Are the Sharpmaker UF stones worth it?

Re: Are the Sharpmaker UF stones worth it?

I highly recommend every grit of stone that Spyderco has to offer. The UF stone I find extremely good for sharpening straight razors and woodworking tools like plane blades and chisels. Yes I also do use all of my UF stones on knife blades as well. To me having the 204 Sharpmaker and not having all the stones you can get with it truly puts a guy at a disadvantage IMO.

But everyone's individual needs and wants are different. I consider myself somewhat of a sharpening fanatic and I've got dozens of stones I like to experiment with. Also different blade steels react differently to a wide array of benchstones. I guess it just depends on why you got the 204 Sharpmaker to begin with>> because if you want a functional sharp edge on your everyday usage knives then the medium & fine stones that come with the kit truly are enough to get you by but it sure is nice to have the diamond and UF stones because I can sure do a much better sharpening job with them.

But everyone's individual needs and wants are different. I consider myself somewhat of a sharpening fanatic and I've got dozens of stones I like to experiment with. Also different blade steels react differently to a wide array of benchstones. I guess it just depends on why you got the 204 Sharpmaker to begin with>> because if you want a functional sharp edge on your everyday usage knives then the medium & fine stones that come with the kit truly are enough to get you by but it sure is nice to have the diamond and UF stones because I can sure do a much better sharpening job with them.

Always use my UF rods.

Always use my UF rods.

Hi Folks!

I always finish my sharpening with my UF rods. Regularly it is Medium > Fine > Ultra Fine, but when I have to deal with really tough stuff like S110V I begin with Diamond / CBN rods, and then go on.

For my kind of cutting, UF rods work great. But it's not for everyone. It'll depend on what do you cut and do you cut it. :rolleyes:

I always finish my sharpening with my UF rods. Regularly it is Medium > Fine > Ultra Fine, but when I have to deal with really tough stuff like S110V I begin with Diamond / CBN rods, and then go on.

For my kind of cutting, UF rods work great. But it's not for everyone. It'll depend on what do you cut and do you cut it. :rolleyes:

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Always use my UF rods.

Does anyone know of a list of standard or less frequent cutting tasks that different grits are better for? I'll list 3 things I can think of without trying.LC Kid wrote:Hi Folks!

I always finish my sharpening with my UF rods. Regularly it is Medium > Fine > Ultra Fine, but when I have to deal with really tough stuff like S110V I begin with Diamond / CBN rods, and then go on.

For my kind of cutting, UF rods work great. But it's not for everyone. It'll depend on what do you cut and do you cut it. :rolleyes:

1. Lots of rope, net, etc.: Serrated I suppose but for this conversation I guess very toothy may be best. Spyderco med. or coarser I guess. :confused:

2. Opening mail, cardboard boxes with a new knife inside, anything you may see frequently, :confused: again.: :) Spyderco fine grit I think. IMO, for my needs the fine grit is a pretty fine grit in the grand scheme of grits so I'd guess it's as fine as needed for about any EDC pocket knife. Some would even opt for coarser like 600 grit.

3. I'd guess the UF grit is only "required" for something like a straight razor or any cutting requiring or made better by a very smooth edge. In the example of the razor think of shaving your face with a very smooth edge or a fine tooth hacksaw blade. The smoother the better in any language for shaving.

People who play with sharpening and have tried several stone types and different grits within each type may know what they like for their needs from trial and error and probably a considerable amount of money spent. But someone new to sharpening may have no idea what to shop for. This would be important for someone wanting to spend a max of $100-$150 on sharpening tools and still have a wide variety of options. Actually, I think Spyderco has the optimum set as medium and fine grits as the standard for the Sharpmaker. Anything other than that would be for very dull knives needing lots of work or edges needing to be super smooth. If you don't want the angles controlled for you I'd still stick with the medium and fine grit bench stones for the grit range. Just my thoughts.

Jack

Re: Are the Sharpmaker UF stones worth it?

I think it also depends on the knife steel. There appear to be knife steels, like 440A, that will always be toothy because the steel is not very refined. In the case of a steel like that, its probably futile to sharpen finer than a steel can be sharpened to.

Ryan

“Every created being is so constituted as to be capable of vice and virtue. For he can do nothing praiseworthy, if he had not the power of turning either way.” - Justin Martyr

“Every created being is so constituted as to be capable of vice and virtue. For he can do nothing praiseworthy, if he had not the power of turning either way.” - Justin Martyr

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Are the Sharpmaker UF stones worth it?

A category of cutting I should have thought of in my previous post instead of shaving is cutting wood, especially if it's wood carving instead of cutting branches with a knife. A smooth edge like is needed on a chisel for accurate cutting is much better with a smooth edge and the UF stones do a good job at that. If you want the chisel type edge on your knives the UF rods would do it.

Jack

Jack

Re: Are the Sharpmaker UF stones worth it?

I shave with my knives, 8Cr and 52100 get very smooth with UF. From my limited experience, UF is useless for D2. It (D2) likes toothy, and I'm experimenting with DMT EF as highest grit. Even DMT EEF didn't work well with D2.

Hope it helps making the point that it also depends on the steel and what user wants out of it.

Hope it helps making the point that it also depends on the steel and what user wants out of it.

Chris :spyder:

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Are the Sharpmaker UF stones worth it?

Anagarika, do you get good results with any steel when using the DMT EEF grit stone? Also, what type stone do you have? I ask because...anagarika wrote:I shave with my knives, 8Cr and 52100 get very smooth with UF. From my limited experience, UF is useless for D2. It (D2) likes toothy, and I'm experimenting with DMT EF as highest grit. Even DMT EEF didn't work well with D2.

Hope it helps making the point that it also depends on the steel and what user wants out of it.

I have tried two or three different 4" size DMT EEF grit stones. The kind with the holes. I have never tried the continuous surface DMT EEF stone. I tried and tried and NEVER, EVER could get the EEF stones borken in to the point they would produce a more polished bevel (or edge apex I assume) than the DMT EF grit did. I repeatedly tried but the EEF grit no matter how much I tried to break in the stone would always scratch up a nice looking surface created by the EF stone. I need to add that the EF stone was a full size continuous surface stone that has been broken in for some time. I break diamond stones in by using them to go through the motion of flattening a water stone. This ensures the entire surface gets broken in at the same speed. Shapton glass are the water stones I have but I don't know if that matters for this subject. The conversations we've had here about DMT EEF stones has resulted in me not messing with them any more. Even the few people who say they have gotten good results with the continuous surface EEF stone say it took a LONG time to get them broken in properly. Months in a couple of cases. Maybe a year. Don't remember exactly. There are several other options to get a super polished edge and/or bevel surface that don't require much if any work at all. I do remember using some 400 (I think) grit wet/dry sandpaper on my Spyderco 3" UF stone to remove a couple of very tiny little bumps on one side of it. They were so tiny I couldn't feel them with my finger tips but when stroking an edge along the stone I could feel them if the edge hit them. After the sandpaper they were gone and the stone is perfectly smooth on both sides as far as I can tell. 30-60 seconds under running water is all it took for the tiny bumps. And this was for what I'd call a minor defect in that particular stone. It had nothing to do with the grit, breaking it in after some use or anything like that. Having said all that I consider diamond stone a completely different animal than ceramic stones. A discussion about them would be better in a different thread I think.

Jack

Re: Are the Sharpmaker UF stones worth it?

Jack,

Never found any EEF that's continuous. I have one as gift from bluntcut, well worn in & very smooth. Recently purchased one new diafold EF/EEF. In the process of breaking it in, by sharpening. I remember you wear them by using them as flattener.

The D2 was on old EEF but didn't work out. Using UF made it worse (carbide tear out due to burnishing effect?). Used EF (semi broken in), it's holding up well so far.

Caveat, I'm very light user, & mostly shave & open some packages. The D2 is not a shaver for sure.

Never found any EEF that's continuous. I have one as gift from bluntcut, well worn in & very smooth. Recently purchased one new diafold EF/EEF. In the process of breaking it in, by sharpening. I remember you wear them by using them as flattener.

The D2 was on old EEF but didn't work out. Using UF made it worse (carbide tear out due to burnishing effect?). Used EF (semi broken in), it's holding up well so far.

Caveat, I'm very light user, & mostly shave & open some packages. The D2 is not a shaver for sure.

Chris :spyder:

Re: Are the Sharpmaker UF stones worth it?

I have a D2 becker that I can shave with at 20 dps. I did find that going from medium to fine did not help much but using .5 micron diamond paste on a strop did.anagarika wrote:Jack,

Never found any EEF that's continuous. I have one as gift from bluntcut, well worn in & very smooth. Recently purchased one new diafold EF/EEF. In the process of breaking it in, by sharpening. I remember you wear them by using them as flattener.

The D2 was on old EEF but didn't work out. Using UF made it worse (carbide tear out due to burnishing effect?). Used EF (semi broken in), it's holding up well so far.

Caveat, I'm very light user, & mostly shave & open some packages. The D2 is not a shaver for sure.

Ryan

“Every created being is so constituted as to be capable of vice and virtue. For he can do nothing praiseworthy, if he had not the power of turning either way.” - Justin Martyr

“Every created being is so constituted as to be capable of vice and virtue. For he can do nothing praiseworthy, if he had not the power of turning either way.” - Justin Martyr

but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

Hello guys, hello Chris (funny to see how people travels through different forums).

This thread is very nice, it touches exactly the themes I am researching.

I am new to knives and to sharpening.

I have just ordered a Sharpmaker to sharpen my garden tools, the cheap knives I own, and the good ones I am ordering soon.

I was searching about the UF rods to understand if I need them.

I am just learning things like teethed edge vs fine edge. So I do not yet really understand when is a fine or a coarse edge better.

So, yeah, it would be super cool if somebody could explain that! :)

Which kind of cuts are performed better by a coarse edge? Which by a super razor edge?

This on a general basis, as I am a eager learner.

Now, more specifically, this is what I need to sharpen:

bypass pruners, garden shears, snippers, grass shears, hedge shears, a cord cutting hook, a mattock, and a few knives.

Apart for a knife with "karambit style" blade which is to cut wood (specifically, to leave a clean cut on a sawed branch, so to avoid fungi), the other knives are used randomly for any of the following: cut tiny ropes/cords, open thick-paper sacks of construction materials, open plastic sacks of garden soil, cut plastic tubes, open packages, cut cardboard, cut plastic pots when I have to plant a plant which was left too long in the pot and it grow in there so much that it is impossible to take it out.

I must admit that I am so ignorant that I cannot even say which of these tasks are "slice cut" or "push cut".

I would guess that the pruner is push, the shears is... slice?, snippers is... maybe a mix?, grass shears? (do they slice the grass?), hedge shears should slice soft stuff and push cut woody stuff, cord hook is push?, the mattock is clearly push, opening a paper or plastic sack is slice, cut plastic tubes is mostly push (right??? I mean, you do not slice a tube, you have to push the knife and you do not use the whole edge, am I right?), cardboard is... big question... it can be push if you just push the knife into it without moving the blade (=not using the whole edge) or slice if you use the whole edge...

So, I am confused!!!

Should I sharpen some knives coarse and some fine?

For which of those tasks is better coarse and for which fine and for which would a UF rod be useful?

In my mind, till a couple of weeks ago, there was the peaceful calm of ignorance. To me sharp was just sharp.

And to cut anything, a knife had just to be sharp.

Now all is becoming complicated :)

But I like it. I like to learn new stuff.

It keeps me young.

This thread is very nice, it touches exactly the themes I am researching.

I am new to knives and to sharpening.

I have just ordered a Sharpmaker to sharpen my garden tools, the cheap knives I own, and the good ones I am ordering soon.

I was searching about the UF rods to understand if I need them.

I am just learning things like teethed edge vs fine edge. So I do not yet really understand when is a fine or a coarse edge better.

So, yeah, it would be super cool if somebody could explain that! :)

Which kind of cuts are performed better by a coarse edge? Which by a super razor edge?

This on a general basis, as I am a eager learner.

Now, more specifically, this is what I need to sharpen:

bypass pruners, garden shears, snippers, grass shears, hedge shears, a cord cutting hook, a mattock, and a few knives.

Apart for a knife with "karambit style" blade which is to cut wood (specifically, to leave a clean cut on a sawed branch, so to avoid fungi), the other knives are used randomly for any of the following: cut tiny ropes/cords, open thick-paper sacks of construction materials, open plastic sacks of garden soil, cut plastic tubes, open packages, cut cardboard, cut plastic pots when I have to plant a plant which was left too long in the pot and it grow in there so much that it is impossible to take it out.

I must admit that I am so ignorant that I cannot even say which of these tasks are "slice cut" or "push cut".

I would guess that the pruner is push, the shears is... slice?, snippers is... maybe a mix?, grass shears? (do they slice the grass?), hedge shears should slice soft stuff and push cut woody stuff, cord hook is push?, the mattock is clearly push, opening a paper or plastic sack is slice, cut plastic tubes is mostly push (right??? I mean, you do not slice a tube, you have to push the knife and you do not use the whole edge, am I right?), cardboard is... big question... it can be push if you just push the knife into it without moving the blade (=not using the whole edge) or slice if you use the whole edge...

So, I am confused!!!

Should I sharpen some knives coarse and some fine?

For which of those tasks is better coarse and for which fine and for which would a UF rod be useful?

In my mind, till a couple of weeks ago, there was the peaceful calm of ignorance. To me sharp was just sharp.

And to cut anything, a knife had just to be sharp.

Now all is becoming complicated :)

But I like it. I like to learn new stuff.

It keeps me young.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

The more the material travels along the edge the more it is a slicing motion. There is no such thing as a pure slice because in all cutting the material has to move partially as a push or otherwise it would not actually cut into the material.Sir Joe wrote: I must admit that I am so ignorant that I cannot even say which of these tasks are "slice cut" or "push cut".

As for how to know, you sharpen and see what happens. In general :

-the more the material travels along the blade, the more it tends to benefit from a coarse edge

-the harder the material, the less it tends to benefit from a coarse egde

For example you can easily cut rope on a slice so it typically benefits from a long draw and low grit finish. In contrast you can't slice copper wire efficiently so it will be efficiently cut with a push cut and a fine finish.

As you move in between, for things like scissors for example, then you are likely to find that an inbetween finish is optimal.

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

So, pruner is mostly push, shears are mixed, snippers mixed.Cliff Stamp wrote: There is no such thing as a pure slice because in all cutting the material has to move partially as a push or otherwise it would not actually cut into the material.

- Yeah, good point. Maybe "slice" could be defined as a cut where you cannot BEGIN to cut if not by moving the edge forward/back?

As for how to know, you sharpen and see what happens. In general :

- well, I know that it can seem easy to you, but if I try to sharpen and SEE what happens I would have a hard time trying to get a piece of truth out of that mess of variables which is a new knowledge which I do not yet master. I would have no idea what is going wrong, where does the problem comes from.

I would say that cutting plastic is mostly push, would you agree? Specially for harder plastic, but also the soft plastic sack for soil, I tend to open it by stabbing it with the knife and then lifting the open part a bit so put the "to be cut" part under tension, and then just pressing a bit with the knife. And I love when the knife is so sharp that if just go through, without having to use the edge like in the slicing.

Cardboard too. Mostly push in my way of cutting it.

Cement Sacks, this is more slicing.

I would say that 50% of my cuts are push and 30 or more % are mix (with bigger part push).

So, would I benefit from a UF rod?

The problem is, for me it is as Jack said: I had just today this experience of making a knife duller with fine stone than it was with coarse stone.

Why does this happen? How is it even possible? It makes no sense to me. If the edge is sharp, and the fine stone just takes the teeth away, how can I manage to make the thing dull??? What am I doing wrong? What should I change?

Any tips?

Is it just a matter of time? Do I have to do with the fine stones more passages than I do with the coarse?

It was not even a super steel. It was a **** Opinel 8 (I hate this knife so much, I cannot understand why people like it).

I have used the DMT diafold coarse/fine, then a lansky medium ceramic rod, then a lansky fine ceramic rod (the two are for the Lansky system. I bought them so, to use free hand).

Apart for the strange fact that I had the very clear impression that the white fine lansky was beating more than the black one (I could hear it), I have no idea what went wrong.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

About a very fine grit stone dulling an already sharp edge, I don't understand why I had that problem most of my life. In the past 6-7 years I've been working on my sharpening skills a lot. As my skill got better I started noticing I could use finer grit stone and they didn't dull the edge. The UF stone was suddenly doing as it should. It would not get the knife "sharper" so to speak. It takes a very, very sharp, slightly toothy edge and smooths it. My theory is a person needs more skill to get the good results from the higher grit stones. It's a matter of the ability to control the edge angle. You need to look at the edge apex with some magnification to be able to see the difference. Other than that, if you pay attention to how a knife cuts different materials is about the only way to determine a difference if no magnification (at least 60x I think) is possible. Check out Cliff's pictures of highly magnified edges. Those can show how an edge that looks perfectly to the naked eye actually has microscopic "teeth". Picture slicing a tomato. A plain edge that is very smooth may slide along the skin without breaking it. And if the knife is somewhat dull you may find yourself pushing down enough to flatten that spot on the tomato. A plain edge with a toothy edge will dig in and slice the tomato skin immediately. Then the slicing is about the same I think.Sir Joe wrote:So, pruner is mostly push, shears are mixed, snippers mixed.Cliff Stamp wrote: There is no such thing as a pure slice because in all cutting the material has to move partially as a push or otherwise it would not actually cut into the material.

- Yeah, good point. Maybe "slice" could be defined as a cut where you cannot BEGIN to cut if not by moving the edge forward/back?

As for how to know, you sharpen and see what happens. In general :

- well, I know that it can seem easy to you, but if I try to sharpen and SEE what happens I would have a hard time trying to get a piece of truth out of that mess of variables which is a new knowledge which I do not yet master. I would have no idea what is going wrong, where does the problem comes from.

I would say that cutting plastic is mostly push, would you agree? Specially for harder plastic, but also the soft plastic sack for soil, I tend to open it by stabbing it with the knife and then lifting the open part a bit so put the "to be cut" part under tension, and then just pressing a bit with the knife. And I love when the knife is so sharp that if just go through, without having to use the edge like in the slicing.

Cardboard too. Mostly push in my way of cutting it.

Cement Sacks, this is more slicing.

I would say that 50% of my cuts are push and 30 or more % are mix (with bigger part push).

So, would I benefit from a UF rod?

The problem is, for me it is as Jack said: I had just today this experience of making a knife duller with fine stone than it was with coarse stone.

Why does this happen? How is it even possible? It makes no sense to me. If the edge is sharp, and the fine stone just takes the teeth away, how can I manage to make the thing dull??? What am I doing wrong? What should I change?

Any tips?

Is it just a matter of time? Do I have to do with the fine stones more passages than I do with the coarse?

It was not even a super steel. It was a **** Opinel 8 (I hate this knife so much, I cannot understand why people like it).

I have used the DMT diafold coarse/fine, then a lansky medium ceramic rod, then a lansky fine ceramic rod (the two are for the Lansky system. I bought them so, to use free hand).

Apart for the strange fact that I had the very clear impression that the white fine lansky was beating more than the black one (I could hear it), I have no idea what went wrong.

Push versus slicing when cutting. You are slicing when you move the edge along the material so you use a larger portion of the edge. Same motion as is used when sawing with fine tooth hacksaw blade. To picture a push cut think of how a wood chisel cuts when you just push the edge into some wood with no "sawing" movement. But as you said, I can't explain it. But I believe as you improve your consistency to keep the same angle throughout a stroke, you may stop dulling the edge even if it doesn't seem to change it. Later you will be able to tell the difference because the knife cuts better on push cuts into wood (like a chisel).

Another reason I belive an UF stone is not necessary on EDC knives. You normally don't know what you will be cutting throughout the day. You will probably cut something that a toothy edge may excell. Then two minutes later you may have to cut something that a smooth edge would be better. So, I think the fine grit is a perfect grit to use last. It's not a toothy edge but it's not a really smooth edge either. The decision to leave an edge toothy by stopping after a 600 grit stone or to continue into the higher grits is probably really important on knives used for a specif purpose. One edge that is sharpened really smooth is a straight razor. You want them as smooth as you can humanly get them.

Hang on. I just came up with a theory as to why a UF stone may dull the edge that has a very sharp edge after using the fine grit stone. It may very well be the accuracy of holding a consistent angle. Let's say the knife is already sharp but needs just a touch up. When stroking on a coarser stone it will remove enough steel that it creates a new, slightly different than the angle on the edge already. But when using the UF grit it removes only enough steel to round off the edge apex. It doesn't remove enough steel to completely re-set the bevel angle at the apex. I don't know if that's the reason though, just a theory.

A suggestion though is when using the UF stone try your best to maintain the exact (did he say EXACT? :) ) angle at the apex or JUST BARELY raise the spine to create a micro-bevel. Another suggestion is when you do use the UF stone try stropping afterward. Use extremely light pressure to remove a very small burr. Microscopic burrs that you can't detect with normal ways of finding them can still degrade the cutting ability. Also, be sure to use a marker to paint the edge. Then when you stroke the knife you can see where you made contact with the edge to stone.

For now if you just can't get great results from the UF stone or rod stop using it. Don't try it again for 6 months. Focus on angle control with the fine grit and coarser. After six months, if you have been practicing you may see a big difference when you use the UF. I mean quite a bit of practicing. Don't just sharpen all your knives and not sharpen any more until one or more gets dull. I'd suggest 30 minutes or one hour (or more) per day. Get a cheap knife and sharpen it to the best of your ability. Then dull it and resharpen it. The goal isn't to get the knife sharp. The goal is to improve you skill. Improvement on anything takes lots of practice.

Good luck with this and let us know how it goes.

Jack

The key though is

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

Anyone with even a basic understanding of science is always in the same position, it is only the ignorant that make conclusions rapidly. Lets say you get a new knife, the Spyderco Duper in S666V, you sharpen it at 15 dps with the UF stones and you do a little work with it pruning some vegetation. Now the knife goes dull rapidly, what is the cause?Sir Joe wrote: [...] but if I try to sharpen and SEE what happens I would have a hard time trying to get a piece of truth out of that mess of variables which is a new knowledge which I do not yet master. I would have no idea what is going wrong, where does the problem comes from.

-the polish is too high?

-edge angle isn't optimal

-sharpening technique was off, left the apex/edge fatigued

-cutting technique was off

-wood was dirty

-the edge/apex actually hit / contacted something else that you didn't notice

-the initial edge was over heated and needs to be cut back

and the list goes on. How do you determine what factor is causing the performance loss? Well it is a step wise process where you slowly build up experience by changing various aspects and noticing patterns that develop. Any time you get frustrated you find someone else interested in similar, discuss your results ask questions and see if any helpful suggestions can be made.

In general yes, it is pretty hard to actually saw cut plastic which is essentially what it means to slice.I would say that cutting plastic is mostly push, would you agree? Specially for harder plastic, but also the soft plastic sack for soil, I tend to open it by stabbing it with the knife and then lifting the open part a bit so put the "to be cut" part under tension, and then just pressing a bit with the knife.

I don't think you are likely to see any benefit from the fine rod, the materials sound too dirty. Even if you are push cutting, dirty materials are so abrasive that they wear an apex very fast and hence you will very rapidly lose an ultra-high polish. In general, unless you are cutting very clean and non-abrasive material then moving above a Spyderco medium is not likely to see an increase in edge retention, though you likely may notice a small increase in initial push cutting performance. But you also have to consider the time it takes and if you enjoy sharpening. There are people who like sharpening as much or more than using knives so sitting for an hour producing perfect bevels is something they enjoy.So, would I benefit from a UF rod?

When you use an abrasive on a steel then three things in general happen :The problem is, for me it is as Jack said: I had just today this experience of making a knife duller with fine stone than it was with coarse stone.

Why does this happen? How is it even possible? It makes no sense to me. If the edge is sharp, and the fine stone just takes the teeth away, how can I manage to make the thing dull??? What am I doing wrong? What should I change?

-the steel is deformed, ploughed

-the steel fractures, cracks

=the steel is rubbed and compacted

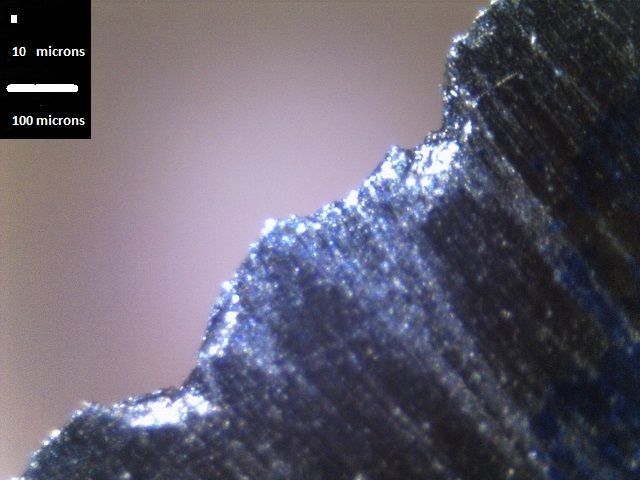

With coarse abrasives mainly the first two happen and it leaves the edge with an apex which looks very much like an irregular serrated finish :

As with any serrated finish, they don't need to actually be sharp to cut because of all those points and scallops will cut on a slice regardless. However as the finish is raised then these are all cut away and for the knife to actually cut well the apex has to be free of deformation, burrs and generally make a nice straight, continuous and very fine line.

Here is the simplest method to apply a very high polish, it is almost fool proof :

-use a King 1000 or other similar stone (weak bond, forms thick slurry) to over grind the edge

-apex bevel with a fine Spyderco, ultra- light, water on the stones, alternate passes, 5-10 pps

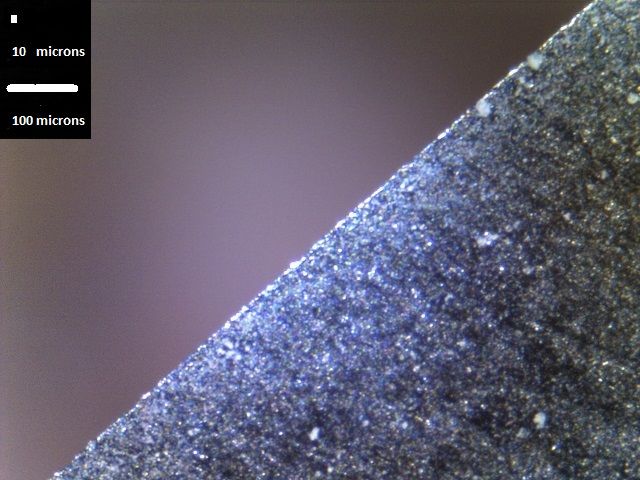

The reason the King works so well is that thick slurry grinds into the apex as much as it does on the sides and thus it keeps the apex free of any burr, deformation or general damage. Keep grinding until the edge starts to slice newsprint well, it will be difficult to get it to shave or push cut newsprint (unless you remove the slurry) but at this point it is perfect for the application of the apex bevel as it will look like this :

That is 121REX which is a duper-stuper steel, ~70 HRC, full of carbides, and none of it matters because a stone like the King ignores all of that due to the high friability of the abrasive. All of that swirling mass of slurry means it will cut off the burr and leave it perfectly ready to take an apex/micro-bevel.

Now what most people do is something like :

-grind the edge with the coarse stone

-grind the edge with the medium stones

-grind the edge with the fine stones

-grind the edge with the UF stones

This is possible, it can work, but it is the hardest and least efficient way to make the apex take the UF finish. If you have a girlfriend and she has jeans you don't like then that method is like saying "Hey, those pants make you look really fat, you might want to cut back on the pizza.". This can work, it might make the jeans stop having an appearance, but it is also likely to be frustrating and it takes a fair amount of skill and charm to make it work.

If you are not interested in making things difficult, then plateau sharpen and micro-bevel :

http://www.youtube.com/watch?v=mSt2mCWGFII

It has one of the slimmest grinds on a production knife and has high cutting ability. It is easy to grind though can be difficult to sharpen because the hardness can be a bit lower than what people are expected to and that combined with the very thin section means you can push the metal around easily vs abrading it.It was not even a super steel. It was a **** Opinel 8 (I hate this knife so much, I cannot understand why people like it).

Re: Are the Sharpmaker UF stones worth it?

So after a while using the UF stones, I've been using them as what I'd call a "high end touch up" stone. What that means for me is, when you've just sharpened a knife, before you cut anything you have that perfect edge, and for me no matter what steel I use that edge seems to be lost within the first couple cuts. But, the knife is still far from dull, so it doesn't take much abrasion to bring it back to that fresh edge feeling. That's where these stones come in. I literally use them as a barber would use a strop, routinely touching up the edge pretty much any time I think to do so. This works great unless you use the knife enough to warrant stepping up to a more course grit. Now that I type this out, it seems like common sense to match the course or fineness of your stones according to how dull you've made your knife. So for this use I'd say yes they're absolutely worth it especially if you have lighter uses than some of is knuckle dragger types.

Re: Are the Sharpmaker UF stones worth it?

I stop at the brown rods now. Don't even touch the fines and haven't used the uf's since I first got them

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

About 3 months ago I put up vinyl siding on a small room in the yard (6'x8'). I used tin snips to cut when I needed to have accurate cuts. But I cut a lot of it with my Mule team 20 knife. I'd say 99% of my EDC or work knives I put a smoother rather than coarser edge apex on them. I will finish the edge with a DMT EF stone or the Spyderco fine or a Shapton glass 2k or higher. So the example I will talk about is cutting with a smooth edge. I may have finished it with my UF stone as well. So of all the cutting I did on vinyl siding was done with the knife which may have had a different level of toothiness. But the edge was always on the smooth side. What I'm thinking of now is the slicing or push cutting plastic. One thing that I think is important is I had the edge bevel at a pretty low angle. 25 degrees inclusive possibly. Anyway, a push cut and slicing have been mentioned. There is another type stroke that is used when shaving with a straight razor. I believe it's called a guillotine cut. Picture a guillotine and how the blade edge is not at a 90 degree angle. When you shave you hold the razor at approx. a 45 degree angle (compared to horizontally level) and pull the razor straight down. While you are not "slicing" exactly, the whiskers are cut with an edge that is at an angle with the direction of motion. I HOPE this is making sense. Another stroke when shaving is a scythe stroke. With this you don't pull the razor straight down but it is still at an angle. But you pull the razor down and there is a distinct slicing on each whisker. I learned these strokes while learning to shave with a straight razor but I realized the same type of slicing goes on with a knife but I had never really thought about it and didn't know there were different names for the cutting techniques. So let's think about the different type of cuts I'm thinking of. We are cutting thin plastic like vinyl siding but it could apply to any number of materials. The issue I'm focusing on is the different angle of the knife edge with the direction of force when slicing or pushing.Cliff Stamp wrote:Sir Joe wrote:

In general yes, it is pretty hard to actually saw cut plastic which is essentially what it means to slice.I would say that cutting plastic is mostly push, would you agree? Specially for harder plastic, but also the soft plastic sack for soil, I tend to open it by stabbing it with the knife and then lifting the open part a bit so put the "to be cut" part under tension, and then just pressing a bit with the knife.

1. Knife edge at a 90 degree angle with the vinyl and you SLICE as you cut as you would a tomato.

2. Knife edge is at a 90 degree angle with the vinyl and you PUSH down using the same spot on the edge.

3. Knife edge is at a 45 degree angle with the vinyl and you PUSH straight down using the same spot on the edge. (guillotine)

4. Knife edge is at a 45 degree angle with the vinyl and you SLICE as you cut using a larger section of the edge. (scythe)

Testing (if you can call it that) these techniques as I worked I think for cutting the vinyl the best cut was 3. Number 4 is good too but you have to pay more attention to not using all the edge and the tip falling out of the material. A bit more control is needed but it's still a great technique IMO. However, number 3 is kind of like a push/slice cut (for lack of a better term). It's the guillotine stroke in the shaving world. Evidently, this a better slicing technique for lopping off heads. Has anyone ever seen a picture of a guillotine with a blade edge NOT at an angle? Back in those days I wonder how many people were used for "testing" to determine the best angle for the blade. :)

I do believe a knife for cutting vinly siding would best be finished with the UF stone for a smoother edge. Then use the "angled/push" (number 3) technique.

Off subject note: My opinion is my knife is NOT the best tool for cutting the siding when an accurate cut is needed. I'd use my knife mainly when I want a fast cut when accuracy wasn't needed. To get accurate cuts I'd use the tin snips or with my knife I'd mark a line, score the vinly with my knife and bend the vinly. But when just grabbing a piece of vinyl and wanting to cut approximately two feet of a big piece I'd hold the vinly with left hand and cut it with the knife. The knife always wanted to turn creating a curved cut. This would be due to either my direction of force, the angle I hold the knife blade at or maybe the bevels aren't exactly the same angle. Think of the knife blade cutting through the material as a rudder cuts through the water. The angle of the rudder going through the water will turn the boat. Same thing with a knife.

Does anyone have an opinion of the angle of the blade edge in regard to the direction of force? Is it good, bad or just ugly?

Jack

- dreadpirate

- Member

- Posts: 784

- Joined: Wed Feb 25, 2015 10:42 pm

Re: Are the Sharpmaker UF stones worth it?

Ok - at first I did not get the point of the brick video but after hearing the conclusion - sounds like the case is being made for not getting the UF stones as these may be over-kill or not even needed for most applications. I have the UF rods and feel it does put a nice polish on the edge - guess it depends on how you use your knives as to whether or not it's worth it. The guy in the video used a course brick and sharpened up a knife in no time to a nice working edge.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Are the Sharpmaker UF stones worth it?

I would not make the argument they are not worth it as a general case, they could be worth it simply because people enjoy it. However from a performance perspective, you would need to be doing very particular cutting on very clean materials with very particular steels for the UF stones to be optimal. The other thing to consider is that the UF stones are just polished F stones. There is nothing stopping you from polishing one side of your F stones, or just using one side of your F stones until they wear smooth. Or using lubricant, or using low force, etc. to increase the polish.dreadpirate wrote:Ok - at first I did not get the point of the brick video but after hearing the conclusion - sounds like the case is being made for not getting the UF stones as these may be over-kill or not even needed for most applications.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: but, when is the UF rod (or generally a fine edge) needed, and when is a coarse edge needed?

There is a fair amount of research on why having the blade as an angle increases the cutting ability and reduces damage to the medium being cut. There are many reasons such as the initial point of contact is reduced (thus the pressure is much higher) and as well the angle in the cut means that there is tensile strain in the material which increases crack formation and in effect makes the blade effectively sharper. Roman Landes talks about this in his book and notes you can also look at it another way which is that it creates a pseudo-smaller edge angle.jackknifeh wrote:

Does anyone have an opinion of the angle of the blade edge in regard to the direction of force? Is it good, bad or just ugly?