Most that time I took my edges to a high polish, generally finishing with highest grit I had available to me. I'd finish my edges with a Spyderco ultrafine benchstone or sharpmaker rods, then strop.

Reading about sharpening on different knife forums convinced me that polished edges would always be sharper than a coarse edge, and therefore cut better.

Over the past two years I've come to find out that this isn't always true.

In fact I'd say the majority of the time a lower grit edge will show superior performance VS a highly polished.

-------------------------------

I started experimenting with low grit edges a few years ago. I had a PE Pacific Salt I was carrying frequently at the time. It was one of my favorite work knives, but the edge holding left a little to be desired.

One thing I observed with PE H1 is that the apex starts to feel really slick after some use when you run a polished apex. I got the idea to use a lower grit finish to give the edge some teeth. The idea was after a little dulling those teeth would help grab the materials I was slicing, rather than sliding around like a dulled polished edge.

H1 with a polished edge quickly lost its bite

Instead of touching up the knife on the ultrafine sharpmaker rods, I used the brown medium rods that I never used. I was surprised to find I could still get the knife shaving sharp despite using what I considered at the time a very low grit finish.

That PE Pacific Salt would still lose shaving sharpness after cutting some cardboard, but with the microserrations at the apex it'd keep slicing well past that point.

Pacific Salt sharpened at 15 dps on medium rods

I had what I wanted - a PE Pacific Salt with enhanced edge retention!

-------------------------------

After experimenting with the Pacific Salt, I started trying this out on the rest of my knives.

The Aqua Salt was the next one I did. I took the edge down to the brown rods just like with the Pacific Salt, then used it to break up tons of cardboard. The edge was able to slice much longer than it did before.

Next up was my Szabo folder. Again I went from the UF rods to the medium rods, and found myself preferring that edge. The toothier edge worked particularly well with the Szabos blade shape.

I didn't limit myself to PE. I did the same thing with serrated knives. The SE Pacific Salt I was sharpening with my UF rod got taken down to medium. The difference felt less drastic on SE, but edge longevity still increased.

-------------------------------

After a while I got curious to take my experiment further. I ordered a set of diamond sharpmaker rods to compliment my DMT diamond benchstones. Now I could sharpen any knife, PE or SE, to very coarse grits.

First, I experimented with a SE Pacific Salt. I ground it the same way I did with the medium rods: 15 degrees, no microbevel. I tested it out and it was easily the most aggressive slicing edge I had ever tried, hands down.

Pacific Salt sharpened on UF rods

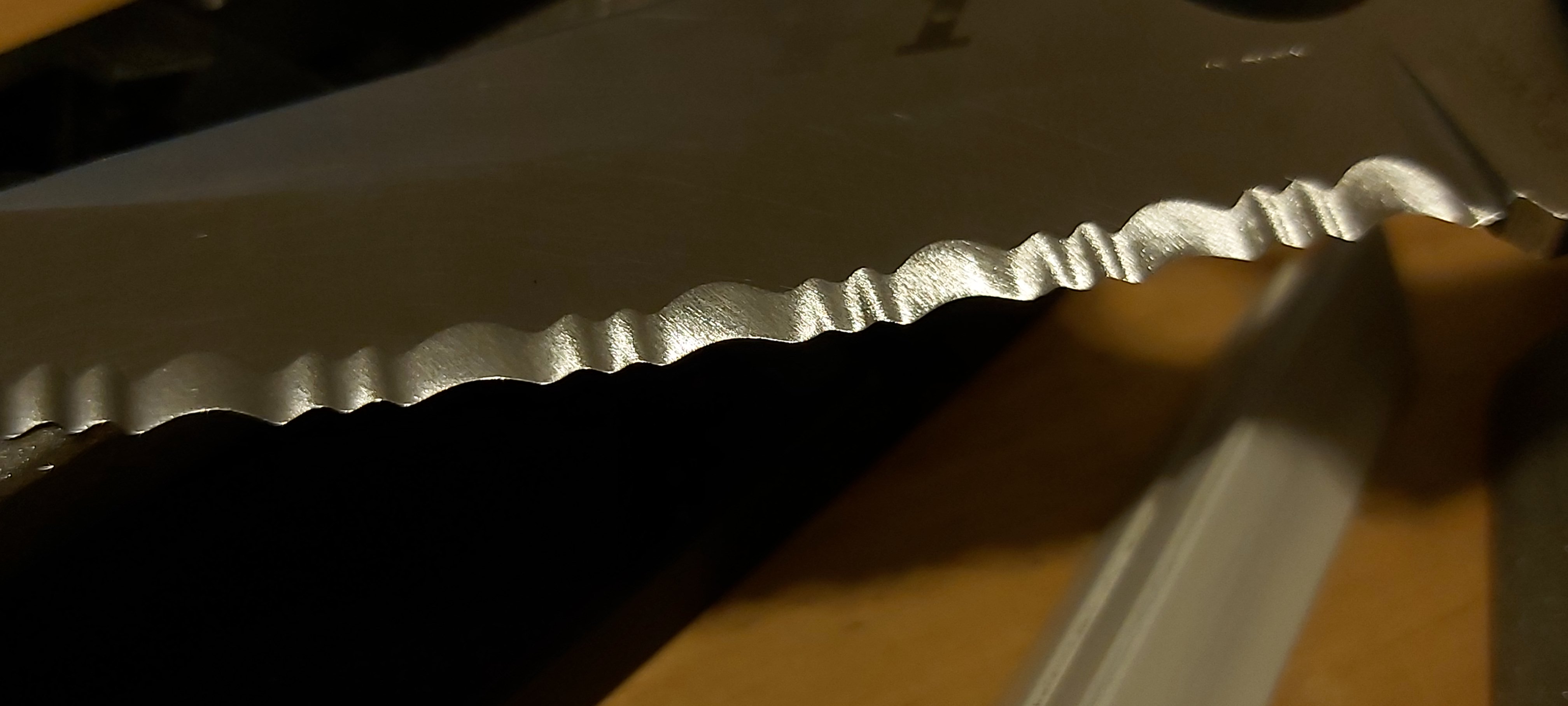

Serrated Pacific Salt ground on diamond rods at 15 degrees

Next was a Manix XL PE. I ground off the microbevel on my DMT reprofiling stone, then using feather light strokes I refined the apex well enough to cleanly shave. I didn't think I was capable of shaving sharpness off this stone, this was a surprise. The edge sliced very aggressively for plain edge. I was immediately hooked. It grabbed materials much better VS the polished edge, bringing it closer to the performance of my SE Pacific.

Manix XL sharpened around 10 degrees per side on a DMT Extra Coarse diamond plate

I kept going, dropping the grit finish on nearly every knife in my collection. I experimented with edges straight off the diamonds, diamonds followed by stropping, and even tried some edges where I'd grind at 15 degrees with diamonds then do two strokes per side with the fine rods at 20 degrees to refine the apex withiout completely grinding off the teeth.

Serrated Pacific Salt ground on diamond rods at 15 degrees finished with two strokes per side with fine rods at 20 degrees.

-------------------------------

For me, the benefits of this sharpening journey have been numerous. I've learned more about my abilities, the steels in my collection, and how different grits affect the performance of the knife.

These days I switch between two knives for my EDC. A serrated Pacific Salt and a PE DLC Manix XL. Both have edges straight off my diamond rods, and both are shaving sharp. These toothy edges have changed how I approach sharpening:

- I'm going further between sharpenings. Polished edges dulled to the point they don't scrape shave cut poorly. Very toothy edges that no longer shave cut great! I'm touching up after a few weeks rather than a few days.

- Sharpening times have decreased. Coarser stones work much faster, and no grit progression means I only have to setup a single stone. Fully refreshed apexes in under a minute, easily.

- My edges grab materials better. Have you ever tried to slice poly rope or plastic wrap with a dulled plain edge and felt it slip around? These toothy edges do the opposite, they grab a hold of material and don't let go until its cut. It's not only more efficient, its safer.

- Sharpening is more fun. At the risk of sounding conceited, getting shaving sharpness from a full progression up the the ultrafine stones was trivial for me. Getting shaving sharpness right off the diamond sharpmaker rods takes a more concentrated effort, and feels more rewarding when accomplished. Between the added challenge and reduced sharpening times, I look forward to touch-ups a lot more now.

- They're awesome slicers! I've always considered myself a connoisseur of cut. I spent years as a chef and developed an appreciation for a well sharpened knife. These low grit edges cut extremely well, and cut differently. It's been a pleasure using them on a variety of materials.

-------------------------------

If you're like me and never experimented with low grit edges, I suggest giving it a try! See how refined of an edge you can achieve with your lowest grit stone, then try cutting with it. You might be surprised!

https://youtu.be/rnuY-Ib2jVg