Practical methods for making Salt knives pointier

Practical methods for making Salt knives pointier

Help me out guys, I wanna try to make my Salt 2 a bit pointier, but I have no belt sander.

What other methods have you used successfully?

Thanks in advance.

What other methods have you used successfully?

Thanks in advance.

Re: Practical methods for making Salt knives pointier

Metal file?

Spydergirl88

3 Nats, 1 Chap, 1 Sham, 1 Urb

3 Nats, 1 Chap, 1 Sham, 1 Urb

Re: Practical methods for making Salt knives pointier

Well, I know I can use a file, or sandpaper, or stones... Just any practical trick or advice to make it easier and less prone to errors...

I may try a sanding machine that I have...

Re: Practical methods for making Salt knives pointier

Use painter's tape on any parts you don't want marred. Do you have a dremel and a vise?

Spydergirl88

3 Nats, 1 Chap, 1 Sham, 1 Urb

3 Nats, 1 Chap, 1 Sham, 1 Urb

Re: Practical methods for making Salt knives pointier

Just buy a cheap belt sander. You can use other methods but you'll be spending hours instead of five minutes. Unless you make minimum wage it doesn't factor out when one can get a sander for $30-60.

Re: Practical methods for making Salt knives pointier

I don't... I can get to a vise at my parents, by I have no dremel.Spydergirl88 wrote: ↑Fri Mar 12, 2021 4:58 pmUse painter's tape on any parts you don't want marred. Do you have a dremel and a vise?

Won't take my angle grinder close to my pocket knives either :D :eek:

I'll take a look at it, thanks.vivi wrote: Just buy a cheap belt sander. You can use other methods but you'll be spending hours instead of five minutes. Unless you make minimum wage it doesn't factor out when one can get a sander for $30-60.

Re: Practical methods for making Salt knives pointier

I'd buy a Dremel, that's what I reprofile all my blade spines on.

All SE all the time since 2017

~David

~David

- Cambertree

- Member

- Posts: 1640

- Joined: Tue Sep 09, 2014 6:48 am

- Location: Victoria, Australia

Re: Practical methods for making Salt knives pointier

Belt sander’s the best option, as Vivi said. Dip the blade in water often to limit heat buildup.

I’ve used 80 or 100 grit sandpaper too, but it obviously takes a while. If you use a compressible substrate like a mousepad or thin packing foam, you can radius the edges to make a crowned spine. I avoid the tip area and finish that with coarse benchstones to keep it crisp and pointy.

Then go up through your grits to attain a higher polish.

I haven’t tried a Dremel for the job.

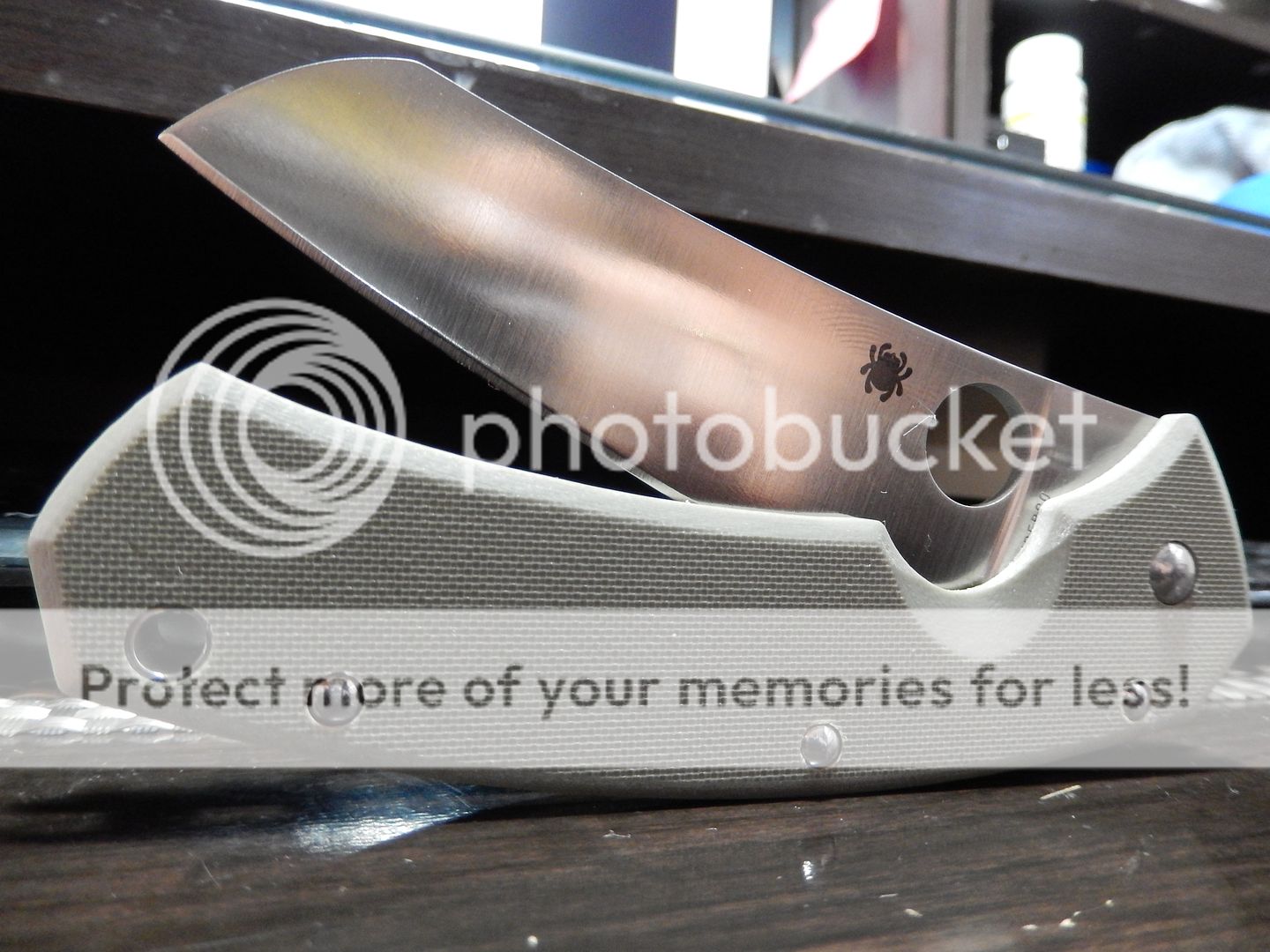

Here’s my Pac Salt 2 which was done on a belt sander:

I’ve used 80 or 100 grit sandpaper too, but it obviously takes a while. If you use a compressible substrate like a mousepad or thin packing foam, you can radius the edges to make a crowned spine. I avoid the tip area and finish that with coarse benchstones to keep it crisp and pointy.

Then go up through your grits to attain a higher polish.

I haven’t tried a Dremel for the job.

Here’s my Pac Salt 2 which was done on a belt sander:

Re: Practical methods for making Salt knives pointier

I don't think I've ever taken before and after shots but it's not hard to compare..

I do draw a line and work out how I want it shaped, and if I'm removing a LOT of steel I have a mini bench grinder I'll use to take off more steel faster (as mentioned, keep the blade cool by dipping in water often). I like the Dremel because it's slow and I have more control than with a belt sander where things can quickly go south. I use barrel sanders and I use a similar carving motion as you'd use to cut a slice off an apple.

You can get crazy or do subtle changes like this Rock Lobster..

I also use a similar method for fixing chipped/rounded off tips.

All SE all the time since 2017

~David

~David

Re: Practical methods for making Salt knives pointier

Wow, that's Dremel work with barrel sanders? I'm amazed. You don't even use a Dremel cutoff disc? How many minutes does a barrel sandpaper last you?

- Doc Dan

- Member

- Posts: 14815

- Joined: Thu Nov 08, 2012 4:25 am

- Location: In a dimension as vast as space and as timeless as infinity.

Re: Practical methods for making Salt knives pointier

Just be careful of overheating. Those belt sanders can really heat up a knife blade fast. I made that mistake on a knife I modded years ago. I was making a sheepfoot blade and ruined the temper because the blade quickly got hot. I've had better luck when I could have a constant drizzle of water on the blade while I sanded. But, that's just my experience.

I Pray Heaven to Bestow The Best of Blessing on THIS HOUSE, and on ALL that shall hereafter Inhabit it. May none but Honest and Wise Men ever rule under This Roof! (John Adams regarding the White House)

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

Re: Practical methods for making Salt knives pointier

Cambertree wrote: ↑Fri Mar 12, 2021 6:37 pmBelt sander’s the best option, as Vivi said. Dip the blade in water often to limit heat buildup.

....

Is it that important to avoid heat buildup when just working the spine (but not the edge)?

Could this really go so far that the structural integrity of the whole blade gets endangered (on the very edge it is obvious that even slightest changes in the hardening could be very bad, but on the spine?)

Honest question, I have no idea and experience here.

Top three going by pocket-time (update March 24):

- EDC: Endura thin red line ffg combo edge (VG10); Wayne Goddard PE (4V), Endela SE (VG10)

-Mountains/outdoors: Pac.Salt 1 SE (H1), Salt 2 SE (LC200N), and also Wayne Goddard PE (4V)

- EDC: Endura thin red line ffg combo edge (VG10); Wayne Goddard PE (4V), Endela SE (VG10)

-Mountains/outdoors: Pac.Salt 1 SE (H1), Salt 2 SE (LC200N), and also Wayne Goddard PE (4V)

Re: Practical methods for making Salt knives pointier

They last a long time actually. You're working with a small surface and it grinds faster than you'd think. There are also at least two grits for those barrels and the heavier grit is pretty aggressive, I think like 60 grit or so and it'll remove metal quick. I'm sure it's slower than a belt sander or bench grinder but to me slow and steady is better than screwing it up. I finish them with sandpaper and try to make them look factory or in most cases better than factory.

Most of my knives I will smooth down the grind finish on the spine even if I don't tweak the shape, and I use small sanding barrels to clean up the finish on the inside of the thumb hole and sharpen up the edge of the hole.

Here's a comparison, it's kind of an old pic but you can see the changes made to the bottom one vs the top.

Here's another before and after I found of a cleaned up thumb hole

All SE all the time since 2017

~David

~David

- Cambertree

- Member

- Posts: 1640

- Joined: Tue Sep 09, 2014 6:48 am

- Location: Victoria, Australia

Re: Practical methods for making Salt knives pointier

Short answer: I don’t know.Wartstein wrote: ↑Sat Mar 13, 2021 12:33 amCambertree wrote: ↑Fri Mar 12, 2021 6:37 pmBelt sander’s the best option, as Vivi said. Dip the blade in water often to limit heat buildup.

....

Is it that important to avoid heat buildup when just working the spine (but not the edge)?

Could this really go so far that the structural integrity of the whole blade gets endangered (on the very edge it is obvious that even slightest changes in the hardening could be very bad, but on the spine?)

Honest question, I have no idea and experience here.

A bit more detailed take: The blade’s been tempered to a certain level, and even superficial heat damage on the spine, at best, probably won’t improve the characteristics of the blade.

At worst it might possibly allow sites of microcracking to initiate when the blade’s under stress. Perhaps dimensional changes in the structure of the steel might introduce other stresses, or possibly a degree of blade warping?

The potential detrimental effects of heat buildup from powered grinding may well be minimal on the spine area of a blade, but I feel it doesn’t hurt to keep the area cool. The tip area will obviously heat more rapidly, so I avoid grinding too close to that area and finish that spot with benchstones.

I dip the blade in a can of water every couple of passes.

On the photo of my Pac Salt 2 above, you can see I haven’t quite finished grinding the tip to a needle point. I decided to just let a few resharpenings of the PE tip area carry the sharpened portion up to meet the spine at the point.

Re: Practical methods for making Salt knives pointier

If you let the blade get hot you'll definitely blue the steel.

All SE all the time since 2017

~David

~David

-

pantagana23

- Member

- Posts: 461

- Joined: Mon Apr 08, 2019 9:52 am

- Location: Croatia

Re: Practical methods for making Salt knives pointier

Another option on what Cambertree suggested:Cambertree wrote: ↑Fri Mar 12, 2021 6:37 pmBelt sander’s the best option, as Vivi said. Dip the blade in water often to limit heat buildup.

I’ve used 80 or 100 grit sandpaper too, but it obviously takes a while. If you use a compressible substrate like a mousepad or thin packing foam, you can radius the edges to make a crowned spine. I avoid the tip area and finish that with coarse benchstones to keep it crisp and pointy.

Then go up through your grits to attain a higher polish.

I haven’t tried a Dremel for the job.

Here’s my Pac Salt 2 which was done on a belt sander:

If you can get 2 pieces of copper busbars (like the ones used in MCBs or similar, 0.3"x1"x whatever length, put the knife between 2 pieces in a table vice, with the part being sanded off above the copper.

Copper is a great heat sink, and will take away the heat almost instantly to the vice and around.

-

Lonehunter

- Member

- Posts: 92

- Joined: Fri Sep 24, 2004 10:33 am

Re: Practical methods for making Salt knives pointier

I used a file on my Salt , went pretty quick ,a few minutes . Then I hit it with some emery cloth , to smooth it out .

Re: Practical methods for making Salt knives pointier

man... i thought this was a coated blade for a second.

keep your knife sharp and your focus sharper.

current collection:

C253GBBK, C258GFBL, C101GBBK2, C11GYW, C11FWNB20CV, C101GBN15V2, C101GODFDE2, C60GGY, C149G, C189, C101GBN2, MT35, C211TI, C242CF, C217GSSF, C101BN2, C85G2, C91BBK, C142G, C122GBBK, LBK, LYL3HB, C193, C28YL2, C11ZPGYD, C41YL5, C252G, C130G, PLKIT1

spyderco steels:

CPM 20CV, CPM 15V, CTS 204P, CPM CRUWEAR, CPM S30V, N690Co, M390, CPM MagnaCut, LC200N, CTS XHP, H1, 8Cr13MoV, GIN-1, CTS BD1, VG-10, VG-10/Damascus, 440C

current collection:

C253GBBK, C258GFBL, C101GBBK2, C11GYW, C11FWNB20CV, C101GBN15V2, C101GODFDE2, C60GGY, C149G, C189, C101GBN2, MT35, C211TI, C242CF, C217GSSF, C101BN2, C85G2, C91BBK, C142G, C122GBBK, LBK, LYL3HB, C193, C28YL2, C11ZPGYD, C41YL5, C252G, C130G, PLKIT1

spyderco steels:

CPM 20CV, CPM 15V, CTS 204P, CPM CRUWEAR, CPM S30V, N690Co, M390, CPM MagnaCut, LC200N, CTS XHP, H1, 8Cr13MoV, GIN-1, CTS BD1, VG-10, VG-10/Damascus, 440C