Edge retention slicing cardboard (15 dps, x-coarse DMT)

- Surfingringo

- Member

- Posts: 5824

- Joined: Sun Sep 01, 2013 2:02 pm

- Location: Costa Rica

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Correct me if I'm wrong here Cliff but it almost sounds like you are saying that the differences in what we are cutting have such a huge and unpredictable effect on edge retention that the average user would not with any degree of accuracy tell the difference between 3cr13 and m4. Are you proposing that a steel like m4 has no discernible advantage over 3cr13 in edge retention? Sorry if the question sounds silly (it does to me anyway) but it seems like that is what you are trying to say.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Not unless they really carefully controlled the material cut and made sure to correct/or allow for the influences of edge angle/grit finish.Surfingringo wrote:Correct me if I'm wrong here Cliff but it almost sounds like you are saying that the differences in what we are cutting have such a huge and unpredictable effect on edge retention that the average user would not with any degree of accuracy tell the difference between 3cr13 and m4.

Here is a simple experiment I did recently on sharpening/edge retention-durability. I had been using the Naniwa Aotoshi 2000 for resharpening and then micro-beveling without cutting the apex back first to remove the strained metal as a different technique. I was using a fairly coarse micro-bevel (x-coarse DMT) and I figured that it might be cutting off enough steel anyway. I took a OTK k390 blade and loaned it to a friend and would just sharpen it when they returned it.Are you proposing that a steel like m4 has no discernible advantage over 3cr13 in edge retention?

Here is the experiment - I would at random either cut the edge off or not. There was a large spread in the data but it soon became apparent that not cutting the edge off and removing the strained metal was having a detrimental effect. But here is the more interesting thing, or maybe more practical thing, my friend could see no difference. Yes I could pick it up on an Anova readily, but the scatter was so high that they could see no difference in use.

So what is the answer to the question does cutting the strained metal off increase edge durability or not? It is true in the sense if you do a controlled experiment and look at some statistics you can see it fairly easily. But in a practical sense, in day to day use, if you didn't know which way the edge was sharpening it would be very unlikely you would be able to tell because of all the random sources of error.

As a more concrete example, here are the edge retention numbers for the 420J2 and M4 blades (which are almost 10 HRC points apart) :

TCE (1.5%) 420 J2 : 16, 12 , 4, 3.4, 3.2

TCE (1.5%) CPM M4 : 3, 21, 2.3, 7.1, 9.7

Now if you did the M4 run and got 21 and then did a 420 run and got 3.4 you might think M4 is a super-duper steel. But what about if you did the 420 run which got 16 and the M4 run which got 2.3 - what might you think then? This is why there are often so many contradictory reports on steels because of the random errors which are not accounted for and which can easily end up dominating the conclusion.

Based on the MC runs I did previously, after 10 runs then there should be two groups, 420J2 vs other. But just think about what that means and how much work had to be done, how much statistics to even see a difference which is about the largest you can see in steels - 420 vs 10V/M4.

Or look at it another way. You are likely a decent fisherman, I used to fish a long time ago but have not picked up a rod in a long time. But imagine if you were to try to compare our skills based on how often and how much (weight) fish we caught. I could easily go to a local stocked fish pond and catch fish as fast as I could cast. Or maybe I could go to a salmon run and use a less than legal lure and do the same. In order to be able to pick out our difference in skills, even though it is likely very large, we would have to start restricting all the influences to try to make the comparison ideally just have only that being the difference. If we didn't then I could easily catch more/bigger fish - but it have nothing to do with skill.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Cliff, I did some cutting tests on cardboard and got micro chips on an edge. The second and third time I tested on cardboard there were no ussues. I believe cardboard can have some hard debree in it. I can see the variances from type to type. Manila and sisal natural ropes can have "dirty" sections along the way that can cause variables. The stacked graphs are rad!

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Yeah, and unless you buy new materials you get a lot of dirt as well, but even new natural ropes like you said can vary a lot. If you repeat things a few times and do a little statistics you can get a handle on large differences, but trying to see small ones is really tricky. Just consider the speed that you cut with for example. It is know that the faster the cutting the higher the rate of blunting and how well do you control the speed alone, and then the angle, the force applied, etc. . There are a lot of sources of error so it takes a bit to normalize them all out.edge-e wrote:Cliff, I did some cutting tests on cardboard and got micro chips on an edge. The second and third time I tested on cardboard there were no ussues. I believe cardboard can have some hard debree in it. I can see the variances from type to type. Manila and sisal natural ropes can have "dirty" sections along the way that can cause variables.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I want so bad to have something like the Native and Military models in Spyderedge with M-4 and XHP>> I truly believe with the great luck I've had with my XHP Military that it would be awesome in Spyderredge. With the makeup of M-4 I can't help but believe that it would also make a super Spyderedged blade.Donut wrote:I think from the testing in this thread that I can conclude that M4 is awesome and we still need a Para in M4. :)

The reason I want both steels in Spyderedge so bad is because I use Spyderedges almost exclusively to cut cardboard with.

It always sort of amazed me how quickly cardboard can dull the best of blade steels in short order.

Last edited by JD Spydo on Fri Jan 16, 2015 9:19 pm, edited 1 time in total.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

What properties are you referring to?JD Spydo wrote: With the makeup of M-4 I can't help but believe that it would also make a super Spyderedged blade.

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Well in regards to M-4 and with the Vanadium and Tungsten contents I believe creates a super toughness and the Vanadium being similar to what it is in 440V I just believe in my gut it would endure punishment in a similar manner. I've had excellent luck with 440V in the 2 Spyderedged blades I have with that steel to me have been impressive.Cliff Stamp wrote:What properties are you referring to?JD Spydo wrote: With the makeup of M-4 I can't help but believe that it would also make a super Spyderedged blade.

It seems like blade steels with significant amount of Vanadium just makes for great Spyderedged blades. And with XHP having similar properties to D-2 I just can't help but believe it also would make great steel for Spyderedges. Based on my great luck using 440v in Spyderedges I just think those 2 blade steels would be right for Spyderedges.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Vanadium and Tungsten, in the amounts in M4 don't increase toughness, in fact they reduce it severely.JD Spydo wrote:...to M-4 and with the Vanadium and Tungsten contents I believe creates a super toughness

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

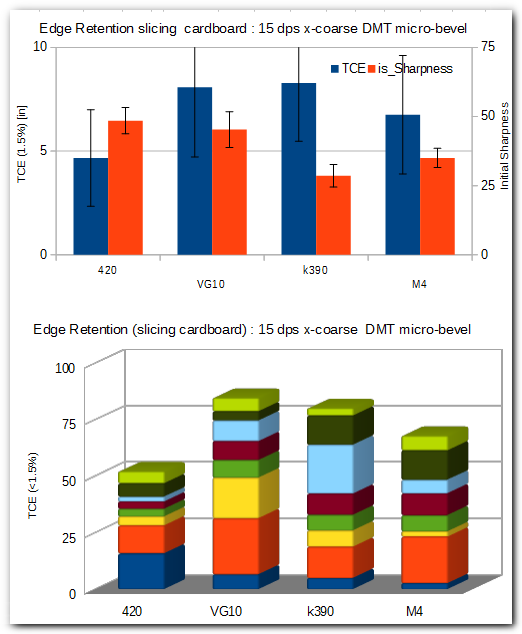

Here is an update with size runs with each :

I included the bar chart with CI intervals (error bars) as it is another way of looking at the data and in this case it shows clearly that the scatter is so large that there isn't even good evidence that any of the steels are different from each other. I think I am going to stop at 10 runs and I might repeat this again using actual random sampling this time as I am curious about the k390 and M4 knife.

I included the bar chart with CI intervals (error bars) as it is another way of looking at the data and in this case it shows clearly that the scatter is so large that there isn't even good evidence that any of the steels are different from each other. I think I am going to stop at 10 runs and I might repeat this again using actual random sampling this time as I am curious about the k390 and M4 knife.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

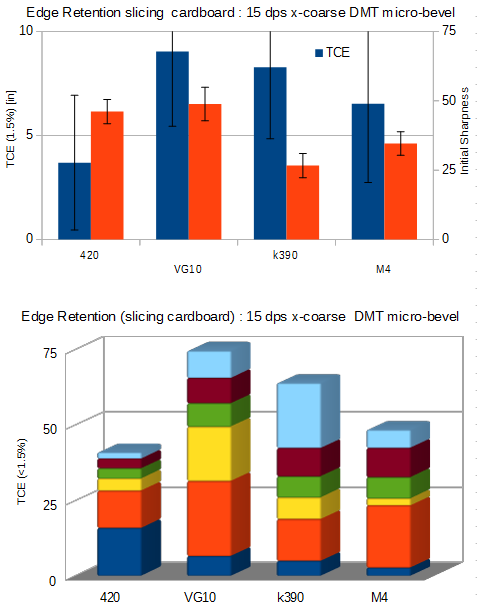

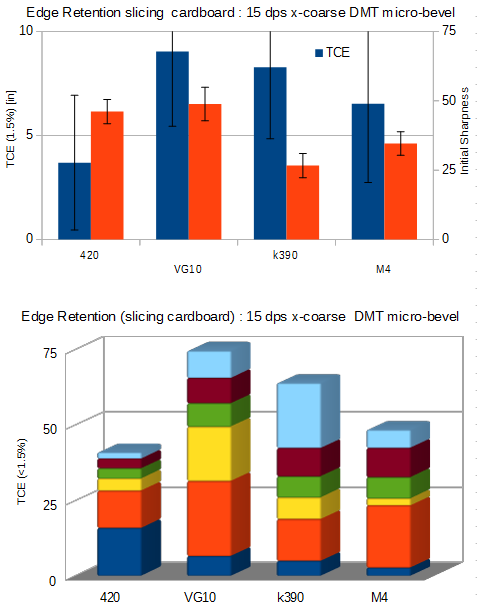

The end of 10 cutting trials for each knife, and approximately 10, 000 meters of cardboard is all reduced down to, as one of my favorite professors used to say, a pretty picture, science loves pretty pictures :

In summary, at most, there is weak statistical evidence that the edge retention of VG-10, k390 and M4 may be higher than the 3Cr13 blade in the method/media shown. But again it is weak and it will fail most statistics readily (ANOVA for example) as there is simply too much spread in the data. There is no evidence at all that VG-10, k390 or M4 are different from each other.

What does that mean? Well it means that even if you keep apex angle, finish very constant, measure initial sharpness and keep it at a very high level, cut one type of material (1/8" ridged cardboard in this case), use the same length of edge (2"), use the same method to cut with a consistent force/speed - even if you do all of that, it is still not possible to know from the result if 10V has different edge retention than 420J2 UNLESS you also constrain the influence from the type of cardboard (either cut all the same type of box, or random sample on the stock).

Is this a surprising result? Well not to a lot of people who use working knives. Chum, Chris, Old Spice etc., have all noted that in general they don't see a difference in edge retention. Chris has done edge retention comparisons and has turned up similar results noting how VG-10 and 20CV are very similar and can oscillate around each other. It is easy to show why this has to be true with a little math, the above is just a physical experiment to ensure you worked out the sums right in the math. And it is always nice to do the experiment and show the math is right.

Now does this mean that steel makes no difference? Well yes and no. What it does mean is that in order to see a difference in practical use then you need very long comparisons or ultra-specific ones. A carpenter for example using a VG-10 pocket knife vs a M4 one is not likely to see large differences from one sharpening session to the next. But if they looked at in one year the amount of times they sharpened one vs the other then they could see a difference.

As I noted in the original simulations, if you carry the experiment out really far and do 50 trials with each vs 10 then it is very likely that all of the steels will separate from each other. But just think about how much work that actually means, it is ~50, 000 meters of cardboard. Keep in mind as well that in general, most of this cardboard was very clean, if it is dirty then the spread only gets larger. If you have different angles/finishes it gets larger. If the handle on one knife makes you cut a different way, then the spread gets larger.

I am almost curious enough to see if the simulations do predict the behavior accurately at 50 trials for each knife, but I have other things of interest and the time it would take to do that is staggering. It takes about 1.5 hours to do one trial, so that would be 300 hours of cutting.

In summary, at most, there is weak statistical evidence that the edge retention of VG-10, k390 and M4 may be higher than the 3Cr13 blade in the method/media shown. But again it is weak and it will fail most statistics readily (ANOVA for example) as there is simply too much spread in the data. There is no evidence at all that VG-10, k390 or M4 are different from each other.

What does that mean? Well it means that even if you keep apex angle, finish very constant, measure initial sharpness and keep it at a very high level, cut one type of material (1/8" ridged cardboard in this case), use the same length of edge (2"), use the same method to cut with a consistent force/speed - even if you do all of that, it is still not possible to know from the result if 10V has different edge retention than 420J2 UNLESS you also constrain the influence from the type of cardboard (either cut all the same type of box, or random sample on the stock).

Is this a surprising result? Well not to a lot of people who use working knives. Chum, Chris, Old Spice etc., have all noted that in general they don't see a difference in edge retention. Chris has done edge retention comparisons and has turned up similar results noting how VG-10 and 20CV are very similar and can oscillate around each other. It is easy to show why this has to be true with a little math, the above is just a physical experiment to ensure you worked out the sums right in the math. And it is always nice to do the experiment and show the math is right.

Now does this mean that steel makes no difference? Well yes and no. What it does mean is that in order to see a difference in practical use then you need very long comparisons or ultra-specific ones. A carpenter for example using a VG-10 pocket knife vs a M4 one is not likely to see large differences from one sharpening session to the next. But if they looked at in one year the amount of times they sharpened one vs the other then they could see a difference.

As I noted in the original simulations, if you carry the experiment out really far and do 50 trials with each vs 10 then it is very likely that all of the steels will separate from each other. But just think about how much work that actually means, it is ~50, 000 meters of cardboard. Keep in mind as well that in general, most of this cardboard was very clean, if it is dirty then the spread only gets larger. If you have different angles/finishes it gets larger. If the handle on one knife makes you cut a different way, then the spread gets larger.

I am almost curious enough to see if the simulations do predict the behavior accurately at 50 trials for each knife, but I have other things of interest and the time it would take to do that is staggering. It takes about 1.5 hours to do one trial, so that would be 300 hours of cutting.

- Stuart Ackerman

- Member

- Posts: 2084

- Joined: Tue Dec 07, 2004 2:39 pm

- Location: New Zealand

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

And folk still ask me why I like VG10 the most... :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Ha, I was reminded recently that in many of the recent comparisons I have done, VG-10 and S30V hit a sweet spot very consistently in regards to many performance applications. It is almost as if they were intended to be cutlery steels.Stuart Ackerman wrote:And folk still ask me why I like VG10 the most... :)

In the above though, the most important factor to me were other properties, both the k390 and s45 have very nice handles for extended work. The kitchen knife is fairly poor in that regard and I would never pick it for such work, similar with the Lum for ergonomic issues.

If i was doing it then the Air is a really nice knife for that. It slim, lightweight, you can forget about it in the pocket, ultra thin point for making light surface cuts. The Serrata is nice on the heavier cardboard as the point easily takes out those big staples and it easily prys apart the thicker stuff.

People might laugh about prying in cardboard, but industrial cardboard can be inches thick, easily able to stand on, and is stuck together with thick layers of hot melt glue. I would not want to ram the edge on the Air into that, but the grind on the Serrata does it well.

- Surfingringo

- Member

- Posts: 5824

- Joined: Sun Sep 01, 2013 2:02 pm

- Location: Costa Rica

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Ahh, the Air. That's one fine little knife isn't it? I would have bought one long ago but I have a hard time buying clipless knives as so often my "beachwear" doesn't include pockets.

- 3rdGenRigger

- Member

- Posts: 2405

- Joined: Sat Jul 20, 2013 8:01 pm

- Location: Calgary Alberta Canada

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Not Cast 440C? Lol...kidding of course. Absolutely loving my Serrata...definitely my favourite fixed blade thus far and I find it surprising useful in the kitchen, much more so than I ever anticipated and as such it sees a lot more use than I foresaw when I bought it. And has the most comfortable handle I've ever held on a fixed blade.Stuart Ackerman wrote:And folk still ask me why I like VG10 the most... :)

I wasn't aware you'd tested a Serrata Cliff...what are your thoughts on the design? I've read your thoughts on dendritic steel before, but I don't recall it being the Spyderco specific iteration of the Serrata (Though I could be mistaken...was a while ago).Cliff Stamp wrote: The Serrata is nice on the heavier cardboard as the point easily takes out those big staples and it easily prys apart the thicker stuff.

All Glory To The Hypno-Toad

---> Branden

---> Branden

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Surfingringo wrote:... so often my "beachwear" doesn't include pockets. :(

Carry it between your teeth like a pirate, that is what I do.

It reminds me of Boye's work as it is a very heavy blade grind but has a decent taper so it does well on shallow cutting and has a lot of strength for prying. If all you are doing is light cutting then you would be better off with very thin steel, but if you are doing a lot of shallow cutting then a thicker spine is nice as a point of grip contact.3rdGenRigger wrote:...what are your thoughts on the design?

In the kitchen it works well peeling a potato, but needs a lot of force to slice one. But for joint work on chickens for example you can do cuts through joints without the very heavy care you need on a much slimmer blade to prevent the edge from denting/turning.

A lot of people also just like a heavier weight in hand. I like the Boye Deerhunter for example but very many times I have handed that knife to someone and got a look of puzzlement as it just feels cheap to them as it is so light and extremely thin through the blade.

- 3rdGenRigger

- Member

- Posts: 2405

- Joined: Sat Jul 20, 2013 8:01 pm

- Location: Calgary Alberta Canada

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

I use my Spyderco kitchen knives for slicing duty (Hard to beat 1.3mm stock for slicing), but the Serrata is definitely used more for shallow cuts and for prying apart meat...separating joints etc.

All Glory To The Hypno-Toad

---> Branden

---> Branden

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Write up of the above : http://www.cliffstamp.com/knives/articl ... board.html" target="_blank

i think it is critical, as with most things, if you are really interested in a performance based perspective to ask a few questions when talking about knives, some of them are not popular but they are necessary and put bluntly can be stated as :

-the current knife I use for this activity that I am interested in "upgrading" where/how does it fail

and then

-what would the knife need to act like for the failures to be removed, or at least reduced

Failure isn't the brutal negative it often gets implicated for on the forums, things fail all the time. A glove might fail to keep you warm, a coat might fail to be a decent wind break, your boots might fail to keep out water. When you go look for "better" items you have to look at the failure points. Of course you also have to think about where the product succeeded, but those points are usually discussed very well.

Sometimes, when things are done well it is hard to see any failure points, or those you want are not possible. I would like the Serrata to cut the carrot as well as a Deerhunter for example but still have the strength and stiffness for the heavier work which would break a Deerhunter. But you would need a steel which has a 10X increase in strength to do that and metallurgists get excited when a 10% advantage is found.

As an aside, the Serrata reminds me of Scagels work :

3rdGenRigger wrote:... but the Serrata is definitely used more for shallow cuts and for prying apart meat...separating joints etc.

i think it is critical, as with most things, if you are really interested in a performance based perspective to ask a few questions when talking about knives, some of them are not popular but they are necessary and put bluntly can be stated as :

-the current knife I use for this activity that I am interested in "upgrading" where/how does it fail

and then

-what would the knife need to act like for the failures to be removed, or at least reduced

Failure isn't the brutal negative it often gets implicated for on the forums, things fail all the time. A glove might fail to keep you warm, a coat might fail to be a decent wind break, your boots might fail to keep out water. When you go look for "better" items you have to look at the failure points. Of course you also have to think about where the product succeeded, but those points are usually discussed very well.

Sometimes, when things are done well it is hard to see any failure points, or those you want are not possible. I would like the Serrata to cut the carrot as well as a Deerhunter for example but still have the strength and stiffness for the heavier work which would break a Deerhunter. But you would need a steel which has a 10X increase in strength to do that and metallurgists get excited when a 10% advantage is found.

As an aside, the Serrata reminds me of Scagels work :

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Cliff,

Can you offer your take on what difference in performance may have arisen from the differing geometries of the four knives in this test? Even with identical included angles (edge bevels) and edge finish, these knives have differences that certainly affect ergonomics and must also affect cutting dynamics.

For example, I believe you mentioned that the 420J2 kitchen knife was thin and whippy, which made it ill-suited to cutting cardboard. Surely you had to adjust your grip and cutting style to adapt to the idiosyncrasies of each of the four knives. Care to speculate what effect, if any, those bodily adaptations might have had on the results of the test? My own guess is that variability in the cardboard dwarfs any ergonomic factors, but that ergonomic factors probably have a nonzero effect upon the observed results. I'm curious to hear your thoughts on this.

Can you offer your take on what difference in performance may have arisen from the differing geometries of the four knives in this test? Even with identical included angles (edge bevels) and edge finish, these knives have differences that certainly affect ergonomics and must also affect cutting dynamics.

For example, I believe you mentioned that the 420J2 kitchen knife was thin and whippy, which made it ill-suited to cutting cardboard. Surely you had to adjust your grip and cutting style to adapt to the idiosyncrasies of each of the four knives. Care to speculate what effect, if any, those bodily adaptations might have had on the results of the test? My own guess is that variability in the cardboard dwarfs any ergonomic factors, but that ergonomic factors probably have a nonzero effect upon the observed results. I'm curious to hear your thoughts on this.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention slicing cardboard (15 dps, x-coarse DMT)

Bill,

That is an interesting question, in regards to comfort in cutting, using a scale of 1-5 (poor to excellent) :

-EE Chef, 1

-Lum, 2-3

-EDC and s45, 4-5

I would suspect that this would bias the results making in general the EE Chef and Lum lower than the others. This difference is large enough I would look forward to the s45 and EDC runs, as they were much more comfortable in hand. Each run was ~250m of cardboard so it was ~1000 slices, given I did ten of them, that was 10k slices with each knife so ergonomics from a practical perspective were much more important than anything else, if I wasn't playing around with numbers.

I don't think that bias is large enough to compete with the cardboard, though it could easily be large enough to compete with differences in steels which are much closer, ATS-34 vs S30V for example which is only a CATRA difference of ~30%. It isn't hard to imagine a control issue having that kind of size of an effect on how you cut with the knife and thus produce that kind of difference in force.

That is an interesting question, in regards to comfort in cutting, using a scale of 1-5 (poor to excellent) :

-EE Chef, 1

-Lum, 2-3

-EDC and s45, 4-5

I would suspect that this would bias the results making in general the EE Chef and Lum lower than the others. This difference is large enough I would look forward to the s45 and EDC runs, as they were much more comfortable in hand. Each run was ~250m of cardboard so it was ~1000 slices, given I did ten of them, that was 10k slices with each knife so ergonomics from a practical perspective were much more important than anything else, if I wasn't playing around with numbers.

I don't think that bias is large enough to compete with the cardboard, though it could easily be large enough to compete with differences in steels which are much closer, ATS-34 vs S30V for example which is only a CATRA difference of ~30%. It isn't hard to imagine a control issue having that kind of size of an effect on how you cut with the knife and thus produce that kind of difference in force.