Police 4 K390 SE Testing Log

Re: Police 4 K390 SE Testing Log

And if/when you break the tip off the Police, the fix will match the tip profile of the Caribbean. I can’t imagine grinding the whole spine down to a point on a K390 blade. Reprofiling my K390 Ladybug was quite enough!!

- Doc Dan

- Member

- Posts: 14836

- Joined: Thu Nov 08, 2012 4:25 am

- Location: In a dimension as vast as space and as timeless as infinity.

Re: Police 4 K390 SE Testing Log

I've never seen anyone chip this steel, though no doubt it can be done if doing something silly. I've got a K390 blade I've opened food cans with by cutting off the tops, and cut through a lot of stuff, like straps and etc. but have yet to have any issues at all. Any other steel and I would have.Evil D wrote: ↑Sat Oct 02, 2021 7:05 amskeeg11 wrote: ↑Fri Oct 01, 2021 3:30 pmWill be really interesting to see how it holds up to one of David's torture tests. Chips in K390 are no bueno. Serration patterns may be regional or dependent upon steel selection, but I gotta say that I'm very impressed with the factory teeth on my serrated UKPK Salt.

I am honestly concerned about chipping. This is also my first experience with K390 so it's all around new ground, and judging by how slowly it grinds I have a feeling it'll be a nightmare to fix chips. I don't know if I have the courage to cut up that coax cable with this one

I Pray Heaven to Bestow The Best of Blessing on THIS HOUSE, and on ALL that shall hereafter Inhabit it. May none but Honest and Wise Men ever rule under This Roof! (John Adams regarding the White House)

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

-

on_the_edge

- Member

- Posts: 184

- Joined: Sat Apr 15, 2017 9:05 am

Re: Police 4 K390 SE Testing Log

I think I would be very nervous about trying to open a food can with the tip of the Police. I know that's not the knife you used when you did it, but I have plenty of other knives more than capable of that. This baby will be reserved for "pocket chainsaw" duty only.

Re: Police 4 K390 SE Testing Log

The blade isn't really ground THAT thin at the tip, but with serrations I've noticed they tend to be way thinner at the actual edge tip than plain edge. I recently bent the tip on my Jumpmaster 2 just by stabbing it into a plank of what I assumed was pine, it was a really cheap soft wood that was part of the frame of a couch. I didn't stab/twist/pry, I just stabbed it and left it sticking into the wood and when I pulled it out I noticed the tip was bent.on_the_edge wrote: ↑Sat Oct 02, 2021 9:09 amI think I would be very nervous about trying to open a food can with the tip of the Police. I know that's not the knife you used when you did it, but I have plenty of other knives more than capable of that. This baby will be reserved for "pocket chainsaw" duty only.

Anyway, I plan on cutting up some Coke cans at least. I'm gonna try to do all the same torture tests I've done for LC200N if I still have all the same materials.

All SE all the time since 2017

~David

~David

Re: Police 4 K390 SE Testing Log

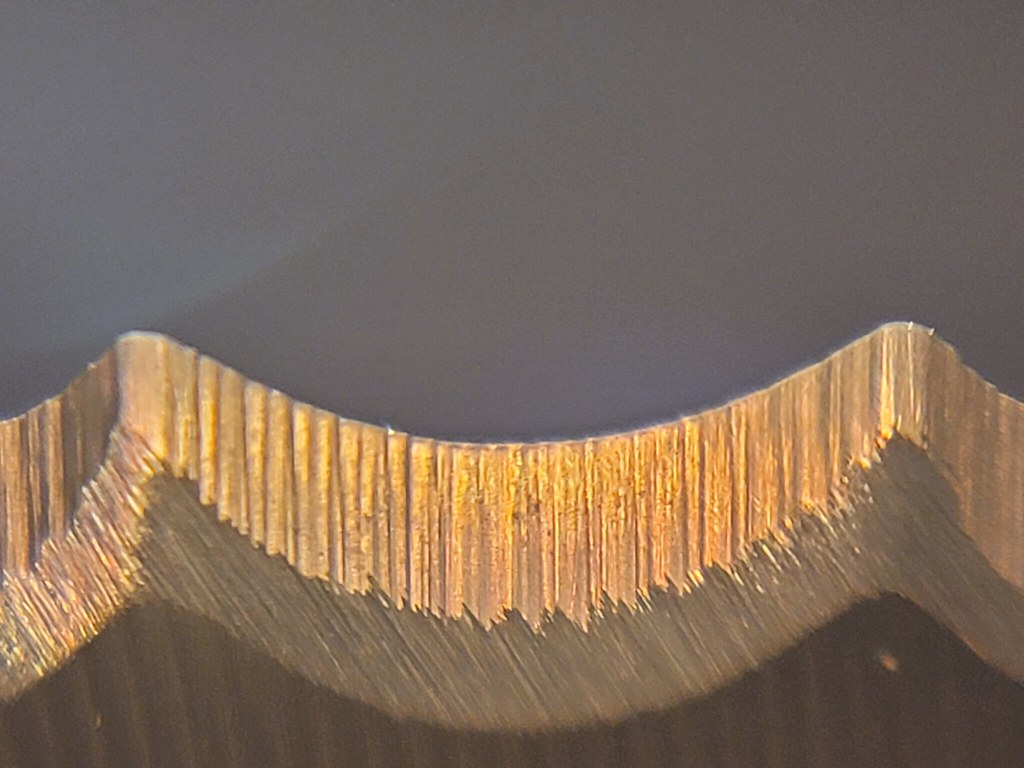

I wish I had thought about counting from the beginning but here's what the progress of 1000 strokes on diamond rods looks like. I'd say I've done at least 2000 total, maybe even closer to 3000.

I think I'm stopping here for now, I don't wanna remove any more of the factory edge. Also it seems either I'm trailing off the rods with less pressure through each pass or maybe it's due to distal tapering, but the heel of the blade is reprofiling faster than the tip. I see this on all my knives, so it may be my technique. It always seems to take way longer to get the tips of the blade done than the heel.

It's looking really nice though, nice even bevel along the whole edge. These smaller serrations do seem to slide along the rods smoother and less "jumpy". Seems to me most serrations reprofile much faster starting out and seem like it's gonna be quick and easy and then they slow to a crawl, but this knife almost seems to be the opposite, it was super slow starting out and felt like the steel was just so wear resistant that I wasn't getting anywhere, but now it's moving along pretty quick all considering. I'm doing sets of 100 passes and then taking a break, that's just about my limit before my shoulder is on fire and then my accuracy holding the blade at 90 degrees starts to get sloppy. I'll tell ya though, if you wanna develop muscle memory and get good at the Sharpmaker this is one way to get there.

I think I'm stopping here for now, I don't wanna remove any more of the factory edge. Also it seems either I'm trailing off the rods with less pressure through each pass or maybe it's due to distal tapering, but the heel of the blade is reprofiling faster than the tip. I see this on all my knives, so it may be my technique. It always seems to take way longer to get the tips of the blade done than the heel.

It's looking really nice though, nice even bevel along the whole edge. These smaller serrations do seem to slide along the rods smoother and less "jumpy". Seems to me most serrations reprofile much faster starting out and seem like it's gonna be quick and easy and then they slow to a crawl, but this knife almost seems to be the opposite, it was super slow starting out and felt like the steel was just so wear resistant that I wasn't getting anywhere, but now it's moving along pretty quick all considering. I'm doing sets of 100 passes and then taking a break, that's just about my limit before my shoulder is on fire and then my accuracy holding the blade at 90 degrees starts to get sloppy. I'll tell ya though, if you wanna develop muscle memory and get good at the Sharpmaker this is one way to get there.

All SE all the time since 2017

~David

~David

-

The Meat man

- Member

- Posts: 5858

- Joined: Wed Jan 03, 2018 8:01 pm

- Location: Missouri, USA

Re: Police 4 K390 SE Testing Log

Wow. That's actually not as bad as I thought it might be. Of course, the last bit always takes the longest.

Thanks a lot for documenting this David. Serrated K390 is uncharted waters.

Thanks a lot for documenting this David. Serrated K390 is uncharted waters.

- Connor

"What is a man profited, if he shall gain the whole world, and lose his own soul?"

"What is a man profited, if he shall gain the whole world, and lose his own soul?"

Re: Police 4 K390 SE Testing Log

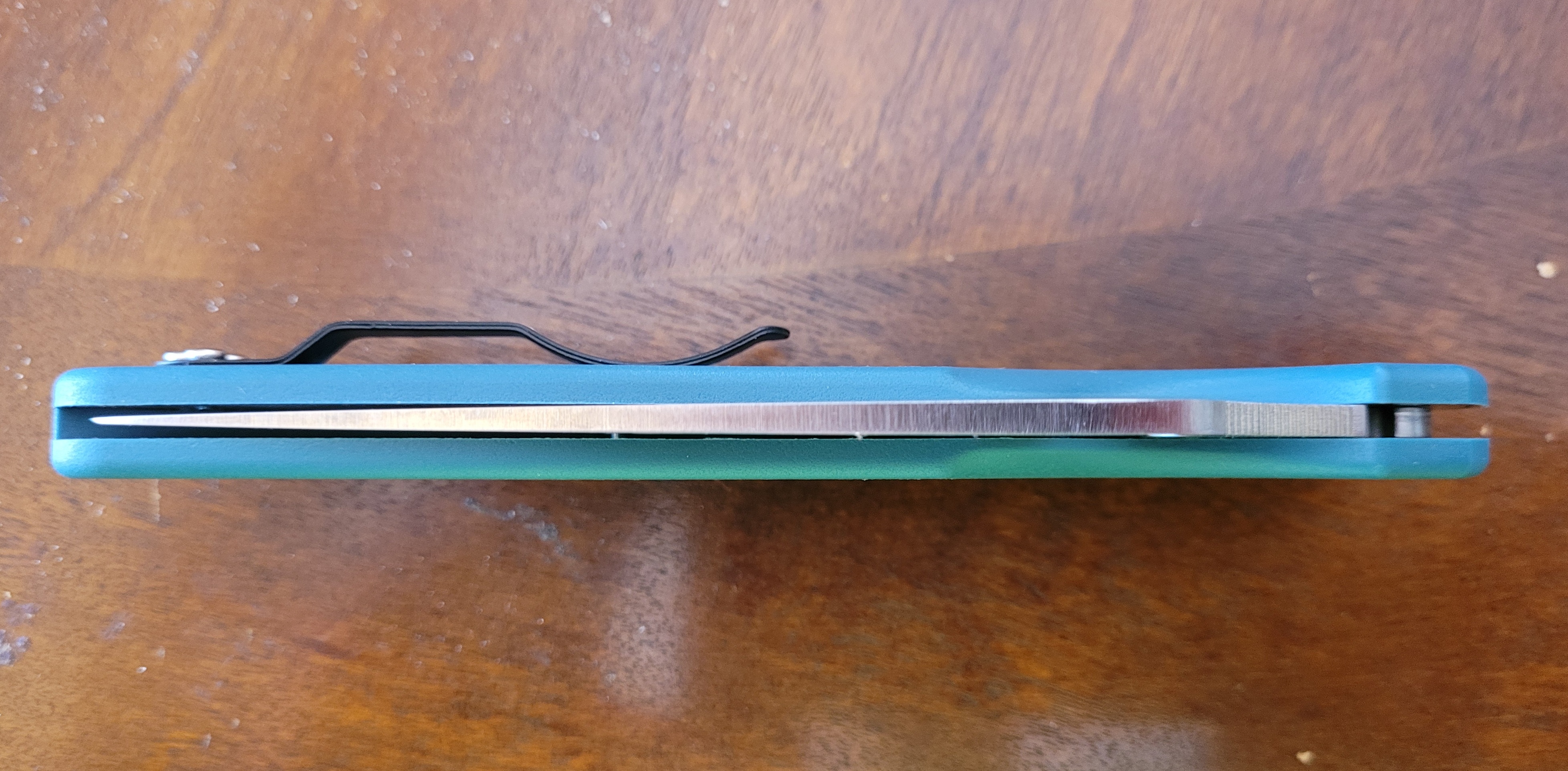

I've been focused a lot on the serrations and steel because the model itself has been out for a while now and I figured most people are somewhat familiar with it already, but it's my first Police 4 so here's a couple minor complaints..

One I already mentioned was blade centering. Even after getting it centered I've noticed that opening the blade is enough to push it off center again. I think a part of that is, the longer the blade is the easier it is to see that it's off center. I can still flex the handle and center it back up. Not a big deal, just an observation.

The inside edge of the handle molds is pretty raggedy. I don't recall having this issue with my Rock Jumper or most other Seki FRN models.

This is super easy to clean up and all you need are your Sharpmaker rods. They even conveniently come in a nice grit progression so you can get a nice smooth beveled edge. Just run the corner of the rods along the inside of the handle and the FRN burr wears off.

All of the screws were lose...all of them. Easy to fix but something to maybe look out for. I would normally just loctite them myself but with this being a steel that may stain, I'll be taking it apart from time to time to inspect the pivot for rust so I'll be routinely tightening the screws anyway.

I feel like the clip should be a bit longer. It just barely makes contact with the "pad" and there's enough bidirectional FRN there that it grabs my pocket quite a lot when pulling it out. This may be the first knife I order an aftermarket clip for if anyone knows for sure what fits it and what may be a little bit longer length. I don't necessarily want a deep carry though, I don't mind how much it sticks out, it makes for easier drawing for work/gloved hands. The black clip does feel out of place on this knife considering none of the other hardware is black.

One I already mentioned was blade centering. Even after getting it centered I've noticed that opening the blade is enough to push it off center again. I think a part of that is, the longer the blade is the easier it is to see that it's off center. I can still flex the handle and center it back up. Not a big deal, just an observation.

The inside edge of the handle molds is pretty raggedy. I don't recall having this issue with my Rock Jumper or most other Seki FRN models.

This is super easy to clean up and all you need are your Sharpmaker rods. They even conveniently come in a nice grit progression so you can get a nice smooth beveled edge. Just run the corner of the rods along the inside of the handle and the FRN burr wears off.

All of the screws were lose...all of them. Easy to fix but something to maybe look out for. I would normally just loctite them myself but with this being a steel that may stain, I'll be taking it apart from time to time to inspect the pivot for rust so I'll be routinely tightening the screws anyway.

I feel like the clip should be a bit longer. It just barely makes contact with the "pad" and there's enough bidirectional FRN there that it grabs my pocket quite a lot when pulling it out. This may be the first knife I order an aftermarket clip for if anyone knows for sure what fits it and what may be a little bit longer length. I don't necessarily want a deep carry though, I don't mind how much it sticks out, it makes for easier drawing for work/gloved hands. The black clip does feel out of place on this knife considering none of the other hardware is black.

All SE all the time since 2017

~David

~David

Re: Police 4 K390 SE Testing Log

The Meat man wrote: ↑Sat Oct 02, 2021 10:22 amWow. That's actually not as bad as I thought it might be. Of course, the last bit always takes the longest.

Thanks a lot for documenting this David. Serrated K390 is uncharted waters.

I'm sure the grueling last leg will show itself eventually. I'm happy to be documenting it. I've been excited for this one for a long time now. We haven't had a new steel with serrations since LC200N and that's been a few years back now.

All SE all the time since 2017

~David

~David

Re: Police 4 K390 SE Testing Log

I've seen this knife compared to the Military a lot but I think that's a bit of a Stretch (pun definitely intended). Aside from blade shape and size I think that's where the similarities stop. The ergonomics are very different, mostly in how the Military has the prominent pommel on the end of the grip and the Police 4 hasn't got one at all.

Ergonomically I like it a lot, considering it's a choiled knife. I like the finger groove contours a lot more than the Endura style and they fit my hand pretty well (most of the swelling from the bee stings has gone down lol).

The only grip I don't really care for is choking up on the choil...it's just too cramped for my thumb. My other 4 fingers are too far forward and my thumb has to jam itself way back to get into position on the thumb ramp.

It's not as bad if I rotate the end of the handle a bit away from my pinky but I'm not sure how this grip will work in actual use.

Ergonomically I like it a lot, considering it's a choiled knife. I like the finger groove contours a lot more than the Endura style and they fit my hand pretty well (most of the swelling from the bee stings has gone down lol).

The only grip I don't really care for is choking up on the choil...it's just too cramped for my thumb. My other 4 fingers are too far forward and my thumb has to jam itself way back to get into position on the thumb ramp.

It's not as bad if I rotate the end of the handle a bit away from my pinky but I'm not sure how this grip will work in actual use.

All SE all the time since 2017

~David

~David

- VooDooChild

- Member

- Posts: 2623

- Joined: Wed Feb 21, 2018 1:29 am

Re: Police 4 K390 SE Testing Log

My solution for the clip so far has just been to ignore it. It only catches a little and its not a big deal. Ignoring it is certainly easy.

I like when the black clips wear in and show some use. So Im fine with black.

Someone else on here sanded that area down to make it grab less.

Keep in mind theres a little bit of side to side adjustability in spydercos spoon clips. Also the pad is oval shaped. It may work better with the clip centered as opposed to off to the side. Or it may work worse, I think it actually depends on your draw how the fabric is "bunching up".

Any of the long lynch clips should be a little better but they are deep carry.

I actually think the Razor Edge Knives 3 hole titanium clip will work well. Its contact point sits further back than the standard spoon clip contact point even though the clip is smaller. They are great looking clips but they are expensive.

I like when the black clips wear in and show some use. So Im fine with black.

Someone else on here sanded that area down to make it grab less.

Keep in mind theres a little bit of side to side adjustability in spydercos spoon clips. Also the pad is oval shaped. It may work better with the clip centered as opposed to off to the side. Or it may work worse, I think it actually depends on your draw how the fabric is "bunching up".

Any of the long lynch clips should be a little better but they are deep carry.

I actually think the Razor Edge Knives 3 hole titanium clip will work well. Its contact point sits further back than the standard spoon clip contact point even though the clip is smaller. They are great looking clips but they are expensive.

"Rome's greatest contribution to mathematics was the killing of Archimedes."

Re: Police 4 K390 SE Testing Log

For those of you with concerns, mine arrived with the blade centered and all the screws tight.

Re: Police 4 K390 SE Testing Log

Thanks so much for doing this thread, it's very helpful. I might hang onto my SE Caribbean and wait for another K390 model, if nothing else then just the wharnie Dragonfly, or more preferably the XL Stretch.

And I'm sure the blade was off-center because of the loose screws.

And I'm sure the blade was off-center because of the loose screws.

Military/PM2/P3 Native Chief/Native GB2 DF2 PITS Chaparral Tasman Salt 2 SE Caribbean Sheepfoot SE SpydieChef Swayback Manix2 Sage 1 SSS Stretch 2 XL G10

Re: Police 4 K390 SE Testing Log

kobold wrote: ↑Sat Oct 02, 2021 2:38 pmThanks so much for doing this thread, it's very helpful. I might hang onto my SE Caribbean and wait for another K390 model, if nothing else then just the wharnie Dragonfly, or more preferably the XL Stretch.

And I'm sure the blade was off-center because of the loose screws.

Yeah I really just planned to buy whatever knife came in SE K390 first but it was convenient that I was also interested in the Police 4 anyway. I will definitely be all over a SE Dragonfly or *fingers crossed* a Rock Jumper.

All SE all the time since 2017

~David

~David

Re: Police 4 K390 SE Testing Log

Evil D wrote: ↑Sat Oct 02, 2021 7:44 am

You are correct. Which means potentially this knife may perform better with the factory edge than any time after sharpening it, if those micro serrations add to cutting performance.

Even the plain edge at the tip has some of those same grind lines.

Also moving right along with reprofiling it. Diamond rods are doing just fine. I also found that a micro fiber towel does a great job of cleaning out the metal dust from diamond/CBN rods as you work. They load up fast. I'm taking it extra slow, I don't even wanna see what a nightmare a burr can turn into with this steel and serrations.

I also plan to stop reprofiling before I make it all the way to the apex, I still wanna see how that factory edge performs and get an idea of what edge retention is like and even how prone it may be to chips.

Also, I was initially not super impressed with how sharp this knife was. It won't push cut phone book paper, but it feels really sharp to the touch. I'm thinking that probably has something to do with those micro serrations. I'll get some boxes and stuff together and cut some stuff up today and see how it goes.

If you only sharpen the serrations on the backside with a Benchstone the original grind pattern of the serrations would be kept for the entire life of the knife.

In my opinion the only correct way to sharpen serrations is with a Benchstone and then just de-bur with a rod, you always keep the original factory scallops.

Re: Police 4 K390 SE Testing Log

Joshua J. wrote: ↑Sat Oct 02, 2021 4:56 pm

If you only sharpen the serrations on the backside with a Benchstone the original grind pattern of the serrations would be kept for the entire life of the knife.

In my opinion the only correct way to sharpen serrations is with a Benchstone and then just de-bur with a rod, you always keep the original factory scallops.

I would think even the deburring process would alter those micro serrations or even remove them. Doing this will eventually shorten the height of the serrations and thicken the edge over time, not to mention move the edge off center of the blade. I have tried honing the flat side of my Stretch this way with somewhat successful results aside from making that side of the blade pretty ugly.

All SE all the time since 2017

~David

~David

Re: Police 4 K390 SE Testing Log

Ya know David... seeing all those "micro serrations" on the factory edge bevel(s) (serrations and short PE tip) makes me think, or re-think, that my initial thought(s) on whoever is making / grinding those blades was using wheels the size of each individual serration / scallop, was incorrect. Instead it looks as if there are many, much smaller "wheels" used to accomplish this machining/grinding. By my old failing eyes count, about 15 small grooves ("wheels") in each of the large scallops...

I'm glad you're doing the tread, and looking forward to future posts from you on this knife. Thank you for taking the time, and sharing

u.w.

I'm glad you're doing the tread, and looking forward to future posts from you on this knife. Thank you for taking the time, and sharing

u.w.

Re: Police 4 K390 SE Testing Log

Thanks for recording your usage and impressions, Evil D. I've been hoping for serrated K390 since the Police 4 was originally released, so it makes for very interesting reading.

- Brock O Lee

- Member

- Posts: 3326

- Joined: Thu Jul 21, 2011 3:34 am

- Location: Victoria, Australia

Re: Police 4 K390 SE Testing Log

Keep up the good work! Subscribed.

Hans

Favourite Spydies: Military, PM2, Shaman, UKPK

Others: Victorinox Pioneer, CRK L Sebenza 31, CRK L Inkosi

Favourite Spydies: Military, PM2, Shaman, UKPK

Others: Victorinox Pioneer, CRK L Sebenza 31, CRK L Inkosi

Re: Police 4 K390 SE Testing Log

u.w. wrote: ↑Sat Oct 02, 2021 6:09 pmYa know David... seeing all those "micro serrations" on the factory edge bevel(s) (serrations and short PE tip) makes me think, or re-think, that my initial thought(s) on whoever is making / grinding those blades was using wheels the size of each individual serration / scallop, was incorrect. Instead it looks as if there are many, much smaller "wheels" used to accomplish this machining/grinding. By my old failing eyes count, about 15 small grooves ("wheels") in each of the large scallops...

I'm glad you're doing the tread, and looking forward to future posts from you on this knife. Thank you for taking the time, and sharing

u.w.

It'll be interesting to see this knife maybe a year from now to see if this changes any, if they are indeed ground by a wheel maybe this is just a texture from diamond or CBN particles on the grinding wheel and maybe over time we'll see that pattern on the scallops change as the grinding wheel wears.

Today is my first day carrying it at work and the forecast calls for rain for about the next whole week. I did Tuf-Glide the pivot and the tang where the Spyderco font and stuff are engraved but I left the blade untreated. I do wear a rain jacket and pants at work when it's really raining but that also makes me sweat so my pocket will be humid. I'm anxious to see how it compares to other non stainless steels and even some stainless that didn't fare well at work.

Last edited by Evil D on Sun Oct 03, 2021 4:56 pm, edited 1 time in total.

All SE all the time since 2017

~David

~David