Taking off the burr

Taking off the burr

I usually strop my knives to take of the burr but sometimes I simply draw the edge through wood and it seems to do the same thing. Anyone else have any pros or cons to the method?

Re: Taking off the burr

I have a felt block that I use to finish my edge...never tried a soft wood

- Brunzenstein48

- Member

- Posts: 100

- Joined: Sat Apr 11, 2015 1:38 pm

- Location: Antananaivo

Re: Taking off the burr

Re: Taking off the burr

I use a leftover cork from a wine bottle - works perfect.

“It is not the strongest of the species that survives, nor the most intelligent that survives.

It is the one that is the most adaptable to change.”

Charles Darwin

It is the one that is the most adaptable to change.”

Charles Darwin

- jimmyjohnjohn

- Member

- Posts: 250

- Joined: Fri Jan 30, 2015 8:49 am

- Location: Austin, TX

Re: Taking off the burr

I use the ceramic hone/rod that came with my EdgePro.

Re: Taking off the burr

Not sure how good the wood actually works, because I can whittle all day and it's still there... but I'm doing that and/or just cutting it off on the fine or ceramic, then stropping on the stone after. I'm finally winning the battle of the burr/wire edge.

- best wishes, Jazz.

Re: Taking off the burr

I have my Sharpmaker attached to a piece of wood then clamped to my work bench. I'll often pull the blade through the edge of the wood. Seems to work as you said. Been doing it for years. Does knock off that wire edge I get sometimes. I don't even recall now why I started doing that.Skidoosh wrote:I usually strop my knives to take of the burr but sometimes I simply draw the edge through wood and it seems to do the same thing. Anyone else have any pros or cons to the method?

Re: Taking off the burr

Taking off the burr using the end of a piece of wood is a technique used by carpenters and woodworkers. It is often done after the initial sharpening on a medium stone, before going to finer stones, like a hard Arkansas. I have never tried this with high chrome steels, but have used this method with plane irons, chisel blades, and other woodworking blades.

- bearfacedkiller

- Member

- Posts: 11412

- Joined: Sat Jan 04, 2014 1:22 pm

- Location: hiding in the woods...

Re: Taking off the burr

I know this doesn't really answer your question but just avoid the burr in the first place. I stop and cut the burr off with the stone and then keep sharpening if I do produce one. A burr is stressed and weakened metal and you don't want any of that in your edge if you want your edge to last. Even removing the burr the way you are describing could leave some of that weakened metal in your edge. That is my take on it and I know there are many ways to sharpen but that is how I do it.

-Darby

sal wrote:Knife afi's are pretty far out, steel junky's more so, but "edge junky's" are just nuts. :p

SpyderEdgeForever wrote: Also, do you think a kangaroo would eat a bowl of spagetti with sauce if someone offered it to them?

Re: Taking off the burr

I try to keep burr formation to a minimum. As I apply the finishing strokes on a fine or ultra fine stone, I increase the angle and decrease the pressure to the lowest amount possible. I used to strop but no longer think it's necessary and it saves a step.

- Brunzenstein48

- Member

- Posts: 100

- Joined: Sat Apr 11, 2015 1:38 pm

- Location: Antananaivo

Re: Taking off the burr

Re: Taking off the burr

I think by that clever strategy one get the best of all worlds with minimum effort.ABX2011 wrote:I try to keep burr formation to a minimum. As I apply the finishing strokes on a fine or ultra fine stone, I increase the angle and decrease the pressure to the lowest amount possible. I used to strop but no longer think it's necessary and it saves a step.

Chapeau! :spyder:

“It is not the strongest of the species that survives, nor the most intelligent that survives.

It is the one that is the most adaptable to change.”

Charles Darwin

It is the one that is the most adaptable to change.”

Charles Darwin

Re: Taking off the burr

I normally use hard plastic to remove the wire edge, just cut straight into it one or two times.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Taking off the burr

The way to approach this is to think about the nature of the burr physically, it then becomes clear why both stropping and especially drawing the knife through something to remove the burr are both less than ideal and really make no sense at all to do.Skidoosh wrote:I usually strop my knives to take of the burr but sometimes I simply draw the edge through wood and it seems to do the same thing.

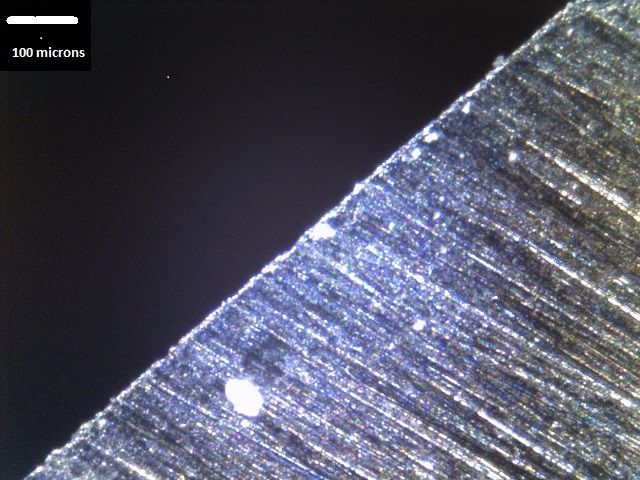

Here is an edge at 50X magnification (this entire picture is ~1 mm wide) :

Note the very apex is well formed and has irregularities the size of the grit of the stone. It has a very minimal burr. In contrast :

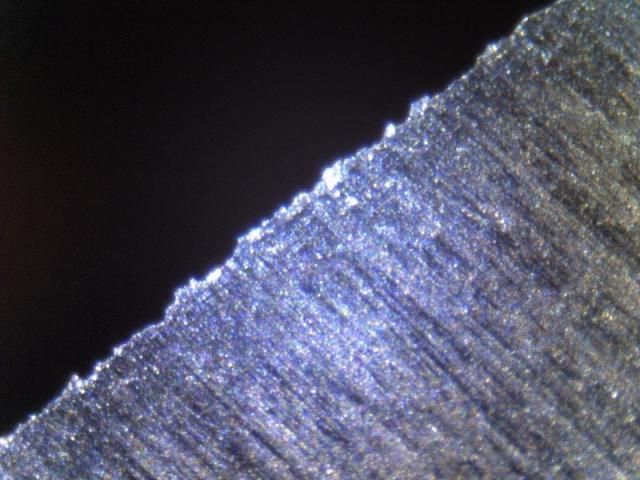

The apex has started to pick up damage far greater than the size of the abrasive scratches. This is because the edge was ground to an apex and the grinding continued and it is just wasting steel.

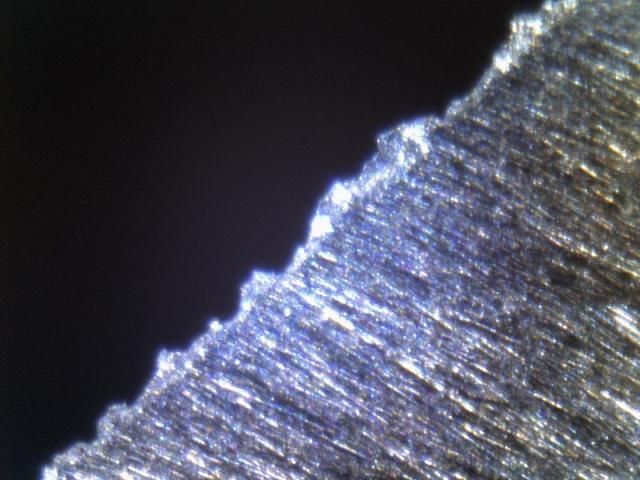

Here is the process continued, the burr is much larger. At this point you can just start to feel and see a burr but just barely. The burrs that people talk about that they can easily see/feel are much larger than this again.

What happens if you strop this to remove the burr? You bend it to one side, then bend it back to the other and keep doing this until it breaks off. Just do that to a spoon (or any piece of metal) and look at the region where it broke, you will see the metal is damaged beyond where it broke off due to fatigue.

What happens when you remove the burr by drawing the knife through something? This takes the damaged metal and smashes it back into the apex as it rips and fractures it. This causes again more fatigue and damage.

All you have to do is cut it off on the stone. The sharpening stone is the abrasive, why not simply cut off the burr on that? The technique is very simple :

-make sure the stone is lubricated

-double the angle

-make 1-2 very light passes (as in 5-10 grams of force total)

This cuts off the weakened metal and doesn't generate any further damage to the edge. As noted in the above there is no reason to form a burr in the first place but when it does happen you can just cut it off.

Re: Taking off the burr

Basically this is what I do. No my idea, I read about this on BF probably 10 years ago. The method was posted by member, who is known as Jeff Clark.Cliff Stamp wrote:

All you have to do is cut it off on the stone. The sharpening stone is the abrasive, why not simply cut off the burr on that? The technique is very simple :

-make sure the stone is lubricated

-double the angle

-make 1-2 very light passes (as in 5-10 grams of force total)

This cuts off the weakened metal and doesn't generate any further damage to the edge. As noted in the above there is no reason to form a burr in the first place but when it does happen you can just cut it off.

see post #14

http://www.bladeforums.com/forums/showt ... ost3152114" onclick="window.open(this.href);return false;

And I use it since than, except I do not use lubricants.

Cliff did a good job explaining.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Taking off the burr

I have the hard felt deburring block and have used it a few time and liked the outcome. This was 2-3 years ago. I've heard about and tried the dragging the edge along the corner of a piece of wood. Personally I'd draw the edge on the corner of a piece of wood that allows the knife blade to be parallel with the grain. Use the corner on the end of a 2x4 would seem to be a good spot because cutting across the grain would make the wood a little harder. But,,, next paragraph.

I've stropped to put a final sharpness on a knife MANY times. Using VERY, VERY light pressure I believe you can "ABRADE" the burr off. But if you use too much pressure you could, after removing the burr on one side, create another burr on the other side. The issue of stropping and burrs was discussed in great detail a couple of years ago. Cliff Stamp was mostly against stropping to remove a burr. He was saying it's best to use the stone to remove the burr. I decided to stop stropping and only use stones on my knives to sharpen them. It took many months but now my technique is that I just can't get the edge any sharper by stropping it. Using VERY, VERY light pressure and push strokes I will do one or two final strokes on both sides to remove the burr. Again, you need to ABRADE (grind) the burr down until the edge bevels meet with no burr. After many months of NOT stropping I found myself getting my edges sharper and sharper using only stones. Now, after I am done with any stones I'm using on a knife I try to improve the edge by stropping. However, after stropping I can't tell any difference in the sharpness. Moral of the story??? After becoming proficient enough using only stones you can have a perfectly (well, almost perfect) apexed super sharp, hair whittling, face shaving knife. As I said, this took me a year or more to be able to do this. I mean an additional year or so AFTER I was already getting my edges VERY sharp. If you or anyone else doubts this I suggest you give up the strops and pieces of wood or hard felt blocks as burr removing tools and focus on the technique using just stones.

Having said that, if done properly stropping is a good way to further refine the edge sharpness after using stones IMO. The burr is the enemy. If you ABRADE the burr off without creating a new burr on the other side of the edge I don't think it matters what tool you used to get the edge sharper. The only down side to me learning to refine the sharpness on stones is I now have about $250 worth of strops just sitting there.

Alternate thought regarding stropping. I have a hanging strop I use for straight razors. I have stropped my knives a few times on the hanging strop. Using a hanging strop it seems easier to use lighter pressure because the strop will "give" a little. How much will depend on how tight you are pulling your strop. But regardless of the pressure you use with the knife I think a hanging strop will result in less pressure than a hard bench strop sitting on a table. But, if using a hanging strop I pull it tight enough that for the most part the strop remains straight. If you allow the hanging strop to bend under the pressure of your knife it might convex (round) the edge bevel or worse yet, the edge apex.

Just my opinions at the moment. I find myself changing my opinion after I get more experience. Who knows, I may disagree with what I've just written in a couple of years. :confused: :)

Jack

I've stropped to put a final sharpness on a knife MANY times. Using VERY, VERY light pressure I believe you can "ABRADE" the burr off. But if you use too much pressure you could, after removing the burr on one side, create another burr on the other side. The issue of stropping and burrs was discussed in great detail a couple of years ago. Cliff Stamp was mostly against stropping to remove a burr. He was saying it's best to use the stone to remove the burr. I decided to stop stropping and only use stones on my knives to sharpen them. It took many months but now my technique is that I just can't get the edge any sharper by stropping it. Using VERY, VERY light pressure and push strokes I will do one or two final strokes on both sides to remove the burr. Again, you need to ABRADE (grind) the burr down until the edge bevels meet with no burr. After many months of NOT stropping I found myself getting my edges sharper and sharper using only stones. Now, after I am done with any stones I'm using on a knife I try to improve the edge by stropping. However, after stropping I can't tell any difference in the sharpness. Moral of the story??? After becoming proficient enough using only stones you can have a perfectly (well, almost perfect) apexed super sharp, hair whittling, face shaving knife. As I said, this took me a year or more to be able to do this. I mean an additional year or so AFTER I was already getting my edges VERY sharp. If you or anyone else doubts this I suggest you give up the strops and pieces of wood or hard felt blocks as burr removing tools and focus on the technique using just stones.

Having said that, if done properly stropping is a good way to further refine the edge sharpness after using stones IMO. The burr is the enemy. If you ABRADE the burr off without creating a new burr on the other side of the edge I don't think it matters what tool you used to get the edge sharper. The only down side to me learning to refine the sharpness on stones is I now have about $250 worth of strops just sitting there.

Alternate thought regarding stropping. I have a hanging strop I use for straight razors. I have stropped my knives a few times on the hanging strop. Using a hanging strop it seems easier to use lighter pressure because the strop will "give" a little. How much will depend on how tight you are pulling your strop. But regardless of the pressure you use with the knife I think a hanging strop will result in less pressure than a hard bench strop sitting on a table. But, if using a hanging strop I pull it tight enough that for the most part the strop remains straight. If you allow the hanging strop to bend under the pressure of your knife it might convex (round) the edge bevel or worse yet, the edge apex.

Just my opinions at the moment. I find myself changing my opinion after I get more experience. Who knows, I may disagree with what I've just written in a couple of years. :confused: :)

Jack

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Taking off the burr

Only in the sense that it gets argued that it is necessary. We need to remind ourselves that there is the practical side and the optimal side of a question and that a person may only be interested in the former. If you take a heavy burr and strop it, then at some point it will break off and then as you continue stropping the apex will eventually form again. This tends to make people do a lot of passes, use a lot of force and produced a fully rounded apex which has little to no slicing aggression. This is one of the reasons why so many people think highly polished edges can't slice well, that is how they think a polished edge behaves. The same reason is why people think a coarse edge can't be very sharp because the only coarse edges they have used either have the heavy burr on them or have the burr smashed off and to them the idea that a coarse edge could push cut newsprint isn't possible.jackknifeh wrote: Cliff Stamp was mostly against stropping to remove a burr.

But a lot of people are not interested in some kind of optimal sharpening, they just want to make a knife cut a tomato vs squashing it and thus as a basic technique :

-grind until you form a burr

-smash it off

-grind a little more

works fairly well. It is simple, effective and keeps knives from squashing tomatoes. But once you start looking at high end steels, really start putting money into knives, well at that point I think an argument can be made that technique in sharpening should be looked at a little more carefully because it has much more to do with performance than steels in regards to edge retention.

Re: Taking off the burr

Cliff, does a polished edge, that is properly apexed, maintain sharpness longer / better vs. a more roughly finished edge?

Have you studied it?

Have you studied it?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Taking off the burr

For push cutting yes, for slicing no. This is the reason why there is so much conflict over this issue because people are usually talking about two different things. I looked at a huge range of grits on hemp rope awhile ago in slicing, from ~8000 grit down to 36 grit and the correlation to increasing edge retention as the grit got more coarse is very strong, and you can physically just see it happen and why if you look under even moderate magnification. The very coarse finishes form actual large teeth you can see and they act like a saw and they are very slow to wear.paladin wrote:Cliff, does a polished edge, that is properly apexed, maintain sharpness longer / better vs. a more roughly finished edge?

However if you take the same edge and try to push cut with it, then not only is the cutting ability very low, the edge retention can be non-existent. In the extreme cases I could not make a cut with the very coarse finishes, even ramping up to 50-100 lbs on a push. Even when I could make a cut the performance degraded rapidly as the teeth where just broken off and I could make just a few push cuts and then nothing. But use them slicing and they do ~1000 cuts and easily slice a piece of paper.

At a basic level it is like using an axe and a saw. If you try to chop with a saw you will not think it cuts wood very well and you will quickly beat the teeth apart. If you try to saw with an axe you would wonder why anyone would ever argue it cuts wood well. Now of course that is silly really, but that is the same thing as comparing low vs high grit edges. They excel at different types of cutting and they are pretty horrible when used where the other excels.

This is why Fikes push cuts massive amount of ropes with a high polish and Boye sliced massive amounts with a coarse edge. When you match the finish to the task and you get a nice grind then the performance really can be staggering if you have not seen it before. A lot of people can't imagine taking a basic knife in 420 or a simple carbon steel and cutting 1000 pieces of rope and still cut a piece of paper. But it is easily possible, just match the sharpening to the task.

Which one works best in a given knife is going to come down to how the knife is mainly used. If you don't know how much of a given task then you are better off with some kind of middle ground because if you go too far either way the performance is gutted. I like the DMT 600 as a general working edge for a random knife. If someone complains it is pretty easy to know which way to go by asking them how it failed in use and then the next time either retreat to a x-coarse DMT or jump up to the MXF.

Re: Taking off the burr

Thanks for the succinct answer. :)

So not only could an ELU carry different length blades, with different primary grinds, different points, etc...but different edge finishes as well!

And thanks for the analogy, I will use it on my wife as rationale for why my user rotation NEEDS to effectively double in number!

So not only could an ELU carry different length blades, with different primary grinds, different points, etc...but different edge finishes as well!

And thanks for the analogy, I will use it on my wife as rationale for why my user rotation NEEDS to effectively double in number!

- Brunzenstein48

- Member

- Posts: 100

- Joined: Sat Apr 11, 2015 1:38 pm

- Location: Antananaivo

Re: Taking off the burr

Sorry to say Cliff - that's one of your best postings :)Cliff Stamp wrote:For push cutting yes, for slicing no.paladin wrote:Cliff, does a polished edge, that is properly apexed, maintain sharpness longer / better vs. a more roughly finished edge?

Indeed it shows/explains with a clever analogy the (non existent) gap in views regarding polishing versus rough edge and the common denominator very well.

Chapeau!

“It is not the strongest of the species that survives, nor the most intelligent that survives.

It is the one that is the most adaptable to change.”

Charles Darwin

It is the one that is the most adaptable to change.”

Charles Darwin

Re: Taking off the burr

ABX2011 wrote:I try to keep burr formation to a minimum. As I apply the finishing strokes on a fine or ultra fine stone, I increase the angle and decrease the pressure to the lowest amount possible. I used to strop but no longer think it's necessary and it saves a step.

This.

Also people focus too much on higher grits and expect them to right the wrongs that you've done with the course stones. You need to make the knife as sharp as possible on EACH stone, not just the higher grit stuff. That means you need to not have a burr from the very first stone. Or, that's what works for me anyway.