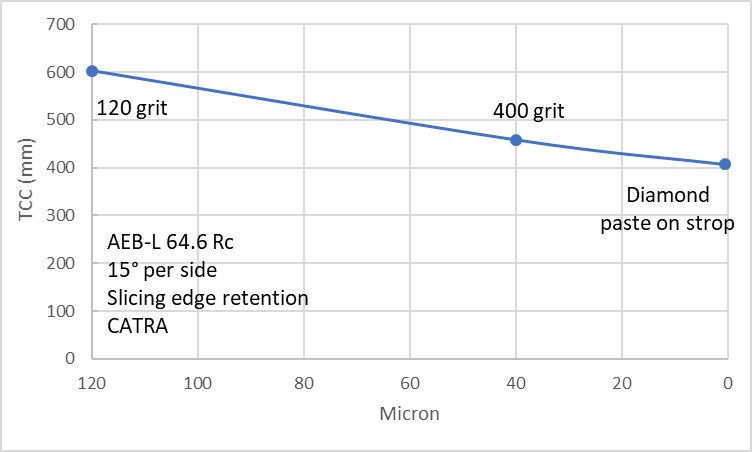

"Total Cards Cut"

The cutting action on catra is a back and forth saw like motion with a fixed load weight and fixed amount of cuts and measures how many "cards" are cut at the end.

The knife that cuts the most cards at the end with the same amount of cuts is said to do more "work" and have more retention with a back and forth motion and fixed weight.

So from the graph you can see the toothier edge finish did better.

That may translate to real world depending on how well the toothy edge is executed and what type of cutting task is being done.

For instance hunters like the toothier edge, it grabs and cuts through the hide better and most cuts are done with a drawing motion.

That doesn't translate to shaving your face better, the cutting motion is also different for that, you "push" cut and cleave off the hairs, polish is the winner for that.

Surfingringo wrote: ↑Thu Mar 26, 2020 8:07 am

I consider myself (perhaps mistakenly) a relatively intelligent human being. I’m even partially educated. That said, I think about 90% of the graphs I see posted on there are complete Greek to me. It probably doesn’t help that I don’t know what TCC (mm) means but even if I did I‘m not sure I would understand what that graph is representing. I don’t know, I’m good with some things and not so much with others I guess.

- Speaking broadly I guess that since the graph has something to do with edge retention and the line is going down then the point is that ER goes down as finish grit goes up? Maybe it is just the TCC (mm) that is leaving me lost. Is that a designation of edge performance in Catra? Thanks