Here are some pictures so far. Any advice on making fixed blade handles is appreciated as well. REALLY appreciated. I have one scale glued to the side of the handle. I need to wait for some pin material to drill holes for it and then finish the other side then shape, polish, etc. But I'm absolutely no expert and any tips on anything I'm open to. Especially the sealing of the handle when finished. Here are some pictures so far. I've taken a pic after just about every step I think.

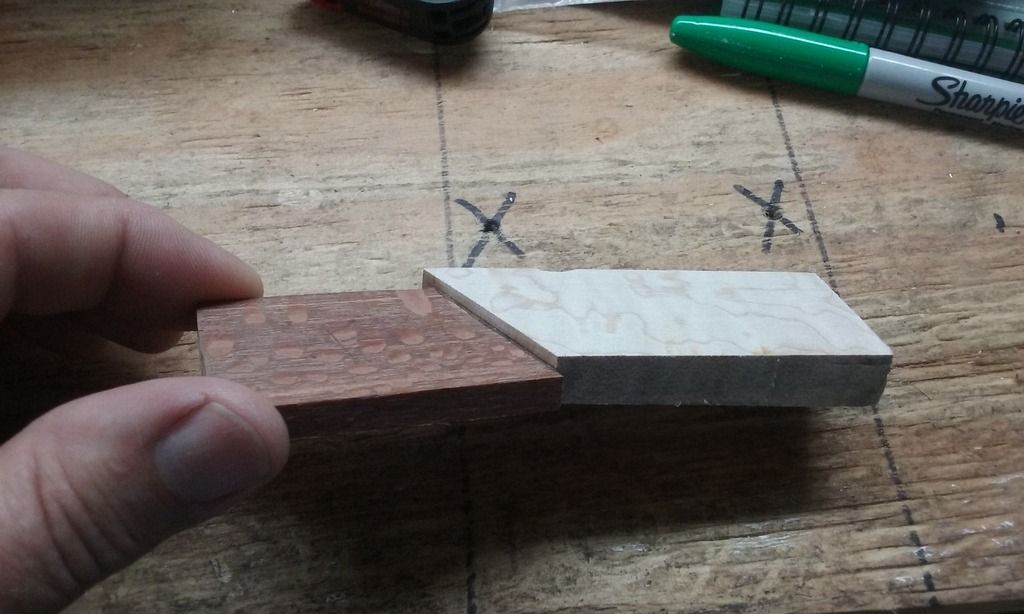

Gluing the two pieces of wood together. BTW, I used Titebond III wood glue. I recently got a Kreg jig and have been on that forum some. I asked about different wood glues as all I've ever used that I can remember is Elmer's. It ISN'T waterproof. The Titebone III is supposed to be 100% waterproof wood glue after it dries. Using it is just like using Elmer's or other common wood glues. It takes a few minutes longer to set I think but that's about it. I read about it on their site. When it comes to gluing wood I've never had anything work better than a good wood glue. Epoxy and other types will work but a glue just for wood is great just for wood. But, not being waterproof has always a drawback. So, I tried the Titebond III for this. They have a I and a II also. I suggest checking them out if you haven't. More than likely I'm the only one who never heard of it before. On a side note, the Kreg jig is a wonderful thing. :) I've been drilling pocket holes all over the house. Wife is mad about the holes in the top of the dining room table. :) Back on subject.

This is the other scale just to show the different thickness of the wood. Not important, just a pic. :)

3

x

This pic shows the polishing compound I used so far. I used the blue one labeled for multiple surfaces. I bought the pack a long time ago to use to polish blades (steel, not wood). SUPER cheap on some site somewhere. Works pretty good though. I may use something a bit more "fancy" to finish it up. Don't really know yet. This is another area I'd love some advice. Getting wood super smooth and polished. Or left a bit less shiny. All help is appreciated.

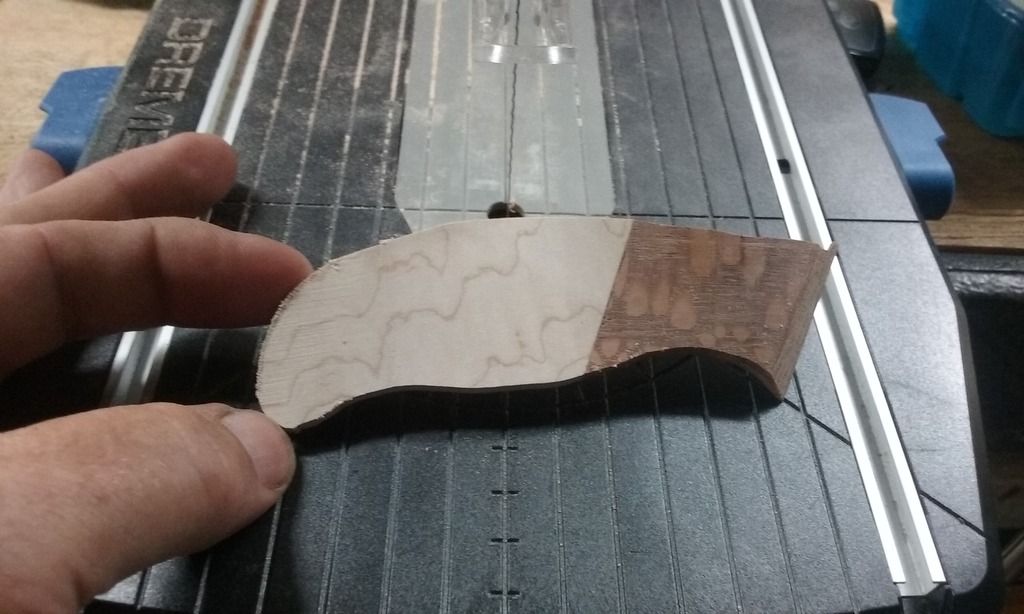

This is what I did today (6/26/15). I've got the front of the scales shaped and polished some and two holes drilled in one scale. I glued the scale with the holes to the knife. The holes are in the center of two of the larger holes in the handle. The pin holes will be 1/4" and the holes in the knife are 3/8" so I have enough margin of error that all is well. When I get the pin material I'll enlarge the holes, drilling through both scales. Then I'll glue it all together. Wonder if I should have waited to glue this one. Any thoughts? They are a mosaic type. Hope they look good. Any advice on adding mosaic pins is really appreciated. There was a warning on the product that they get warm when working with them very easily and can soften epoxy. So I guess working slow with low speed with a Dremel or whatever is important. :confused: :confused: :confused: Please help with this if anyone can.

This is the front of the scale. I finish it as much as I can because after gluing it I can't do any more sanding or anything because the wood is against the steel. Finishing the rest of the outside of the handle will also polish the tang but I don't know of a way to work on the scales right here once they are glued to the knife. Any suggestions about this are appreciated.

I've had this Mule for a month or two I think along with the handle material. Been really busy and am now just getting to it. So far so good I think. We'll see what happens. :)

Jack