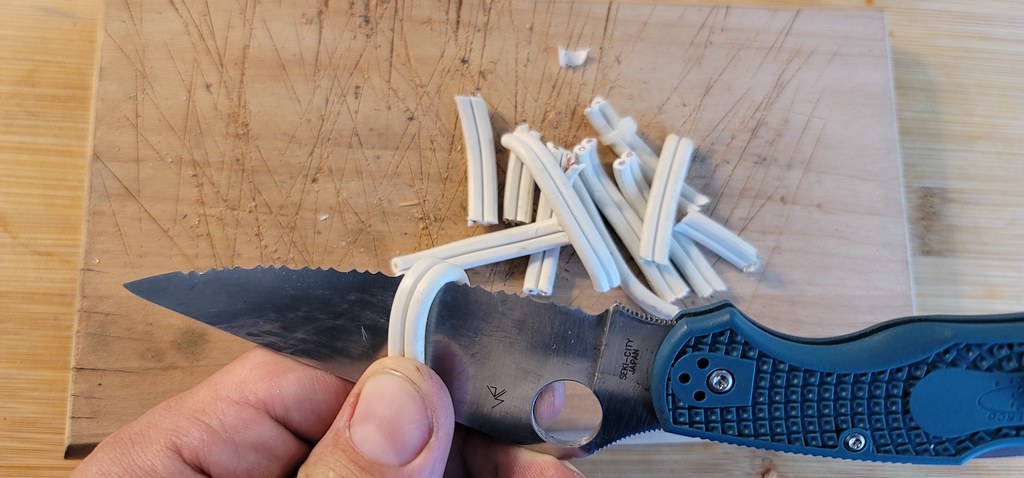

I had to go back and look at the Caribbean thread and try to round up the same stuff I cut with it.

Here's some old tow strap. This stuff is really tough to cut. I must say, this Police doesn't slice it quite as well as the Caribbean did, but keep in mind

this has all been done with the factory edge and has NOT been sharpened or touched up since I received it. Also the Caribbean had already been reprofiled a bit by the time I started doing the torture test, and some of the cutting effort and even edge damage may be due to the factory edge.

I could make it in one fold/pull cut but it took a lot of effort.

Even though that was hard to cut, I tried to cut a "dog bone" which is a few layers of that strap sewn together and almost glued or something, they're really stiff and crazy strong.

I gave it my best effort but was only able to cut through about half of that in one pull swipe, but it sawed through the rest of the way pretty easily.

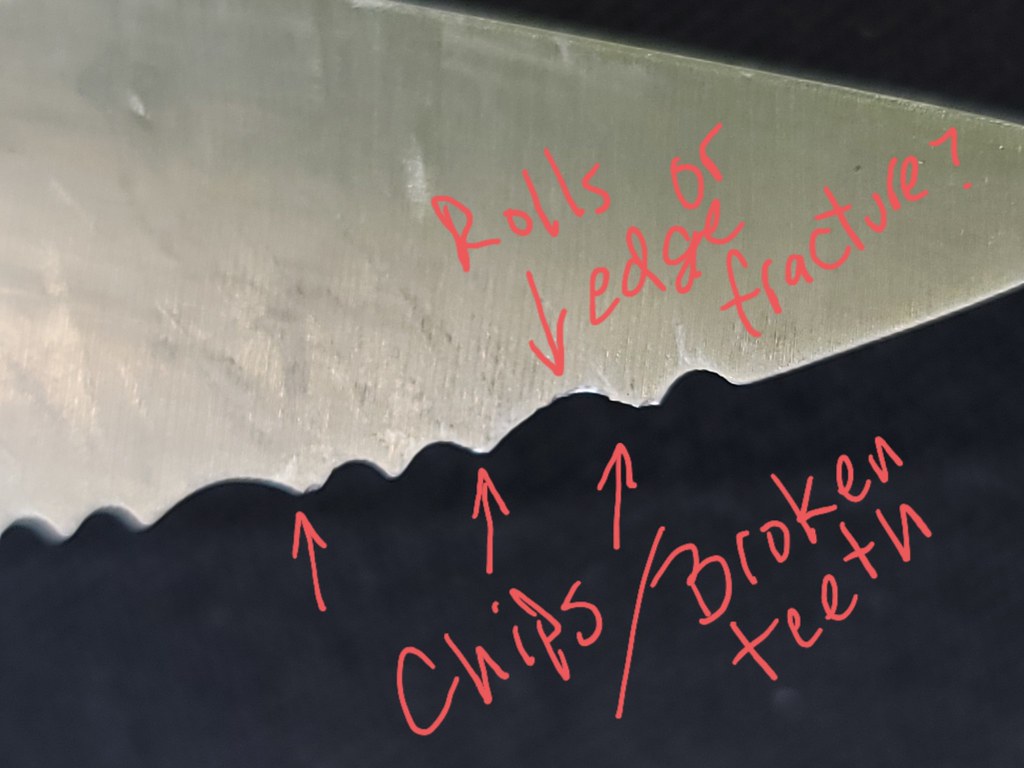

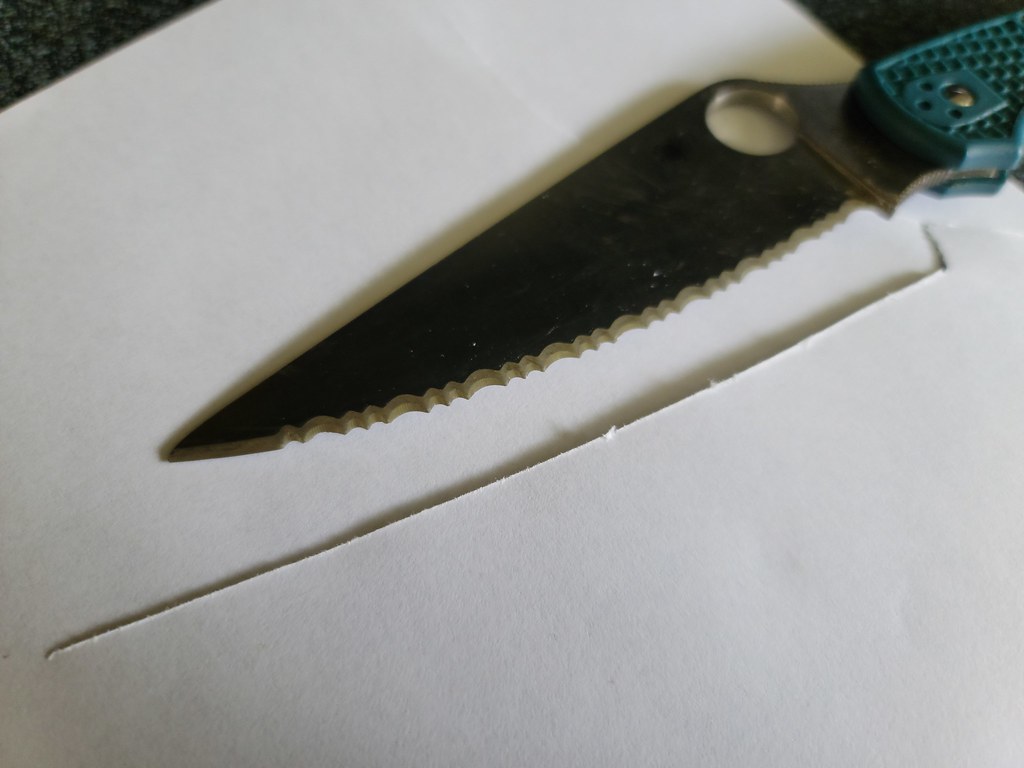

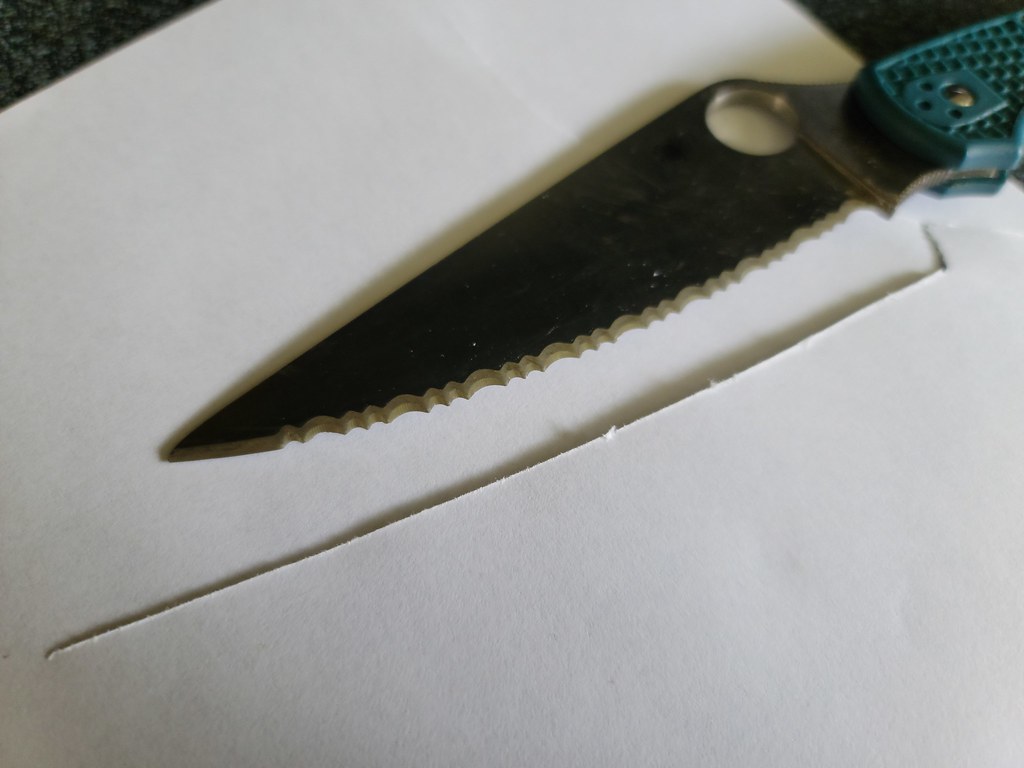

At this point I realized that with the Caribbean I was testing sharpness after each cut test and touching it up as needed, and I noticed it took a lot of strength to cut that strap so I got out some printer paper, and as you might guess it really isn't very sharp. It wouldn't push cut the paper practically at all unless I locked into a single serration that was still sharp. It made more of an "edge geometry rip".

So, at this point in my book this knife is dull. Actually a few cut tests prior to this I would have touched up the edge, but I know there are some of you out there that like to see just how far an edge will go, and I guess if I just keep touching it up we're only learning about toughness and not much about edge retention so I kept forging onward without fixing the edge.