Here are my points and assumptions, which could be completely off.

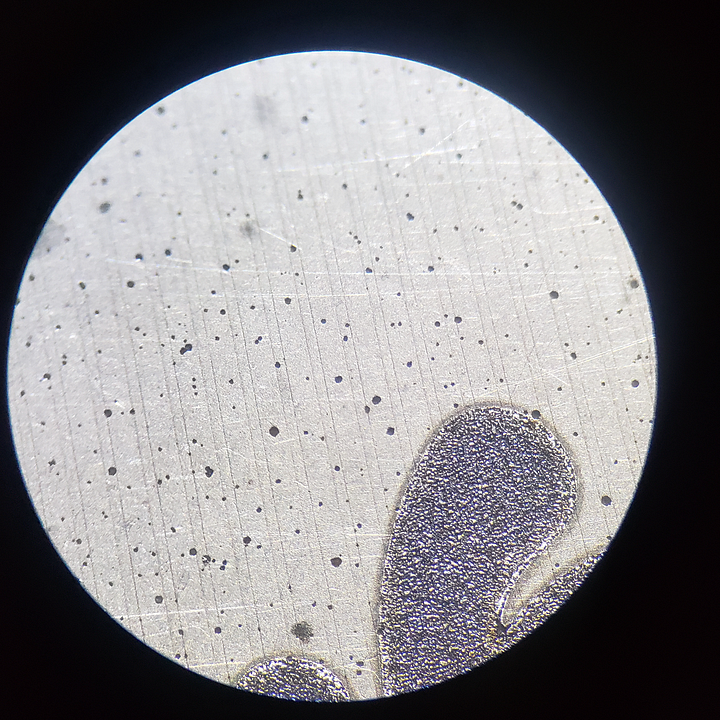

I assume that powder metallurgy produces a more consistent steel. The raw materials are blended together and sintered, and formed into something (sheet?) which is ready for the next step. Is this an exact science? Is it possible that a section of the steel has slightly different properties than a different section of the same sheet some feet/yards away? What about the edge of the sheet vs the center of the sheet? Is it possible that one batch is slightly different than another batch produced months apart?

Then the knife maker gets the steel. The blades are cut, shaped, heat treated - no idea what the order is - and eventually sharpened. Is this an exact science? The machines involved in the process need to be calibrated. If there is variation of the many manufacturing tools used in the process from when they are certified to the end of their calibration cycle, I would assume this would create some variation. Is it possible that a blade being heat treated in the center of the rack will go through the process slightly differently than a blade placed on the edge. Same for the tempering process. And, if that original sheet of steel had some discrepancy, I can only imagine that any variation in the knife manufacturing process would exacerbate any inconsistencies in the final product.

In a mass production process, you can't test and QC every inch of a sheet of steel. Just like you cant test and QC every blade to make sure it has the desired properties. But perhaps good enough where most of us get what is advertised.

So, how much variation is there in the advertised properties of our pocket knives when it comes to toughness and edge retention properties? How many of us could even tell?

These thoughts don't keep me awake at night, but I am curious