Page 2 of 2

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 7:37 am

by utor

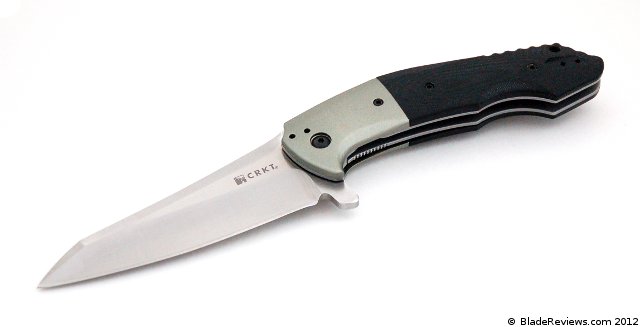

If you print out this picture in 100% you should be good to go.

I re-scaled it from the scan jpm2 according to his measurements,

so better double-check before.

:)

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 7:53 am

by Holland

utor wrote: ↑Tue May 26, 2020 7:37 am

If you print out this picture in 100% you should be good to go.

I re-scaled it from the scan jpm2 according to his measurements,

so better double-check before.

:)

That's the GB1

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 8:00 am

by BornIn1500

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 9:29 am

by Sumdumguy

I've racked my brain over this and I think I've figured it out.

Clip point. Gayle Bradley Worker

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 9:48 am

by zhyla

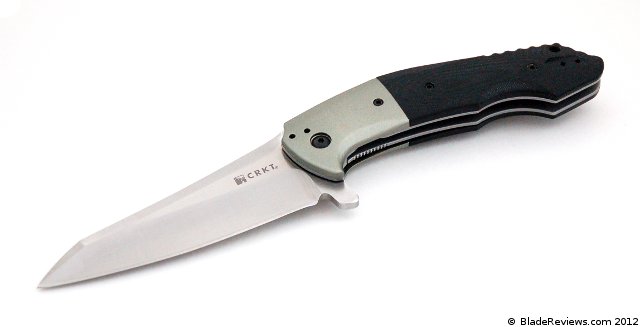

Changing the shape of the edge is a no-go without regrinding the hollow grind. The can be done, but most DIY level people aren't set up for hollow grinding.

What I would do is grind a flat or tanto profile to meet the remaining tip and then start rounding/shaping that until it looks plausible. I'm not sure exactly what to do with the swedge... maybe try to blend the swedge.

Something along these lines:

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 10:21 am

by Ez556

jpm2 wrote: ↑Mon May 25, 2020 4:16 pm

Ez556 wrote: ↑Mon May 25, 2020 3:44 pm

Holland wrote: ↑Mon May 25, 2020 3:25 pm

jpm2 wrote: ↑Mon May 25, 2020 2:08 pm

I would probably do something like this.

That definitely looks nicer than what I posted.

One possible issue however, with it being hollow grind, the tip area might be significantly thicker behind the edge than the rest of the blade

This would be my worry. If you bring the edge up at all, it’s gonna end up being significantly thicker and the edge is gonna end up looking really odd at the tip. I’d just bring the spine down to the edge somehow rather than bringing the edge up at all, that’ll also prevent any issues with the edge ending up above the scales when closed.

I'm not sure that tip placement isn't much different from the original, which would make it the same thickness.

I don't have a GB2, anyone post an image for comparison?

The issue is that the original hollow grind follows the curvature of the original edge. If you shorten the blade and regrind the edge so that the tip profile is the same, the tip ends up right in the middle of the hollow grind. That causes the edge to grow and grow all the way to the tip, which ends up looking a bit odd. The “right” way to do this would be to redo the hollow grind as well so that it matches the new curvature to the tip, but as zhyla said, most wouldn’t have the equipment to do so.

Re: broken BRADLEY FOLDER™ 2 CARBON FIBER Please help

Posted: Tue May 26, 2020 11:45 pm

by torr

Thank you for replies.It is true I do not have tools for recreating hollow grind.Respectively I have Tormek T8 - maybe I will try it on some crap knife and see if it would be usable.