You can change angles like this. Using different sized dowels can yield different angles. You can download an angle finder app for your smartphone to check the angles. It takes a little getting used to rocking it back and forth when switching sides but when reprofiling I will just do a bunch of passes per side (like 20, 50, 100, whatever it takes) until I get closer to apexing. You can get pretty efficient doing like 5 passes per side and then rocking the base to switch sides. You just have to do it and establish a little muscle memory and rocking the base just becomes part of the process. There is a perfect little slot in the top of the base for the rubber band to sit in so it stays centered well.

You can get any grit you want like this. I usually use some 220 grit paper when the diamond rods are not course enough. Try to make sure that you have the paper pulled as tight around the rod as you can or you may get scratches above the bevel on your primary grind, especially when trying to do a steep angle. Creasing the paper before wrapping it around the rods is how I keep it tight/flat on the rod. You can go through a lot of sandpaper this way but it does work well.

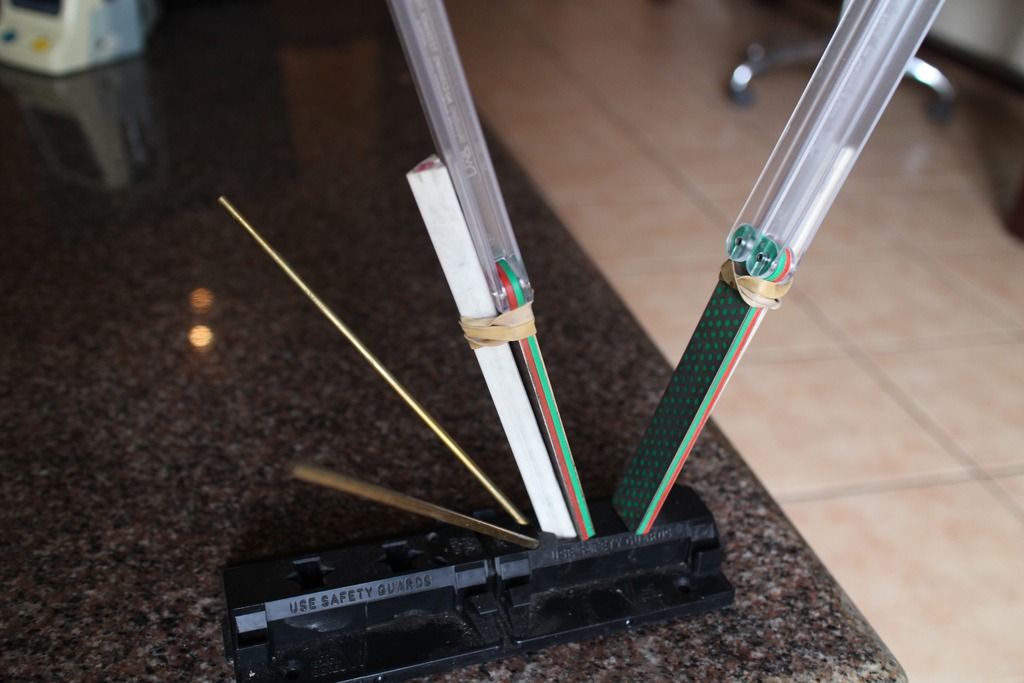

You can carry any combination of the stones in the plastic base. You could even carry one of each of the four stones. I have been successful using a single rod as a hand held stone so having one of each in the base works for me. On a recent hunting trip I brought it just with the diamond and brown rods. On this trip I didn't have time to be sharpening and if I did have to do a quick touch up or repair this would have had me back up and running in no time at all.

Do any of you guys have any good tips or tricks to help get a little more performance or a little more versatility out of this device? I am sure there are many more. I hope this helps someone. :D