Reprofiling!

Reprofiling!

After some months doing all that I can with a broken DMT diafold magna-guide sharpening system I was thinking of getting a replacement. WE was in my wish list but I find it too expensive as you can get pretty good edges with a little patience, a good coarse stone and the SM.

Now I'm leaning towards getting the diamond rods for the SM or a coarse diamond stone from DMT. I'm a little worried about the durability of those rods so I'd like to know what do you think about these options and what do you use when reprofiling is needed... You also can attach some little stones or sandpaper to the SM rods to sharpen at typical angles, but I don't know if this workaround is very popular.

Now I'm leaning towards getting the diamond rods for the SM or a coarse diamond stone from DMT. I'm a little worried about the durability of those rods so I'd like to know what do you think about these options and what do you use when reprofiling is needed... You also can attach some little stones or sandpaper to the SM rods to sharpen at typical angles, but I don't know if this workaround is very popular.

- Johnnie1801

- Member

- Posts: 2219

- Joined: Sat Apr 26, 2014 10:29 am

- Location: Europe

Re: Reprofiling!

Currently enjoying Spyderco's in - S30V, VG10, Super Blue, Cruwear x4, CTS XHP, S110V x2, M4 x3, S35VN, CTS 204P x2, S90V, HAP 40, K390, RWL34, MAXAMET, ZDP 189, REX 45

Jon

Jon

Re: Reprofiling!

Yep, though I prefer WE for working both sides at a time and reaching a narrower angle. Anyway I'm more inclined to invest in the diamond rods or a DMT stone unless someone can convince me about WE.Johnnie1801 wrote:Have you thought about an Edgepro?

http://www.knivesandtools.nl/nl/ct/edge ... stemen.htm

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

The WE isn't really something which excels at heavy stock removal, even with the very low grit diamond abrasives. I would recommend you consider a simple x-coarse benchstone. This will cost the fraction of the price of a DMT plate and have a much longer lifetime. Which one works best is strongly influenced by the type of steel you are grinding. If you pair the stone with a little silicon carbide lapping compound (90X) then you can have a very flexible abrasive which can handle a wide variety of steels.nirvanero wrote:

[...] Anyway I'm more inclined to invest in the diamond rods or a DMT stone unless someone can convince me about WE.

Re: Reprofiling!

Johnnie1801 wrote:Have you thought about an Edgepro?

http://www.knivesandtools.nl/nl/ct/edge ... stemen.htm

I can make quick work of just about anything with my Edge Pro using the 320 grit SIC Congress stone, once in awhile I still bring out the 120 SIC Stone.

-

MacLaren

- Member

- Posts: 12635

- Joined: Wed Apr 16, 2014 12:59 pm

- Location: High in the Blue Ridge of NC

Re: Reprofiling!

I believe you :DAnkerson wrote:Johnnie1801 wrote:Have you thought about an Edgepro?

http://www.knivesandtools.nl/nl/ct/edge ... stemen.htm

I can make quick work of just about anything with my Edge Pro using the 320 grit SIC Congress stone, once in awhile I still bring out the 120 SIC Stone.

Re: Reprofiling!

So far no love for the WE. Cliff, which unexpensive stones do you recommend? Feel free to send me PM. Those DMT diamond coarse 8" benchstones are about $50, not too bad.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

I have a WE, very nice for generating even bevels, but I would not chose it for bevel setting, just look at the stone size and general mechanics .

For simple steels : coarse India, use oil

-L6, 12C27, etc. < 60 HRC

Medium to cut steels, Brico, use water

-ATS-34, Elmax, ~60 HRC

For hard to cut steels : 120 Sigma Power, use water

-M4, 10V, etc. > 60 HRC

For really hard to cut steels : TASK garden hone, use with very little water

The last hone is very brutal, it is < 100 grit and silicon carbide. It cuts steels like Maxamet/70 HRC readily, but again it is extremely coarse, be careful about apexing with it.

I have a Norton economy stone in silicon carbide which may work well either.

For simple steels : coarse India, use oil

-L6, 12C27, etc. < 60 HRC

Medium to cut steels, Brico, use water

-ATS-34, Elmax, ~60 HRC

For hard to cut steels : 120 Sigma Power, use water

-M4, 10V, etc. > 60 HRC

For really hard to cut steels : TASK garden hone, use with very little water

The last hone is very brutal, it is < 100 grit and silicon carbide. It cuts steels like Maxamet/70 HRC readily, but again it is extremely coarse, be careful about apexing with it.

I have a Norton economy stone in silicon carbide which may work well either.

Re: Reprofiling!

Silicon Carbide will eat any steel without much of a problem.

Just match the grit with the task, some stones are harder than others, have less fillers so they don't wear as fast.

And you can put some serious pressure on it to speed things up and not have to worry about scraping off the diamonds.

Just match the grit with the task, some stones are harder than others, have less fillers so they don't wear as fast.

And you can put some serious pressure on it to speed things up and not have to worry about scraping off the diamonds.

Re: Reprofiling!

Thank you for the information Cliff & Ankerson, it's nice to have human steelpedias in this forum! I'll take a look at these stones on the net. I'm also thinking of using a pair of DMT 6" with my SM, which I'm used to work with, and hopefully I can set the angle easily with a little DIY.

Re: Reprofiling!

Yeah SIC is one of the only things Cliff has been correct about in a very time so it's actually good information.nirvanero wrote:Thank you for the information Cliff & Ankerson, it's nice to have human steelpedias in this forum! I'll take a look at these stones on the net. I'm also thinking of using a pair of DMT 6" with my SM, which I'm used to work with, and hopefully I can set the angle easily with a little DIY.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

In regards to abrasives, silicon carbide has two main forms (green and black), aluminum oxide has three (white, pink, brown). In regards to properties how they behave depends not only on the type, but how they are made, how the grits are then prepared, and the binder used.

For example you can get white aluminum oxide which is very friable and designed to cut - HSS and very hard to grind steels and do it without burning in a fast cutting application. You can also get aluminum oxide which does the same thing but not because of the type but how it is made. The so-called ceramic belts for example (Norton Blaze) are aluminum oxide but will fracture like poly diamonds and thus will outlast the normal aluminum oxide belts and far out last the silicon carbide belts (far too friable, the abrasive is more brittle).

In choosing a stone you have decide if you want fast cutting, low rate of wear and what pressure you are going to grind with. A very high pressure will demand a very strong abrasive and a very strong bond - hence Norton India does very well at very high pressures. If the pressure is lower then you want a much more friable abrasive and/or more friable bond (depending on finish desired).

If you are looking at finish you need a very weak binder to generate a thick slurry and you don't want a friable abrasive (the grit size will then be too random). Hence something like a resin bond aluminum oxide stone works well, King for example.

In short, silicon carbide isn't better than aluminum oxide as a grinding abrasive, it is just different. If you understand the properties you can make more informed choices on hones. In more detail :

-http://www.cliffstamp.com/knives/forum/read.php?7,38099

Look at how the coarse India reacts to high low pressure, low high carbide steels, and various fluids. This is very different than something like the TASK which is silicon carbide with a very weak binder. Which is a better abrasive depends strongly on what is desired. Hence why they exist in various forms as abrasives.

For example you can get white aluminum oxide which is very friable and designed to cut - HSS and very hard to grind steels and do it without burning in a fast cutting application. You can also get aluminum oxide which does the same thing but not because of the type but how it is made. The so-called ceramic belts for example (Norton Blaze) are aluminum oxide but will fracture like poly diamonds and thus will outlast the normal aluminum oxide belts and far out last the silicon carbide belts (far too friable, the abrasive is more brittle).

In choosing a stone you have decide if you want fast cutting, low rate of wear and what pressure you are going to grind with. A very high pressure will demand a very strong abrasive and a very strong bond - hence Norton India does very well at very high pressures. If the pressure is lower then you want a much more friable abrasive and/or more friable bond (depending on finish desired).

If you are looking at finish you need a very weak binder to generate a thick slurry and you don't want a friable abrasive (the grit size will then be too random). Hence something like a resin bond aluminum oxide stone works well, King for example.

In short, silicon carbide isn't better than aluminum oxide as a grinding abrasive, it is just different. If you understand the properties you can make more informed choices on hones. In more detail :

-http://www.cliffstamp.com/knives/forum/read.php?7,38099

Look at how the coarse India reacts to high low pressure, low high carbide steels, and various fluids. This is very different than something like the TASK which is silicon carbide with a very weak binder. Which is a better abrasive depends strongly on what is desired. Hence why they exist in various forms as abrasives.

Re: Reprofiling!

Then if you both agree it must be a safe bet... :D those Norton Crystolon are actually quite affordable.Ankerson wrote:Yeah SIC is one of the only things Cliff has been correct about in a very time so it's actually good information.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

If you do get that let me know how it works. I have the economy model and there are wide ranges of comments on that compared to the premium one without clear distinction from Norton on the difference as both of them use the same abrasive. It isn't clear if they are using a different bond, or processing of the abrasive or even the difference in performance between them.nirvanero wrote:... those Norton Crystolon are actually quite affordable.

-

Bugout Bill

- Member

- Posts: 64

- Joined: Sun Sep 07, 2014 12:21 pm

Re: Reprofiling!

I'm a former proponent of coarse diamond abrasives, but I much prefer SiC stones for that sort of heavy work. Diamond stones are a lot less tolerant of high pressure than SiC stones, even fairly friable ones like the Norton. They work well for finishing and rapid resharpening, but you have to be fairly careful if you are doing heavy reprofiling.

" Two guns, flashlight, two 12-gauge cartridges, and a knife because—just because—every little boy should have a knife.." -- Louis Awerbuck on his EDC

Re: Reprofiling!

Done, just don't expect microscopic pictures or graphs... :) I think some of this SiC stones will escort my Rubicon.Cliff Stamp wrote:If you do get that let me know how it works. I have the economy model and there are wide ranges of comments on that compared to the premium one without clear distinction from Norton on the difference as both of them use the same abrasive. It isn't clear if they are using a different bond, or processing of the abrasive or even the difference in performance between them.nirvanero wrote:... those Norton Crystolon are actually quite affordable.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

I never like diamond for heavy stock removal and have used them from DMT, EzLap, and a bunch of the smaller ones, they all have the same basic problems as you noted. However, due to recent conversations with engineers in the abrasives industry, I think that is more to do with the types of abrasives we are seeing vs limitations in the abrasive directly. Not I would not argue diamonds are inherently optimal for hand grinding, but I don't think they are prone to the problems we often see. Imagine for example a diamond stone like DMT where you could just peel off a top layer of abrasive every month and expose a brand new as-boxed surface. How would you feel about that kind of stone?Bugout Bill wrote:I'm a former proponent of coarse diamond abrasives...

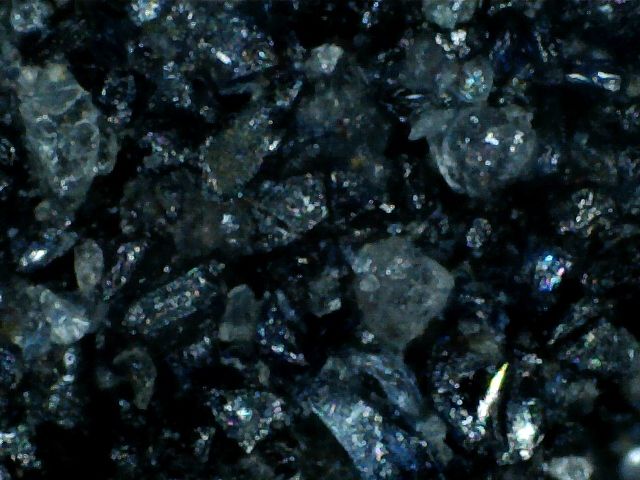

Aluminum oxide as well gets a bad rap mainly due to a lack of understanding about how abrasives work and why. I have spent a lot of time recently with various stones and have come to appreciate the very high toughness of aluminum oxide compared to silicon carbide and the advantages of having an abrasive which doesn't go from this which is a new as-boxed silicon carbide stone :

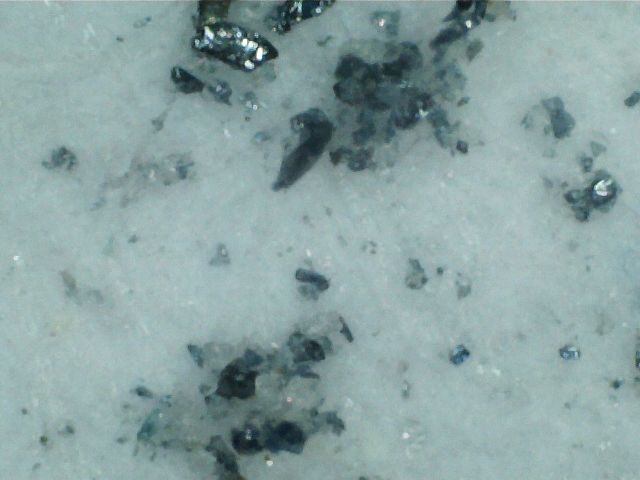

to this which is the slurry it produces due to the extreme friability of the abrasive :

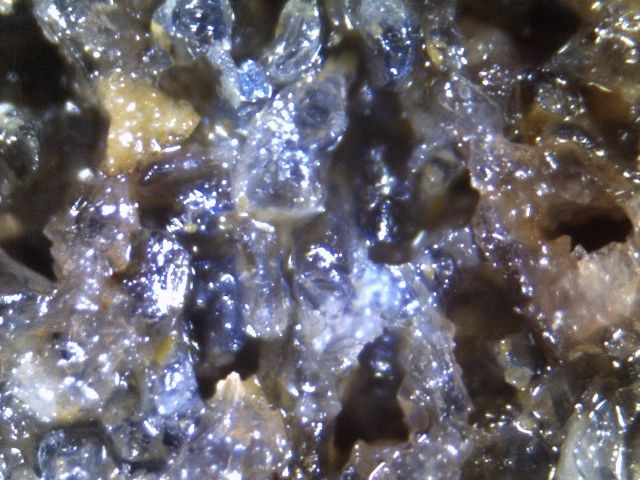

In contrast here is an as-boxed India stone :

and one which is heavily used :

In the second picture there are thousands of passes on the stone on steels such as 1095, L6, 420, Elmax, ATS-34 etc. . Note how the abrasive doesn't fragment and stays in the very large crystal form, very fast cutting with almost no stone dishing because the abrasive is non-friable and it has an extremely strong vitrified bond.

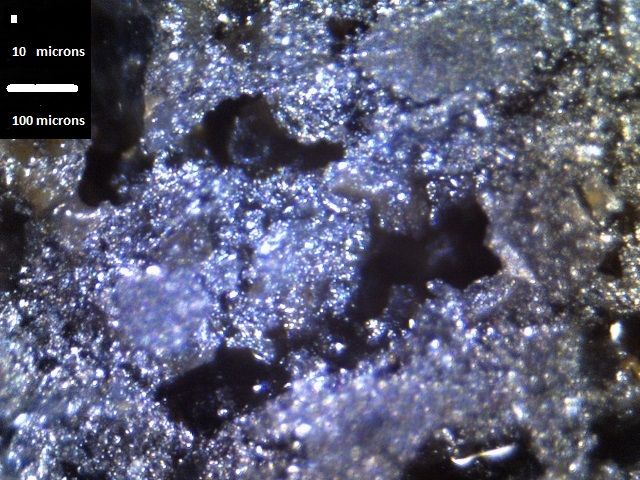

But, here is the critical part, it is pretty easy to turn that aggressive cutting surface into this :

Which doesn't cut anything well as it is worn and loaded.

Sharpening stones, like steels/knives, do need a little experience to bring out what they do well and what they do poorly. Unfortunately it is even harder to find out about abrasives than steels. Just ask someone who sells stones :

-the type of abrasive they used (not just silicon carbide or aluminum oxide but the type of each)

-grit structure

-bond type

-porosity and abrasive density

The problem is that you can use a stone with a very strong vitrified bond, low abrasive density, low porosity and using that stone is like walking a cat. Unless you are Collin you are likely to gift it to someone you don't like. If you conclude from that it is how the abrasive behaves then you would likely be very surprised to see the same type of abrasive and how it behaves in a weak resin bond, high abrasive density, and low porosity stone.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

Ha, we all do what we enjoy. I geek out at times with numbers/pictures as I enjoy it, just like I enjoy watching Uwe Boll movies.nirvanero wrote: Done, just don't expect microscopic pictures or graphs...

I am mainly interested in :

-what kind of force do you use to get it to cut well

-does it load (is a lubricant needed)

-is a slurry generated

-does it stall on high carbide steels or work well broad spectrum

-is the scratch pattern uniform or very random

I am really curious what Norton is doing to make a basic and premium version of the same stone using the same abrasive.

Imagine if Sal started making a Economy version of the Military in S30V and a Premium one which had the exact same materials and same description but one was a fraction of the price of the other ...

Re: Reprofiling!

I've only seen "In the name of the king" (almost to the end) and... well.. I really much prefer your microscopic pictures... :D About the Norton SiC stones I'll give them a try in a month or so,I don't know if the $17 stones are the premium version but If so then the basic ones must be really cheap (I guess both are the same in a different package). I just want them to cut reasonably fast steels like ZDP-189 and S110V while not being very "thirsty" and having a constant wear. So far I've only used diamond and ceramic stones so it'll be interesting.Cliff Stamp wrote:Ha, we all do what we enjoy. I geek out at times with numbers/pictures as I enjoy it, just like I enjoy watching Uwe Boll movies.nirvanero wrote: Done, just don't expect microscopic pictures or graphs...

I am mainly interested in :

-what kind of force do you use to get it to cut well

-does it load (is a lubricant needed)

-is a slurry generated

-does it stall on high carbide steels or work well broad spectrum

-is the scratch pattern uniform or very random

I am really curious what Norton is doing to make a basic and premium version of the same stone using the same abrasive.

Imagine if Sal started making a Economy version of the Military in S30V and a Premium one which had the exact same materials and same description but one was a fraction of the price of the other ...

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Reprofiling!

The economy ones are much more inexpensive and curiously enough, if you read a thread on BF they were changed from aluminum oxide to silicon carbide awhile ago but the promotional material wasn't updated. That however just raises another question as to what was the difference between the original aluminum oxide economy stone and the India stones which are also aluminum oxide (vitrified bond).

In any case, I would be curious of your experience.

In any case, I would be curious of your experience.