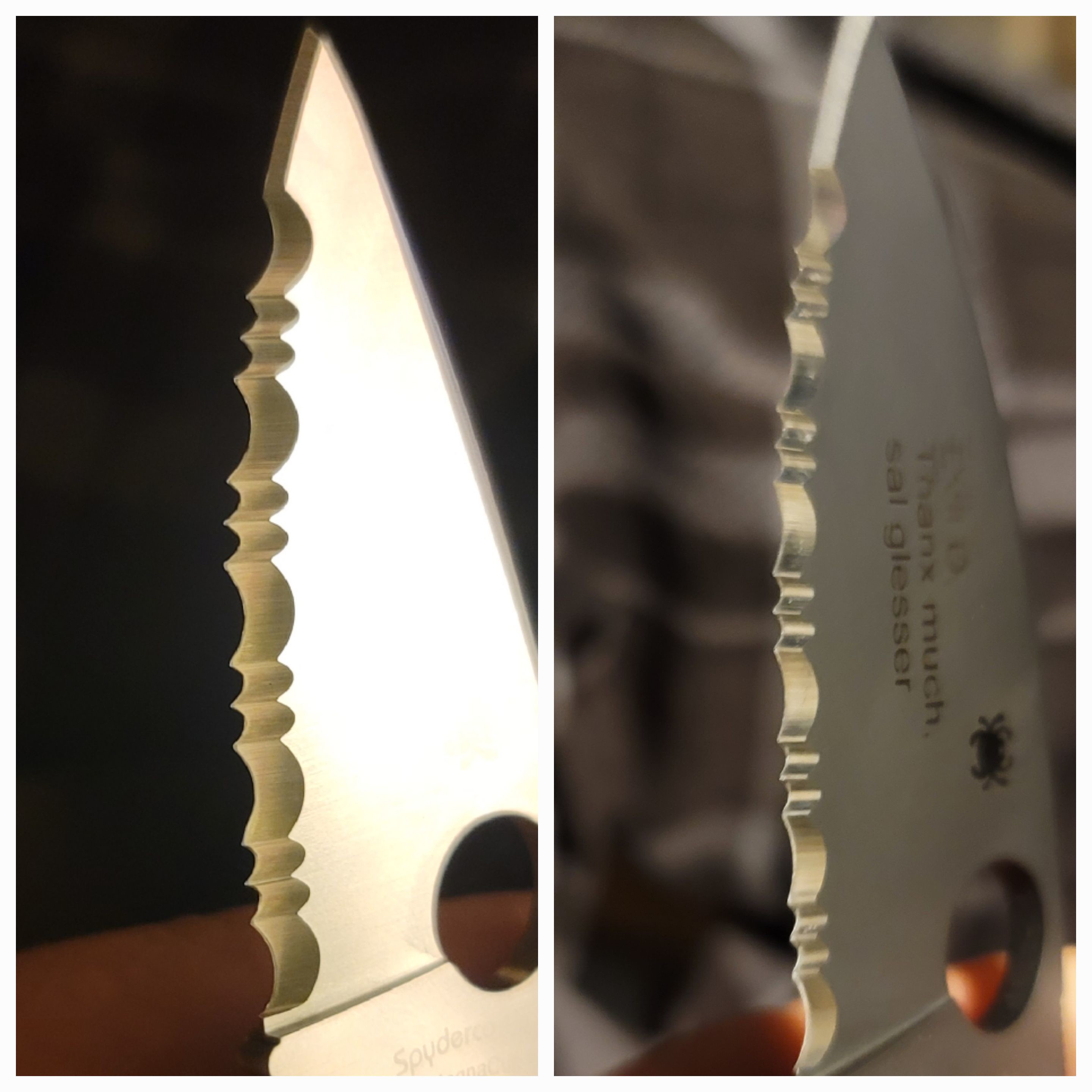

I had to take a pic with some weird shadows just to show that this is indeed a MagnaCut version. The laser engraving is small and somewhat faint and disappears in some light.

It did have a bit of a wire edge in some spots so I ran it over the brown Sharpmaker rods to smooth them out. This also establishes a 30 degrees inclusive edge bevel so others can compare their results (I sharpened the back side at 15 degrees as well as the front so the apex is 30 inclusive).

The shiny spots near the tang are where the edge was a little wavy.

The good news is the serrations are ground quite thin, meaning you can micro bevel and begin sharpening on the 30 degree slots. I can not express how much I appreciate this and I hope Spyderco are doing this on purpose. It eliminates the need to reprofile a brand new knife and is absolutely a blessing. Please do this more!

The bad news is the plain edge at the tip is really steep, something above 20 degrees. I noticed the rods were hitting on the shoulder on the 30 slots so I moved to the 40 slots and it still hits the shoulder. This kinda sucks, it's kinda tricky to reprofile just that PE section. I may do it on my Edge Pro. For now I just freehanded the front side to remove the burr. The cutting performance I'm looking to explore in this thread is regarding the serrations anyway.

I'm going to check back on the Caribbean/LC200N testing I did and try to gather up the same materials to cut up so there's some kind similarities, even though being totally different knives is already not the best for comparison sake.

I will update over the next few days as stuff gets cut.