and not the rule. I can only recall maybe 3 blade steels that I've had equal satisfaction in both PE & SE.

Spyderco really beats everyone to the punch so to speak. Not many other knife companies would explore new options like Spyderco has done over the years. And that truly sets them apart. Yeah in many respects Magnacut is like the new improved version of VG-10.

Re: SE MagnaCut Testing Thread

Hey guys I was just wondering about something, I have a Native in S90V and Carbon Fiber (cant remember if it is backblock or comp lock something is at the back of my mind saying comp lock) in the collection (just need to locate it) anyway I was wondering if anyone has ever swapped an FRN version into a CF or G-10 version of this model.

FRN is okay but I prefer the more substantial feeling handles like the CF and G-10. Magnacut is such a nice steel in this serrated edge it just needs a better handle in my opinion.

Yes FRN is good but it feels and looks cheap.

FRN is okay but I prefer the more substantial feeling handles like the CF and G-10. Magnacut is such a nice steel in this serrated edge it just needs a better handle in my opinion.

Yes FRN is good but it feels and looks cheap.

- cabfrank

- Member

- Posts: 2868

- Joined: Sun May 08, 2011 9:07 pm

- Location: Northern California, USA, Earth

Re: SE MagnaCut Testing Thread

I really like the look and feel of a very functional FRN handle, but to each their own. I also really like the fact that such handles make high performance knives more affordable, but again, to each their own.

Re: SE MagnaCut Testing Thread

Great write up with good pics. But there is at least one little detail, that is not right:

The friction is independent of the surface area.Evil D wrote: ↑Sat Jan 28, 2023 6:10 am.....

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

.....

Re: SE MagnaCut Testing Thread

Senfkarte wrote: ↑Mon Jan 30, 2023 4:05 pmGreat write up with good pics. But there is at least one little detail, that is not right:

The friction is independent of the surface area.Evil D wrote: ↑Sat Jan 28, 2023 6:10 am.....

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

.....

I don't follow. Are you saying a smaller contact area does not effect friction?

All SE all the time since 2017

~David

~David

Re: SE MagnaCut Testing Thread

Yes. As long as the resistance creating cause is friction, the surface area does not affect the force created by the friction. In a folding knife, this is the case.Evil D wrote: ↑Mon Jan 30, 2023 4:08 pmSenfkarte wrote: ↑Mon Jan 30, 2023 4:05 pmGreat write up with good pics. But there is at least one little detail, that is not right:

The friction is independent of the surface area.Evil D wrote: ↑Sat Jan 28, 2023 6:10 am.....

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

.....

I don't follow. Are you saying a smaller contact area does not effect friction?

With a smaller surface area, you increase the pressure on the remaining surface area, and you end up with the same amount of force in the end. It just depends on the coefficient of friction and the force that presses the two parts, that rub against each other, together. The coefficient of friction is dependent on the materials that are involved and if there is any lubricant.

Re: SE MagnaCut Testing Thread

Senfkarte wrote: ↑Mon Jan 30, 2023 5:01 pmYes. As long as the resistance creating cause is friction, the surface area does not affect the force created by the friction. In a folding knife, this is the case.Evil D wrote: ↑Mon Jan 30, 2023 4:08 pmSenfkarte wrote: ↑Mon Jan 30, 2023 4:05 pmGreat write up with good pics. But there is at least one little detail, that is not right:

The friction is independent of the surface area.Evil D wrote: ↑Sat Jan 28, 2023 6:10 am.....

First, I immediately noticed that the blade pivot and lock bar pivot bushing/pins both have grooves cut in the center now. I also have a Maxamet Native 5 and that knife doesn't have these grooves. I assume this is to hold lube, or if that wasn't the purpose they still do that. I'd say they also somewhat reduce the surface contact area and that cuts down on friction a small amount.

.....

I don't follow. Are you saying a smaller contact area does not effect friction?

With a smaller surface area, you increase the pressure on the remaining surface area, and you end up with the same amount of force in the end. It just depends on the coefficient of friction and the force that presses the two parts, that rub against each other, together. The coefficient of friction is dependent on the materials that are involved and if there is any lubricant.

Yeah that went right over my head. I related it to tire width and I'm pretty sure skinny tires don't grip just as well as wider ones but whatever I guess. I never claimed to be an engineer

All SE all the time since 2017

~David

~David

Re: SE MagnaCut Testing Thread

Evil D wrote: ↑Mon Jan 30, 2023 5:22 pmSenfkarte wrote: ↑Mon Jan 30, 2023 5:01 pmYes. As long as the resistance creating cause is friction, the surface area does not affect the force created by the friction. In a folding knife, this is the case.

With a smaller surface area, you increase the pressure on the remaining surface area, and you end up with the same amount of force in the end. It just depends on the coefficient of friction and the force that presses the two parts, that rub against each other, together. The coefficient of friction is dependent on the materials that are involved and if there is any lubricant.

Yeah that went right over my head. I related it to tire width and I'm pretty sure skinny tires don't grip just as well as wider ones but whatever I guess. I never claimed to be an engineer

Tires are a little more complicated in this regard.

Rubber is something between a solid and a fluid. So there the "softness" of the tire is an important thing to consider. The soft rubber deforms into little dimples in the road and a form fit is created. In this case the surface area becomes important.

Furthermore, wider tires can dissipate the created heat better, because of the bigger surface area of the whole tire and they don't get that hot in the first place, because they are more massive. The same amount of heat translates to a lower temperature of the body. This means a wider tire can be softer, without getting too hot, as soon. A softer rubber can form better into the dimples. More grip.

If you go very, very soft, for example a tire for a race car, the rubber becomes even sticky. Then a bigger contact area means more sticking force.

But if you slide over the road (hard/smooth ice without texture or snow to grab to, braking with locking tires...) a skinny and a wide tire generate the same amount of friction, if the same rubber is used.

Re: SE MagnaCut Testing Thread

Sorry for going so OT

Will you do a SE Magnacut torture test with this knife or are you waiting for a longer blade, so that the results are more comparable ... or is there no torture test in the future for SE Magnacut, at least not from you?

Will you do a SE Magnacut torture test with this knife or are you waiting for a longer blade, so that the results are more comparable ... or is there no torture test in the future for SE Magnacut, at least not from you?

Re: SE MagnaCut Testing Thread

I'm working on that, just trying to get the time. I've already got a bunch of stuff to cut up, just waiting for the chance to do it all.

All SE all the time since 2017

~David

~David

Re: SE MagnaCut Testing Thread

Re: SE MagnaCut Testing Thread

Alright here we go.

Touched up the edge on the brown rods. Screaming sharp:

This is the collection of victims, but I didn't do the yellow strap on top or the Coke can, kinda forgot. I can still do both if anyone cares but the rest of the stuff was a heck of a test.

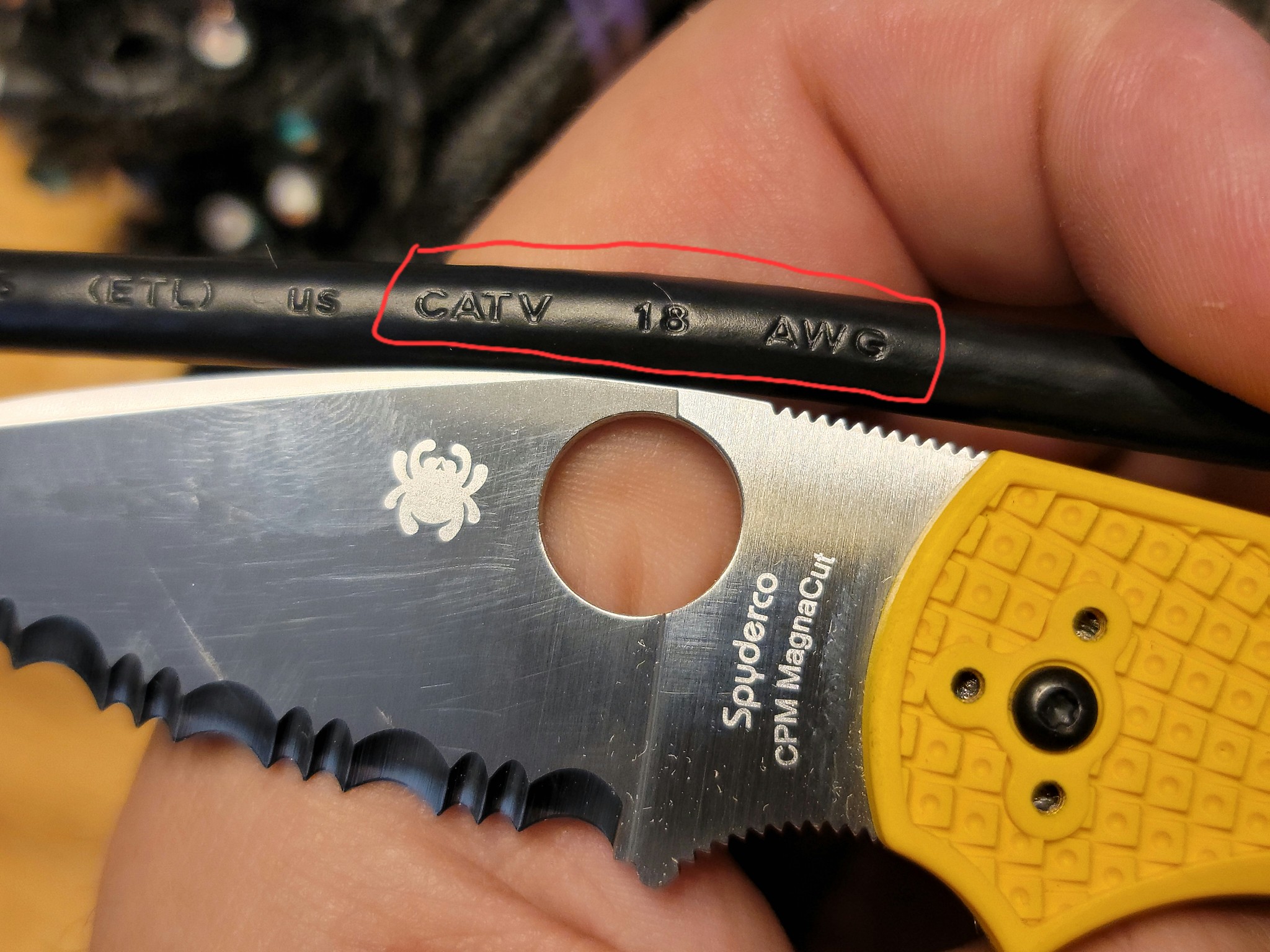

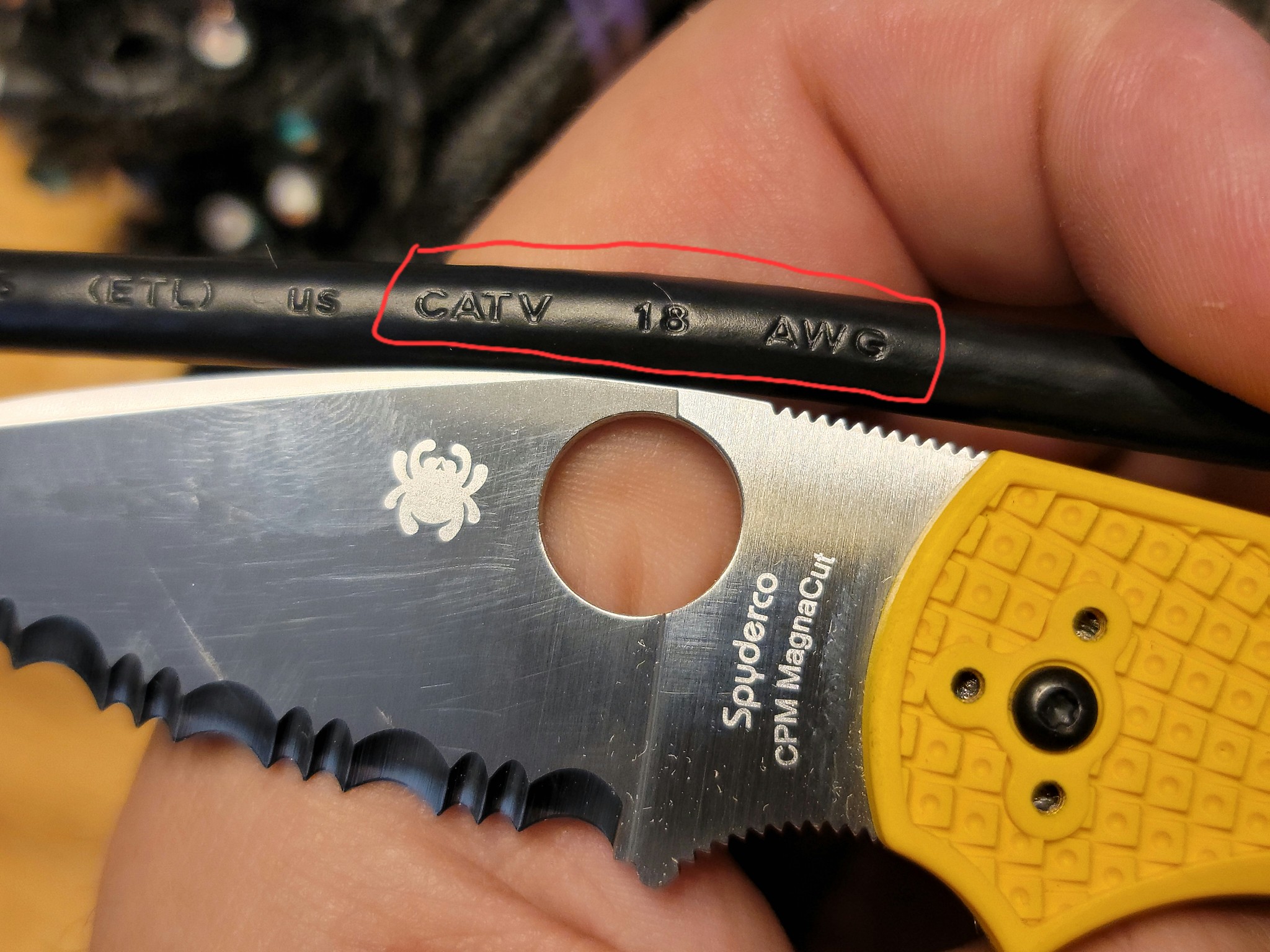

First up we've got some network cable.

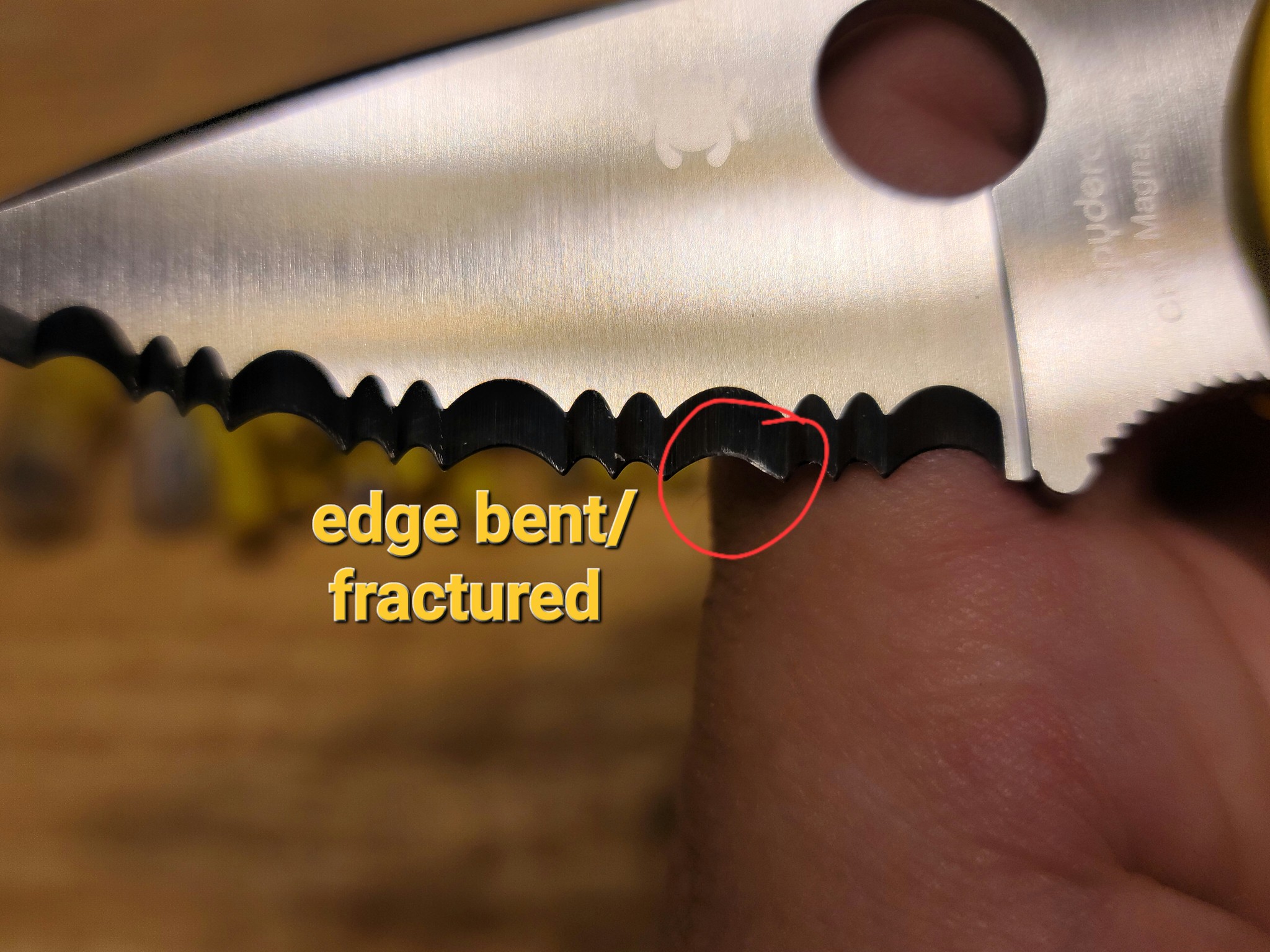

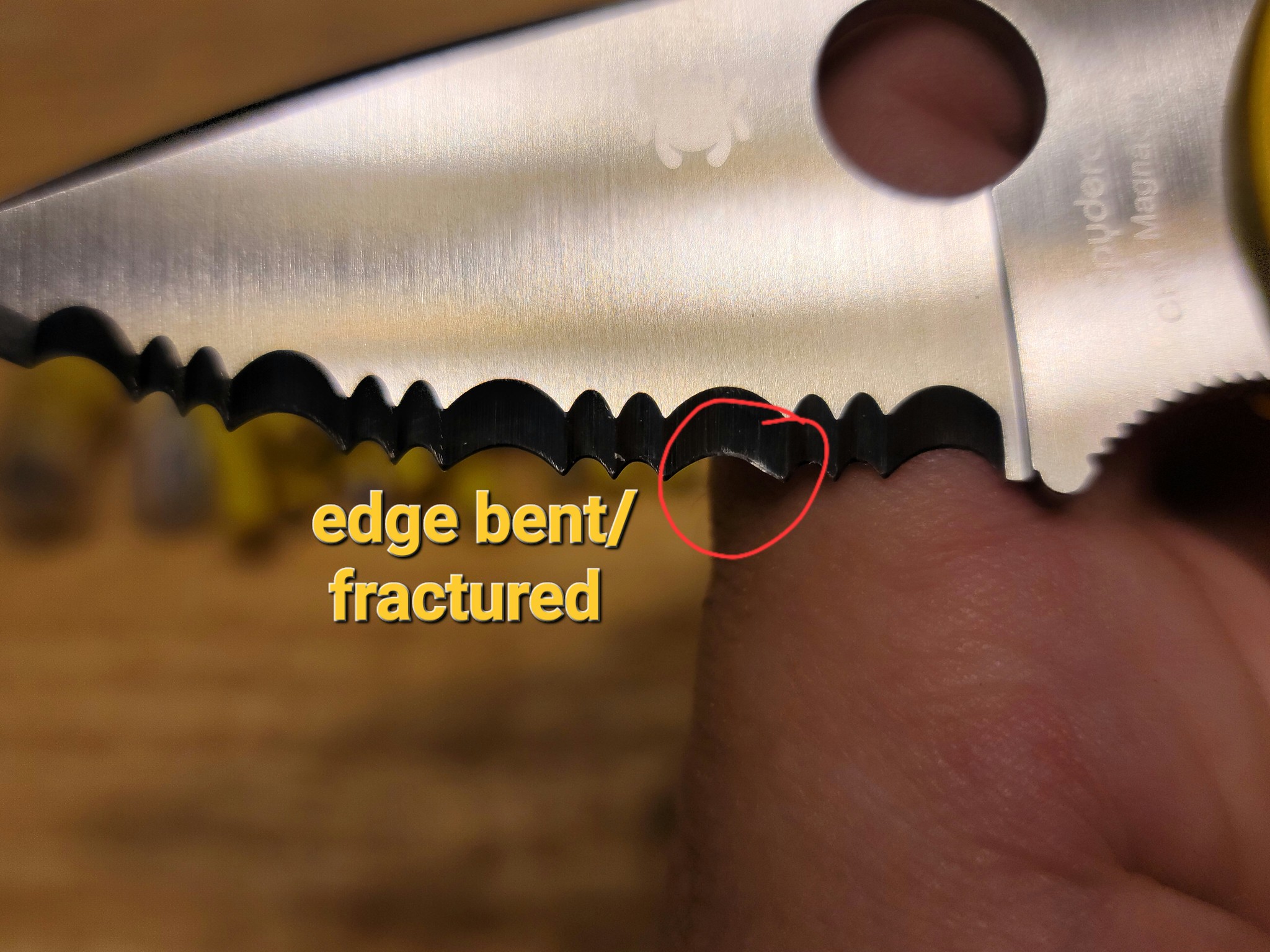

Now if you remember my first few posts I mentioned a ripple in the factory edge, and it appears that section of edge was weak from the factory and that's where the damage started with some bending and eventually in further tests it did chip off here.

I decided to not do any sharpening or touchups during all of this. I forgot to test sharpness after every cut test but I did remember after the first couple tests.

Next we've got some heavy zip tie. That same area of the blade saw further rolling/chipping.

Moving on we've got a heavy cord off of a surge protector.

I was curious about how much the braiding around that cord was fraying and I wondered if serrations were the cause, so I got out my MagnaCut mule and made the cut the same way and it frayed in the same way.

And it was significantly more difficult to cut with the mule.

This is where I remembered to test sharpness between cuts. The serrations that have the chips and rolls obviously weren't doing too hot but the rest of the edge was still plenty sharp enough to cleanly slice phonebook paper. Much of the use was done towards the middle of the blade so I made sure to test the sharpness on the sections I knew I had been using. Notice that there hasn't been any further edge damage anywhere along the edge except for where the edge was rippled from the factory.

Next we've got an old filthy tire strap. These are what tow trucks use to hold your car down during towing. They're a braided strap that's sort of like a seatbelt on steroids. This strap is wide enough that it covers practically the entire edge so it really spread out the wear evenly.

Now that may not seem like much but let me tell ya those straps are hardcore, and that pretty much dulled the edge. It didn't cause any damage but it saw a significant drop in sharpness and would only barely slice phonebook paper.

Touched up the edge on the brown rods. Screaming sharp:

This is the collection of victims, but I didn't do the yellow strap on top or the Coke can, kinda forgot. I can still do both if anyone cares but the rest of the stuff was a heck of a test.

First up we've got some network cable.

Now if you remember my first few posts I mentioned a ripple in the factory edge, and it appears that section of edge was weak from the factory and that's where the damage started with some bending and eventually in further tests it did chip off here.

I decided to not do any sharpening or touchups during all of this. I forgot to test sharpness after every cut test but I did remember after the first couple tests.

Next we've got some heavy zip tie. That same area of the blade saw further rolling/chipping.

Moving on we've got a heavy cord off of a surge protector.

I was curious about how much the braiding around that cord was fraying and I wondered if serrations were the cause, so I got out my MagnaCut mule and made the cut the same way and it frayed in the same way.

And it was significantly more difficult to cut with the mule.

This is where I remembered to test sharpness between cuts. The serrations that have the chips and rolls obviously weren't doing too hot but the rest of the edge was still plenty sharp enough to cleanly slice phonebook paper. Much of the use was done towards the middle of the blade so I made sure to test the sharpness on the sections I knew I had been using. Notice that there hasn't been any further edge damage anywhere along the edge except for where the edge was rippled from the factory.

Next we've got an old filthy tire strap. These are what tow trucks use to hold your car down during towing. They're a braided strap that's sort of like a seatbelt on steroids. This strap is wide enough that it covers practically the entire edge so it really spread out the wear evenly.

Now that may not seem like much but let me tell ya those straps are hardcore, and that pretty much dulled the edge. It didn't cause any damage but it saw a significant drop in sharpness and would only barely slice phonebook paper.

All SE all the time since 2017

~David

~David

Re: SE MagnaCut Testing Thread

Next up we've got an entire medium moving box from U-Haul. I first broke it down into equal sized panels and then made alternating 45 degree cuts cross-flute and whittled it down to a pile.

(cat for scale, pile is approximately 1 cat high)

Now keep in mind I still haven't done any sharpening. At this point it's definitely what I'd consider dull, I wouldn't feel comfortable leaving the house with this knife at this point but it does still continue to cut just fine and had no problem zipping through that box.

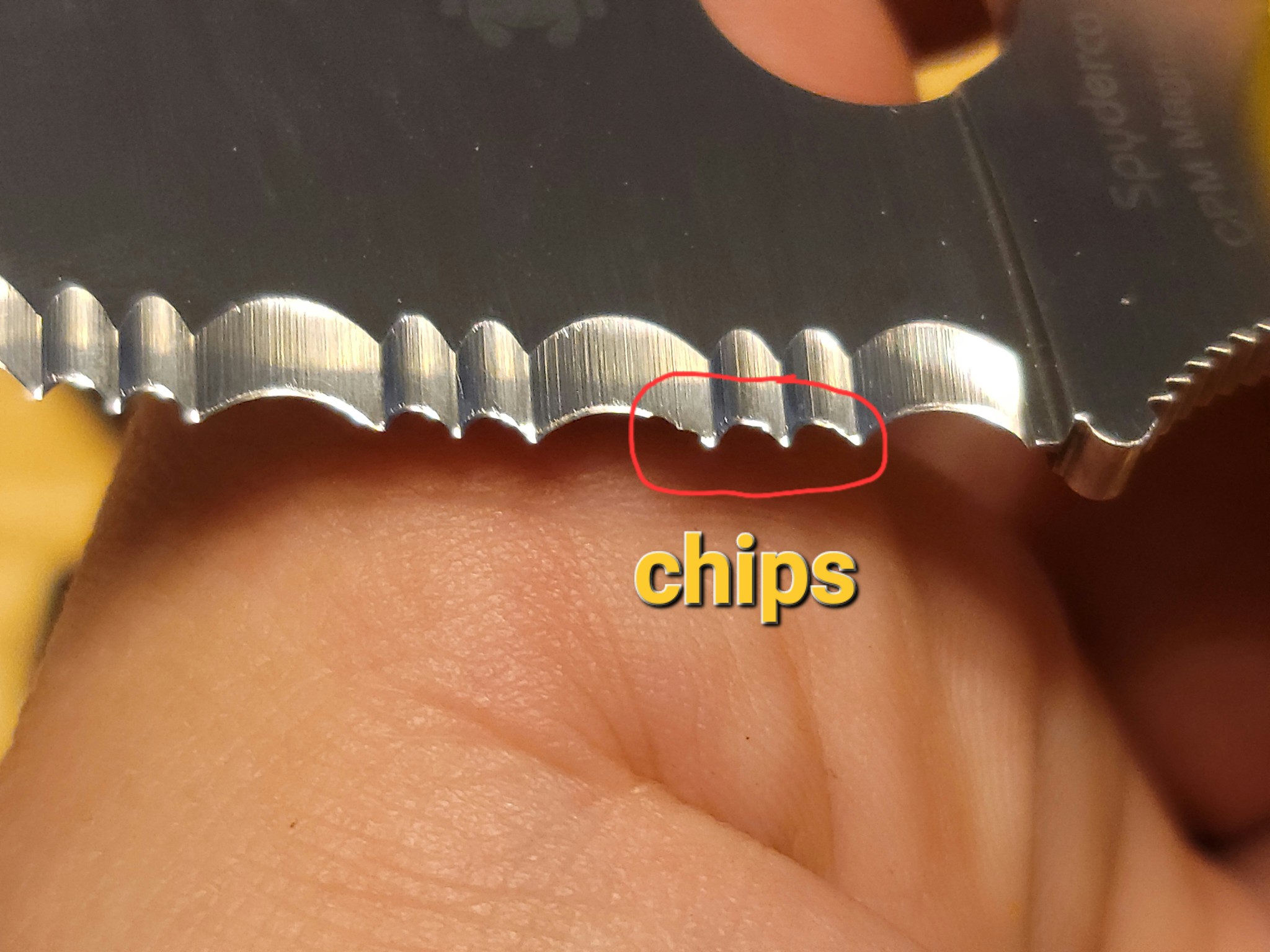

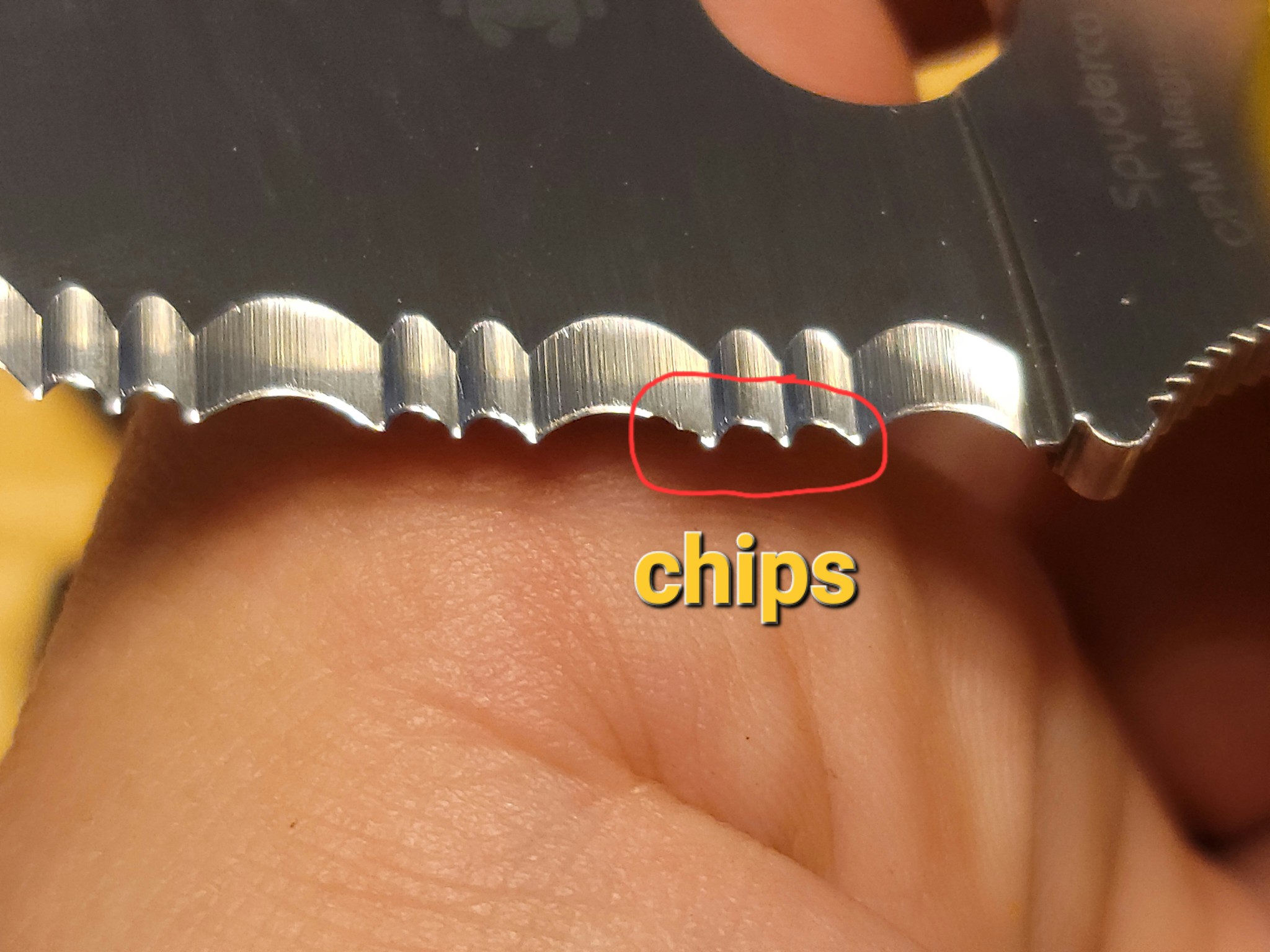

Here's a shot of the edge after all of those tests and the only damage of any kind is still only on the section that was rippled from the factory. There isn't even any shine along the edge when held under a lamp. As I've said before in the mule threads about this steel, the edge just seems to wear down...I don't really know how else to say it and that seems to oversimplify it but it just dulls, it doesn't roll or chip or deform, it just "reduces".

Which brings us to the finale....the CAT 5 cable. I had no doubt that this would destroy the edge since it did so on H1 and LC200N, both steels that are regarded as being very tough steels but when you're cutting a steel core cable like this and you're not cutting against a flat surface to sheer through it, it seems like damage is inevitable.

I made sure to try my best to isolate a single serration away from the rest of the damage. Again...this is with an already dull edge.

It took a good bit of force but it pushed through in one single cut without any sawing motion. Aaaaand it wrecked that one scallop.

Pretty brutal. Can't recommend cutting that stuff with any knife but if you must then it's probably best to push cut it against a hard surface with plain edge, which I may do with my mule later to see how it goes.

Here's the pile..

(cat for scale, pile is approximately 1 cat high)

Now keep in mind I still haven't done any sharpening. At this point it's definitely what I'd consider dull, I wouldn't feel comfortable leaving the house with this knife at this point but it does still continue to cut just fine and had no problem zipping through that box.

Here's a shot of the edge after all of those tests and the only damage of any kind is still only on the section that was rippled from the factory. There isn't even any shine along the edge when held under a lamp. As I've said before in the mule threads about this steel, the edge just seems to wear down...I don't really know how else to say it and that seems to oversimplify it but it just dulls, it doesn't roll or chip or deform, it just "reduces".

Which brings us to the finale....the CAT 5 cable. I had no doubt that this would destroy the edge since it did so on H1 and LC200N, both steels that are regarded as being very tough steels but when you're cutting a steel core cable like this and you're not cutting against a flat surface to sheer through it, it seems like damage is inevitable.

I made sure to try my best to isolate a single serration away from the rest of the damage. Again...this is with an already dull edge.

It took a good bit of force but it pushed through in one single cut without any sawing motion. Aaaaand it wrecked that one scallop.

Pretty brutal. Can't recommend cutting that stuff with any knife but if you must then it's probably best to push cut it against a hard surface with plain edge, which I may do with my mule later to see how it goes.

Here's the pile..

All SE all the time since 2017

~David

~David