'SHOT SHOW Specials' are a series of reviews inspired by, or as a consequence of, my visit to the SHOT SHOW 2015.

These may contain photos taken while travelling, and may be of a slightly different format.

---------------------------------------------------------------------------------------------------------------------

Author's Statement for Transparency and Disclosure

The test sample/s featured in this article have been provided for technical testing and review by the manufacturer. Test samples are retained by the reviewer following publication of the completed review for the purposes of long term testing and product comparisons.

All test results published in this review are the sole work of the reviewer, and are carried out independently and without bias. Test results are reported as found, with no embellishments or alteration. Though best endeavours are made to maintain the accuracy of test equipment, the accuracy of these results is not guaranteed and is subject to the test equipment functioning correctly.

----------------------------------------------------------------------------------------------------------------------

Author's Statement for Transparency and Disclosure

The test sample/s featured in this article have been provided for technical testing and review by the manufacturer. Test samples are retained by the reviewer following publication of the completed review for the purposes of long term testing and product comparisons.

All test results published in this review are the sole work of the reviewer, and are carried out independently and without bias. Test results are reported as found, with no embellishments or alteration. Though best endeavours are made to maintain the accuracy of test equipment, the accuracy of these results is not guaranteed and is subject to the test equipment functioning correctly.

----------------------------------------------------------------------------------------------------------------------

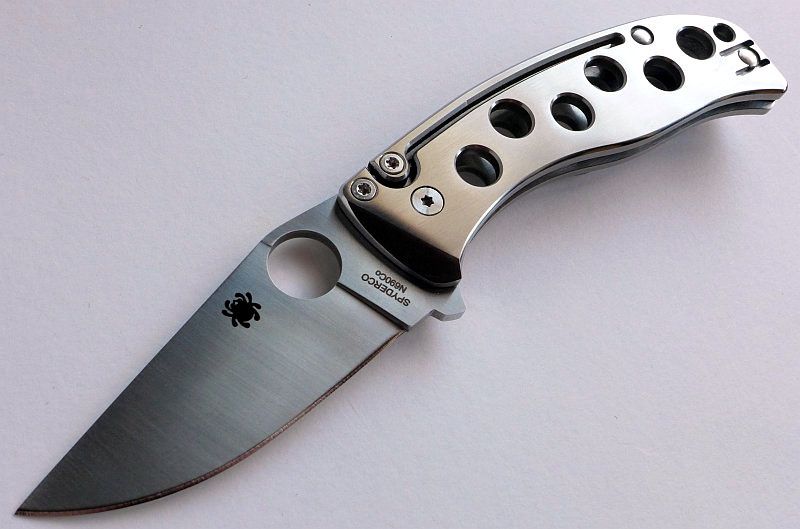

Every great design has a story behind it, as does the Spyderco PITS folder.

The Spyderco PITS folder was designed by Mike Read who hails from England in the UK.

Why the name 'PITS'? This stands for 'PieInTheSky', Mike's online alias, which has nothing to do with knives and is in fact a legacy from a time he was seeking help on the internet following a bicycle purchase gone wrong. As with most of us, our electronic alias is often chosen during that first moment we dive into the online world, and it then follows us forever more.

Mike, who has worked as a marine engineer, did not have a background in knife making or design, so what inspired him to start?

On one rabbit hunting trip, armed with an air-rifle (perfectly legally I should stress), he suddenly found himself the focus of a police helicopter hovering overhead, doubtless the result of a well-meaning citizen reporting seeing 'a man with a gun'.

Concerned there might be an 'overly exciting' visit from the police armed response unit, Mike headed home straight away and thoroughly checked all of his hunting equipment. Determined not to be caught out in the future with anything that could get him into trouble, he went on to buy a chronograph for his sub 12ftlb air-rifle, put away his lock-knife, and began looking for a UK every day carry (EDC) friendly folding pocket knife. In the UK, to be legal for Every Day Carry, a knife must be a non-locking folding knife, with sub 3" cutting edge. Not satisfied with what he found, Mike was sure he could design a better, safer, UK EDC Legal knife - the PITS folder was born.

Mike manufactured his own PITS folder working through various iterations from the prototypes to the current Mk III version before the collaboration with Spyderco. Despite the mature design of Mike's Mk III PITS folder, when it came to designing the Spyderco PITS, Mike actually started with a blank sheet, and re-designed the Spyderco PITS from scratch.

Collaborations such as this require the seamless integration of key features from all parties. With the requirements of a Spyderco knife in mind, instead of trying to shoehorn his own original design into the Spyderco world, Mike went back to the drawing board and designed a new Spyderco knife using his experience and design preferences/characteristics.

The Blade and Handle Geometry:

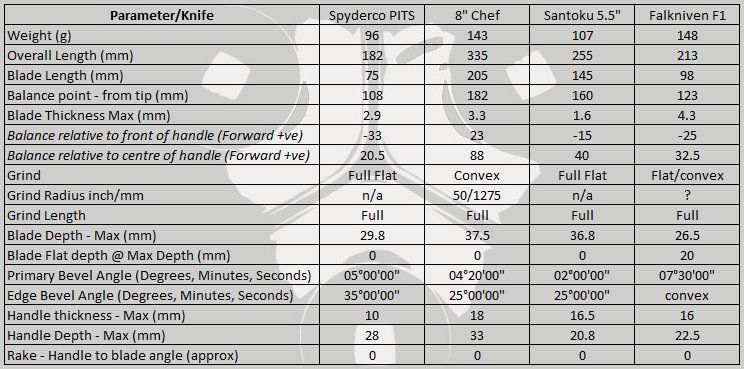

Most knives specifications have a basic description of the blade geometry, but in this section I will be taking a more detailed look at geometry and balance.

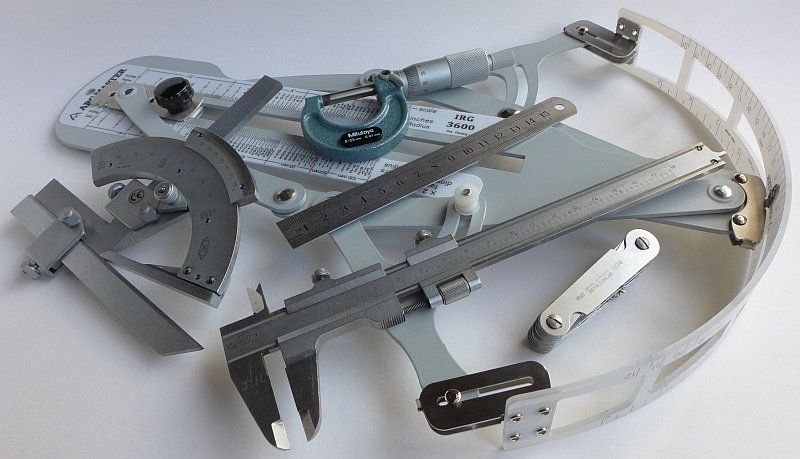

Using a set of gauges and precision measuring equipment including a Vernier protractor, callipers, fixed radius gauges and the unique Arc Master adjustable radius gauge (the one that looks like a crossbow).

These measurements have been tabulated and are presented along with a few reference blades (8" Chef's Knife, 5.5" Santoku and the popular Fallkniven F1).

Key aspects such as the primary bevel angle, grind type, blade depth, blade thickness, length, weight are detailed, along with balance information.

The 'Balance relative to the front of the handle' tells you if the knife will feel front heavy, or if the weight is in your hand (a positive value means the weight is forward of the front of the handle). The 'Balance relative to the centre of the handle' indicates how close to a 'neutral balance' the knife has in the hand.

In the case of convex grinds the approximate centre of the grind is used for the primary bevel angle estimate..

The blade is made from N690Co.

Explained by the Maker:

The reasons for certain design choices may not be clear when simply looking at an object, so this section is intended to give an insight into the thinking behind a design by speaking to the designer themselves.

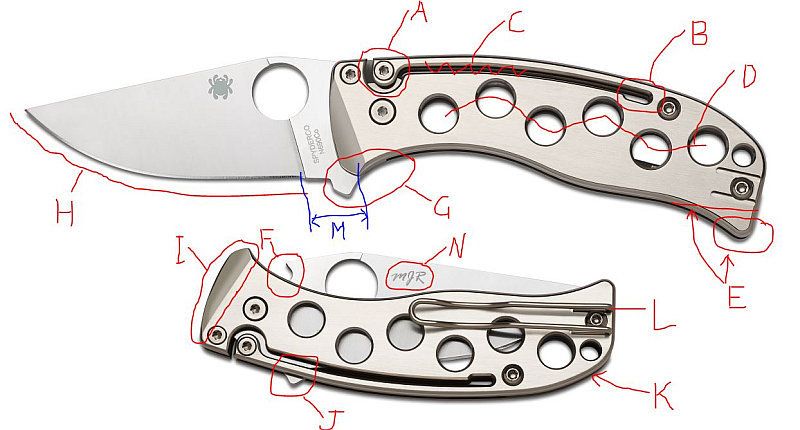

After arranging the interview, I presented poor Mike Read with this scribbled-over picture of his knife – his immediate reaction was "You have written over everything!"

Though not quoting Mike Read directly, the following is an explanation of the various design features I discussed with him during the interview.

One of the most distinctive features of the PITS folder is its back-spring design with a spring cut into each of the handle slabs and both sides of this joined with a pin. This feature was the result of a specific safety aspect Mike wanted to design into the knife. Being a non-locker, Mike was keen to include a finger guard. In a traditional slip-joint knife with a flat back-spring (Swiss Army Knife style), there is very limited space to have any form of guard protruding from the blade ricasso. To get around this, the traditional back-spring was discarded which allowed a much longer finger guard (protruding from the blade ricasso), to simply stick out of the back of the handle once the blade is folded.

The pin that joins both halves of the PITS back-spring allows a type of detent to be used that gives the blade a higher resistance to closing. The pin rests against a ramp cut into the blade tang. As the blade reaches the fully open position and engages with the stop-pin, the back-spring pin starts to slide down the ramp face. This then provides firm resistance to the blade closing, as the pin has to be forced back up the ramp. By using a ramp in this way, over time, as the surfaces wear, the pin will just slide slightly further down the ramp and continue to provide good resistance to closing.

With the back of the handle being used as the spring, and the resulting ramp/pin detent design, Mike found an unintended additional safety benefit. If the user grips the handle firmly, more force is applied to the pin/ramp detent and, just as if the spring were made stronger, the blade becomes more difficult to close. The harder you grip the handle, the harder it is for the blade to close. This was not intended as a feature of the PITS, but does make it even safer to use.

Even though the Spyderco PITS was designed from the ground up, there will inevitably be comparisons made to Mike's original custom knives, so I shall look at some of these.

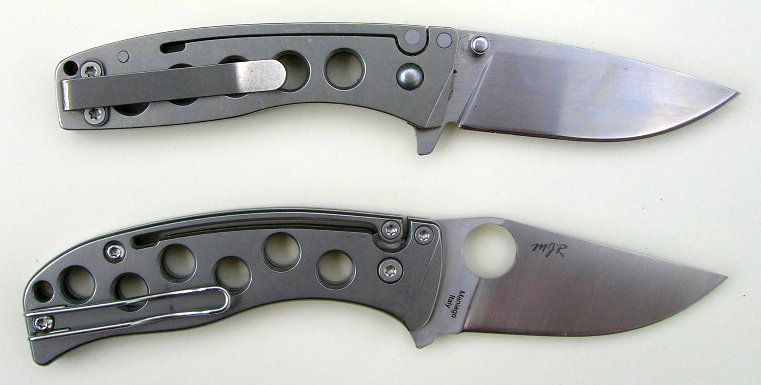

Here is the PITS MKIII with the Spyderco PITS.

Starting with the PITS back-spring, and how it is cut into the handle slabs. In Mike's PITS folders the width of the cut between the handle and spring is much narrower than the Spyderco PITS. One of Mike's early prototypes had a wider gap but without the bevelled edges, and this version pinched the user's hand when opening and closing. To get around this in his own version Mike, made the gap as small as possible and changed the detent design to reduce the spring 'lift' to a minimum. The small gap and small movement of the spring virtually eliminated the pinching.

In which case, why does the Spyderco PITS have a noticeably larger spring gap? Mainly this is down to production method considerations (how this will be cut in the factory). The lift of the spring is also larger due to the revised detent geometry. Greater lift coupled with the larger gap size, meant the edges of the spring needed to be bevelled to reduce their pinching ability. The Spyderco PITS can still pinch, but you quickly learn how to easily avoid this.

Another obvious difference is in the handle slab holes (for weight reduction). In Mike's custom knives these are in a straight line, but the Spyderco version has these in a zig-zag pattern. Wanting to add as many holes as possible in the Spyderco PITS to better balance the larger handle, Mike was able to add one more hole by using the zig-zag layout compared to a straight line. Not only did this allow the extra hole, but fitted in with the pocket clip position, as well as looking good.

Incorporating a 'Spyder-hole' is no small design consideration. It dominates the entire design and effectively the whole knife needs to be designed around that hole.

For the Spyder-hole to be used, it needs to be accessible when the knife is folded. As Mike did not want to have a large hump on the back of the blade, he needed to reduce the blade rotation to stop the hole disappearing into the handle. Doing this leaves the tip of the blade potentially still exposed, so additional handle slab material was incorporated to cover the blade tip. The shaping of this part of the handle happens to also help with the grip and fill the hand.

Looking closely where the blade contacts the stop-pin, the cut out is hook shaped rather than flat. As well as providing a smooth transition from blade to handle without any corners or edges, the round cut out in the blade tang gives a larger contact area on the stop pin.

Mike's fundamental requirement for a finger guard is incorporated with another super smooth transition from blade to handle. The handle contour perfectly follows the guard shape where they overlap, and this gives a large area for the user's hand to engage with the guard.

Another key design feature needed to be retained while designing the blade to incorporating the Spyde-hole, and that is to keep the tip of the blade above the pivot. Doing this makes a non-locker much less liable to close, so much safer to use. Mike has specifically kept the point of the blade as high as possible to help keep the blade open under load when using the tip.

Bevels at the front of the handle slabs not only give the user better access to the cutting edge, but also give more room for the thumb as it sweeps round using the Spyde-hole to open the blade.

Mike's original PITS folder had a more obvious flipper-like protrusion through the back of the handle due to its large finger guard. This was only ever intended as a finger guard, but happened to look like a flipper style knife. It has never functioned as a flipper, so when designing the Spyderco PITS, Mike made a conscious effort to reduce the flipper-like appearance of the finger guard so buyers would not think they had bought a flipper-style of knife which did not flip. Though it might look like the guard is smaller in the Spyderco PITS, there is exactly the same distance from pivot to guard tip as in Mike's original PITS.

Amongst the Spyderco requirements was he inclusion of the wire clip. Mike specifically positioned this low on the handle to line it up with the groove in the user's hand and make it more comfortable. It is also ideally positioned to give right-handers something to grip when opening the blade. (Left-handers need to swap the clip to the other side)

Ricasso width is the product of two aspects of the design. Mike wanted a reasonable blade length and high tip, and needed to stay within the UK restriction of a cutting edge being less than 3". The blade tip is 3" from the handle, so going from the blade tip, along the curved edge of the blade and stopping at 3" of 'cutting edge' gives the final ricasso width as you see it.

A few more details:

To get an idea of the size of the Spyderco PITS, it is shown here with the FRN UKPK, and SPY-DK.

And here with the Fallkniven F1.

The spacer, which is drilled through just like the handle slabs.

The blade is perfectly straight in the handle, but appears slightly off centre when looking at the tip in the folded position.

However this is due to the washers being of different sizes which make the blade sit slightly off centre.

The opening action and spring movement look like this.

What it is like to use

The Spyderco PITS certainly attracts a lot of admiring glances and comments, even from non-knife folk. Like a jewel it seems to catch the light.

Its dimensions seem perfect for a folding EDC knife, even if you forget the UK EDC requirements for a moment. The blade has plenty of depth and strength, and the full-flat grind makes it a great slicer.

The drilled titanium handle slabs mean that overall the knife is not heavy despite its 98% metal construction. Some all-metal knives can feel a bit thin, but the Spyderco PITS has enough thickness to still feel comfortable.

Generally I don't like pocket clips as I find these tend to make a pressure point if using for extended periods. The positioning of the clip on the handle makes it fit pretty well with the hand and provides something to hold onto when opening the knife (left handers will want to reposition the clip to the other side for this advantage). The wire clip does rub on the handle scales in use, making marks on the titanium.

Transition from blade to handle is so smooth you don't notice any catch points at all. The only join that stands out is the end of the back-spring, as despite all the other bevelling, the gap on the back of the handle doesn't have any bevelling, so there are a couple of sharp corners which are most noticeable when the blade is partially open and the back-spring has lifted.

The opening and closing action is satisfactorily snappy and crisp, and despite previous mentions of possibility being pinched by the back-spring, I don't seem to be able to get pinched by it now, even if I try. It was only the first couple of times opening it that I got a little nip, and now I'm not aware of this.

Plenty of the Spyder-hole is exposed to allow for easy one-handed-opening. Compared to locking knives, the action is relatively stiff, but not difficult. The bevels on the front of the handle slabs definitely aid a smooth sweeping action of the thumb when opening the blade.

Obviously there are some tasks where you want a larger blade, and would either choose a larger locking folding knife or a fixed blade, but the Spyderco PITS is more than enough knife for most every-day tasks you will come across, and most other cutting tasks that a folding knife could handle. Its clever design allows it to comply with UK EDC legal limitations but not feel like it has. It does not feel limited or constrained in any way, and even when a locking knife could be carried, I would more than likely carry the Spyderco PITS by choice.

Though being far from a one-knife person myself, the Spyderco PITS is going to get far more than its fair share of carry.

Review Summary

If you enjoyed the review, please remember to 'Like' me on Facebook and follow me on Twitter @Subwoofer_CPF to get all the latest updates and news.